A kind of multilayer composite structure ceramic brake pad material and preparation method thereof

A multi-layer composite, brake pad technology, used in chemical instruments and methods, friction linings, mechanical equipment, etc., can solve problems such as high wear, large pollution, thermal recession, etc., to improve noise reduction and vibration reduction performance, excellent The effect of lubricating performance, wear resistance and moderate friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

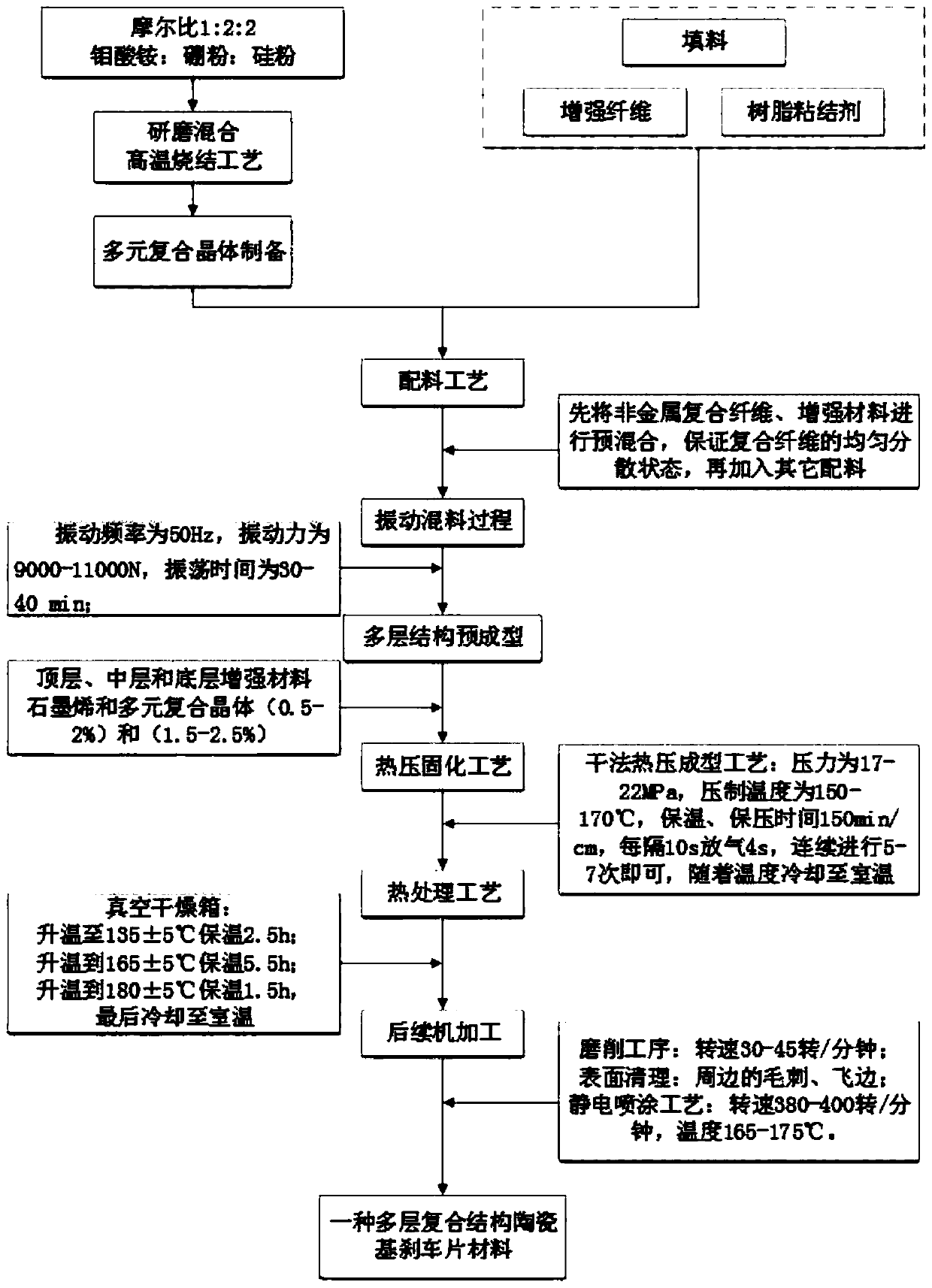

Method used

Image

Examples

Embodiment 1

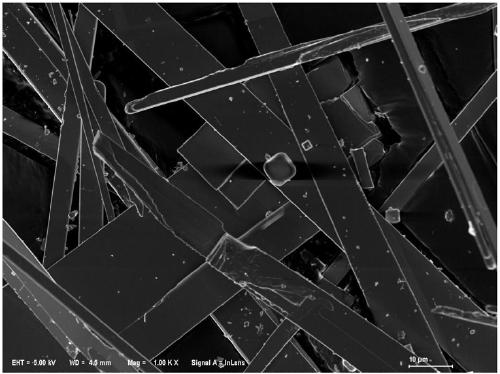

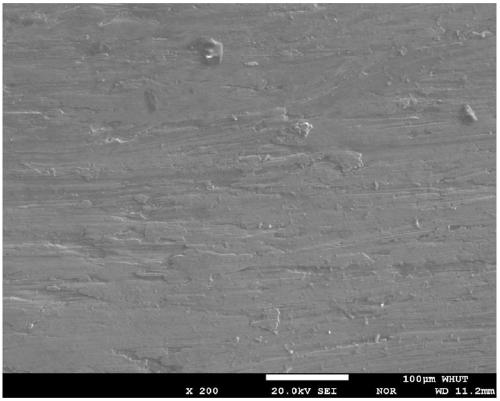

[0033] A multi-layer composite structure ceramic brake pad material, with the ceramic brake pad material as the matrix, adding enhanced performance materials graphene and multi-element composite crystals, the structure is divided into three layers: the top layer, the middle layer and the bottom layer, and the content of the top layer, the middle layer and the bottom layer enhances performance materials Different; the thickness of the top layer structure is 1.5mm, the addition amount of graphene and multi-component composite crystal is 1.5wt.% and 2wt.% of the mass of the matrix; the thickness of the middle layer structure is 2.5mm, and the addition amount of graphene and multi-component composite crystal is the mass of the matrix 1.5wt.% and 3wt.%; the thickness of the underlying structure is 4mm, and the addition of graphene and multi-element composite crystals is 2wt.% and 3.5wt.% of the mass of the matrix. Among them, the raw materials of the matrix include: ceramic fiber (1...

Embodiment 2

[0045] A multi-layer composite structure ceramic brake pad material, with the ceramic brake pad material as the matrix, adding enhanced performance materials graphene and multi-element composite crystals, the structure is divided into three layers: the top layer, the middle layer and the bottom layer, and the content of the top layer, the middle layer and the bottom layer enhances performance materials Different; the thickness of the top layer structure is 2mm, the addition amount of graphene and multi-component composite crystal is 1wt.% and 2.5wt.% of the mass of the matrix ceramic brake pad; the thickness of the middle layer structure is 2.5mm, the addition amount of graphene and multi-component composite crystal 1.5wt.% and 3.5wt.% of the mass of the matrix ceramic brake pad; the thickness of the underlying structure is 3.5mm, and the addition of graphene and multi-element composite crystals is 2.5wt.% and 3.5wt.% of the mass of the matrix ceramic brake pad. Among them, the...

Embodiment 3

[0057]A multi-layer composite structure ceramic brake pad material, with the ceramic brake pad material as the matrix, adding enhanced performance materials graphene and multi-element composite crystals, the structure is divided into three layers: the top layer, the middle layer and the bottom layer; the thickness of the top layer structure is 2mm, graphene and The addition amount of multi-component composite crystals is 1.5wt.% and 2.5wt.% of the mass of the matrix ceramic brake pad; 3.5wt.%; the thickness of the underlying structure is 4mm, and the added amount of graphene and multi-component composite crystal is 2wt.% and 4wt.% of the mass of the matrix ceramic brake pad. Among them, the raw materials of the matrix include: ceramic fiber (20%), aramid fiber (4%), glass fiber (6%), SiC organosilicon modified phenolic resin (19%), barite (12%) by mass percentage. %), NBR powder (7%), graphite (2%), alumina (3%), potassium titanate whiskers (25%), white vermiculite powder (2%)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com