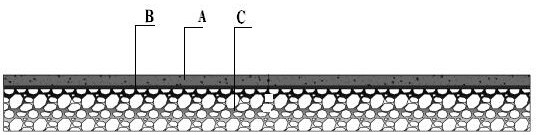

Maintenance and Construction Method of Infiltrating Wear Layer of Asphalt Pavement

A technology of asphalt pavement and construction method, applied in the direction of roads, roads, and on-site coagulation pavement, etc., can solve the problems of unrepairable and improved network cracks, easy wear of the wear layer, limited duration, etc., and achieves fast construction speed, The effect of improving the density and improving the flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment one: the preparation of asphalt pavement cementing agent:

[0049] The cementing agent for asphalt pavement of the present invention is prepared by mixing the following raw materials:

[0050] Heavy naphthenic distillate oil: 300Kg, selected from hydrodesulfurized heavy naphthenic petroleum light distillate (produced by Ergon Company of the United States).

[0051] Petroleum-based asphalt: 200Kg, choose No. 70 petroleum-based asphalt (or No. 90 petroleum-based asphalt);

[0052] Emulsifier weight part 20Kg, choose 18331 type emulsifier (produced by Akzo-Nobel company in the Netherlands)

[0053] Modifier weight part 30Kg, select styrene-butadiene rubber SBR modifier for use.

[0054] 550Kg of water.

[0055] The preparation process of the cementing agent for asphalt pavement: first mix the distilled oil of heavy naphthenic hydrocarbons and petroleum base asphalt to form a base oil mixture for heat preservation, and then mix the emulsifier, modifier and wat...

Embodiment 2

[0056] Embodiment two: the preparation of cementing agent for asphalt pavement:

[0057] The cementing agent for asphalt pavement of the present invention is prepared by mixing the following raw materials:

[0058] 20-40 parts of heavy naphthenic distilled oil;

[0059] 15-30 parts of petroleum base asphalt;

[0060] 1-3 parts of emulsifier;

[0061] Modifier 0-5 parts;

[0062] 40-65 parts of water.

[0063] Heavy naphthenic distillate oil: 250Kg, selected from hydrodesulfurized heavy naphthenic petroleum light distillate (produced by Ergon Company of the United States);

[0064] Petroleum base asphalt: 250Kg, choose No. 90 petroleum base asphalt;

[0065] Emulsifier weight portion 15Kg, select 18331 type emulsifier (produced by Holland Akzo-Nobel Company) for use;

[0066] Modifier weight part 45Kg, select for use: styrene-butadiene rubber SBR modifier;

[0067] Water 450Kg.

[0068] The preparation process of the cementing agent for asphalt pavement: first mix the d...

Embodiment 3

[0069] Embodiment three: the preparation of cementing agent for asphalt pavement:

[0070] The cementing agent for asphalt pavement of the present invention is prepared by mixing the following raw materials:

[0071] Heavy naphthenic distillate oil: 350Kg, selected from hydrodesulfurized heavy naphthenic petroleum light distillate (produced by Ergon Company of the United States);

[0072] Petroleum base asphalt: 100Kg, choose No. 90 petroleum base asphalt;

[0073] The weight part of emulsifier is 28Kg, select 18331 type emulsifier (produced by Holland Akzo-Nobel Company) for use;

[0074] 600Kg of water.

[0075] The preparation process of the cementing agent for asphalt pavement: first mix the distilled oil of heavy naphthenic hydrocarbons and petroleum base asphalt to form a base oil mixture for heat preservation, and then mix the emulsifier, modifier and water in proportion to prepare a soap solution. Finally, the base oil mixture and the soap are produced together throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com