Ramp construction device and construction method thereof

A construction device and ramp technology, which is applied in the direction of formwork/formwork/work frame, building structure, stepped structure, etc., can solve the problems of foot discomfort, loss of line structure, poor friction effect of ramps, etc. Guaranteed friction effect, extended service life, and improved discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: A kind of ramp construction device

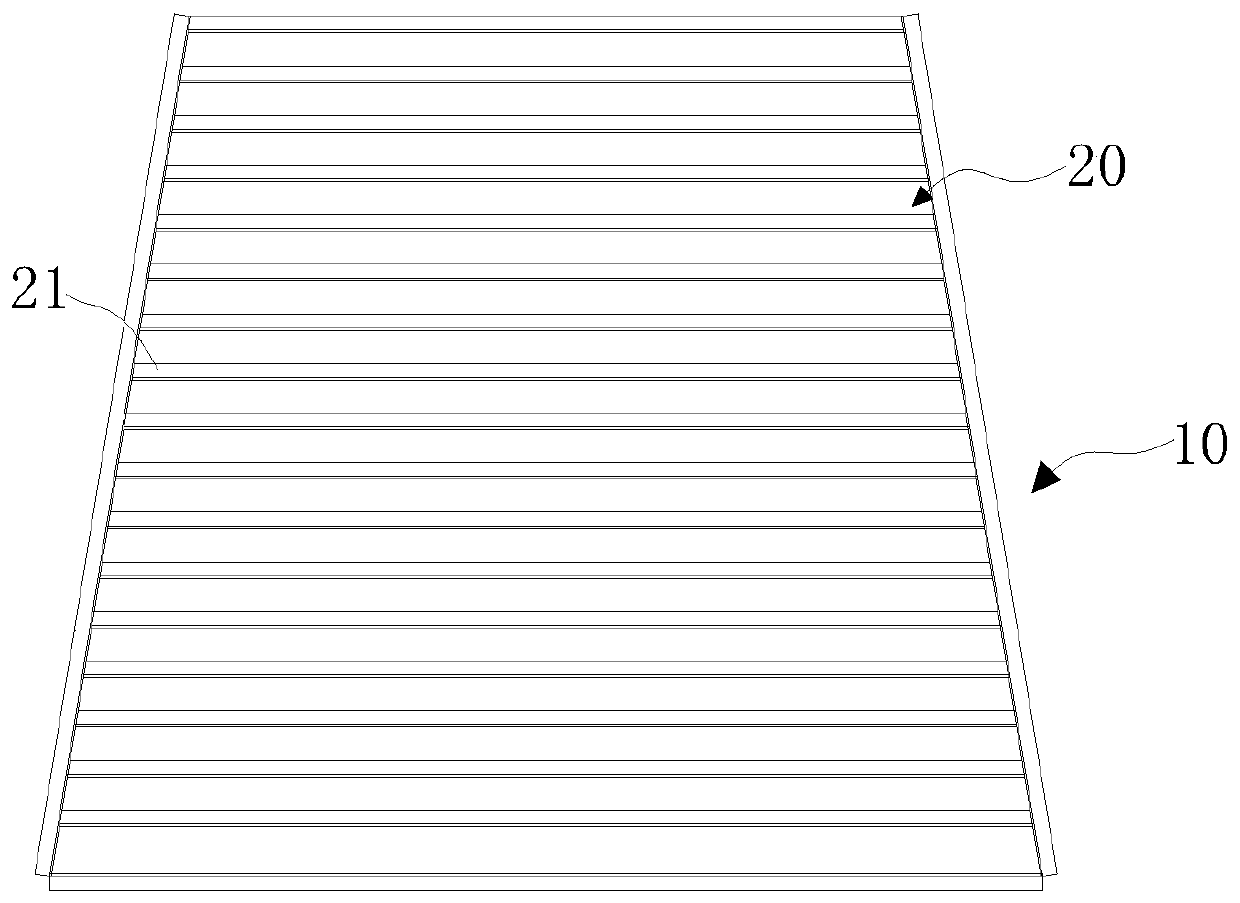

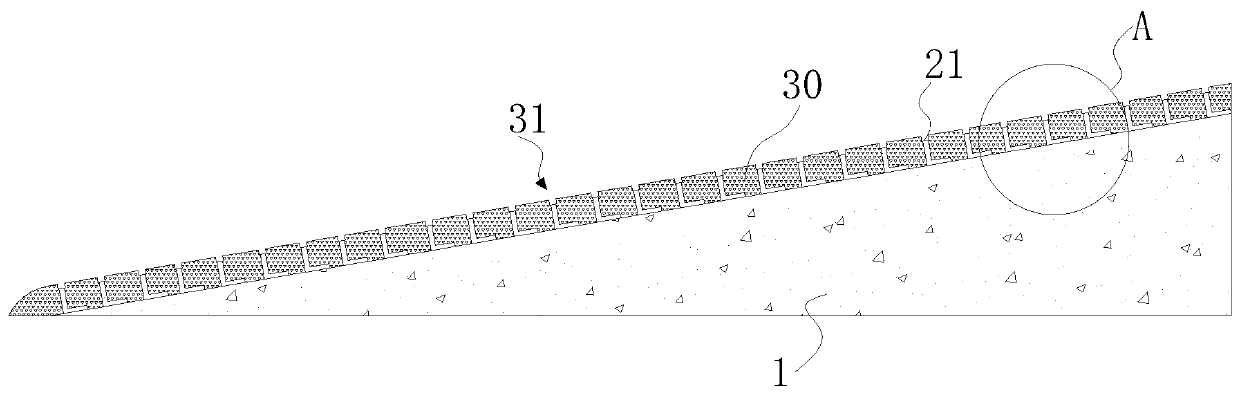

[0038] Such as Figure 1-3 As shown, a ramp construction device, the ramp construction device includes a base shaping part 10, characterized in that: the ramp construction device also includes a set in the base body shaping part 10, and is used in conjunction with the base body shaping part 10 The supporting part 20, the space between the matrix shaped part 10 and the supporting part 20 is provided with a protective body 30 formed after the concrete is cured, and the upper surface of the supporting part 20 and the protective body 30 forms a concave-convex friction surface 31.

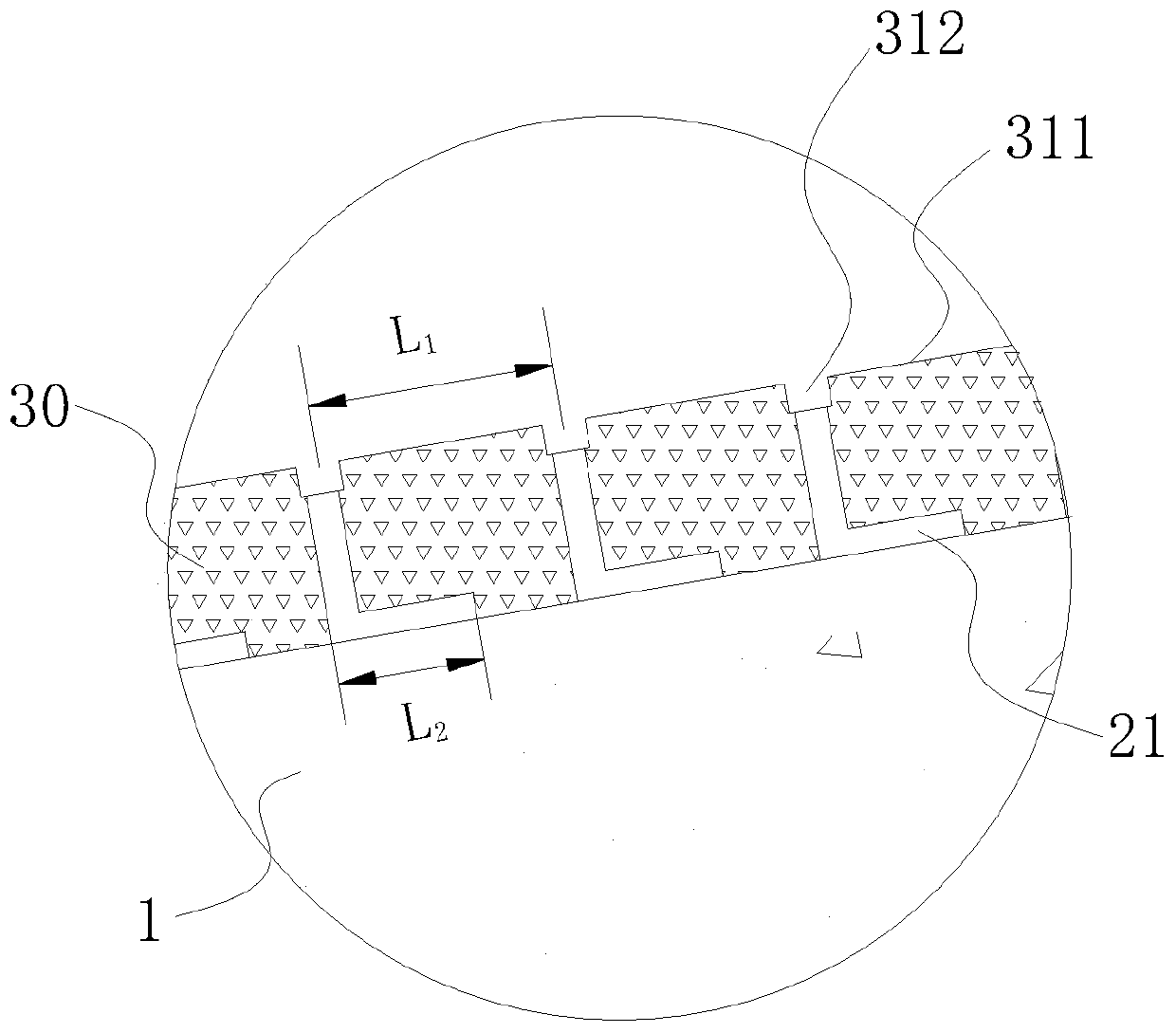

[0039] The support part 20 is composed of several separation parts 21, and the space between the adjacent separation parts 21 is provided with cured concrete, and the surface of the cured concrete is the base surface 311, and friction lines are formed at the junction of every two base surfaces 311 312, the width of the friction lines 312 is 1-3c...

Embodiment 2

[0047] Embodiment 2: A construction method of a ramp construction device

[0048] 1) Concrete pouring and laying cushion 1 at the construction position;

[0049] 2) Lay the base body shaping part 10 on the upper surface of the mat layer 1 after drying, the distance between the adjacent separation parts 21 in the matrix shaping part 10 frame is 10 centimeters; or lay the basic shaping part 10 in the middle of the upper surface of the cushion layer 1 according to the set direction.

[0050] 3) Concrete is poured in the matrix shaping part 10. After the pouring is completed, when the concrete is slightly dry until it no longer flows, use tools to smooth the undried concrete in the entire frame. The leveled concrete is higher than the top of the separation part 21 5mm;

[0051] 4) Utilize a tool to remove the top concrete of the long side where the separation part 21 is arranged upwards to form friction lines 312, so that the width of the friction lines 312 is 2 cm, and the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com