Flat packing belt

A packing belt and embossed technology, which is applied in the direction of packaging, transportation and packaging, flexible and slender components, etc., can solve the problems of the strength breakage of the packing belt and the impact on the tensile strength, so as to ensure the production quality and reduce the weight , the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

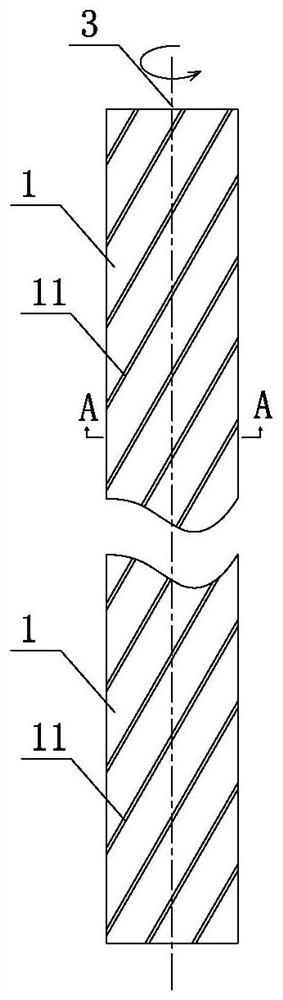

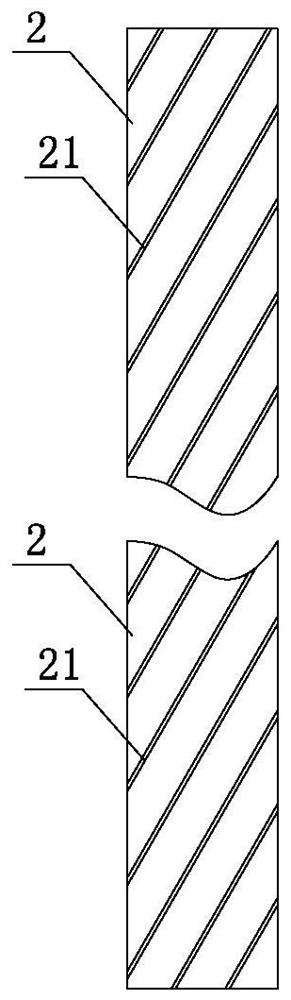

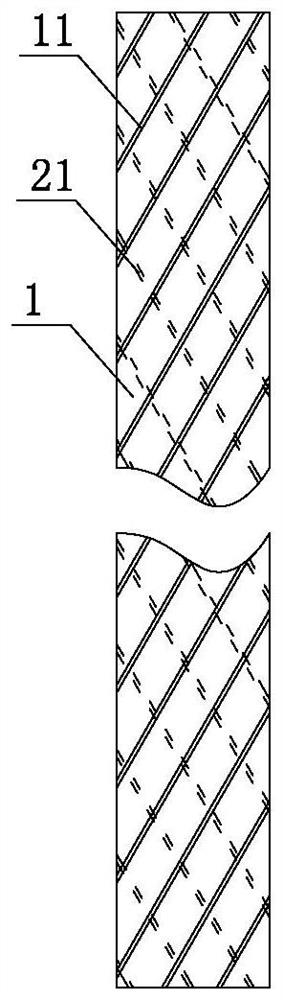

[0021] Refer to attached drawings. The flat packing belt involved in the present invention is a flat packing belt made of polypropylene or polyester material for a strapping machine, and the packing belt can be bonded by hot melt during packing.

[0022] As for the flat packing tape suitable for the desktop strapping machine, its width is 4.5±0.5mm, and the thickness is 0.38±0.05mm. This embodiment takes this packing tape as an example for detailed description. However, the technical solution of the present invention can also be applied to flat packing tapes of other sizes.

[0023] The flat packing belt is provided with a front side 1 and a back side 2, the front side 1 and the back side 2 are made with the same oblique embossing, the oblique embossing on the front is marked 11, and the oblique embossing on the reverse side is marked 21. The diagonal ridges on each side are parallel ridges.

[0024] As shown in the figure, the oblique rib 11 observed from the front orthogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com