Shell porous silicate, preparation method thereof and friction material containing same

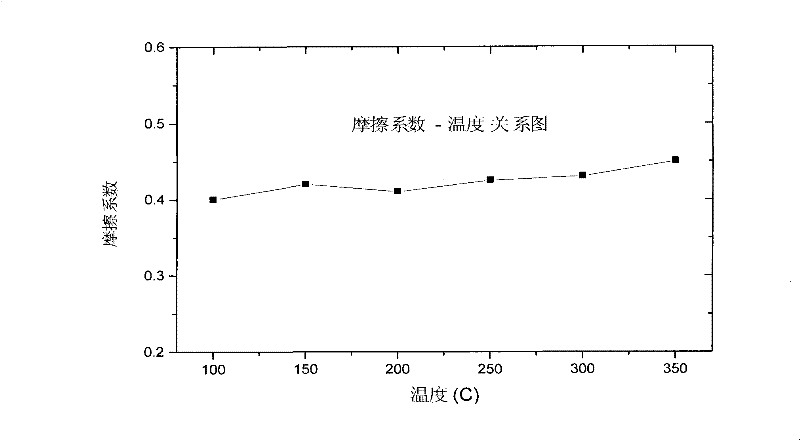

A silicate and shell technology, used in the field of silicate, to achieve good heat resistance and wear resistance, eliminate static charges, and improve permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

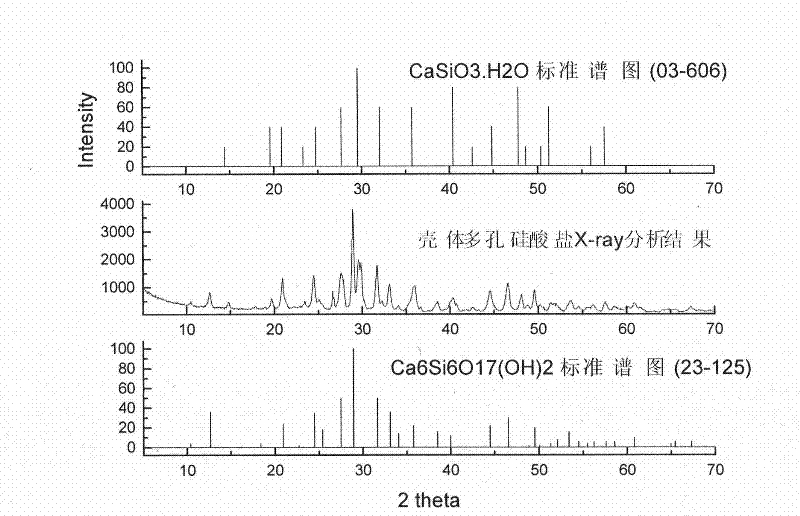

[0025] In a 5L autoclave, first put 3620g of water, then add quartz powder (containing SiO 2 Accounting for 98%) 147.8g, unslaked lime (containing CaO and accounting for 96%) 138g, and metal silicon powder (containing more than Si99%) 2.8g, stir and mix well, seal the reaction kettle lid, heat the kettle with a heating rate of 2°C / min. Heating up to 200°C, pressure 16Kg / cm 2 Next, keep warm for 6 hours. During the process of heating up and keeping warm, in order to prevent the precipitation of the reaction product, the paddles will keep stirring at a stirring speed of 220rpm. Stop heating after keeping warm, and cool down with the furnace. After cooling, the product was taken out, washed with water, filtered, and dried in an electric oven at 120° C. for 8 hours to obtain 180 g of white powder with a bulk density of 86 g / L. According to X-ray diffraction analysis, its main component is the chemical formula Ca 6 Si 6 o 17 (OH) 2 , and contains 6wt.% CaSiO 3 .H 2 Silicate ...

Embodiment 2

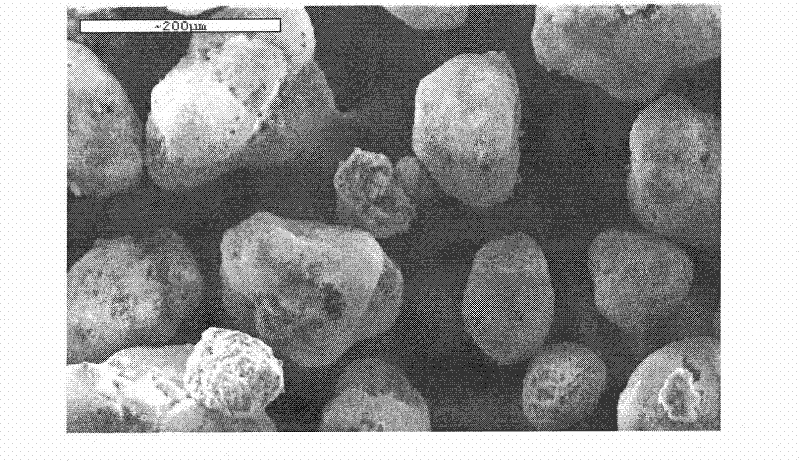

[0027] In a 5L autoclave, first put 3697g of water, then add quartz powder (SiO 2 account for more than 98%) 53.1g, unslaked lime (CaO purity 96%) 49.6g, and metal silicon powder (containing more than Si99%) 1.0g, stir and mix well, seal the reaction kettle lid, with the heating rate of 1.8 ℃ / min. The temperature of the kettle is raised to 210°C, and the pressure is 20Kg / cm 2 Next, keep warm for 6 hours. During the process of heating up and keeping warm, the blades keep stirring at a stirring speed of 230rpm. Stop heating after keeping warm, and cool down with the furnace. After cooling, the product was taken out, washed with water, filtered, and dried in an electric oven at 130° C. for 6 hours to obtain 102 g of white powder with a bulk density of 110 g / L. According to X-ray diffraction analysis, its main component is the chemical formula Ca 6 Si 6 o 17 (OH) 2 , and contains 5wt.% CaSiO 3 .H 2 O represents the silicate. The product was observed with a scanning electro...

Embodiment 3

[0029] In a 5L high-pressure reactor, put 3619g of water first, and then add SiO 2 (Analytical pure) 81g, Ca(OH) 2(Analytical pure) 100g, and metal silicon powder (containing more than 99% Si) 1.8g, stir and mix well, seal the lid of the reaction kettle, heat the kettle to 200°C at a heating rate of 2°C / min, and pressure 16Kg / cm 2 Keep it warm for 6 hours. During the heating and heat preservation process, the paddles keep stirring at a stirring speed of 230 rpm. After the heat preservation finishes, stop heating and cool down with the furnace. After cooling, the product was taken out, washed with water, filtered, and dried in an electric oven at 120° C. for 8 hours to obtain 157 g of white powder with a bulk density of 95 g / L. According to X-ray diffraction analysis, its main component is the chemical formula Ca 6 Si 6 o 17 (OH) 2 , and contains 6wt.% CaSiO 3 .H 2 O represents the silicate. Observing the product with a scanning electron microscope, the morphological fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com