A kind of low-refractive high-viscosity friction silicon dioxide and its preparation method

A silicon dioxide, high viscosity technology, applied in the direction of silicon dioxide, silicon oxide, cosmetic preparations, etc., can solve the problems of low transparency, low powder viscosity, no thickening effect, etc., to improve transparency and production costs The effect of reducing and simplifying the formula and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

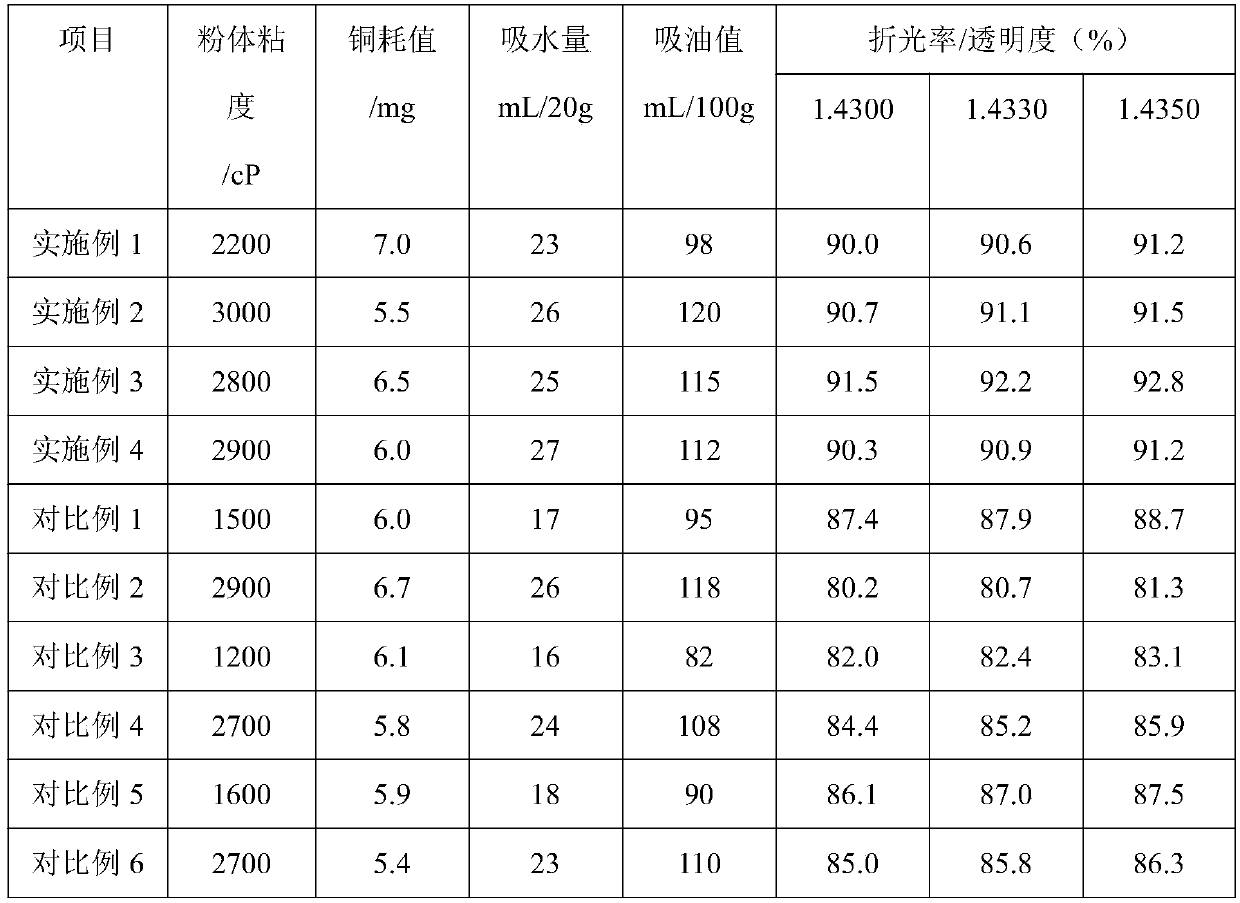

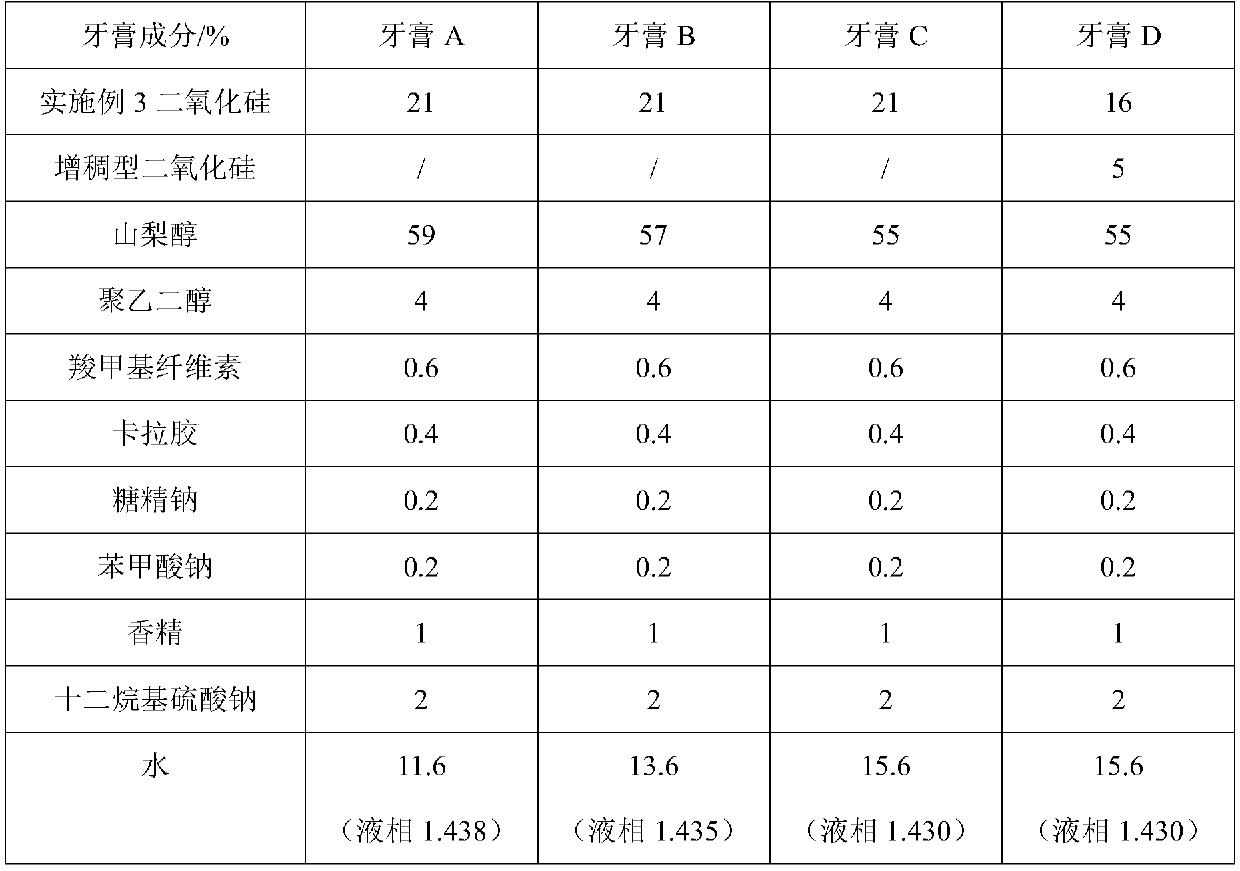

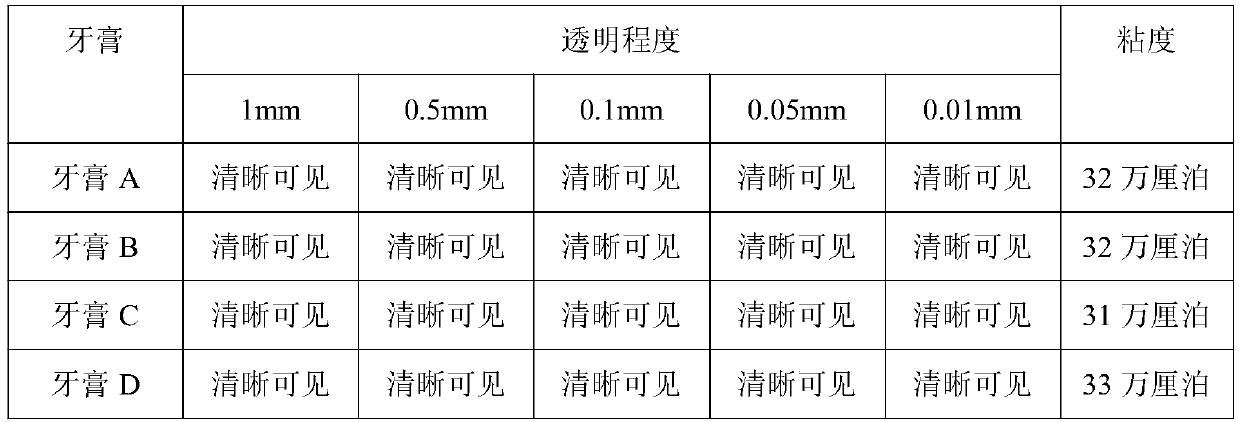

Examples

Embodiment 1

[0027] Example 1. Low-refractive high-viscosity frictional silica of the present invention and its preparation

[0028] S1. Inject the water glass solution A0.8m with a concentration of 0.8M and a modulus of 2.0 into the reaction tank 3 , raise the temperature to 70°C, turn on the stirring, control the stirring speed to 30Hz, at 1.5m 3 The flow rate of / h is dripped the sulfuric acid solution A that concentration is 3M, stops adding acid when pH value is 10, makes thickening type silica sol solution;

[0029] S2. Inject 10m of sodium sulfate solution with a mass percentage concentration of 10.0% into the thickened silica sol solution. 3 , while slowly adding 1 kg of carboxymethyl cellulose, and raising the temperature to 50°C;

[0030] S3, at 14.0m 3 The water glass solution B8m with a concentration of 1.5M and a modulus of 2.0 is added dropwise at a flow rate of / h 3 , at the same time with 2.5 ~ 3.0m 3 The flow rate of / h drips the sulfuric acid solution B with a concen...

Embodiment 2

[0032] Example 2. The low-refractive high-viscosity frictional silica of the present invention and its preparation

[0033] S1. Inject the water glass solution A1.0m with a concentration of 1.0M and a modulus of 2.3 into the reaction tank 3 , raise the temperature to 80°C, turn on the stirring, control the stirring speed to 40Hz, at 2.0m 3The flow rate of / h is dripped the sulfuric acid solution A that concentration is 4M, stops adding acid when pH value is 11, makes thickening type silica sol solution;

[0034] S2. Inject 12m of sodium sulfate solution with a mass percentage concentration of 12.0% into the thickened silica sol solution. 3 , while slowly adding 2 kg of carboxymethyl cellulose and raising the temperature to 60°C;

[0035] S3, at 14.5m 3 Add water glass solution B10m with a concentration of 2.0M and a modulus of 2.3 at a flow rate of / h 3 , at the same time with 2.5 ~ 3.0m 3 The flow rate of / h drips the sulfuric acid solution B with a concentration of 10.0...

Embodiment 3

[0037] Example 3. Low-refractive high-viscosity frictional silica of the present invention and its preparation

[0038] S1. Inject the water glass solution A0.9m with a concentration of 0.9M and a modulus of 2.1 into the reaction tank 3 , heat up to 75°C, turn on the stirring, control the stirring speed to 35Hz, at 2.0m 3 Add the sulfuric acid solution A with a concentration of 3.5M dropwise at a flow rate of / h, stop adding acid when the pH value is 10, and obtain a thickened silica sol solution;

[0039] S2. Inject 11m of sodium sulfate solution with a mass percentage concentration of 12.0% into the thickened silica sol solution 3 , while slowly adding 1.5kg of carboxymethyl cellulose, and raising the temperature to 55°C;

[0040] S3, at 14.0m 3 Add water glass solution B9m with a concentration of 1.8M and a modulus of 2.1 at a flow rate of / h 3 , at the same time with 2.5 ~ 3.0m 3 The flow rate of / h drips the sulfuric acid solution B with a concentration of 9.0M to ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com