Self-aligning roll shaft unit

A self-aligning, roller shaft technology, applied in the direction of bearing components, shafts and bearings, rolling contact bearings, etc., can solve problems such as bearings and shafts stuck, stirring devices can not work normally, etc., to achieve reliable and stable use, reasonable structure, The effect of the service life guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Here, the specific structure and workflow of the present invention will be further described through the following specific implementation methods:

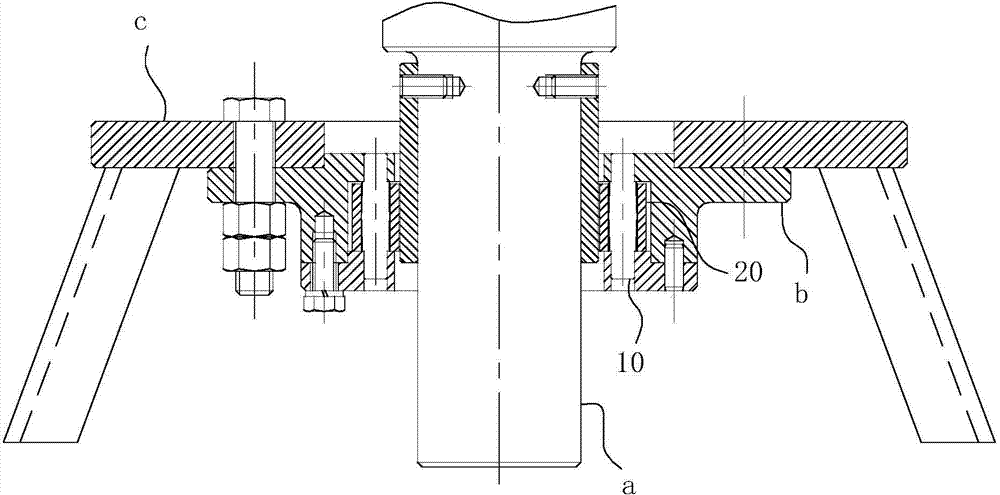

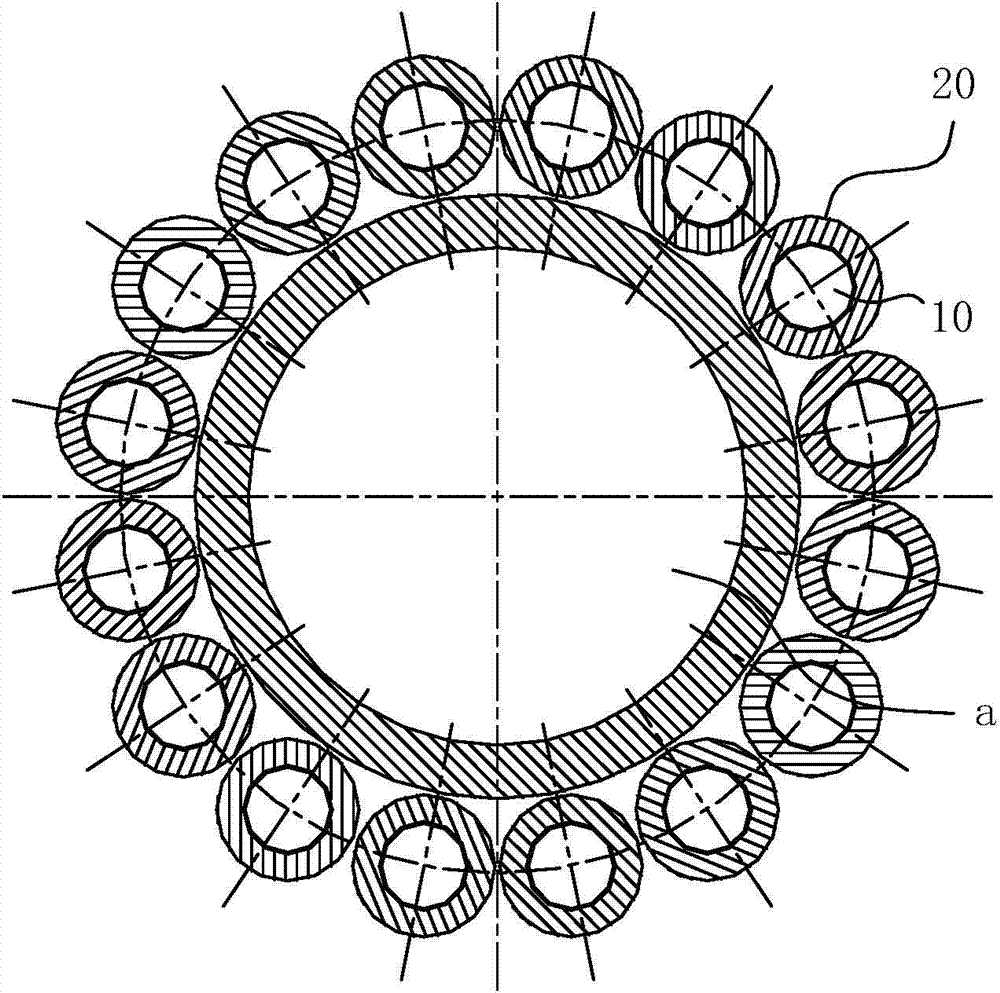

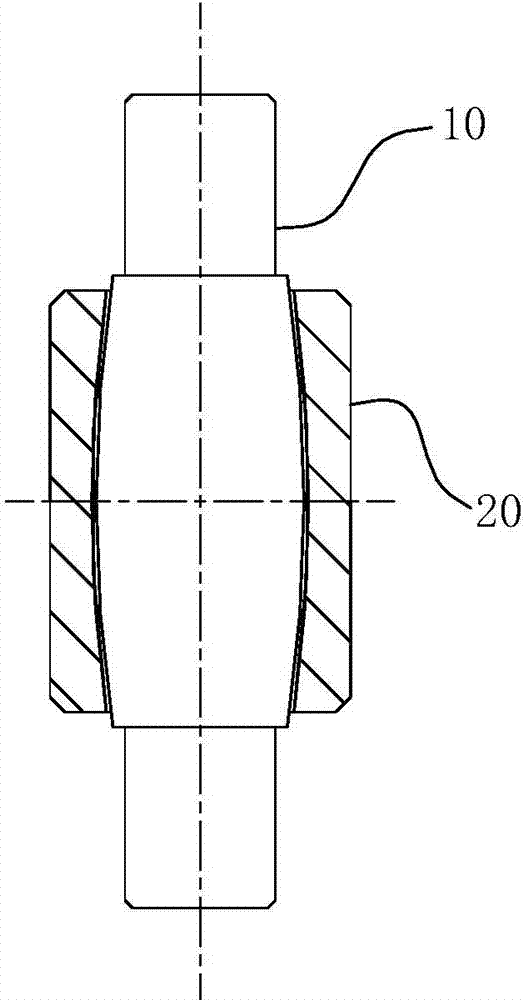

[0027] The practical application structure of the present invention is as Figure 1-2 As shown, it includes a bearing outer ring b sleeved on the shaft body of the stirring shaft 10, and the bearing outer ring b is fixed in the inner cavity of the agitator with a support frame c. The axis of the bearing outer ring b is coaxially arranged with the ideal axis of the stirring shaft a, that is, the axis of the stirring shaft a is in an ideal vertical state, and there is a distance between the hole wall of the bearing outer ring b and the shaft body of the stirring shaft a, So that the agitator shaft a can make a deflection movement within the allowable range. The inner wall of the bearing outer ring b is provided with accommodating grooves along its axis ring, and various components of the present invention are arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com