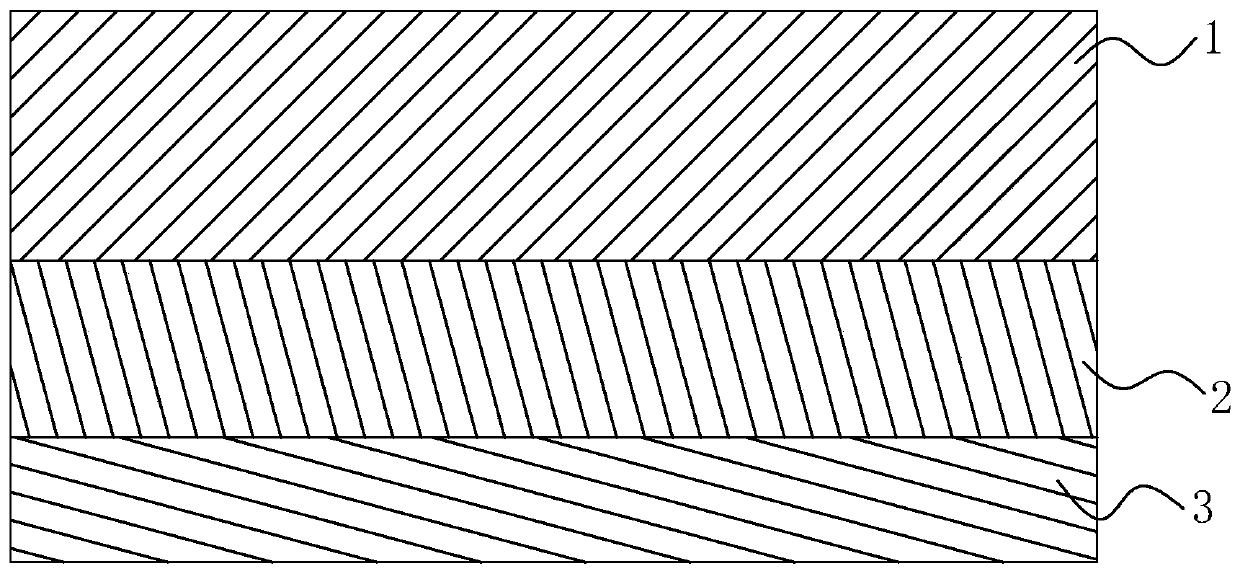

Cast chlorinated polyethylene (CPE) heat-sealing easy-tearing cover film and preparation method thereof

An easy-tear cover and casting technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc. NY/MPET material film lamination and other problems, to achieve the effect of improving the easy-to-release and easy-to-tear properties, the bonding strength and easy-to-tear properties, and the bending strength and impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

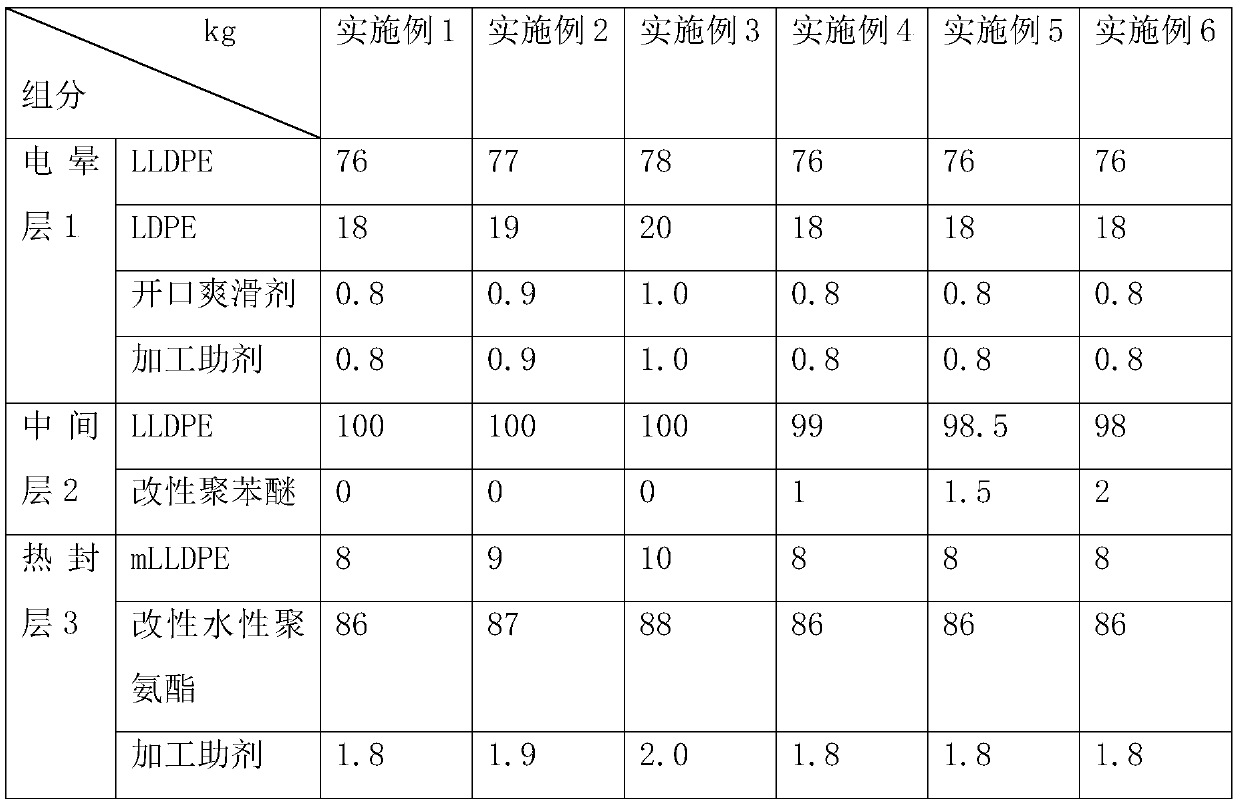

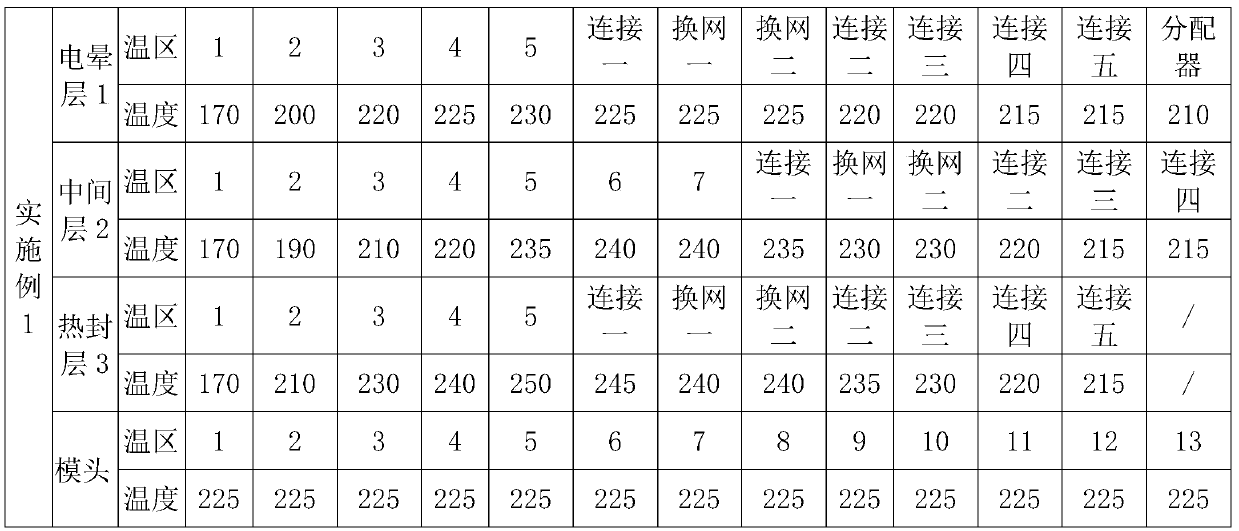

Examples

preparation example 1

[0050] Preparation Example 1: (1) Add 1.4 kg of isophorone diisocyanate to 1 kg of polyether 210, and pass through nitrogen, react at 75 ° C for 2 hours, add 0.3 kg of dimethylol propionic acid and 0.1 kg of dilauric acid diisocyanate Butyl tin, add 1.8kg 1,4-butanediol, 0.8kg trimethylolpropane and 3kg acetone, stir for 1h, cool down to 70°C, add 2kg polydimethylsiloxane and 1.8kg triethylamine, stir for 15min , add 5kg of deionized water, disperse for 30min, and distill under reduced pressure to remove acetone to obtain PU emulsion;

[0051] (1) Mix 1kg PU emulsion, 0.3kg emulsifier, and 3kg water, add 0.5kg initiator AIBN BA solution, stir, polymerize at 80°C for 3h, heat up to 90°C, react for 1h, cool down to room temperature, and discharge , to prepare modified water-based polyurethane.

preparation example 2

[0052] Preparation Example 2: (1) Add 1.9kg of isophorone diisocyanate to 2kg of polyether 210, and pass through nitrogen, react at 78°C for 1.8h, add 0.5kg of dimethylol propionic acid and 0.3kg of dilauric acid Dibutyltin, add 2.2kg 1,4-butanediol, 0.9kg trimethylolpropane and 4kg acetone, stir for 1.3h, cool down to 70°C, add 2.5kg polydimethylsiloxane and 2.1kg triethylamine , stirred for 18 minutes, added 8kg of deionized water, dispersed for 30 minutes, decompressed distillation to remove acetone, and obtained PU emulsion;

[0053] (1) Mix 2kg PU emulsion, 0.4kg emulsifier, and 4kg water, add 0.6kg initiator AIBN BA solution, stir, polymerize at 83°C for 2.8h, heat up to 90°C, react for 1.3h, and cool down to room temperature, Discharging to obtain modified water-based polyurethane.

preparation example 3

[0054] Preparation Example 3: (1) Add 2.4kg of isophorone diisocyanate to 3kg of polyether 210, and pass through nitrogen, react at 80°C for 1.5h, add 0.8kg of dimethylol propionic acid and 0.5kg of dilauric acid Dibutyltin, add 2.6kg 1,4-butanediol, 1.1kg trimethylolpropane and 5kg acetone, stir for 1.5h, cool down to 70°C, add 3kg polydimethylsiloxane and 2.4kg triethylamine, Stir for 20 minutes, add 10kg of deionized water, disperse for 30 minutes, and distill under reduced pressure to remove acetone to obtain PU emulsion;

[0055] (1) Mix 3kg PU emulsion, 0.5kg emulsifier, and 5kg water, add 0.7kg initiator AIBN BA solution, stir, polymerize at 85°C for 2.5h, heat up to 90°C, react for 1.5h, and cool down to room temperature, Discharging to obtain modified water-based polyurethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com