Waste paper treatment device of adhesive sticker machine

A treatment device and waste paper technology, which is applied in the direction of raw material pretreatment, etc., can solve the problems such as the single unusable waste paper ink scouring, affecting waste treatment, etc., to achieve the effect of facilitating classification and treatment, reducing waste treatment process, and optimizing environmental protection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

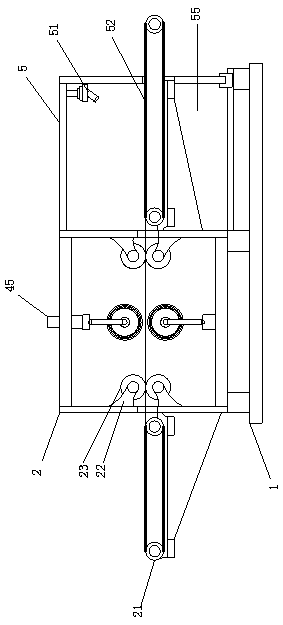

[0023] see figure 1 , a waste paper treatment device for a self-adhesive machine, comprising a frame 1, the frame 1 is provided with an ink removal chamber 2 and an ink flushing chamber 5, the feed port and the discharge port of the ink removal chamber 2 The positions are all equipped with a fixed frame 22, the fixed frame 22 is equipped with a guide roller 23, the feeding end of the ink removal chamber 2 is equipped with a primary conveyor belt 21, and the ink flushing chamber 5 is provided with a secondary The conveyor belt 52, and the top of the ink flushing chamber 5 is provided with a shower head 51. The ink removal chamber 2 is used to rub off the ink on the surface of the tape, and the ink flushing chamber 5 removes the ink by flushing.

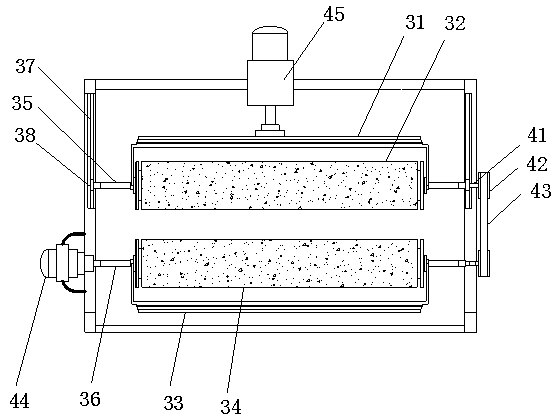

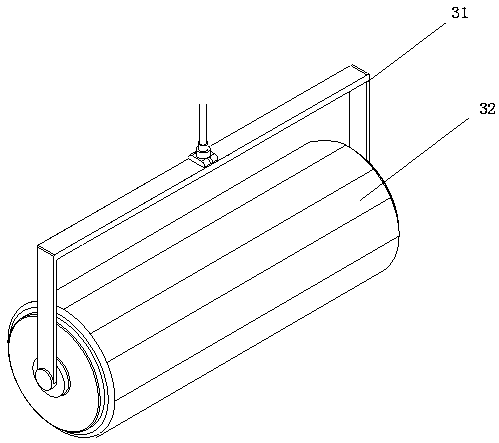

[0024] see figure 2 and image 3 , movable frame 31 and fixed frame 33 are respectively installed in described ink removal cavity 2, movable friction roller 32 is installed on described movable frame 31, fixed friction roller 34 is...

Embodiment 2

[0029] see Figure 4 , this embodiment serves as a further optimization of Embodiment 1, on the basis of which, partitions 53 are provided on both sides of the secondary conveyor belt 52, and several water permeable holes 54 are provided on the partitions 53. The bottom of the ink removal chamber 2 is provided with a water accumulation chamber 55 . During the flushing operation, the partition board 53 places the paper tape and is skewed after being impacted by the water flow. After flushing, the water flow carries the ink and flows into the water accumulation chamber 55 from the permeable hole 54 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com