Gauze product containing X-ray developer and production method thereof

A production method and product technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of difficult detection of wounds, deterioration of patients' condition, and difficult detection, so as to avoid medical accidents, make the composite firm, and not easy to detach Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides a method for producing gauze products containing X-ray developing objects. The gauze products produced by the production method include gauze raw materials, gauze dressings and other gauze products.

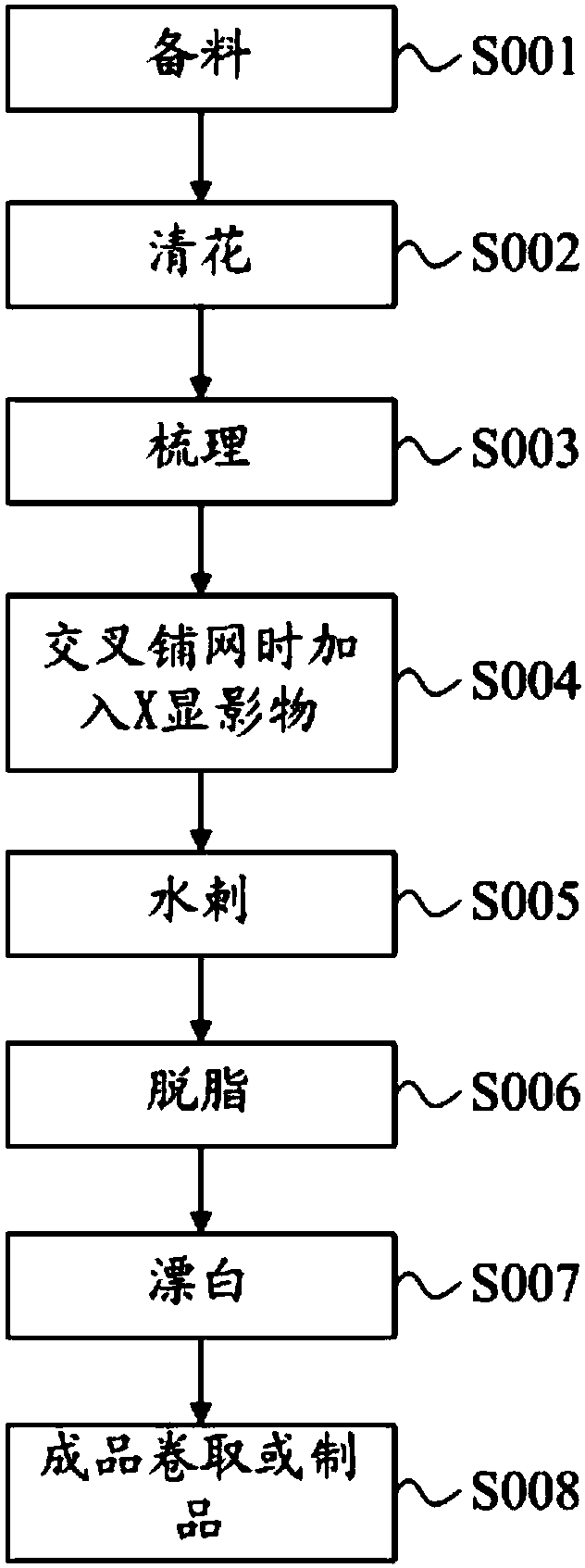

[0022] Such as figure 1 As shown, the production method of the gauze product containing the X-ray developer in the present embodiment comprises the steps:

[0023] S001: Prepare materials;

[0024] S002: clear flowers;

[0025] S003: Combing;

[0026] S004: cross-lapping;

[0027] S005: Spunlace;

[0028] S006: degreasing;

[0029] S007: bleaching;

[0030] S008: Finished coils or products.

[0031] Wherein, the process steps of material preparation, flower cleaning, carding, degreasing, bleaching, and finished product coiling or product process are consistent with the process methods in the prior art.

[0032] In the production method of the gauze product containing the X-ray developing object in this embodiment, before the spunlace, the X...

Embodiment 2

[0038] This embodiment provides a gauze product containing X-ray developing material, and the gauze product includes gauze raw materials, surgical towel dressings made of gauze and other gauze products.

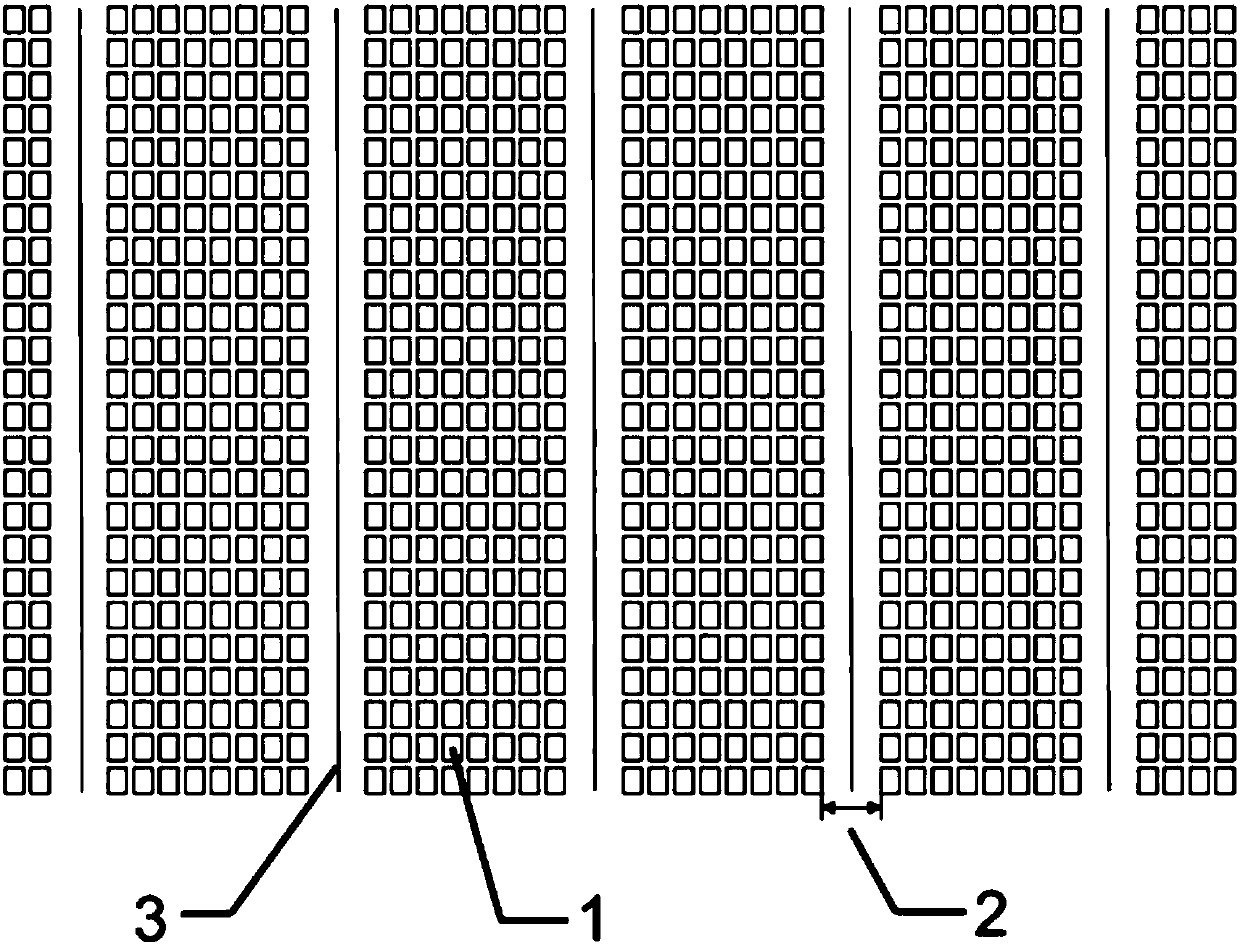

[0039] The gauze product containing X-ray developing matter of this embodiment is prepared by the production method of the gauze product containing X-ray developing matter in the first embodiment above. Such as figure 2 As shown, the gauze (non-woven fabric) has a mesh portion 1 and a plain portion 2, and the X-ray developed object 3 is hydroentangled on the plain portion 2, and the plain portion 2 is arranged side by side along the width direction of the non-woven fabric. In this embodiment , the width of the plain portion 2 is 1mm-200mm, for example, the width is 5mm or 15mm. Correspondingly, the X-ray developing objects 3 are located on the plain portion 2 , and one or more X-ray developing objects 3 are hydroentangled on one plain portion 2 . The X-ray developing objec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com