Garbage bag hot melting sealing device and garbage can

A sealing device and technology for garbage bags, which are applied in the field of hot-melt sealing devices for garbage bags and garbage cans, can solve the problem that the operational sealing quality cannot meet expectations, the automatic packaging function without garbage bags, and simple functions cannot meet people's needs and other issues to achieve the effect of improving quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are only used to more clearly illustrate the technical solutions of the present invention, and are therefore only used as examples, and cannot be used to limit the protection scope of the present invention.

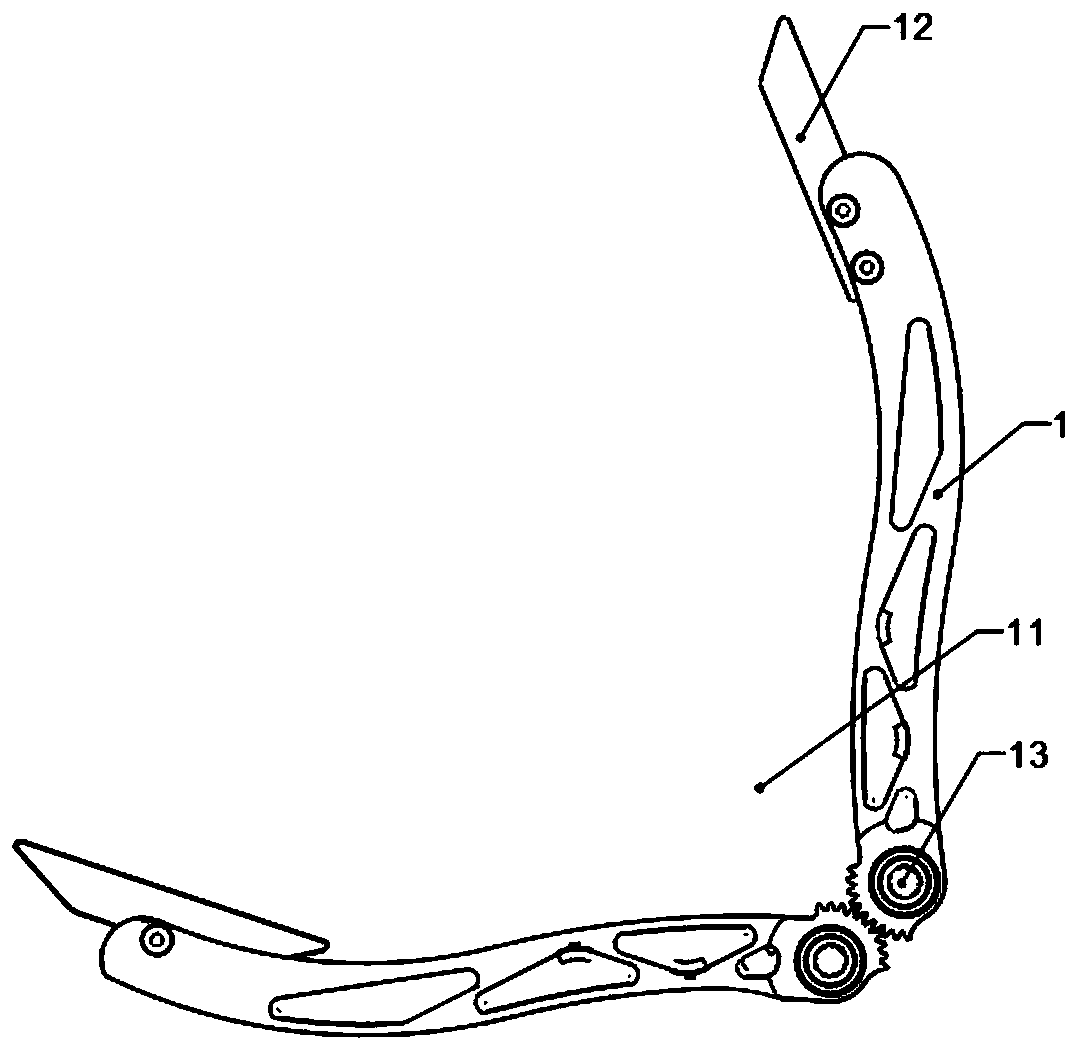

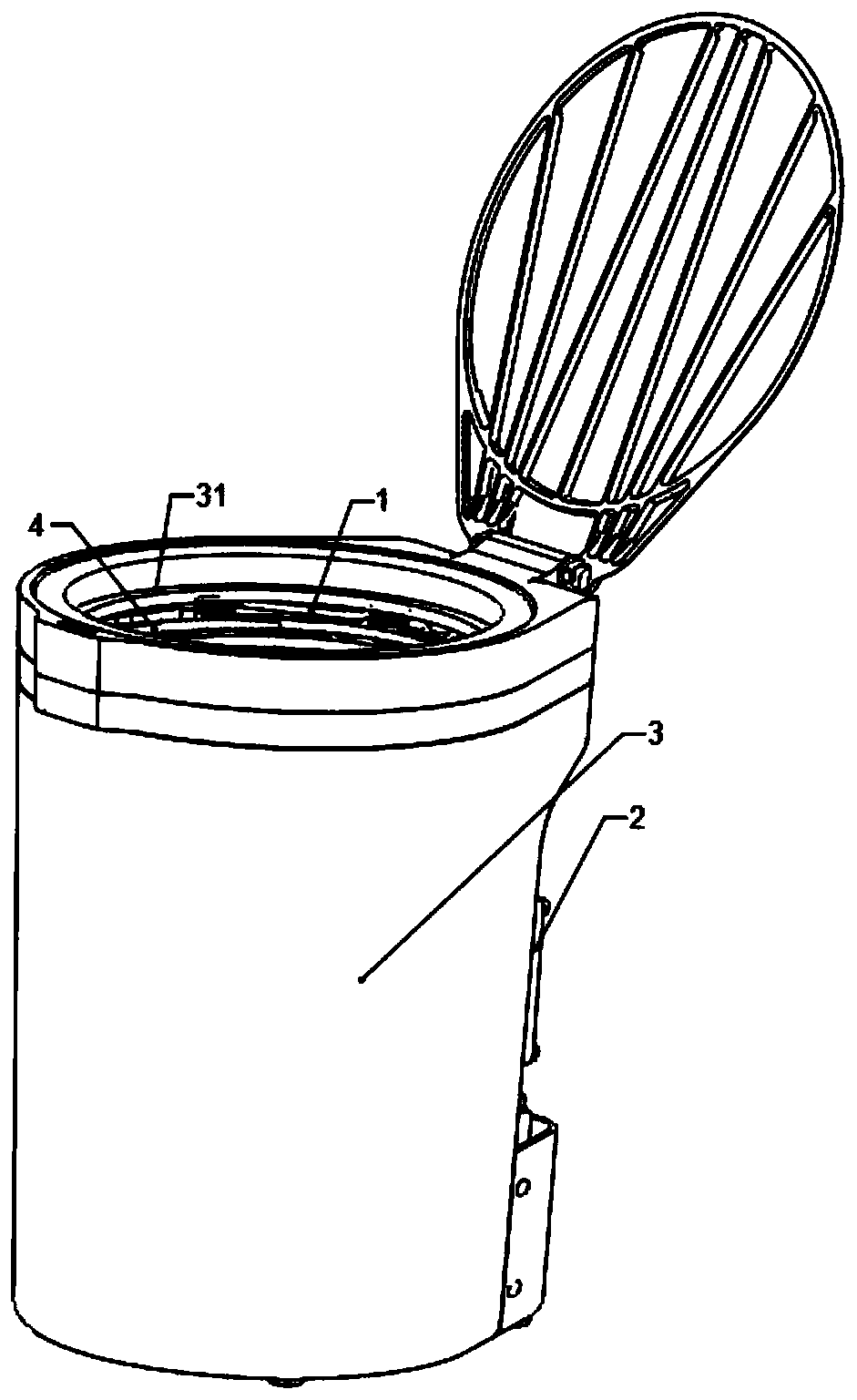

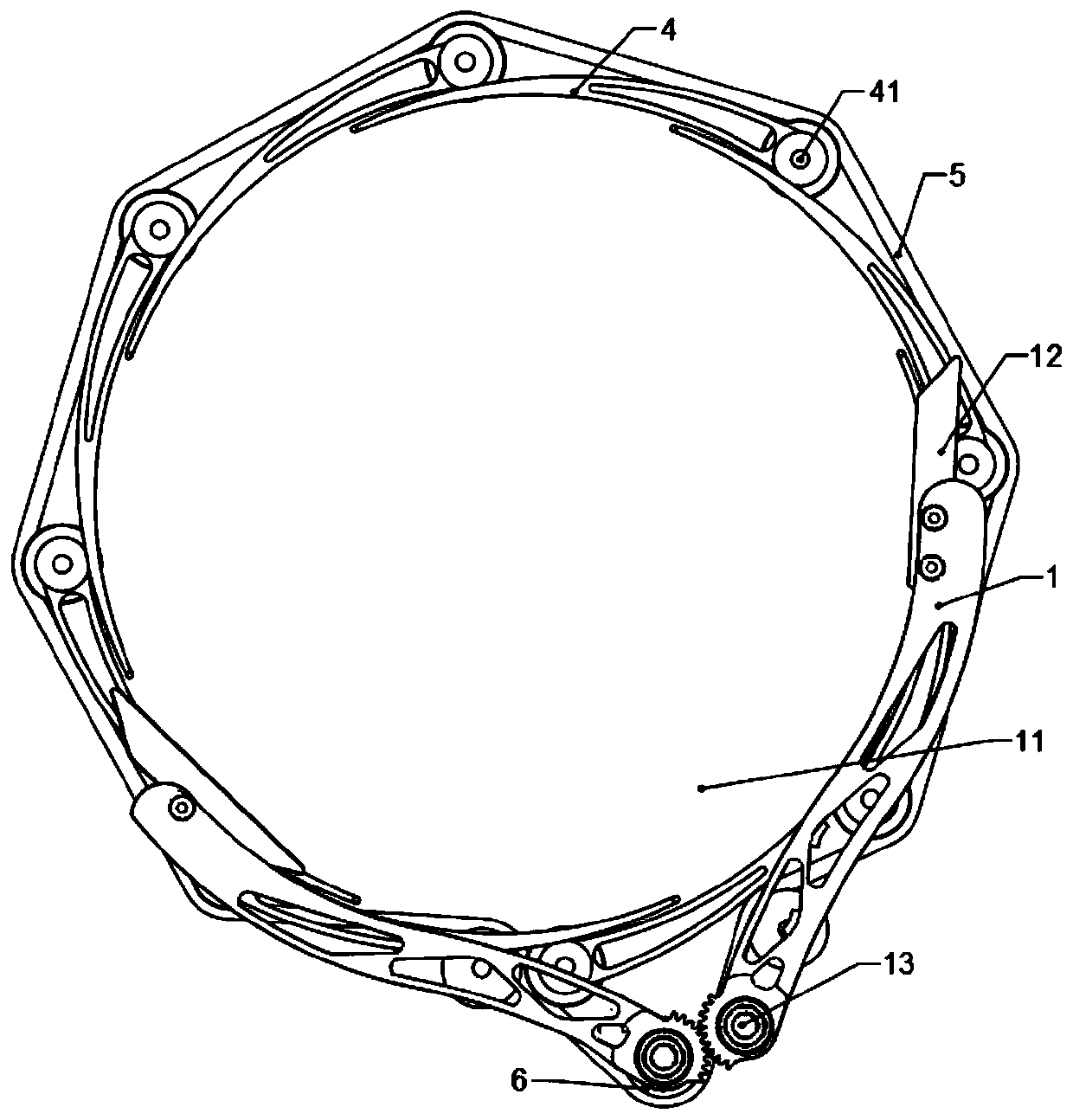

[0021] see figure 1 , a garbage bag hot-melt tying device provided in this embodiment includes two swing arms 1; one end of the two swing arms 1 is rotatably connected, so that a garbage bag is formed between the two swing arms. The other opposite end of the swing arm 1 is installed with a heating piece 12; the heating piece 12 is connected with a hot-melt circuit; the heating piece 12 is used to rotate between the two heating pieces. Melt and heat seal the mouth of the garbage bag when tying the center of the opening space. When in use, one end of the two swing arms 1 is rotatably installed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com