Bimetal cylinder block, friction pair and machining method for axial variable piston pump

A technology of bimetal cylinder block and plunger pump, which is applied to the parts of the pumping device for elastic fluid, the parts of the variable displacement pump, the pump elements, etc. Easy to wear and scratch, eccentric wear of cylinder block and valve plate, etc., to achieve the effect of plane distribution effect and life improvement, improve the accuracy of parts, and evenly distribute the matching gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

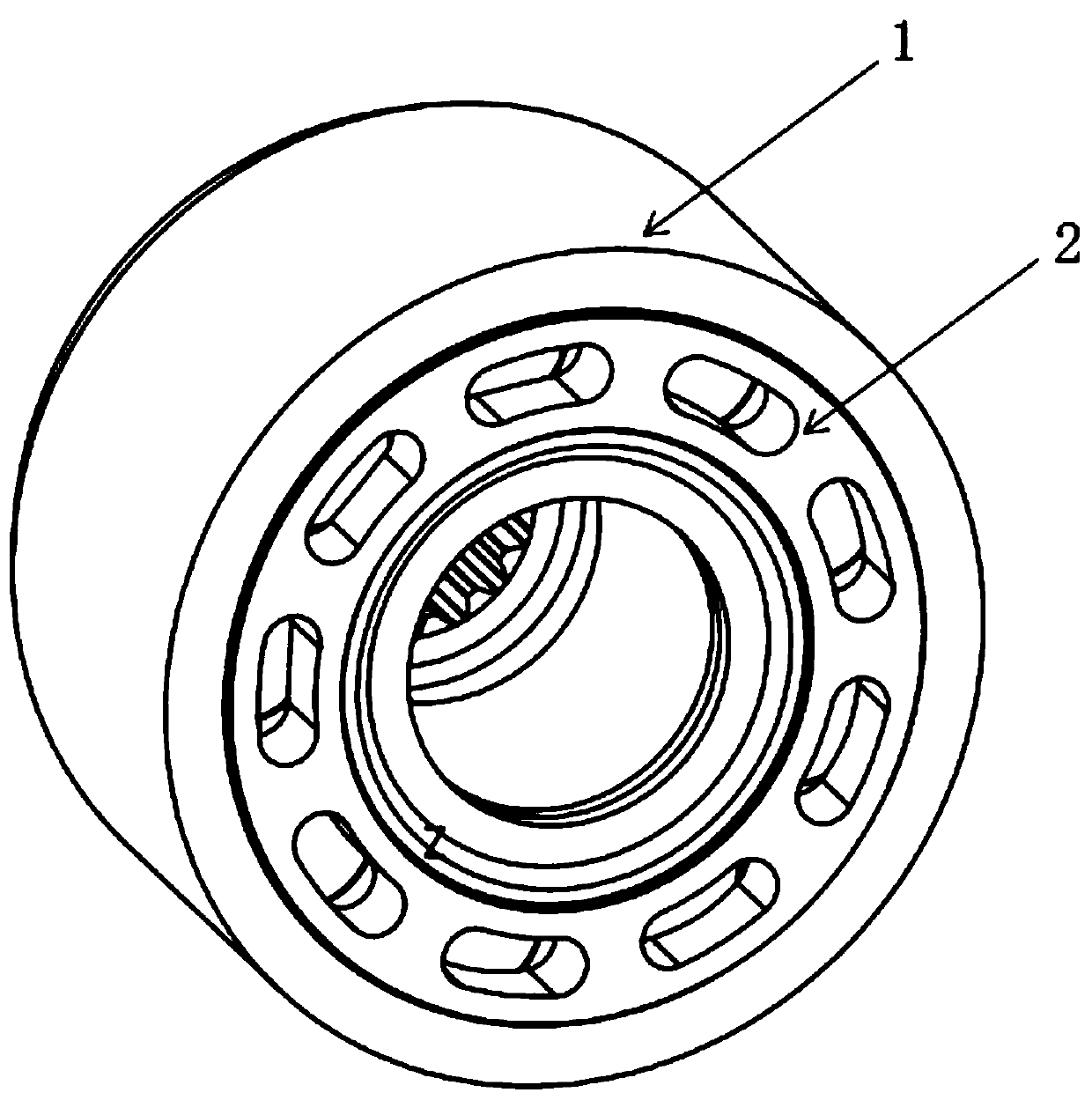

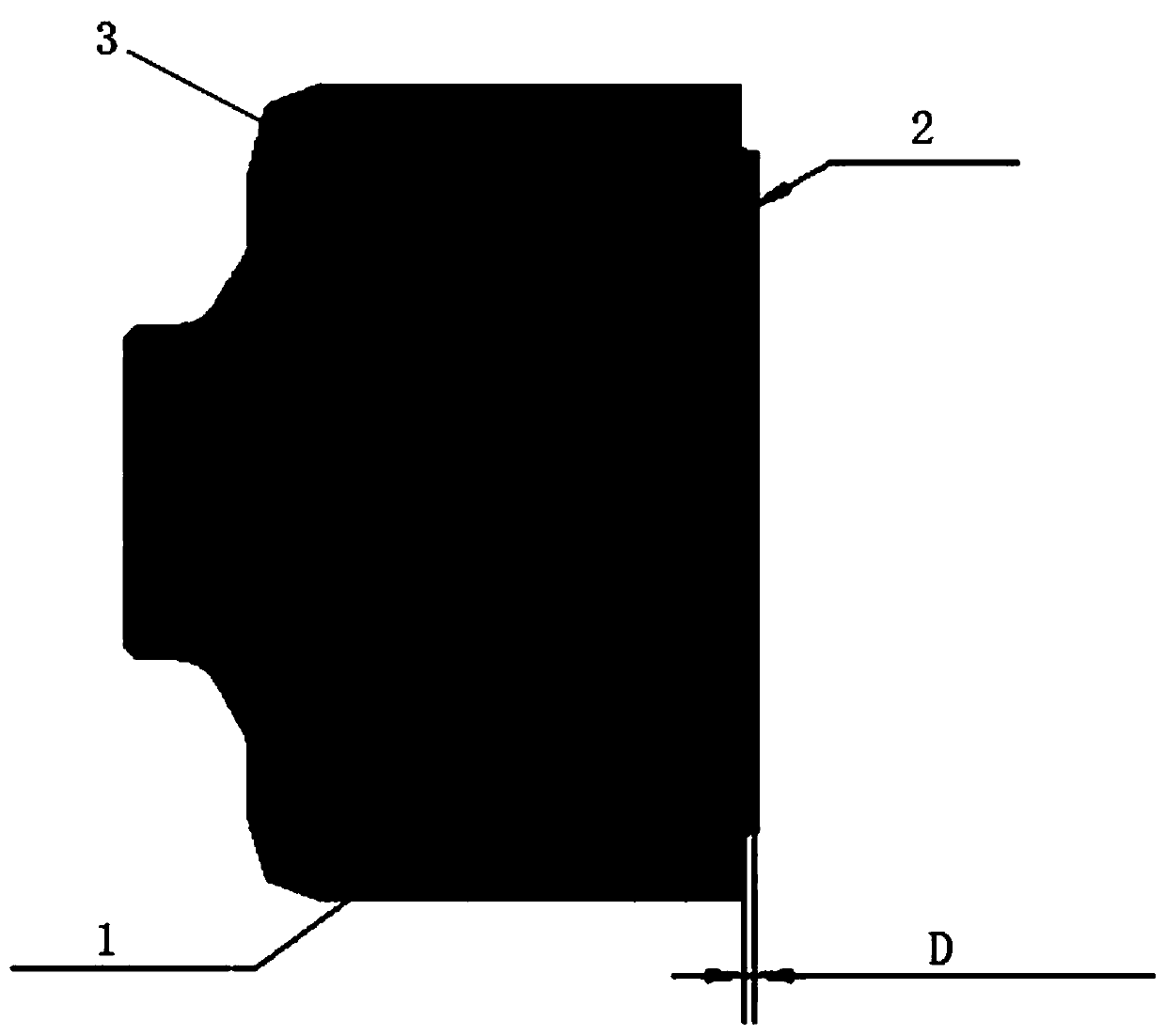

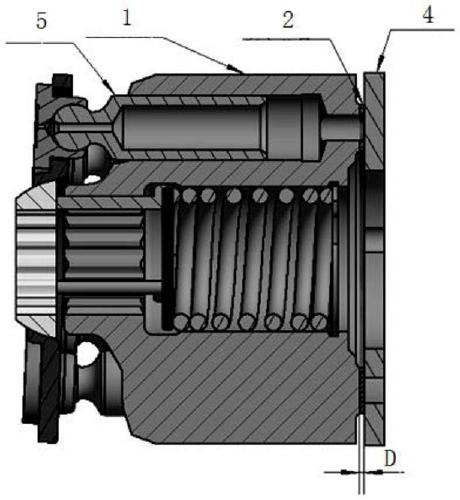

[0026] Such as Figure 1 to Figure 5 As shown, this embodiment discloses a bimetallic cylinder for an axially variable piston pump. The base 1 of the cylinder is made of ductile iron, and the flow distribution surface 2 of the cylinder is made of copper alloy. The copper alloy is welded Fused with the flow distribution surface 2 of the cylinder body, the heat treatment of the base body 1 adopts nitrocarburizing treatment, an effective wear-resistant layer is formed on the surface of the plunger hole 3 of the cylinder body, and the plunger 5 is arranged in the plunger hole. In the above technical scheme, the bimetallic cylinder is adopted, that is, the material combination of nodular cast iron and copper alloy, and nodular cast iron is used as the matrix, which has good machinabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com