Patents

Literature

192results about How to "Appropriate amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods for hydrocarbon recovery

InactiveUS6173775B1Difficult to maintainReduce effectInsulationFluid removalHydrogen compoundsInjector

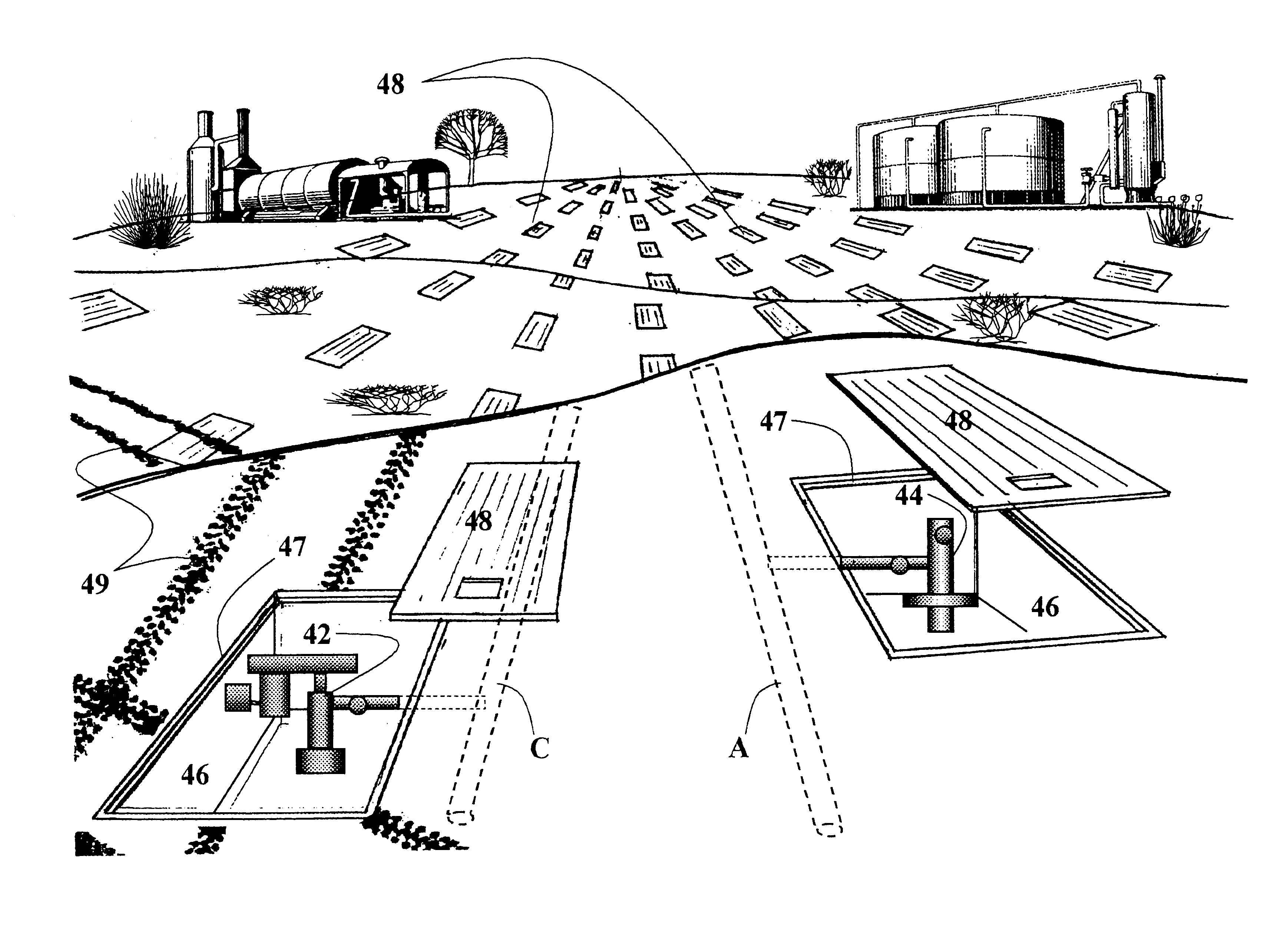

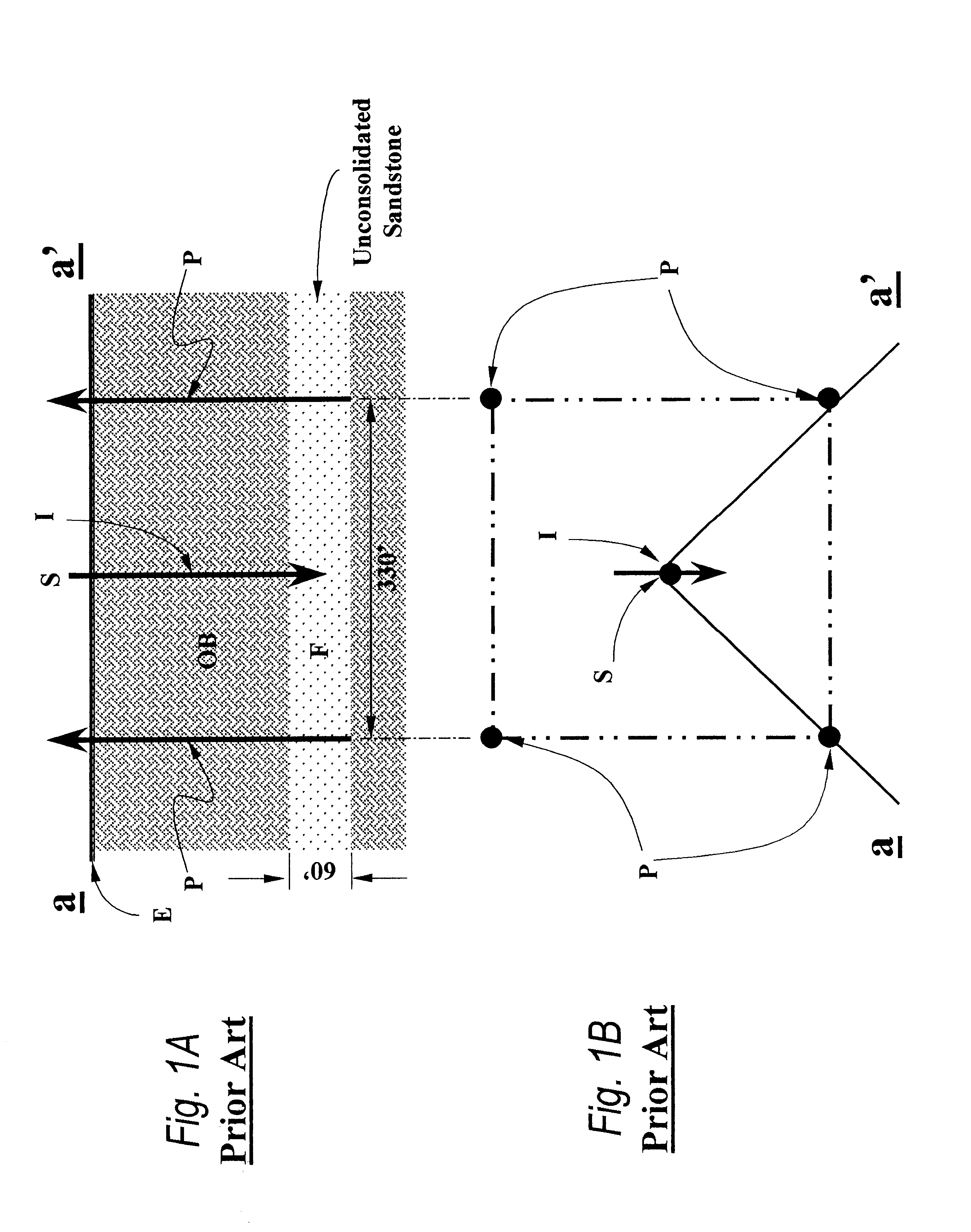

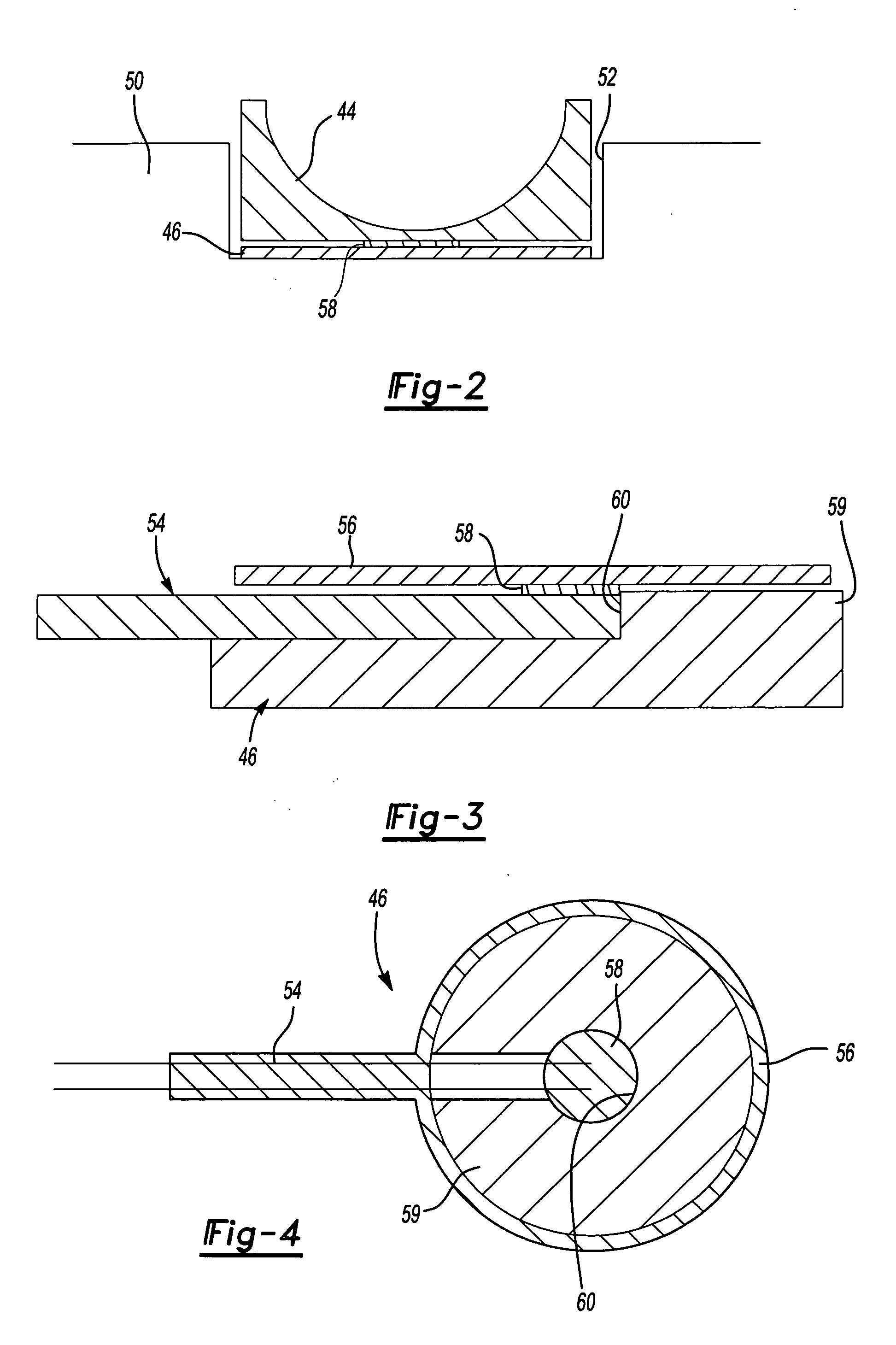

A method has been invented for recovering hydrocarbons from an earth formation containing hydrocarbons, the method including injecting a recovery injectant into the earth formation at a plurality of injection points spaced apart by about 14 to about 208 feet, and producing hydrocarbons from the formation with at least one producer well. In one aspect the method includes injecting steam into an earth formation which contains oil bearing diatomite at a plurality of injection points spaced apart by about 14 to about 208 feet, and producing hydrocarbons from the formation with a one or more producer wells extending into the oil bearing diatomite formation, with a plurality of producer wells spaced apart by a distance ranging between about 14 to about 149 feet, injecting steam into the oil bearing diatomite at an injection rate of between about 10 to about 149 barrels of steam per day per hundred feet thickness of diatomite, and injecting the steam at a pressure between about 10 p.s.i. to about 260 p.s.i. The present invention also discloses a method for treating a hydrocarbon-bearing diatomite formation including applying an artificial overburden over at least a portion of the formation and applying a variable well spacing as needed. A field on an earth formation has been invented for recovering hydrocarbons, the earth formation having an earth surface above it, the field including a plurality of injector well and a plurality of producing wells, the field including at least one injector well per acre of earth surface above the earth formation and at least one producing well per acre. Certain parts of the wells may be in below-grade chambers.

Owner:ELIAS RAMON +2

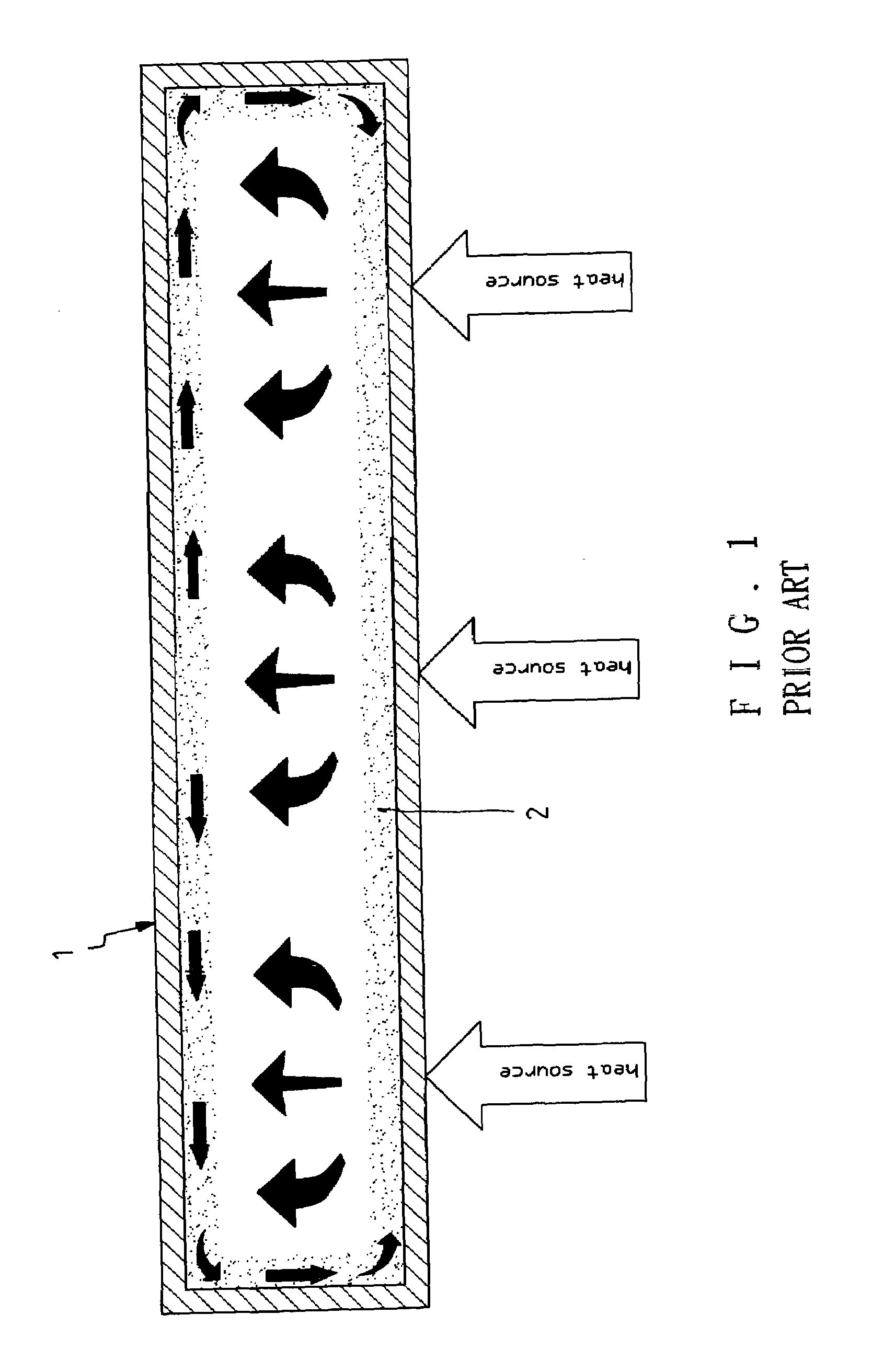

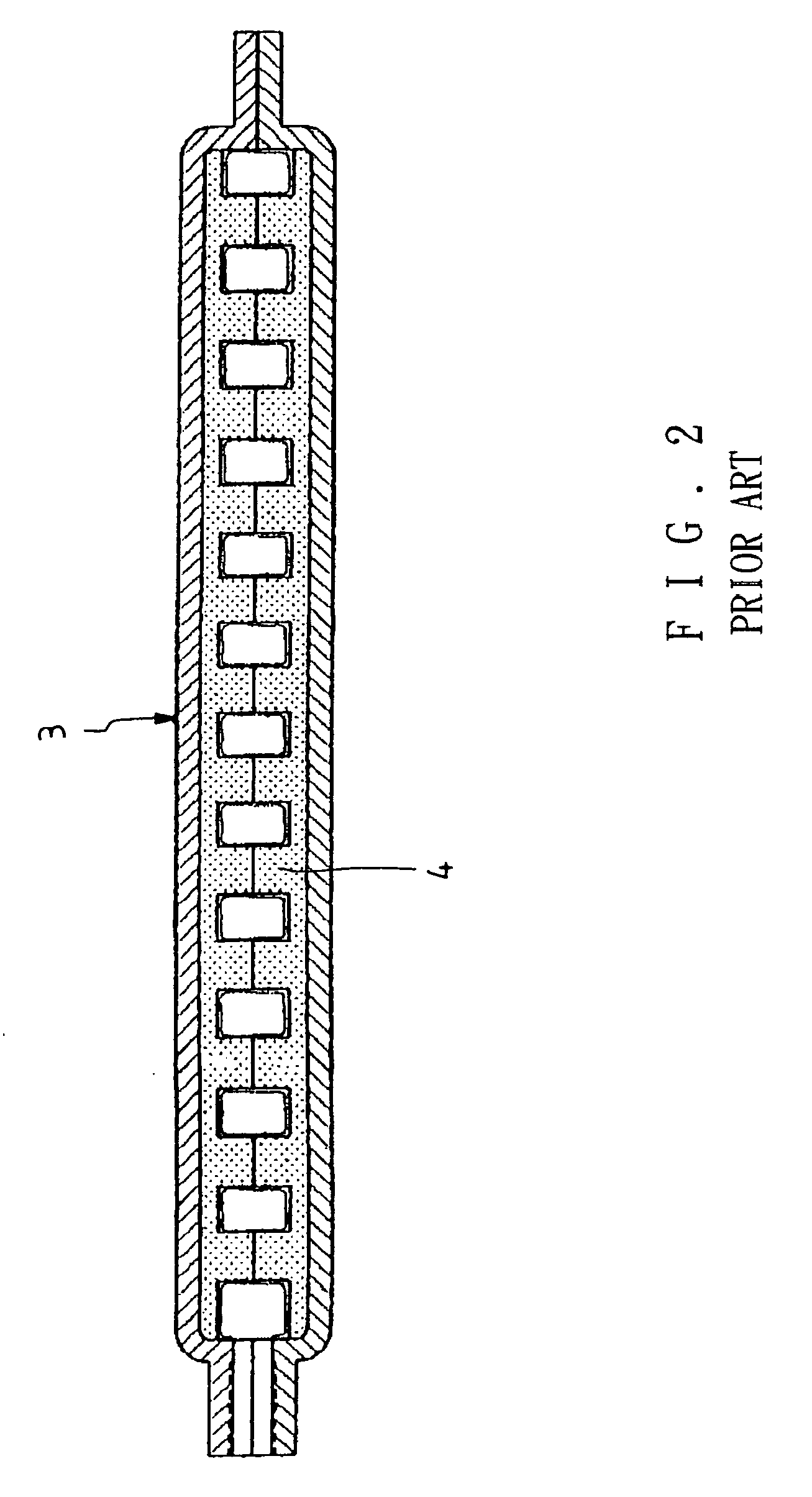

Flat heat pipe provided with means to enhance heat transfer thereof

ActiveUS6901994B1Improve cooling effectUniform temperature distributionSemiconductor/solid-state device detailsSolid-state devicesCyclic processWorking fluid

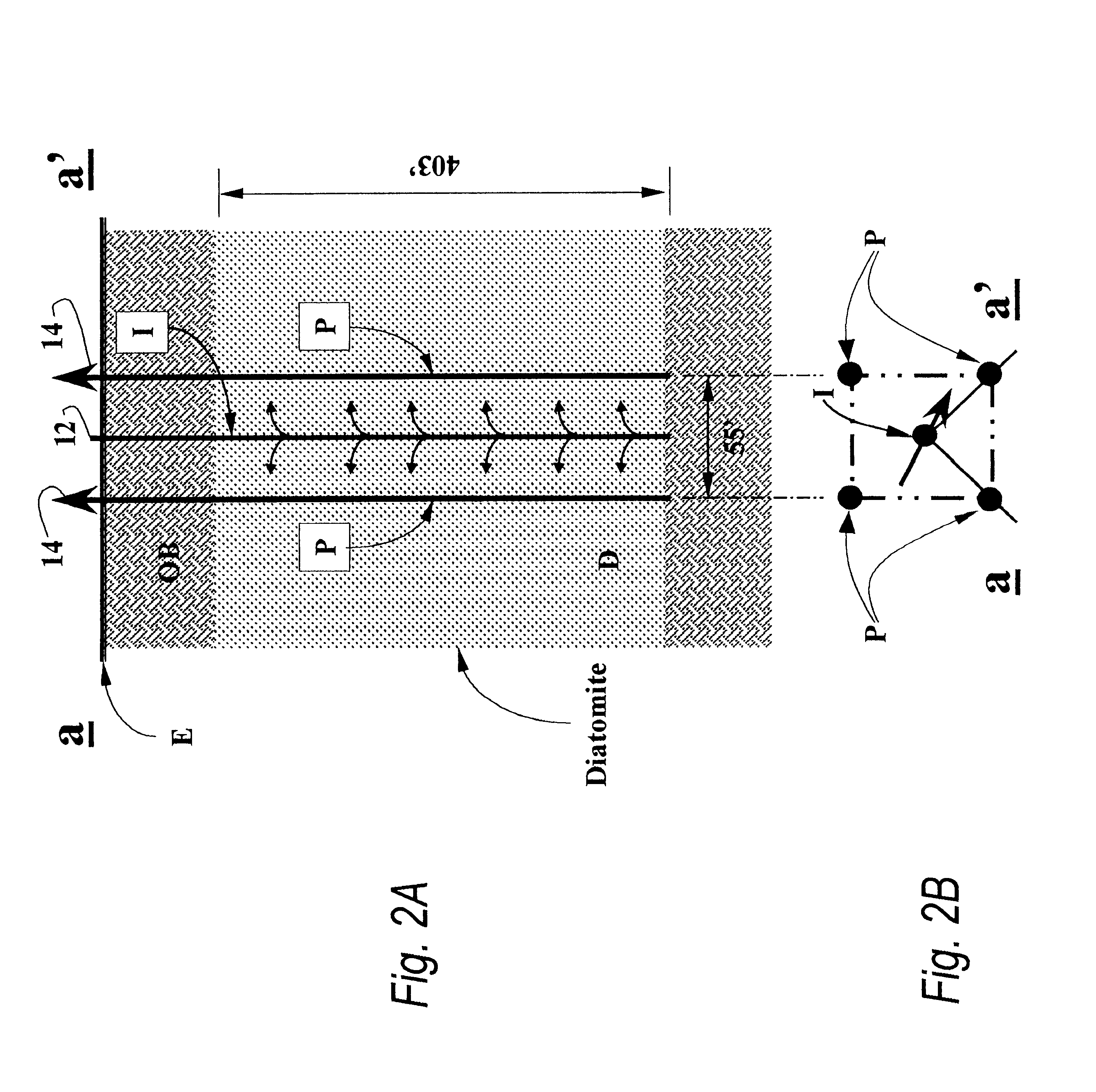

A flat heat pipe has a vacuum chamber, an evaporator connected to a heating element, and a condenser connected to a cooling device. The vacuum chamber is provided in an interior with a wick structure and a working fluid by which an evaporation-condensation cyclic process is effected. The vacuum chamber is further provided in the interior with a plurality of heat conduction pillars, which are confined to the area of the evaporator and are connected with an upper wall and a lower wall of the interior of the chamber. The heat conduction pillars serve to enhance the heat conduction to the condenser from the evaporator.

Owner:IND TECH RES INST

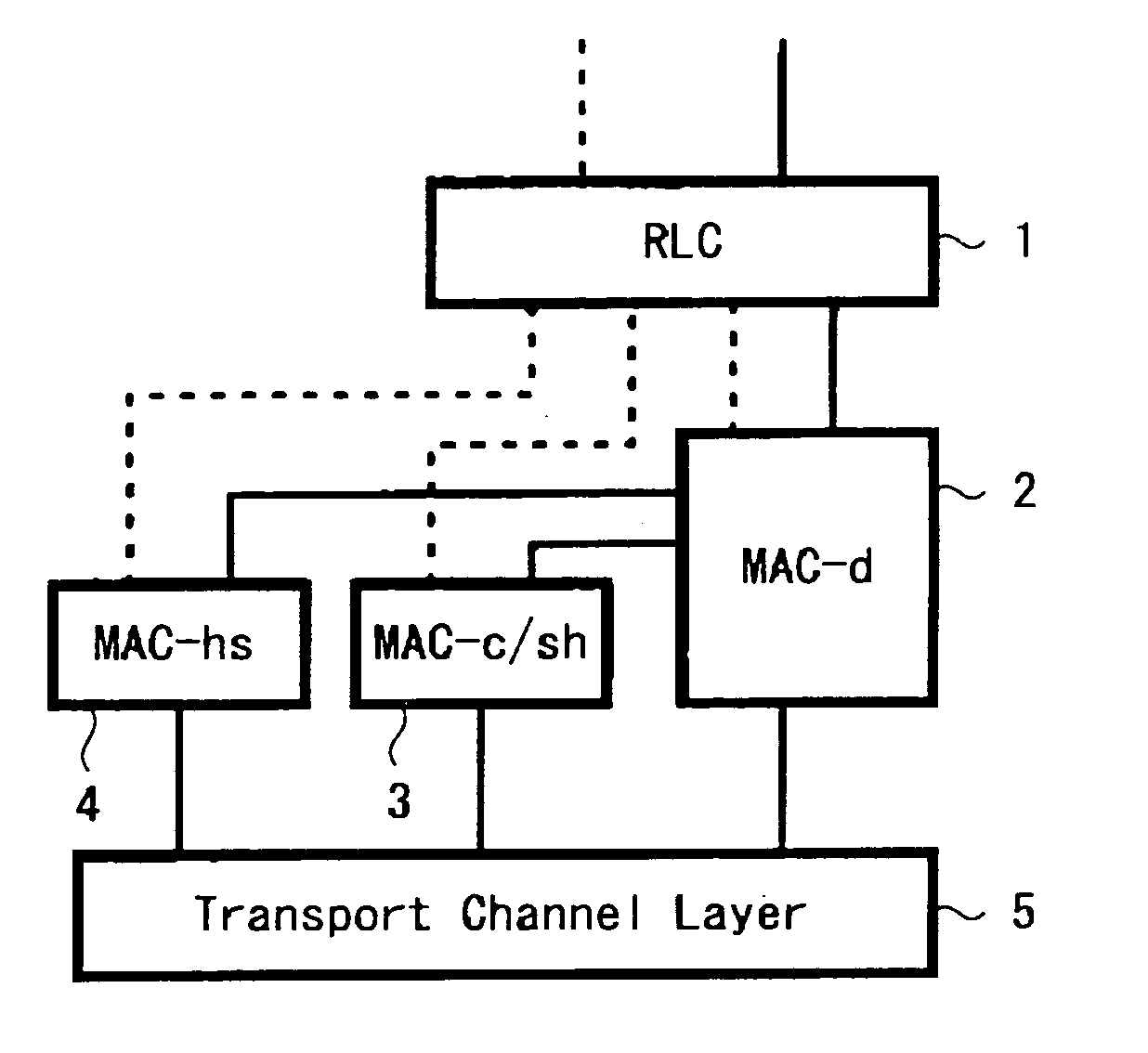

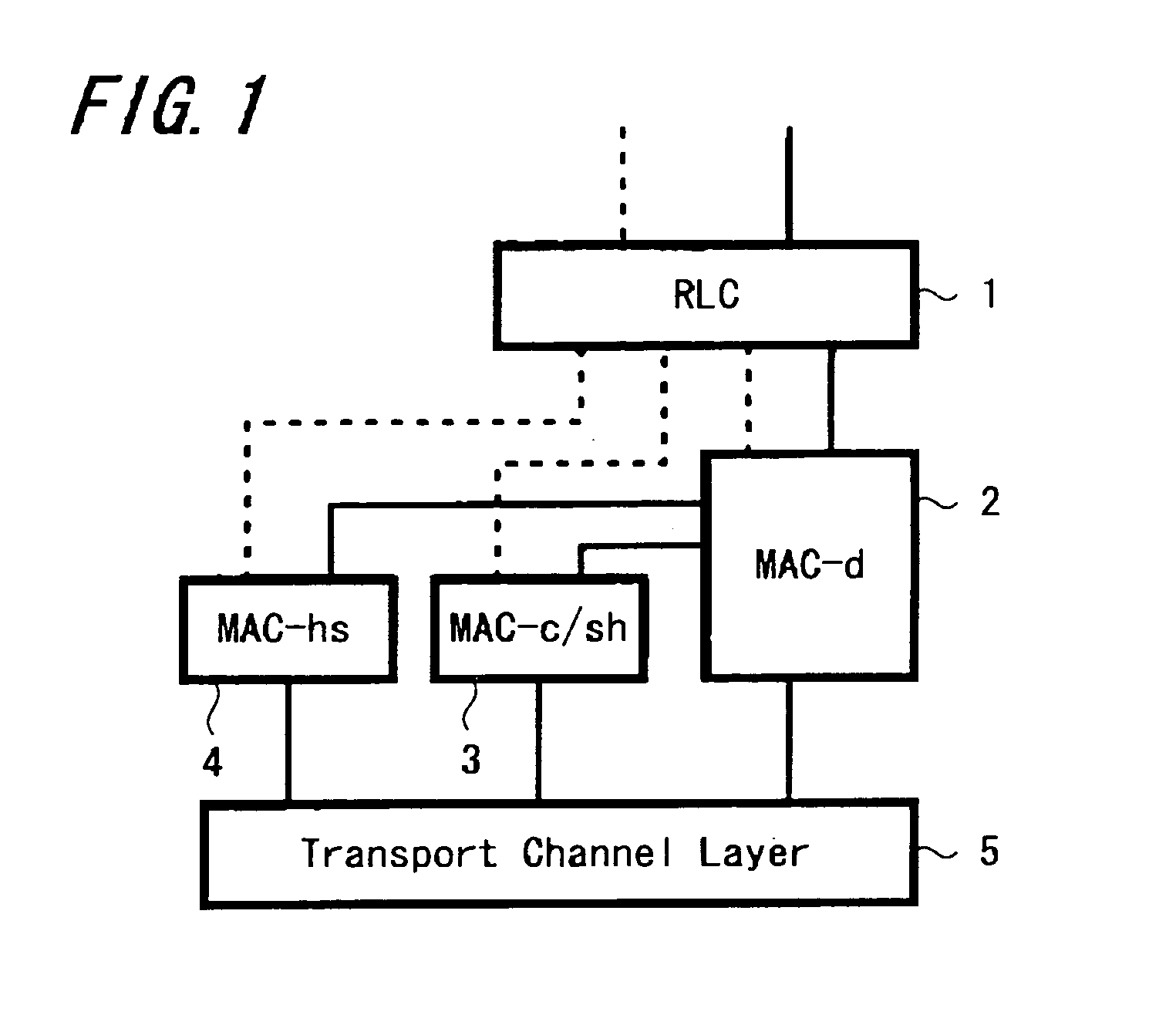

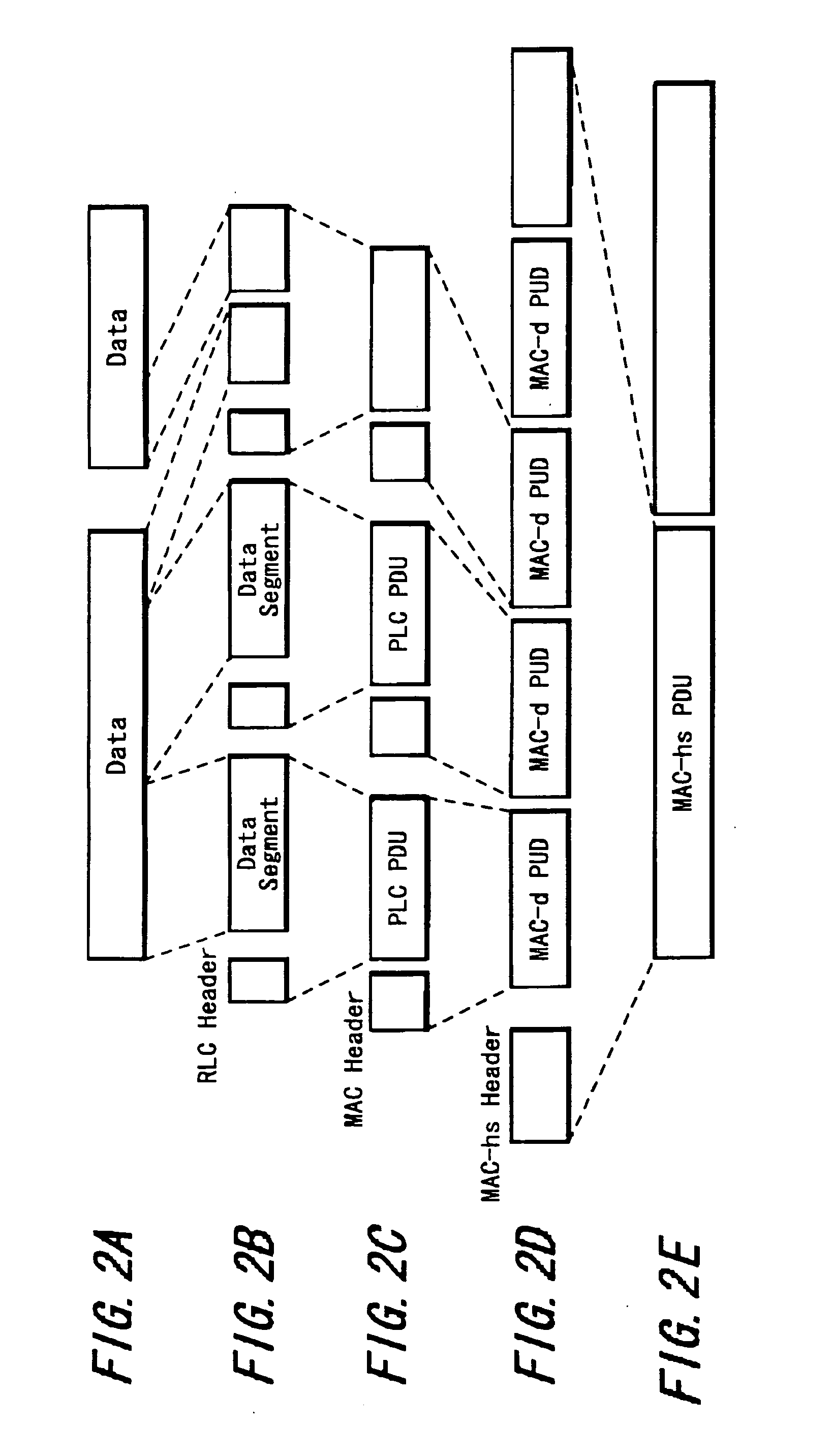

Data transmission method and data transmission apparatus

InactiveUS20050157696A1Degradation of data transmission efficiency can be preventedEfficient data transmissionError prevention/detection by using return channelFrequency-division multiplex detailsData transmissionRadio wave

When retransmission requests are issued based on the results of error-correction decoding of received data packets to perform data transmission, statistical information indicating whether received data packets have been successfully decoded or have not been decoded is acquired, and based on the rate at which correct decoding has been made or the rate at which correct decoding has not been made, which is obtained from the statistical information, a request is transmitted to the transmission source to change the window size, which is the number of data units handled in a predetermined layer, so that when for example the communication environment is not excellent, processing can be performed at a small window size, and the occurrence of circumstances in which data retransmission and the discarding of received data are repeated can be efficiently prevented. Accordingly, data transmission efficiency in a wireless transmission system performing high-speed data transmission is improved under conditions of a poor radio wave environment.

Owner:SNAPTRACK

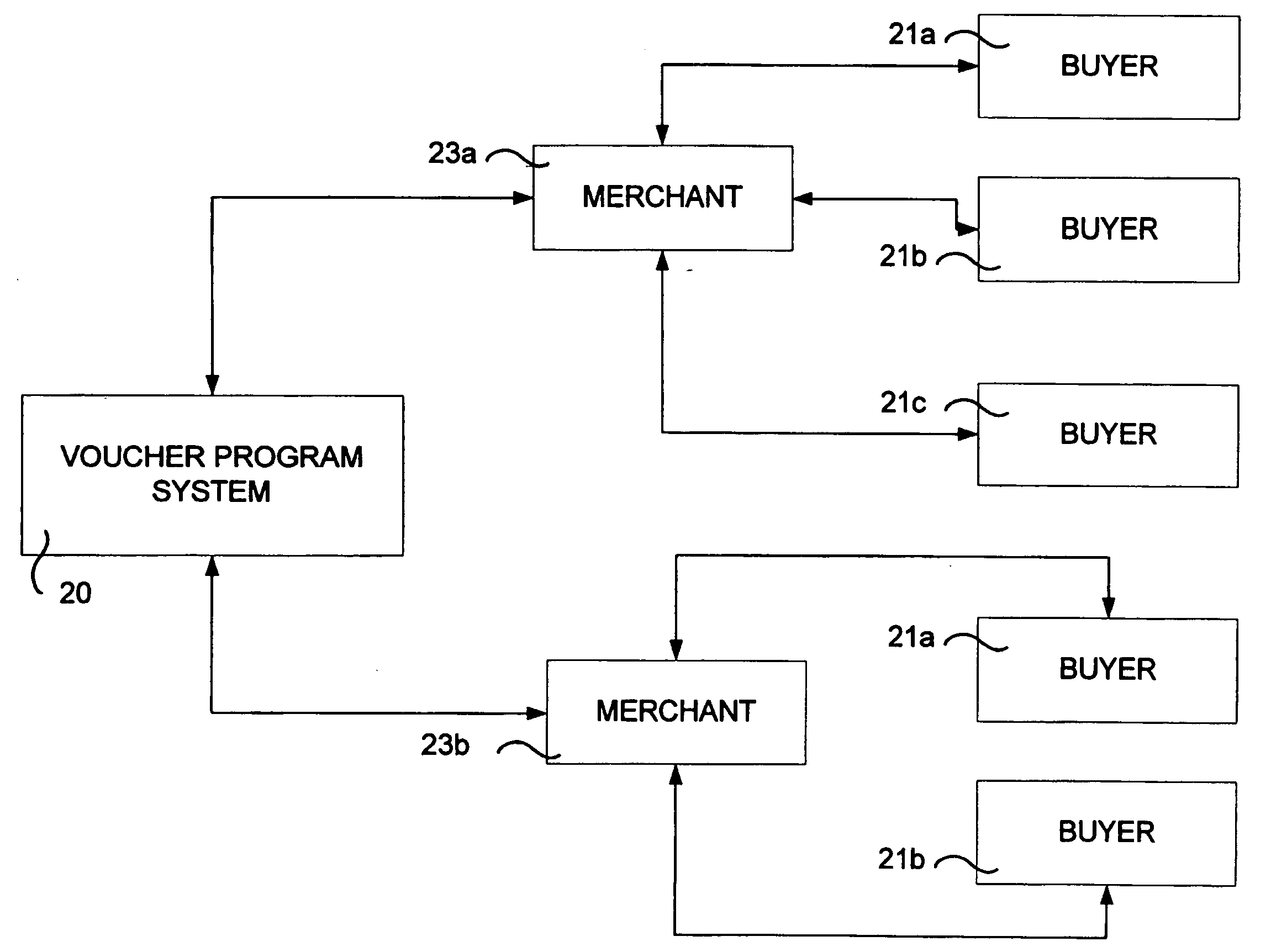

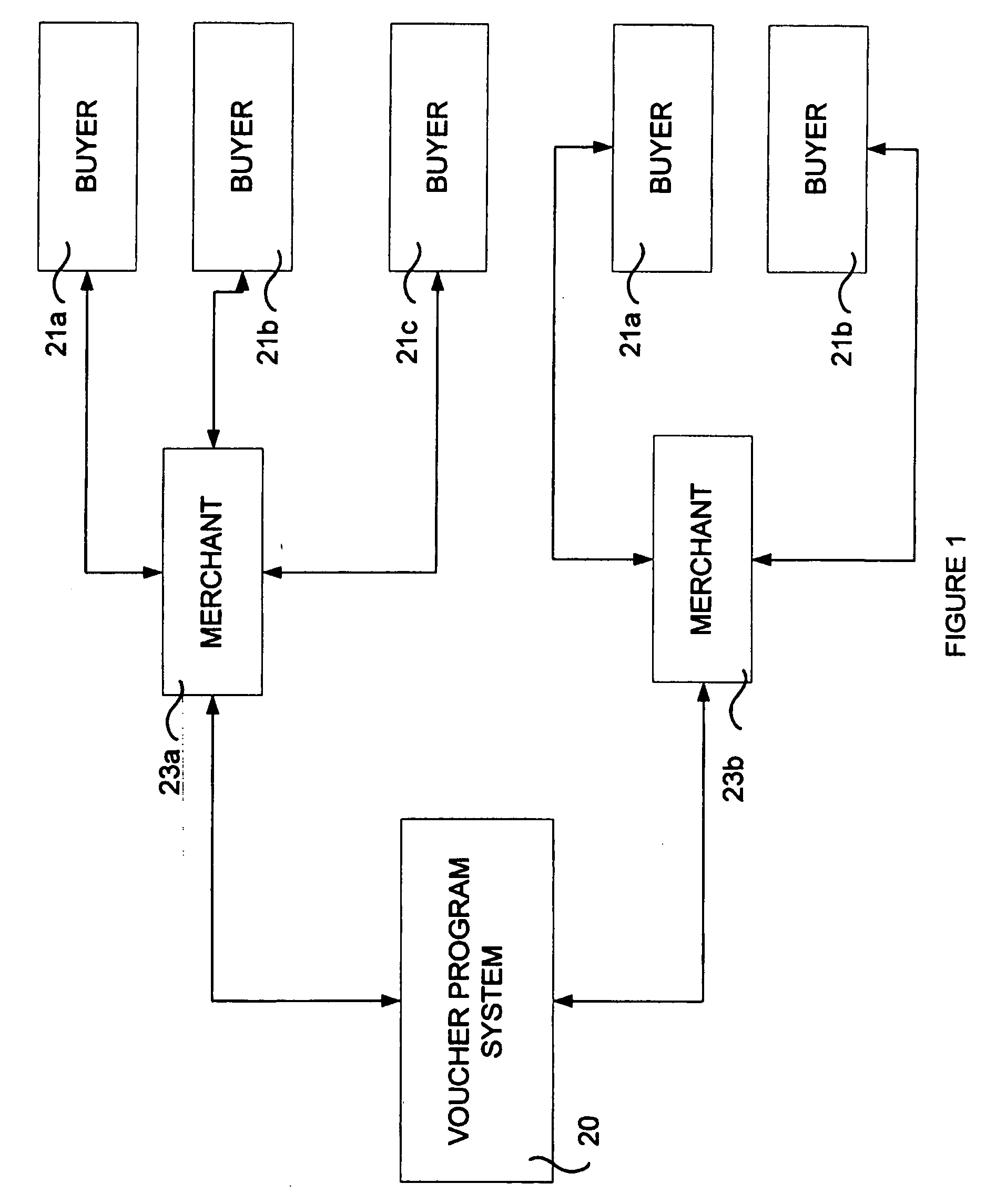

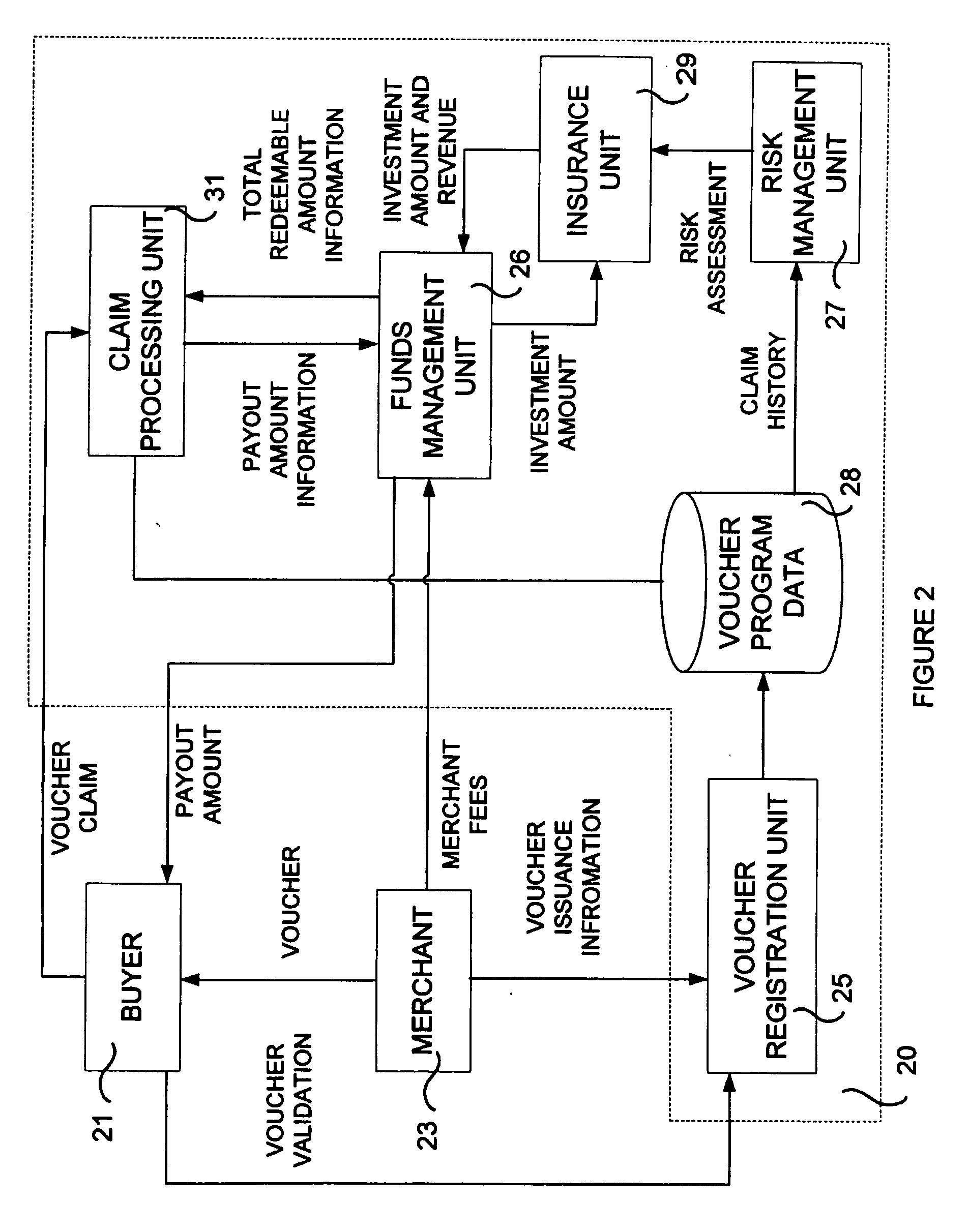

Method and system for redeemable vouchers using an insurance model

InactiveUS20070016508A1Appropriate amountAccurate predictionFinanceMarketingVoucherIndustrial engineering

A method for redeeming a merchant-issued voucher having a potential future value and redeemable during a voucher redemption period is provided. A merchant provides voucher issuance information and merchant fees for a voucher redemption period. During an investment period, an investment amount is invested representing a percentage of the merchant fees, in order to generate an investment revenue amount. Following the investment period, a total redeemable amount is received for the voucher redemption period, representing the investment amount and a percentage of the investment revenue amount. During the voucher redemption period, for at least some of the issued vouchers, receiving a voucher claim for the potential future voucher value and processing the voucher claim using the voucher issuance information, to pay out, from the total redeemable amount, a payout amount up to the potential future voucher value.

Owner:LAPOINTE PIERRE +1

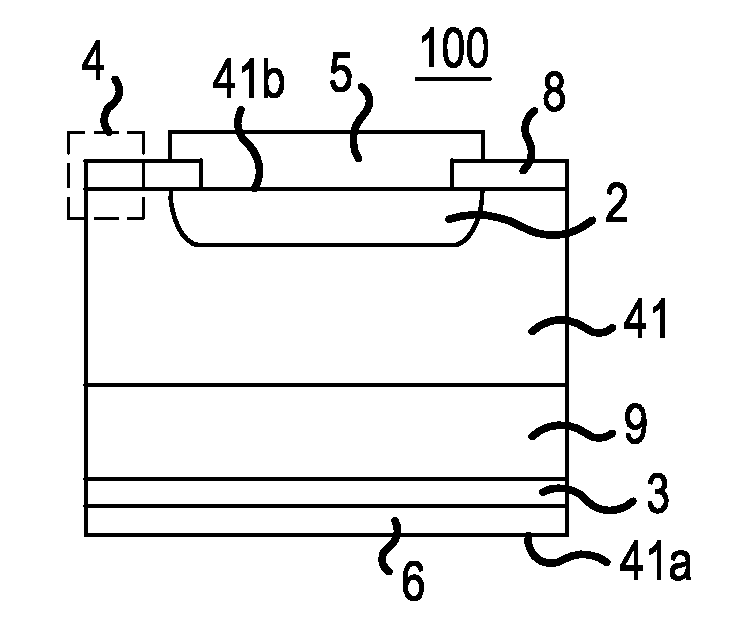

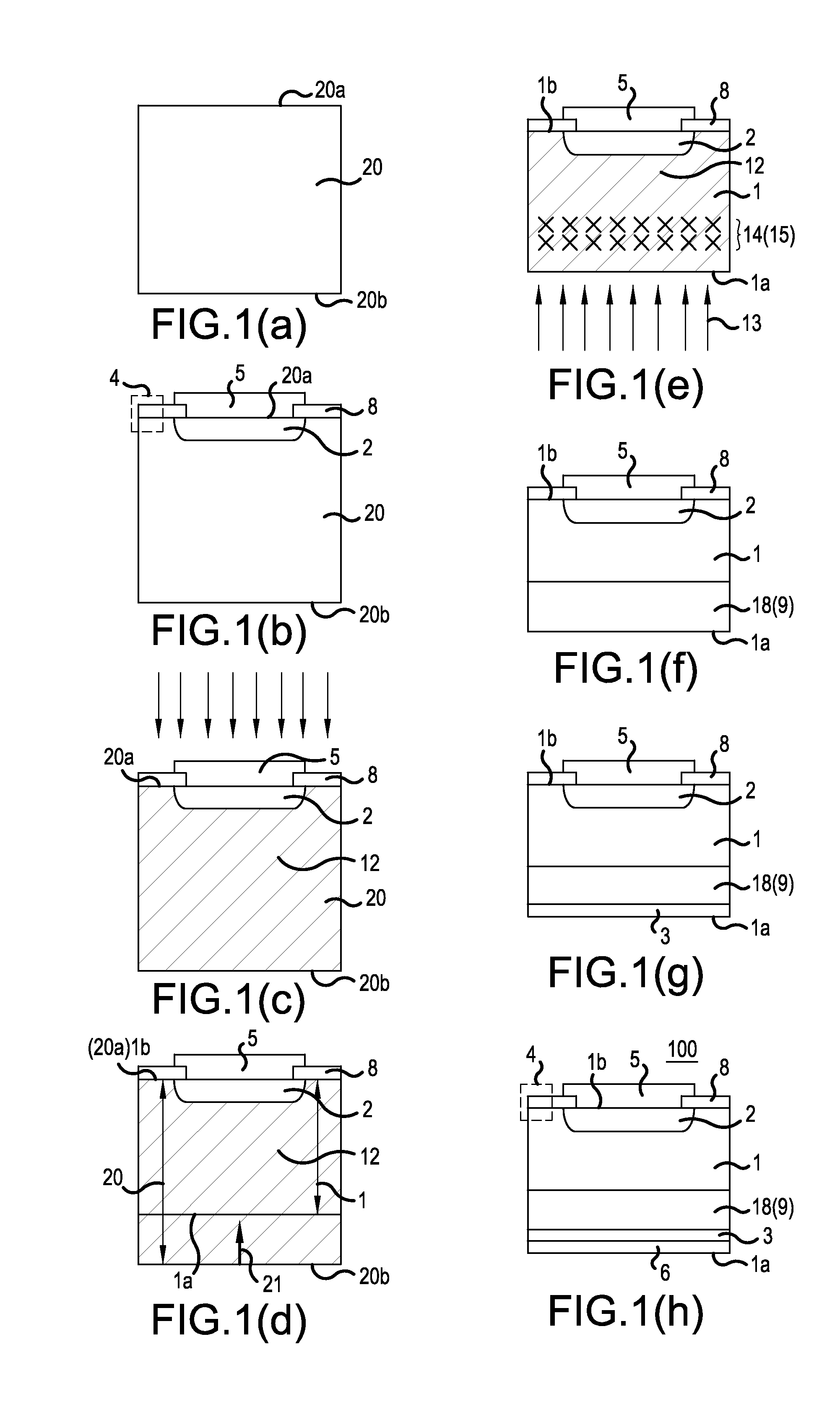

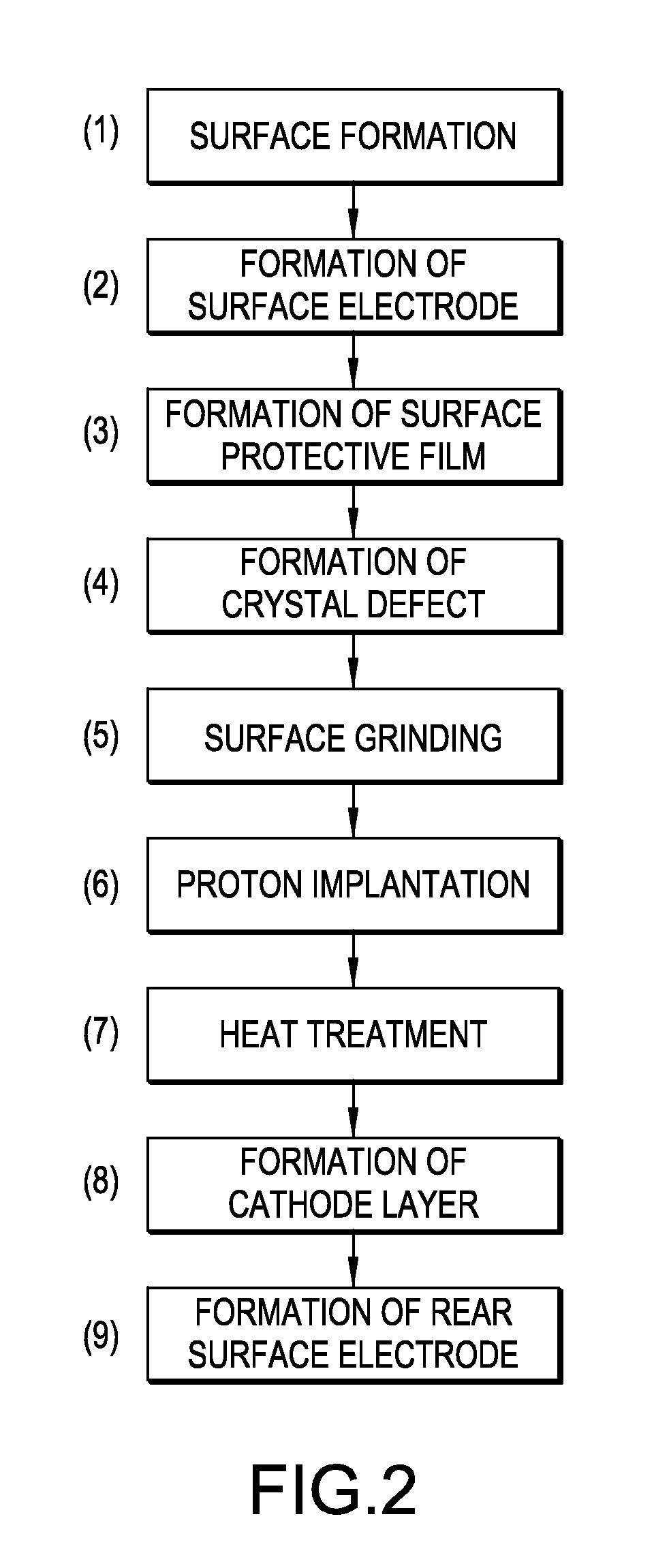

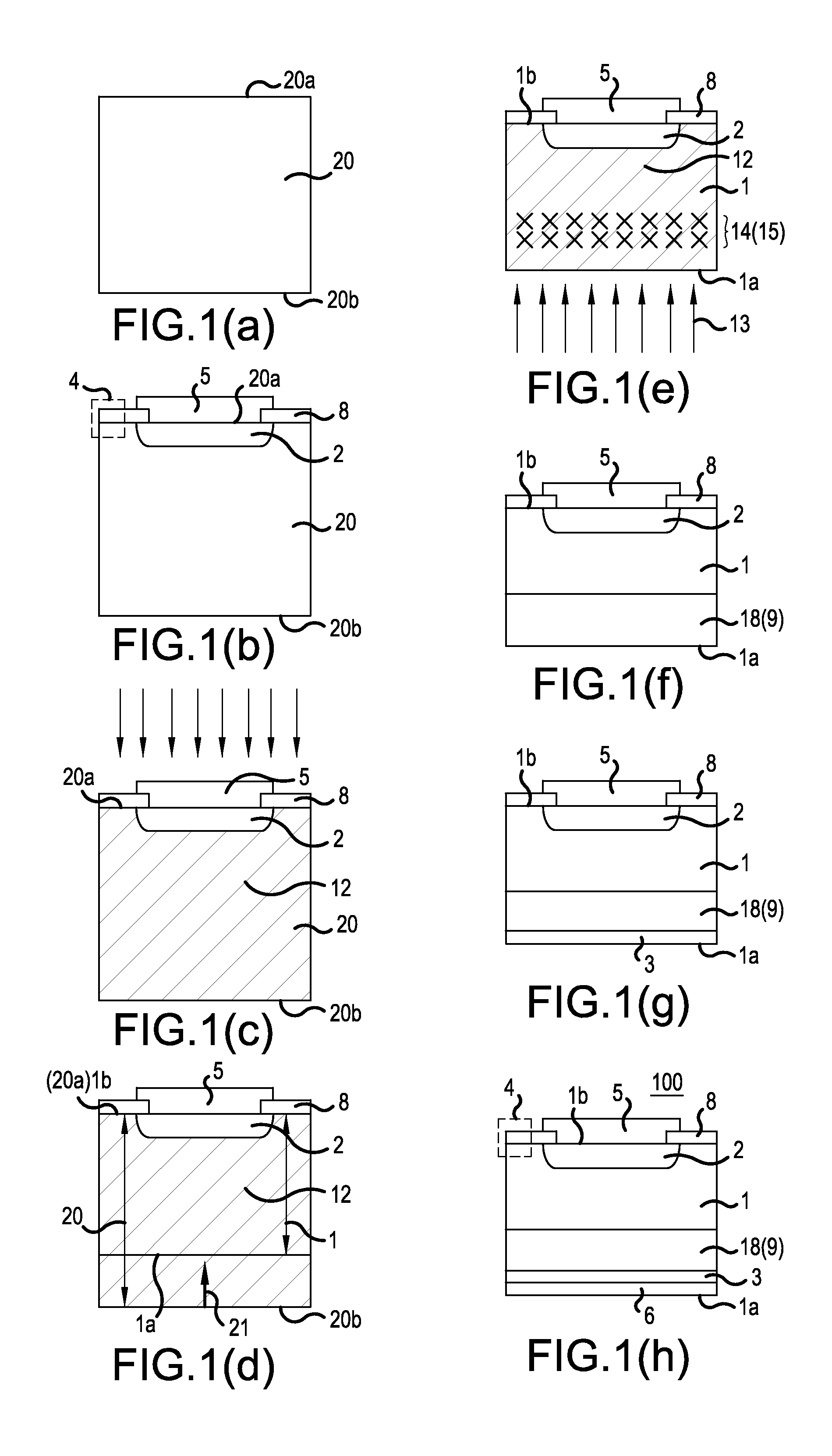

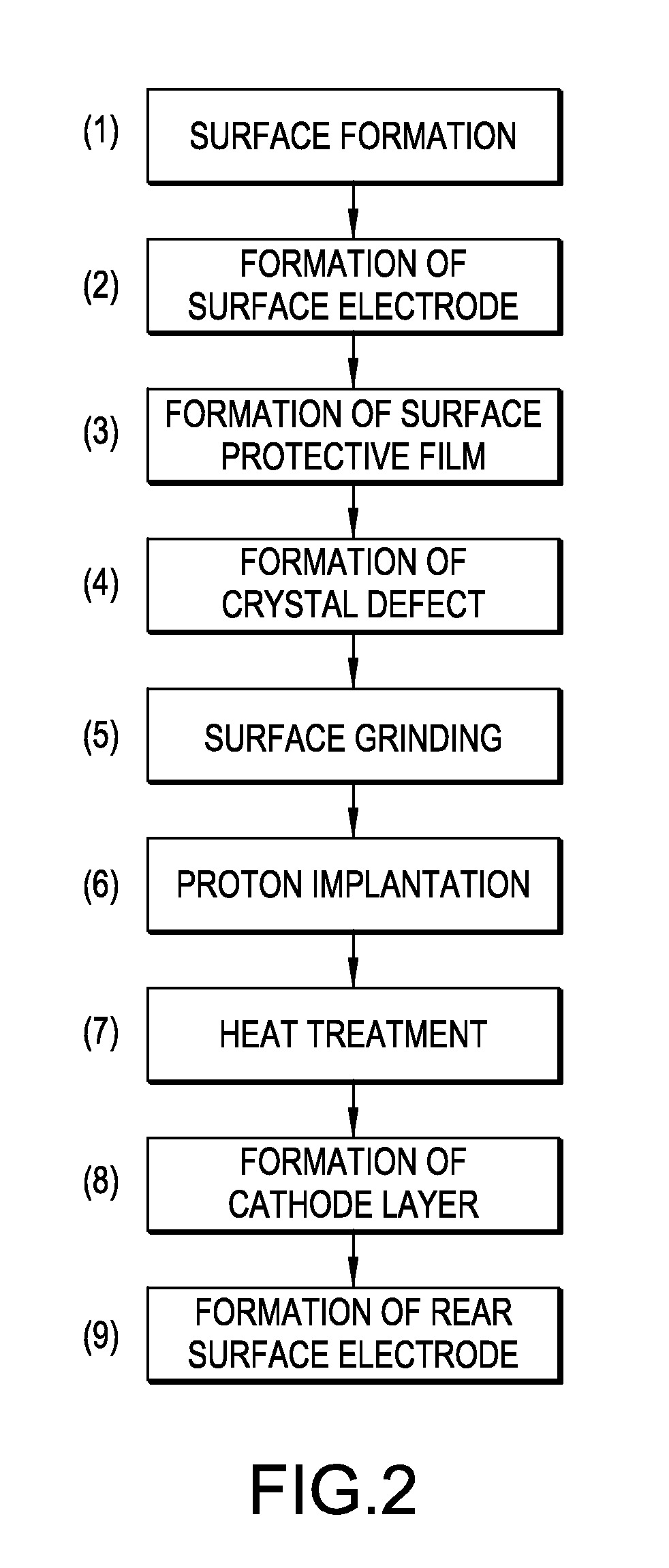

Semiconductor device and method for producing semiconductor device

ActiveUS20140246755A1Limited amountIncrease spawn rateSemiconductor/solid-state device manufacturingSemiconductor devicesProton implantationGeneration rate

Hydrogen atoms and crystal defects are introduced into an n− semiconductor substrate by proton implantation. The crystal defects are generated in the n− semiconductor substrate by electron beam irradiation before or after the proton implantation. Then, a heat treatment for generating donors is performed. The amount of crystal defects is appropriately controlled during the heat treatment for generating donors to increase a donor generation rate. In addition, when the heat treatment for generating donors ends, the crystal defects formed by the electron beam irradiation and the proton implantation are recovered and controlled to an appropriate amount of crystal defects. Therefore, for example, it is possible to improve a breakdown voltage and reduce a leakage current.

Owner:FUJI ELECTRIC CO LTD

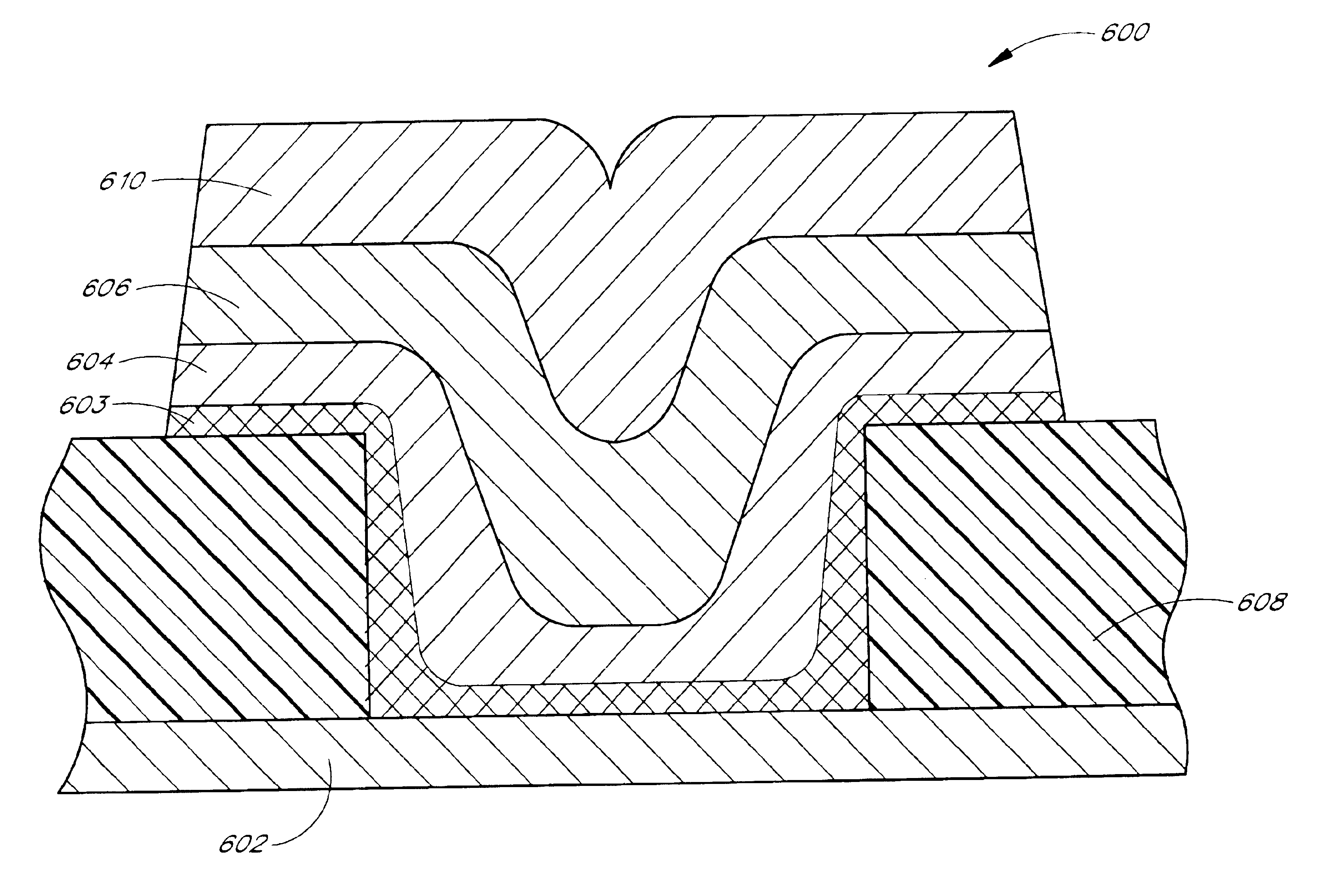

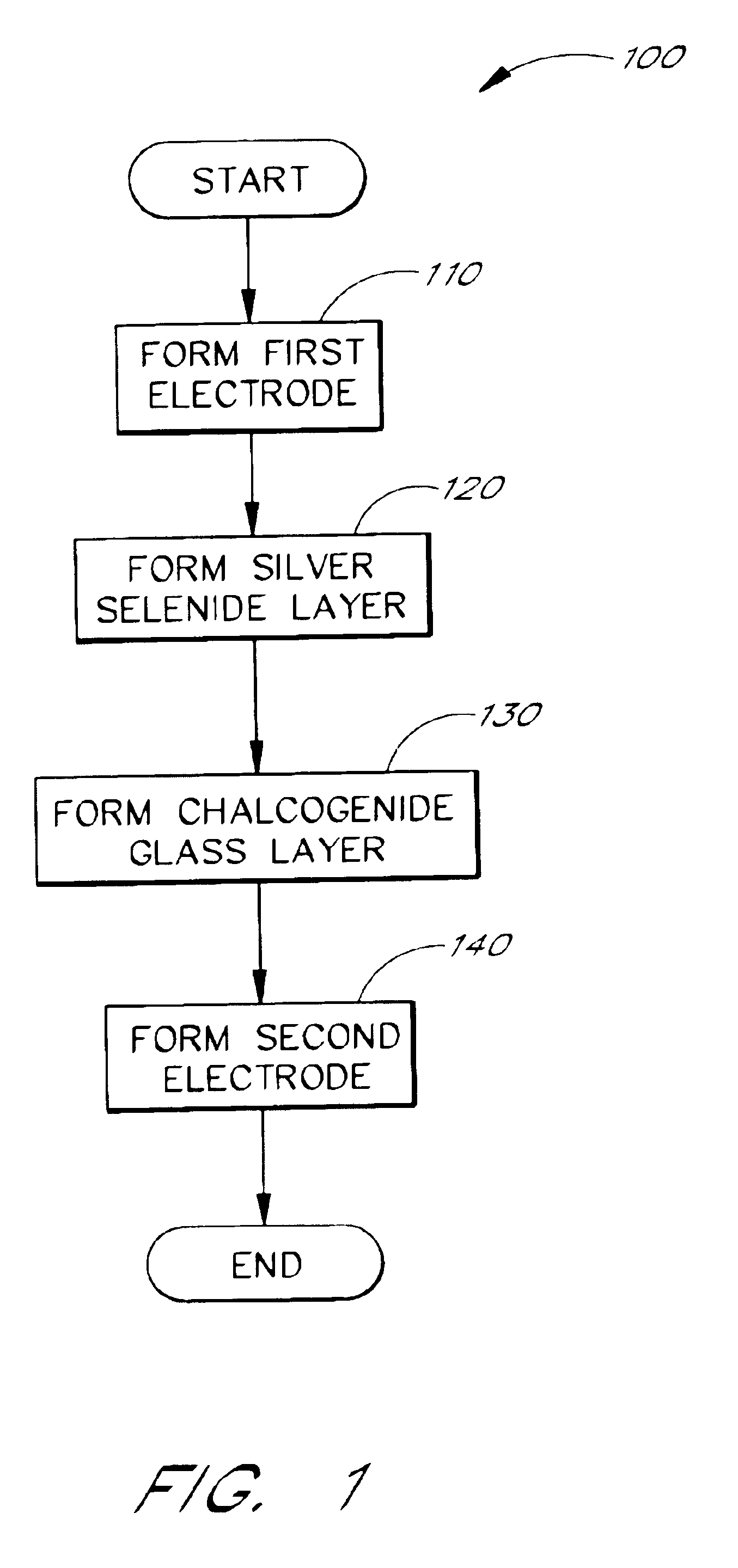

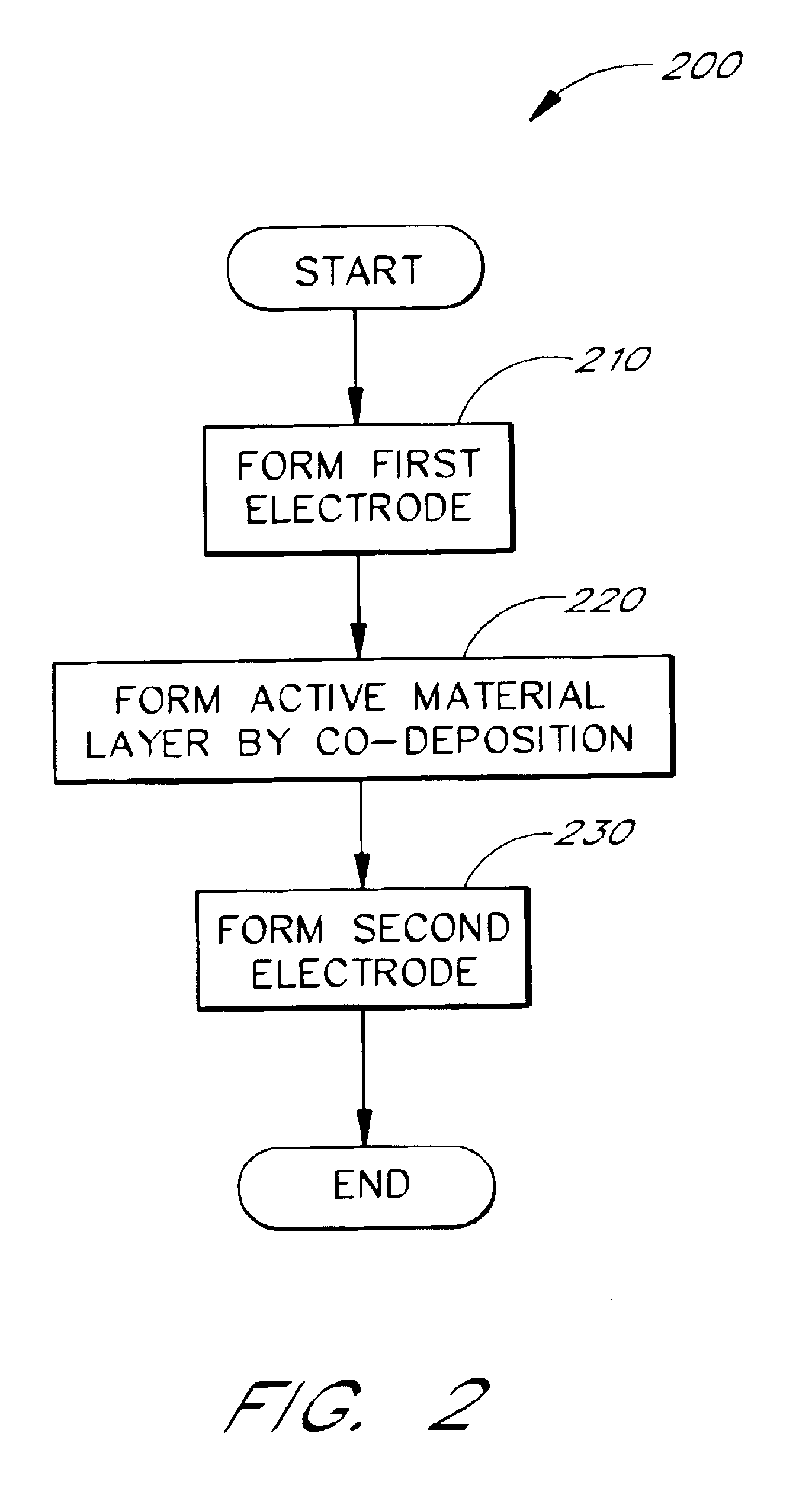

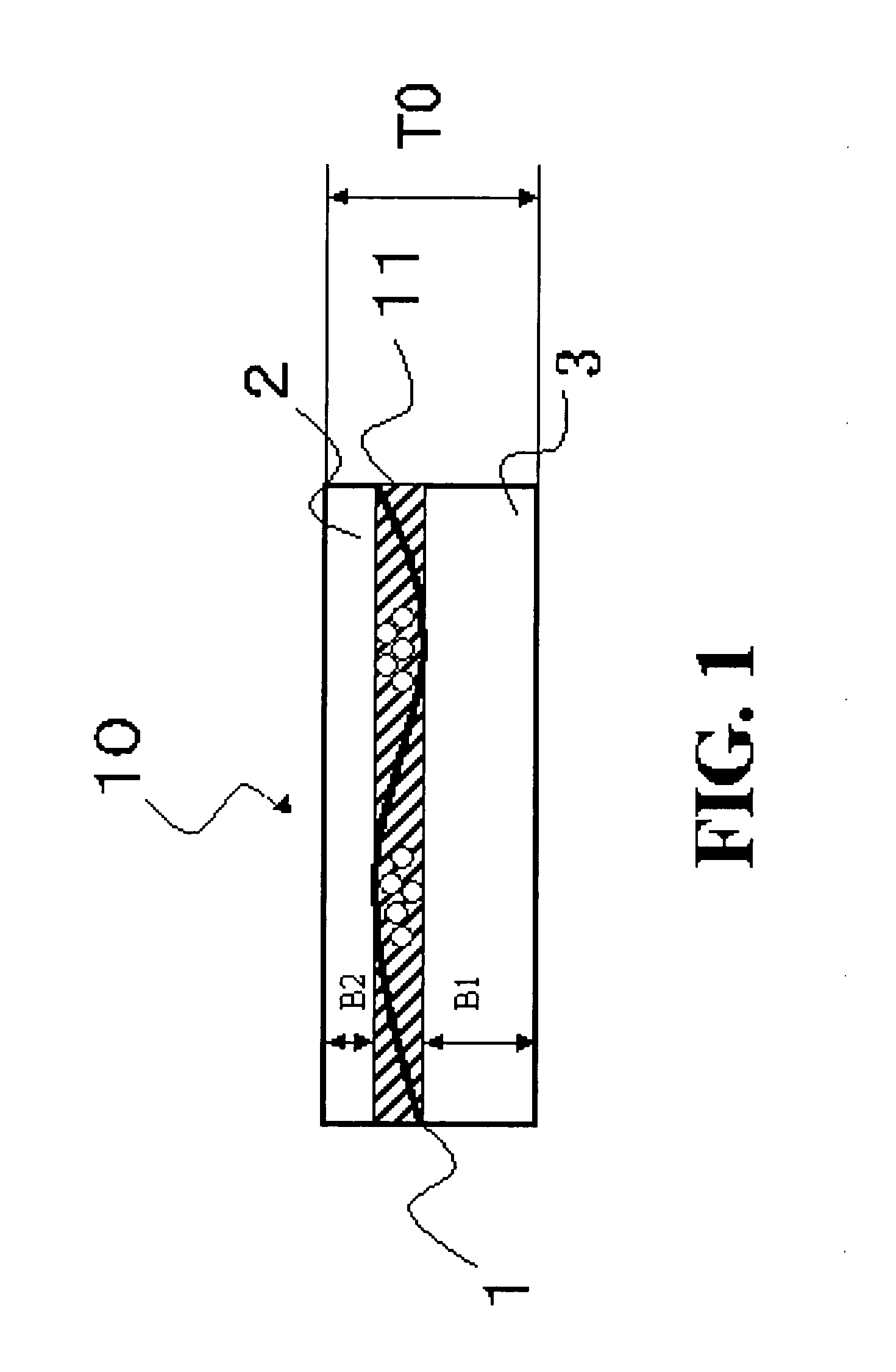

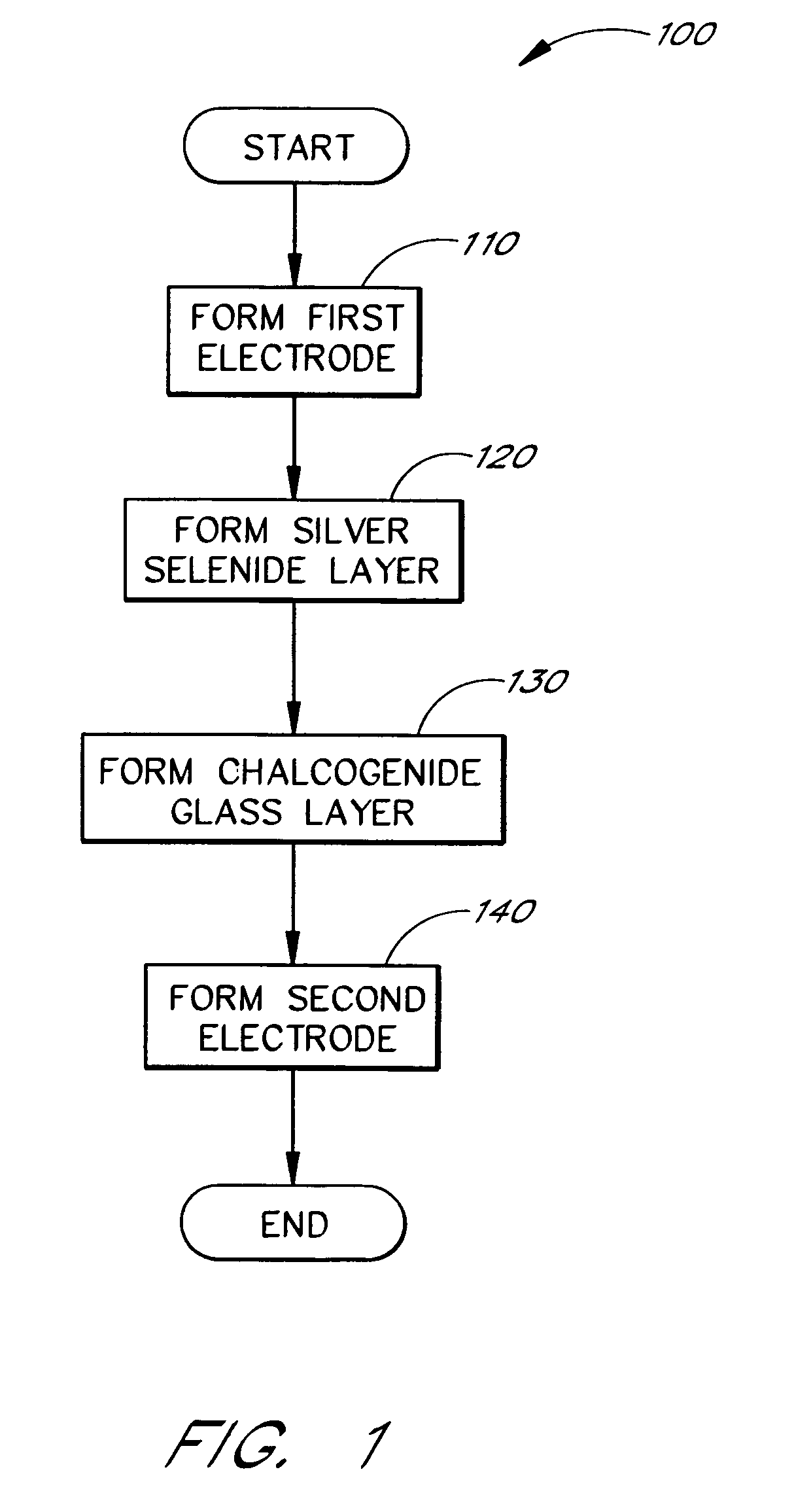

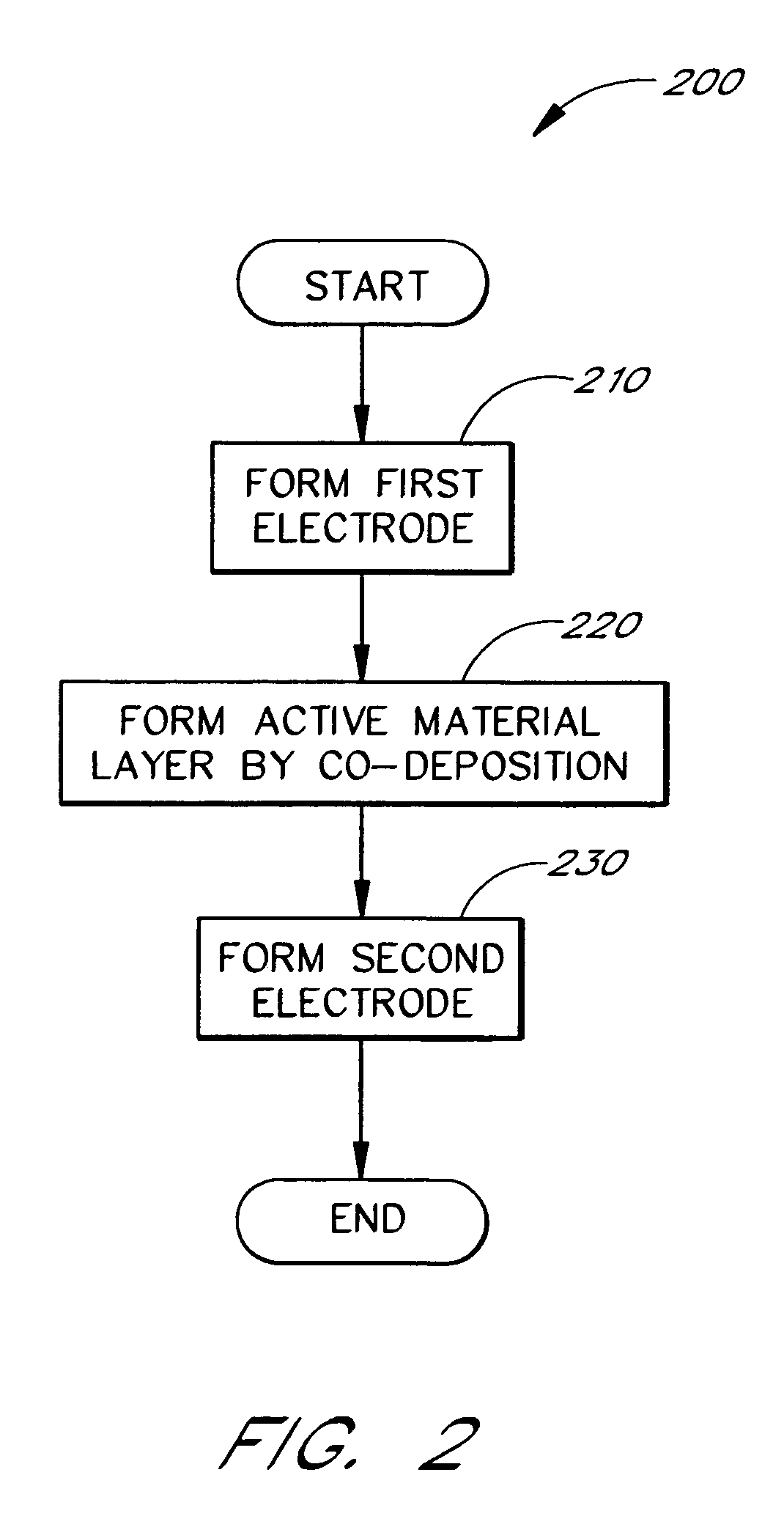

Methods and apparatus for resistance variable material cells

InactiveUS6849868B2Increase chanceFast switching speedSolid-state devicesPhotomechanical apparatusElectrical resistance and conductanceSulfur

The present invention is related to methods and apparatus to produce a memory cell or resistance variable material with improved data retention characteristics and higher switching speeds. In a memory cell according to an embodiment of the present invention, silver selenide and a chalcogenide glass, such as germanium selenide (GexSe(1−x)) are combined in an active layer, which supports the formation of conductive pathways in the presence of an electric potential applied between electrodes. Advantageously, embodiments of the present invention can be fabricated with relatively wide ranges for the thicknesses of the silver selenide and glass layers.

Owner:OVONYX MEMORY TECH LLC

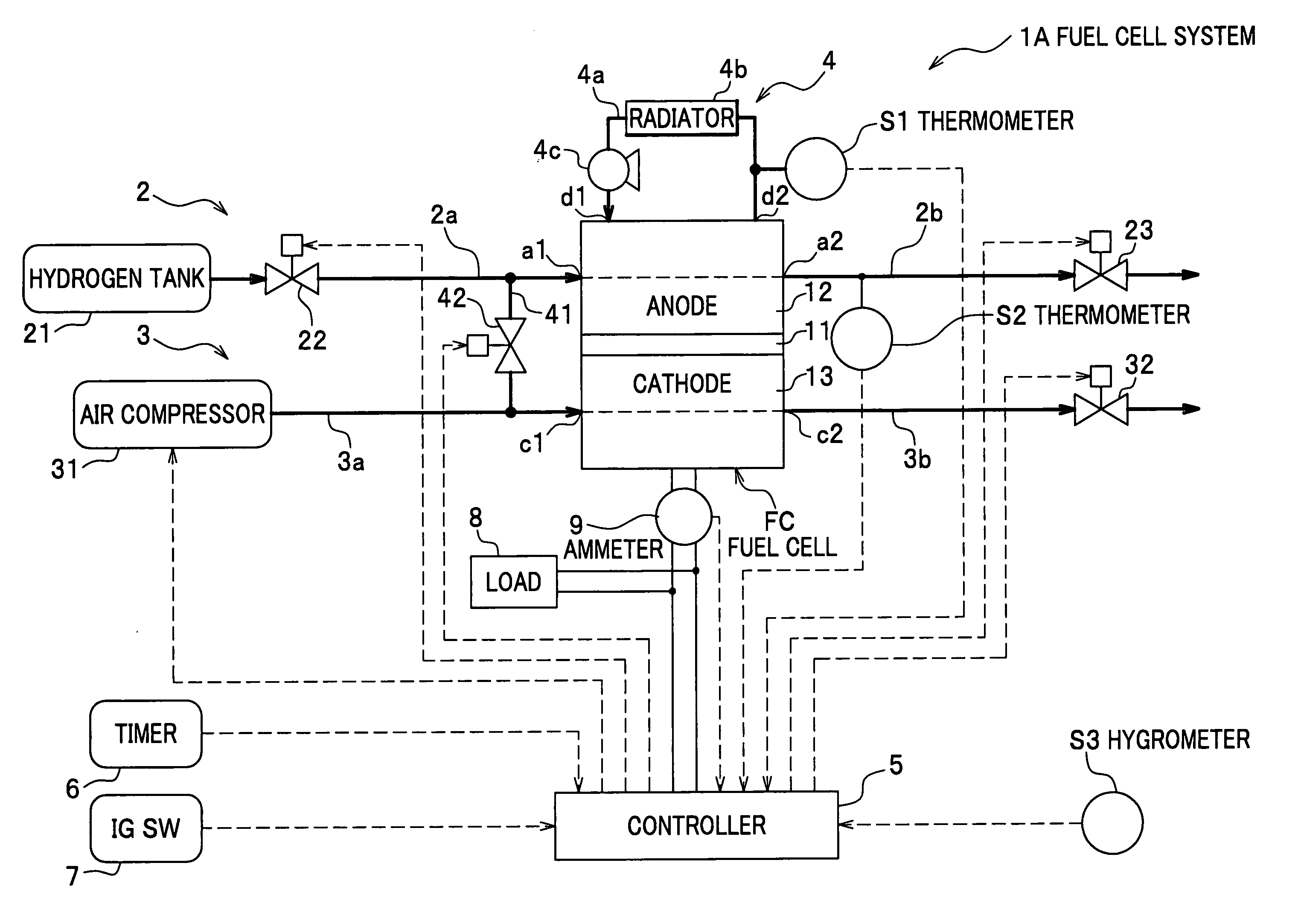

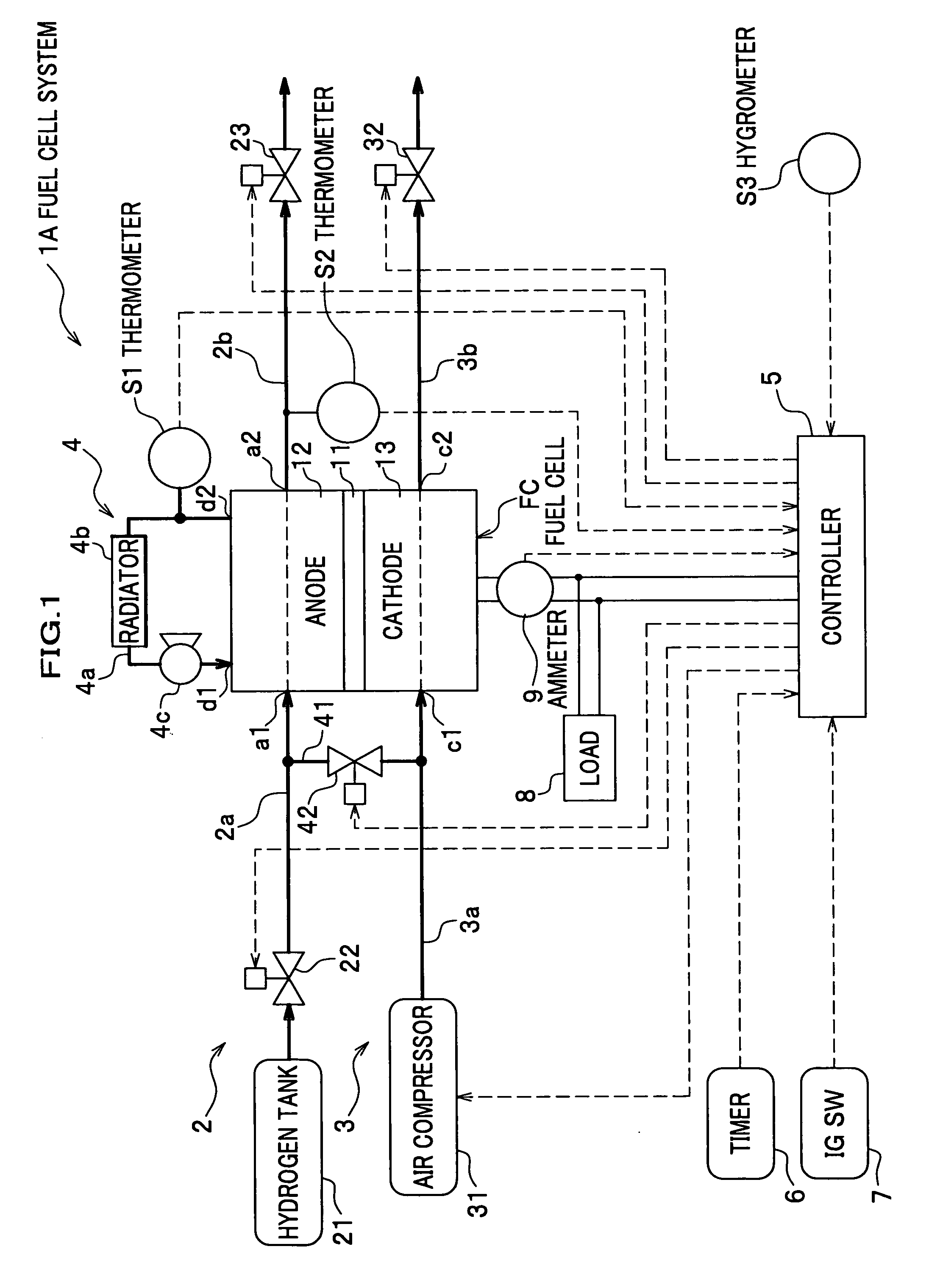

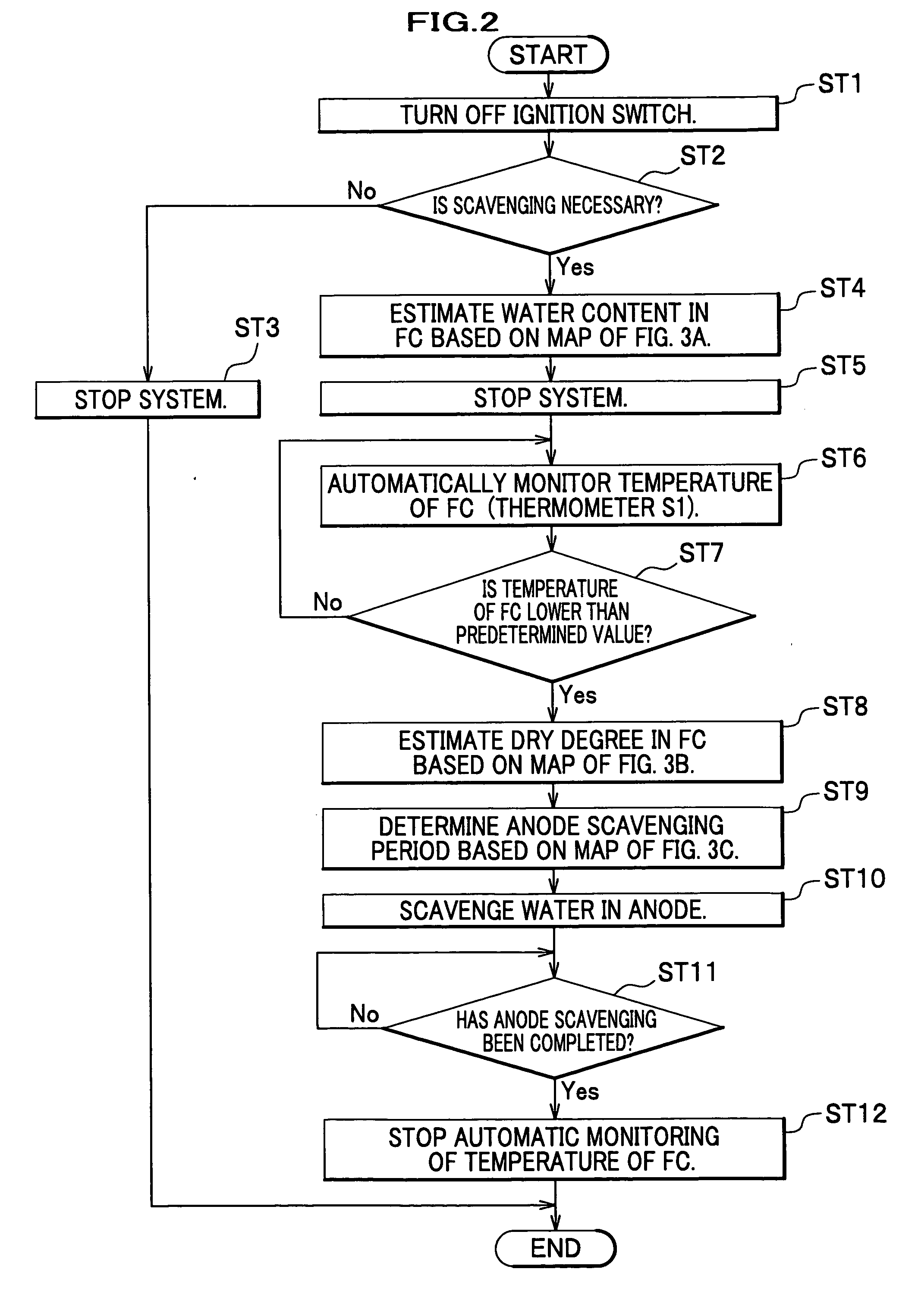

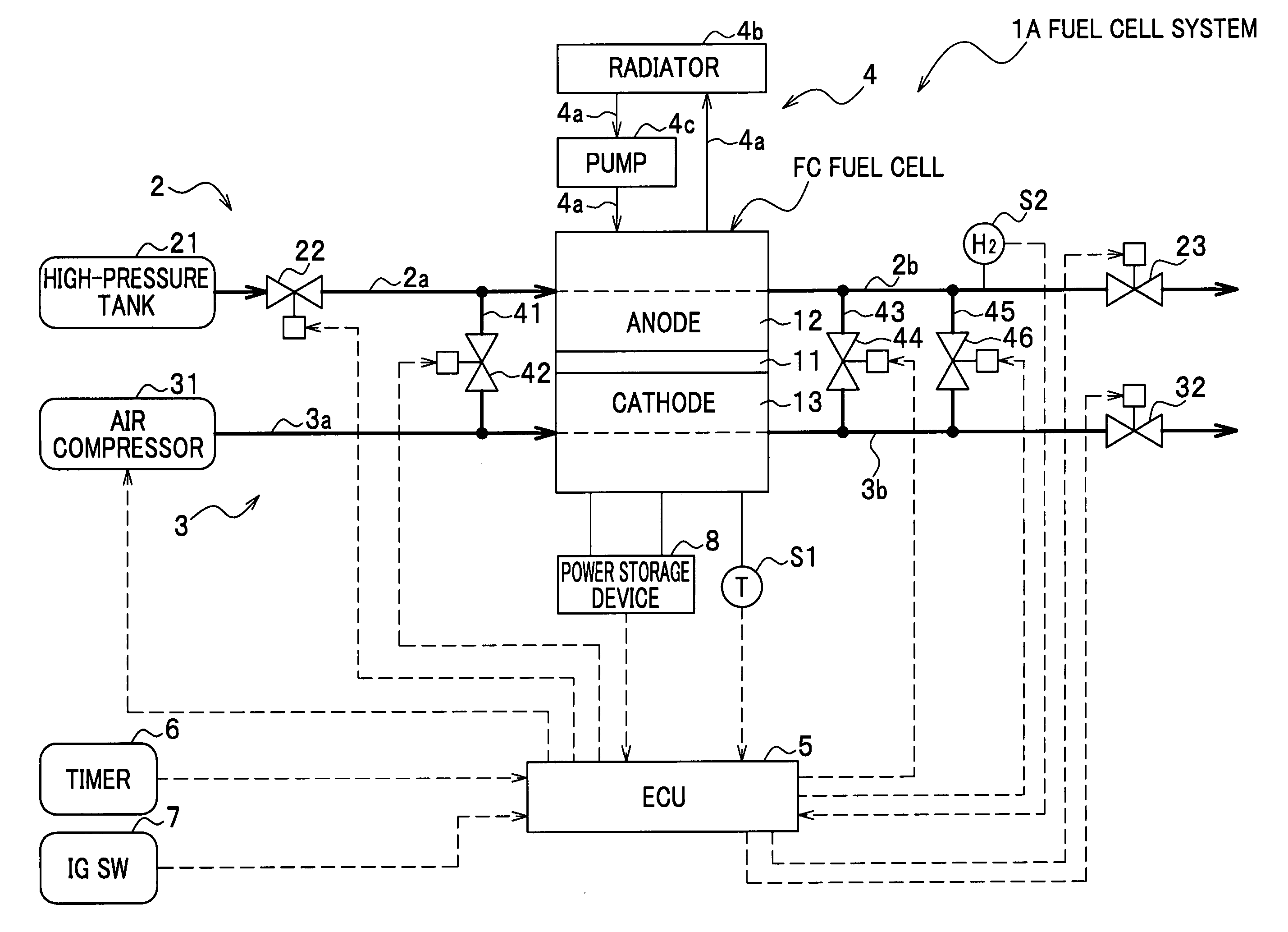

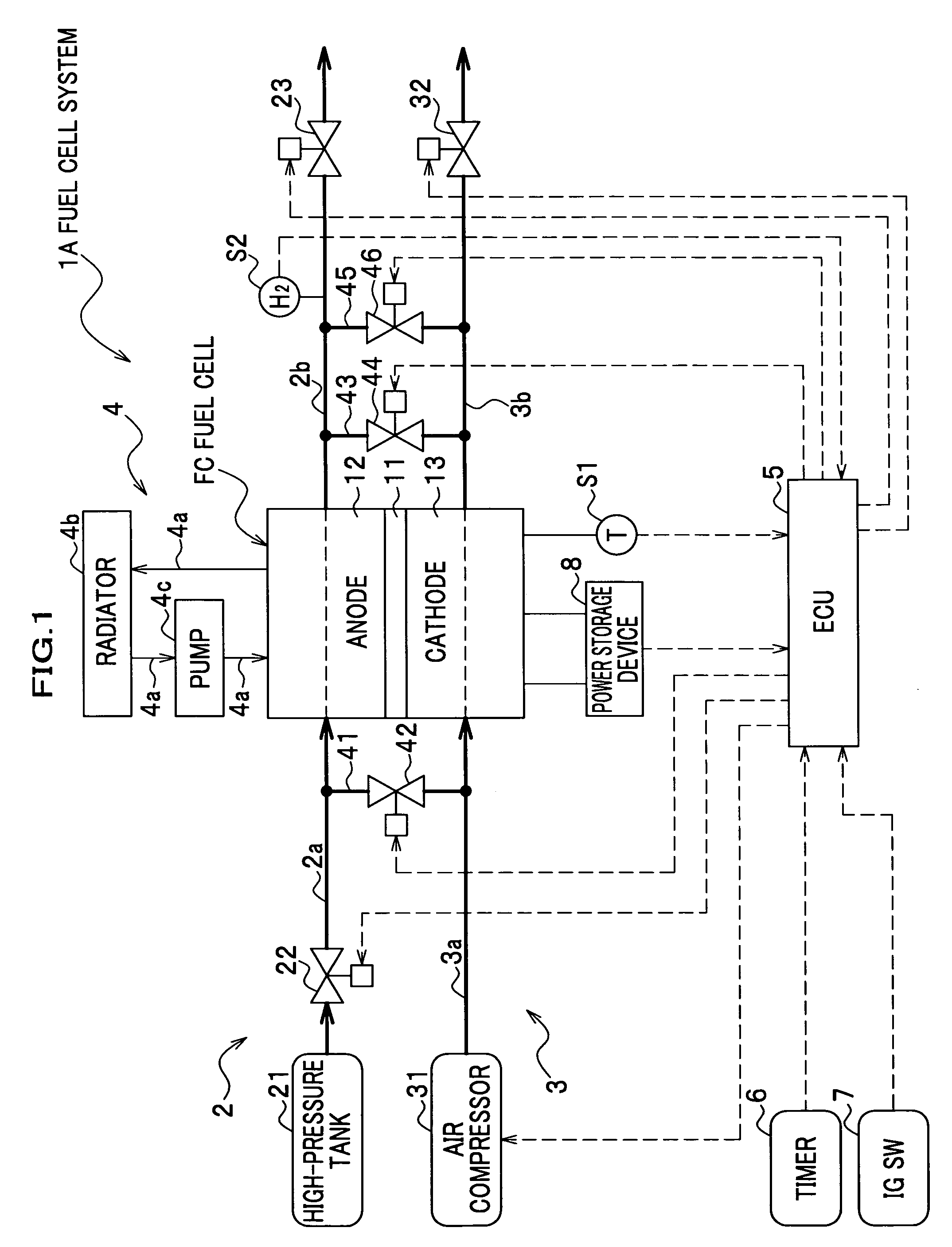

Fuel cell system and control method of fuel cell system

ActiveUS20070026276A1Possible to useLower performance requirementsFuel cell controlFuel cellsWater content

A fuel cell system is provided which estimates a water content in a fuel cell based on a predetermined map using an integrated value of electric current generated by the fuel cell (ST4) before power generation is stopped (ST5). When a temperature of the fuel cell has fallen lower than a predetermined value (ST7) after the power generation is stopped (ST5), the fuel cell system determines a dry degree in the fuel cell (ST8) and an anode scavenging period (ST9) based on predetermined maps. Scavenging is performed in an anode in the fuel cell for the anode scavenging period (ST10).

Owner:HONDA MOTOR CO LTD

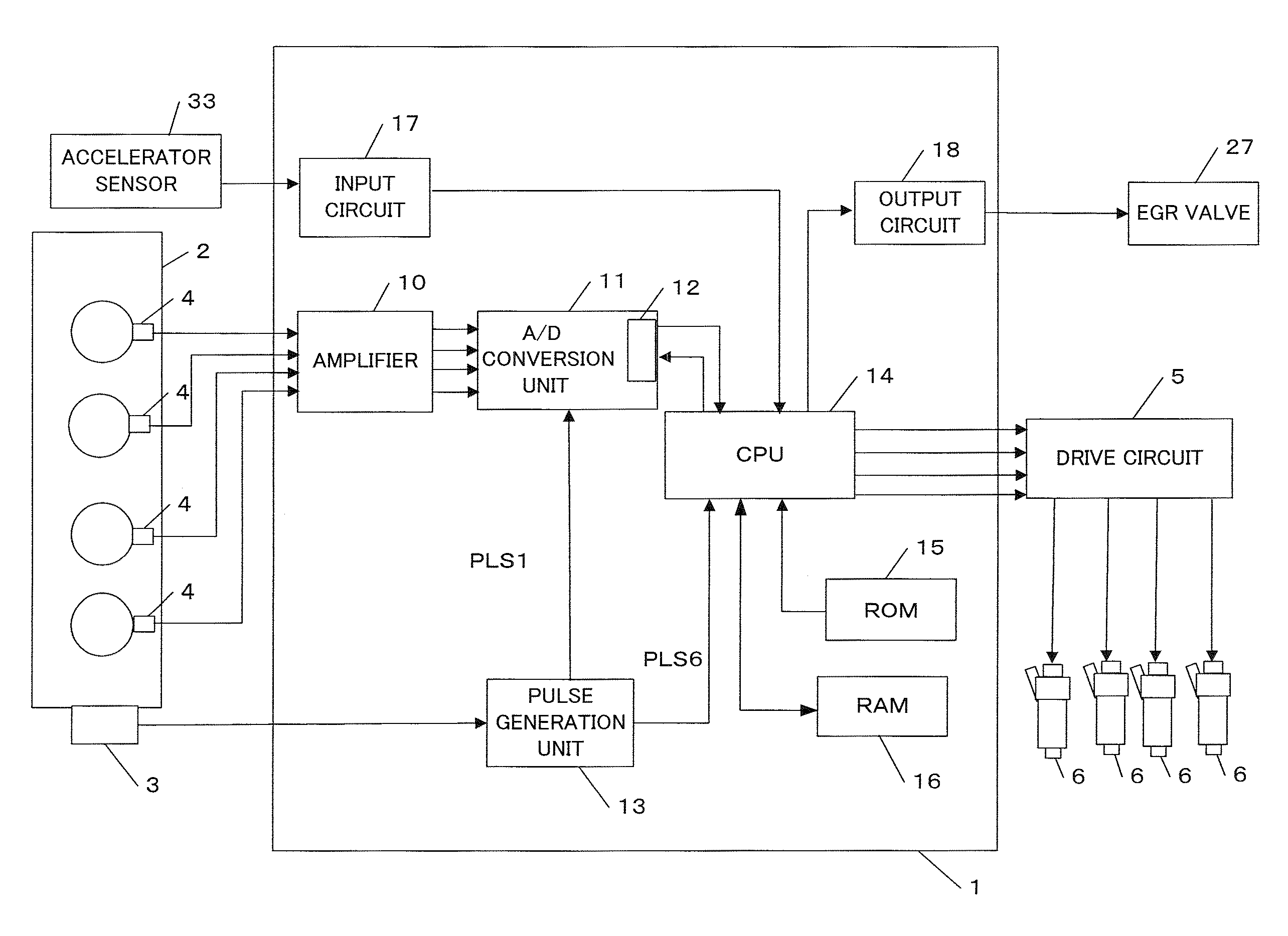

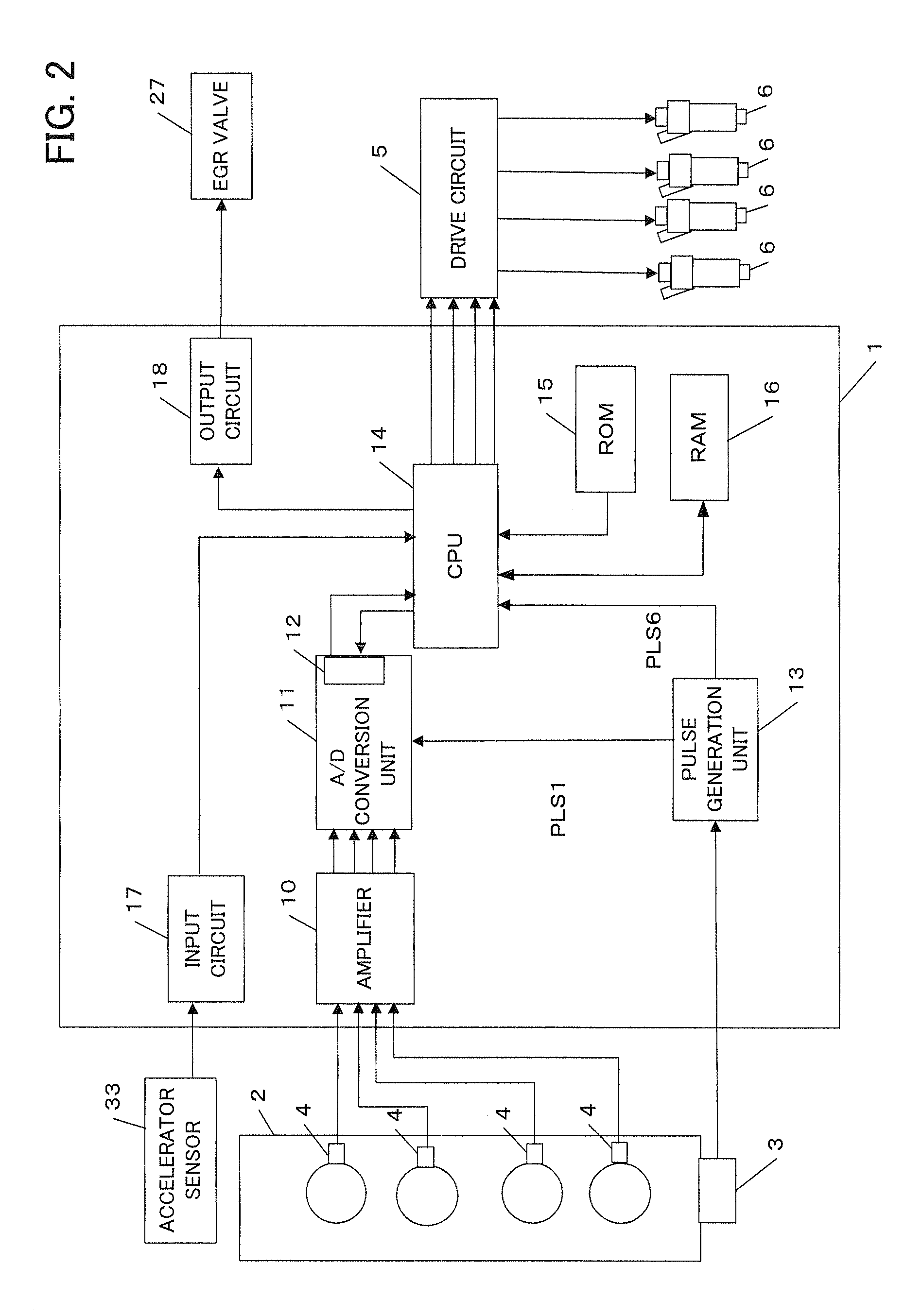

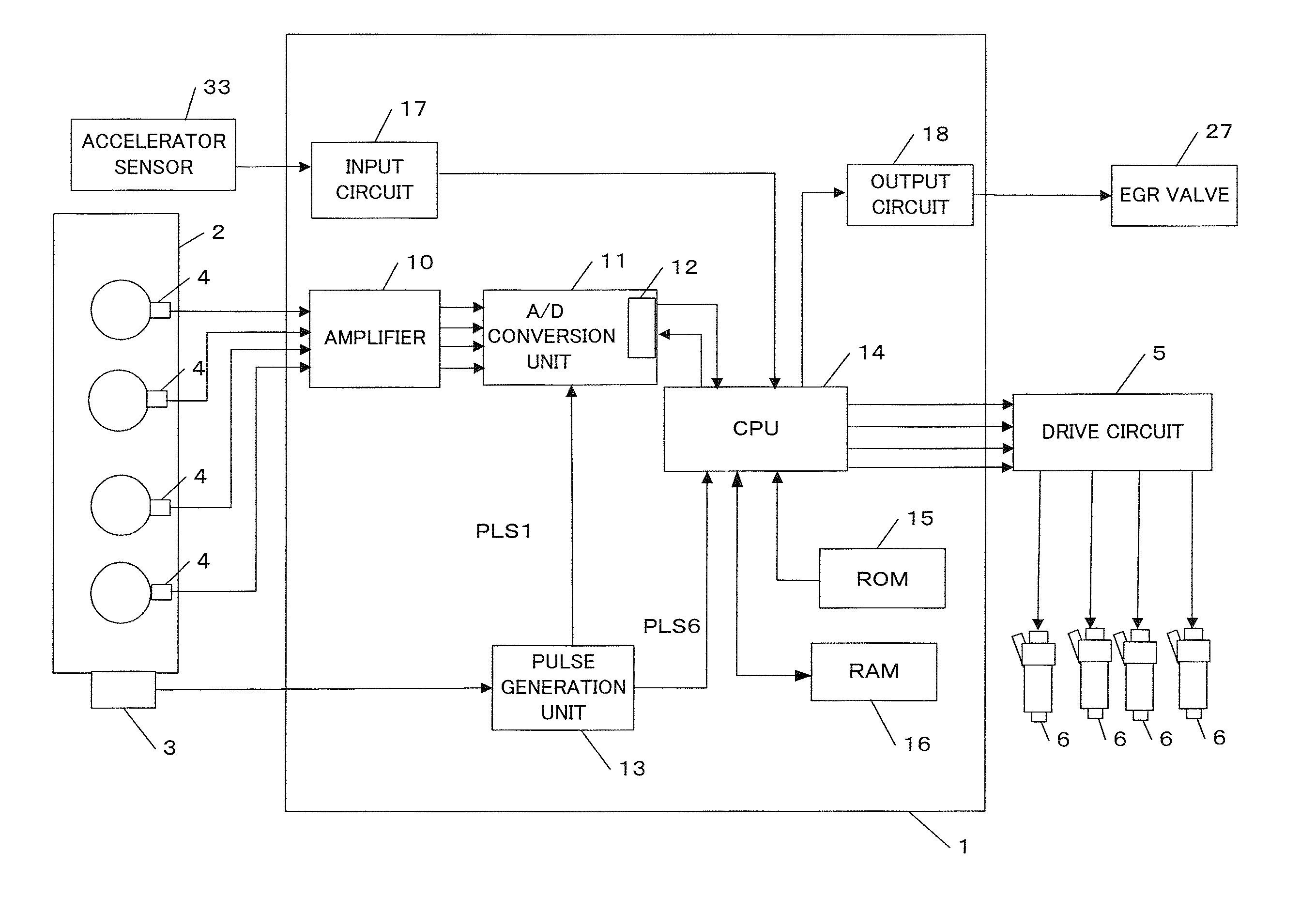

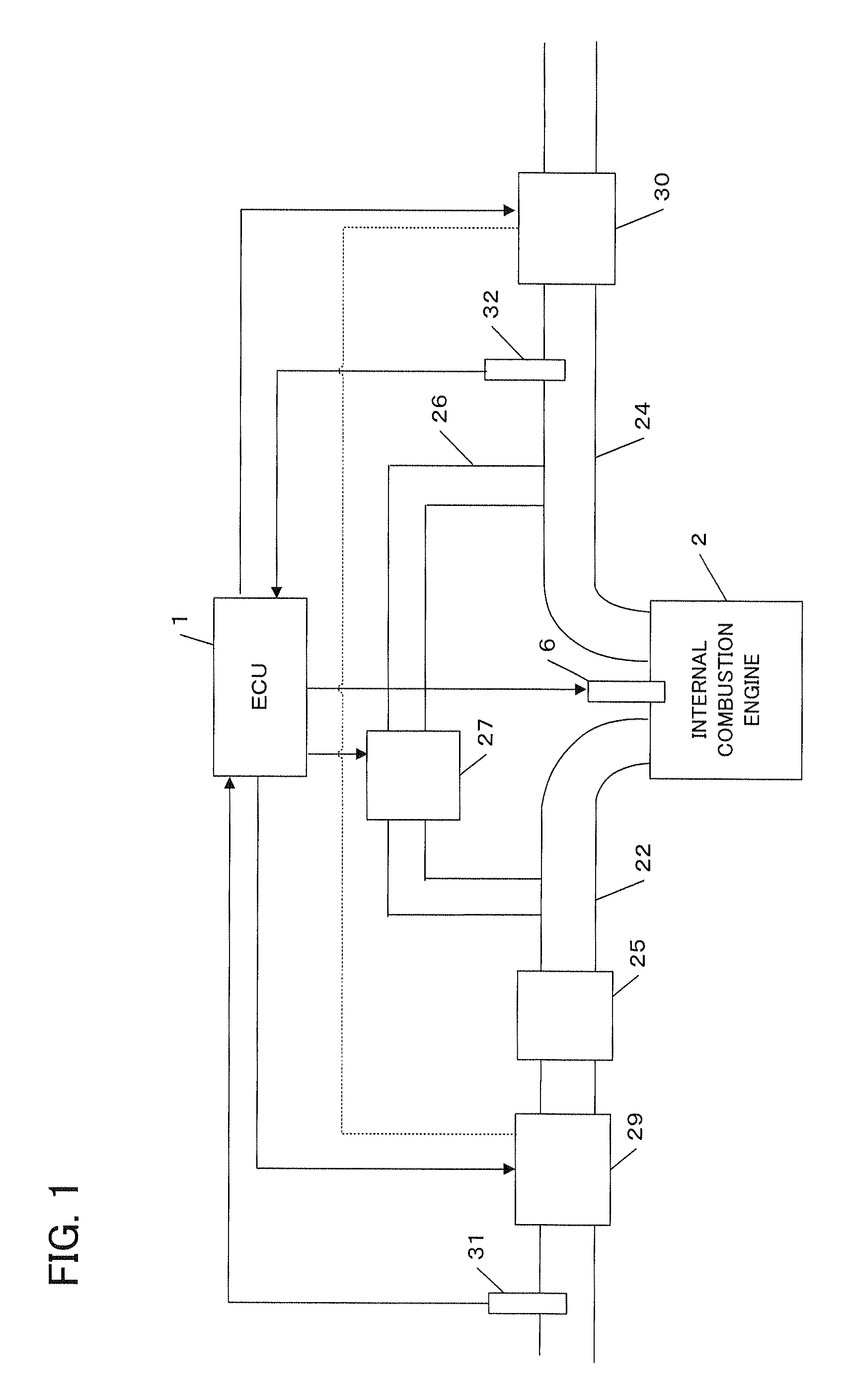

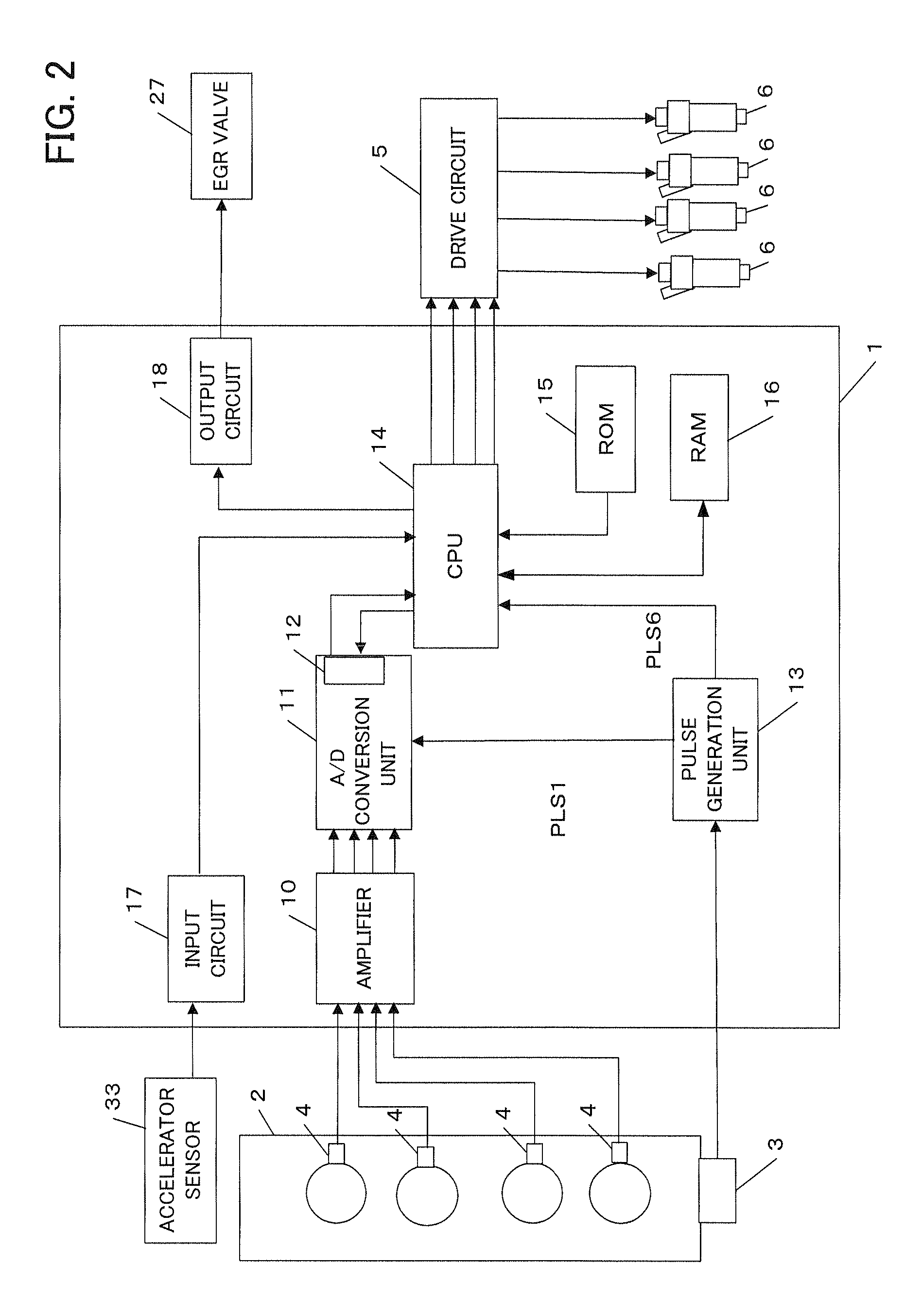

Fuel control for internal combustion engine

InactiveUS20090292447A1Avoids deterioration of combustion noise and deterioration of emissionAppropriate amountElectrical controlInternal combustion piston enginesIgnition timingPilot injection

A fuel injection control for an internal combustion engine is provided. Fuel is injected into a cylinder of the internal combustion engine. The fuel injection is divided into main injection and pilot injection in advance of the main injection. An actual compression ignition timing is detected based on a combustion state in the cylinder. A fuel injection timing of the main injection is controlled based on the actual compression ignition timing. An amount of heat release based on the pilot injection is computed. A fuel injection amount of the pilot injection is corrected based on the computed heat release amount.

Owner:HONDA MOTOR CO LTD

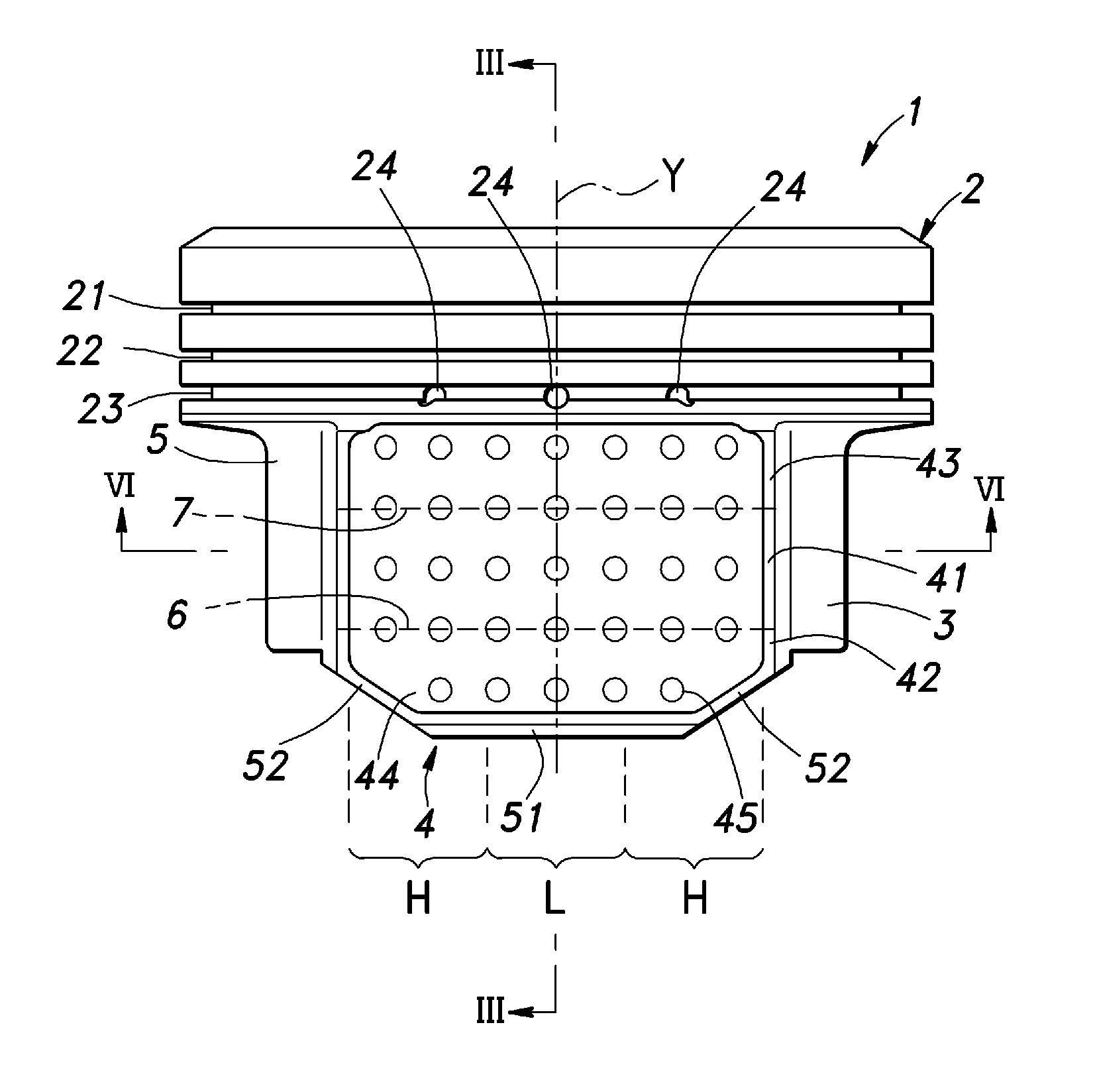

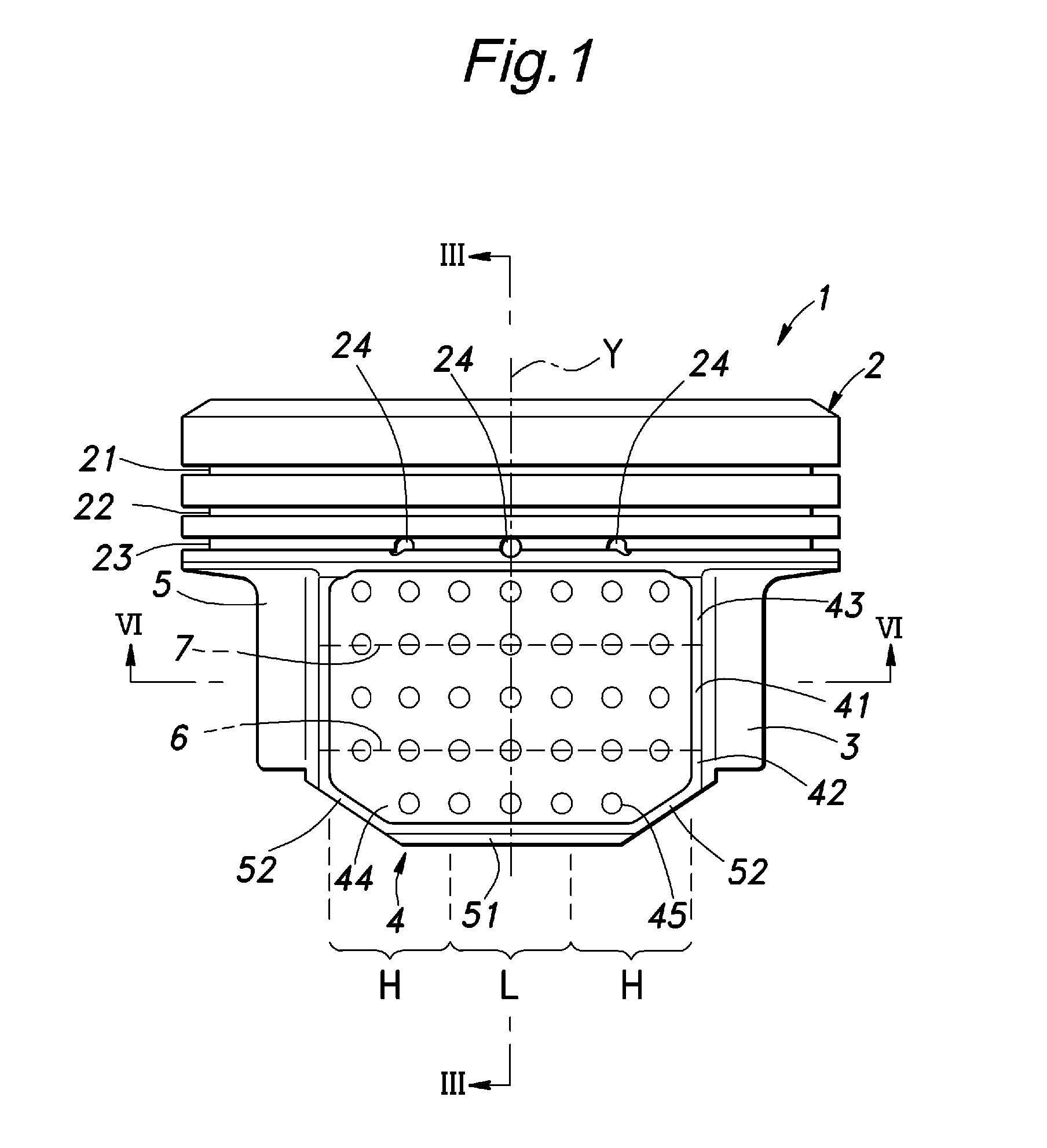

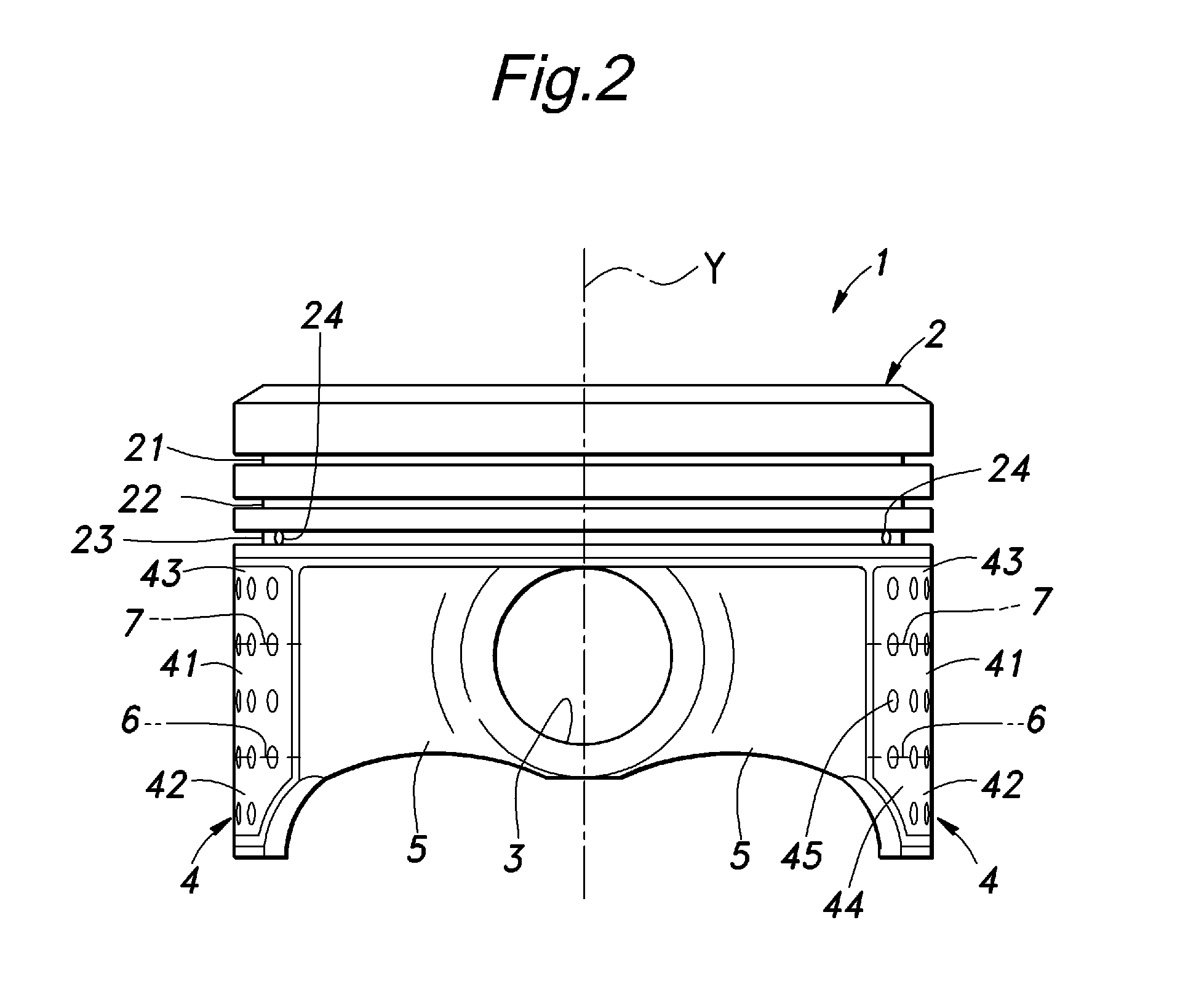

Piston for an internal combustion engine

ActiveUS20110139114A1Improve friction performanceSufficient amountPlungersMachines/enginesResin coatingEngineering

To provide a piston for an internal combustion engine including a skirt which causes a relatively small frictional resistance and can maintain a favorable frictional property over an extended period of time. In a piston for an internal combustion engine having a skirt 4 on whose sliding surface a resin coating layer is deposited, the skirt 4 comprises a thin walled portion 51 located in a circumferentially middle part thereof and a pair of thick walled portions 52 provided on either lateral side of the thin walled portion 51. The resin coating layer 44 at least in the part thereof deposited on the thick walled portions 52 is formed with a plurality of dimples 45. The skirt may comprise a skirt main body 41 extending axially at a fixed distance from the central axial line of the piston in an axially middle part thereof, and a first reduced diameter portion 42 depending from the lower end of the skirt main body and having a progressively smaller diameter toward a lower end thereof. The dimples 45 may be arranged along a first boundary 6 between the skirt main body and first reduced diameter portion.

Owner:HONDA MOTOR CO LTD

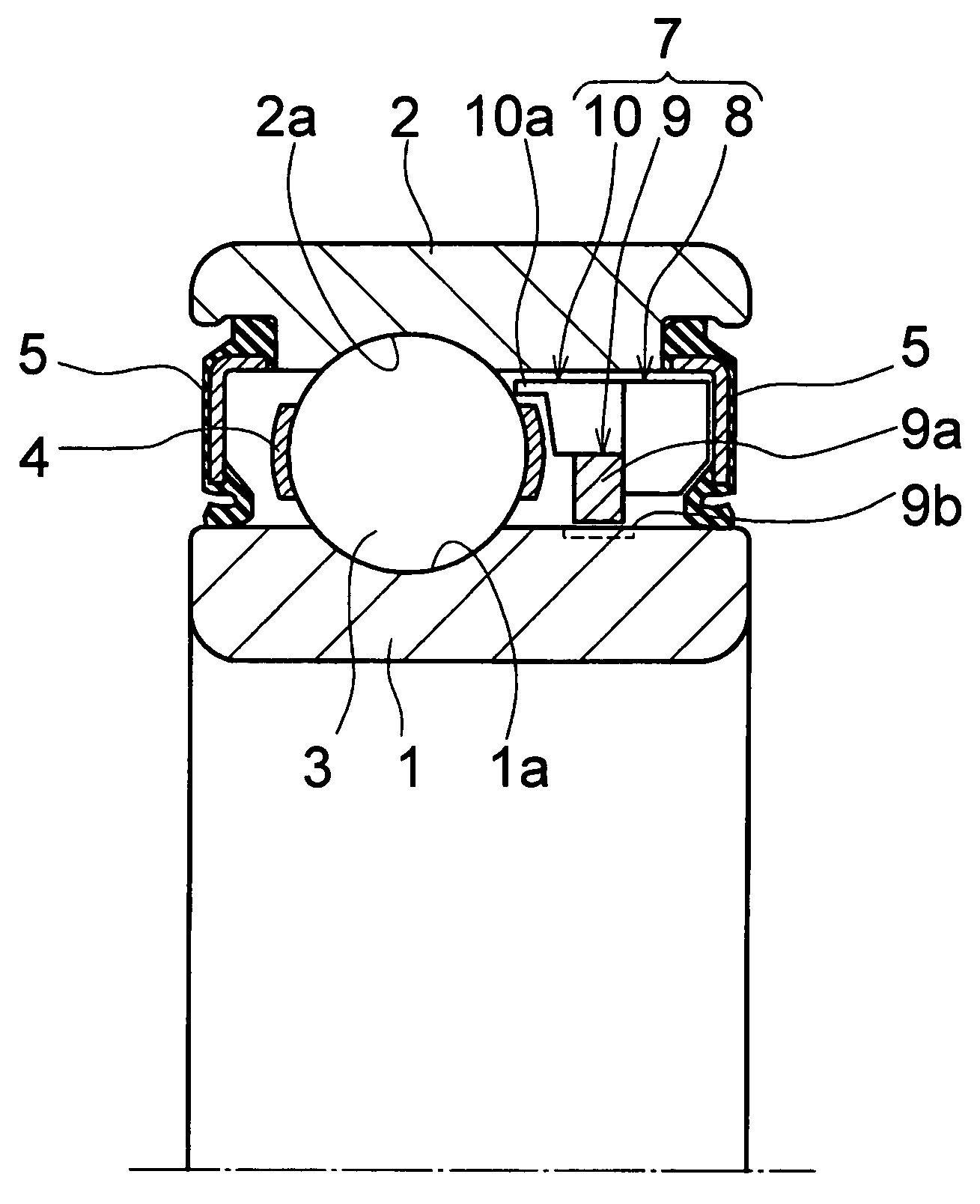

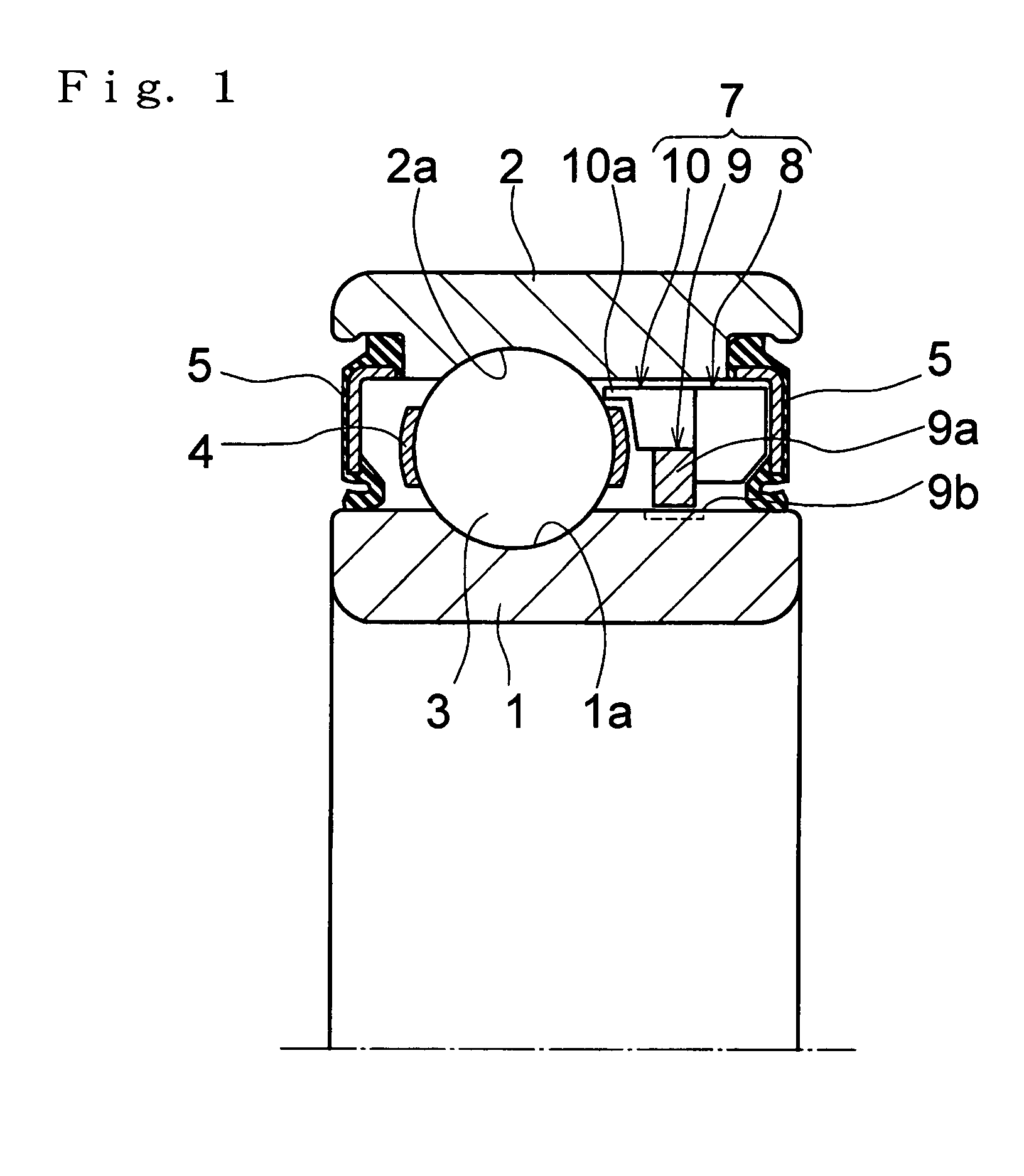

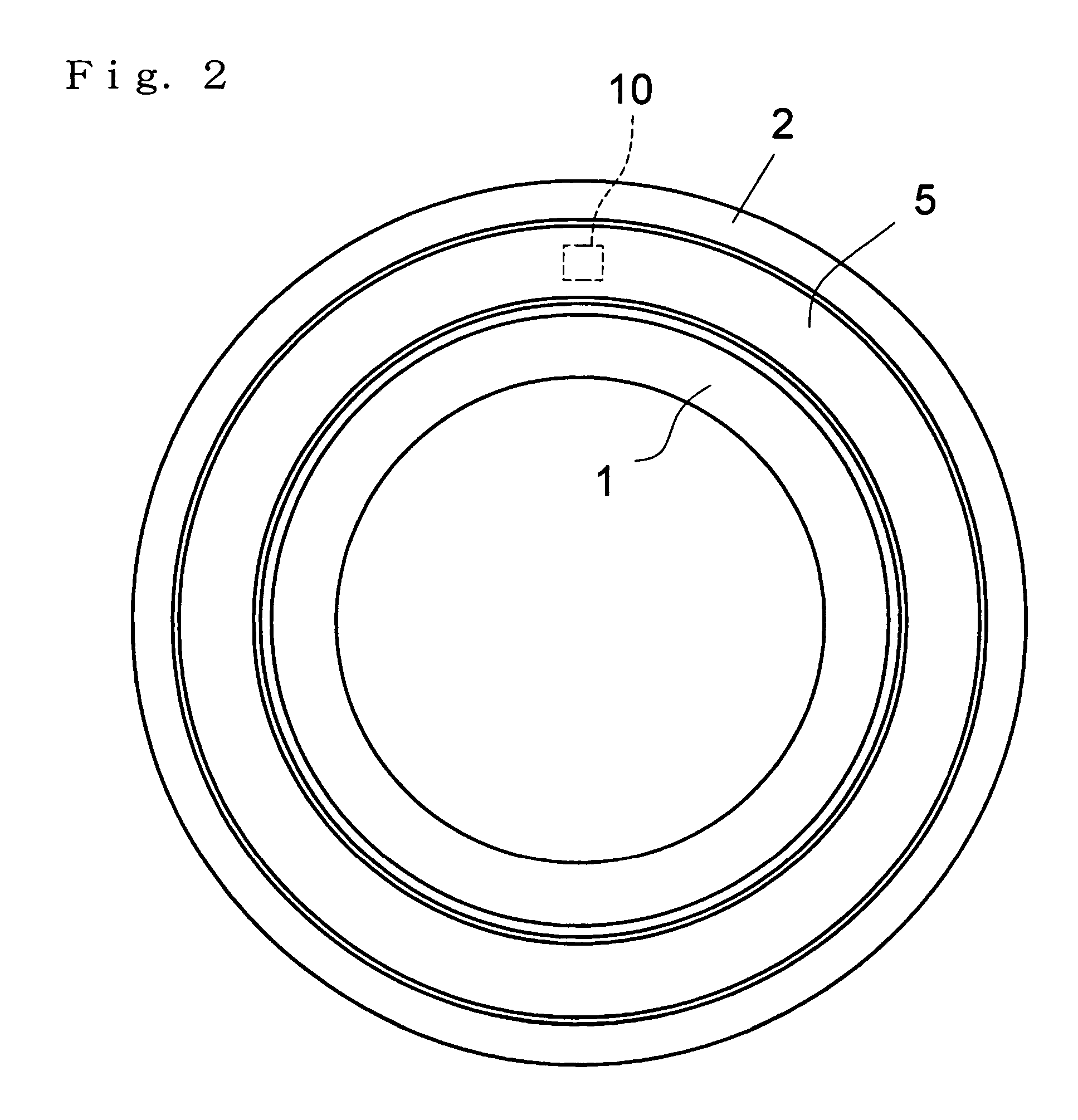

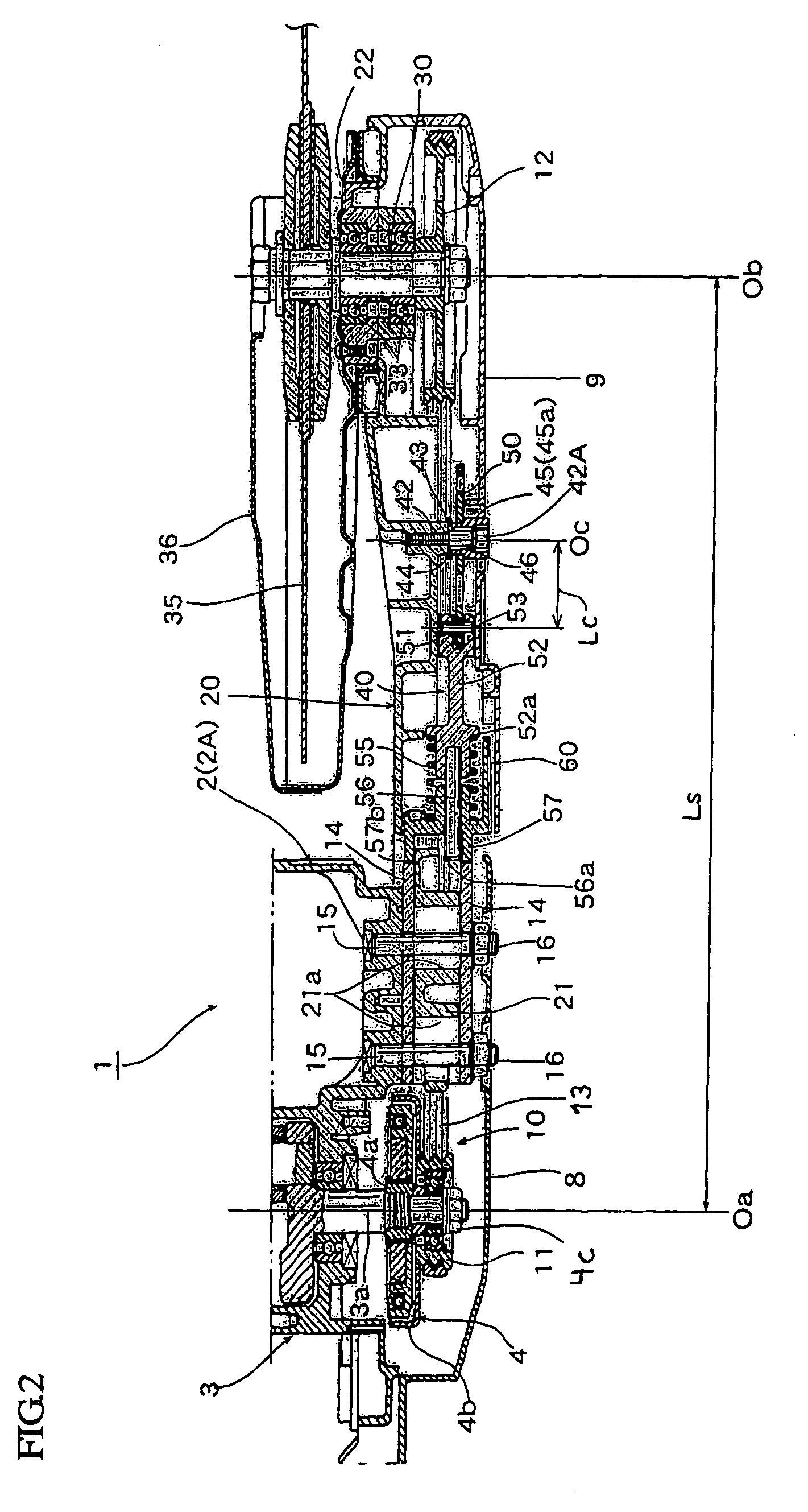

Bearing device

InactiveUS7293919B2Easy to installContribute to long-term stabilization of rolling propertyPositive displacement pump componentsBearing assemblyEngineeringControl circuit

Owner:JTEKT CORP

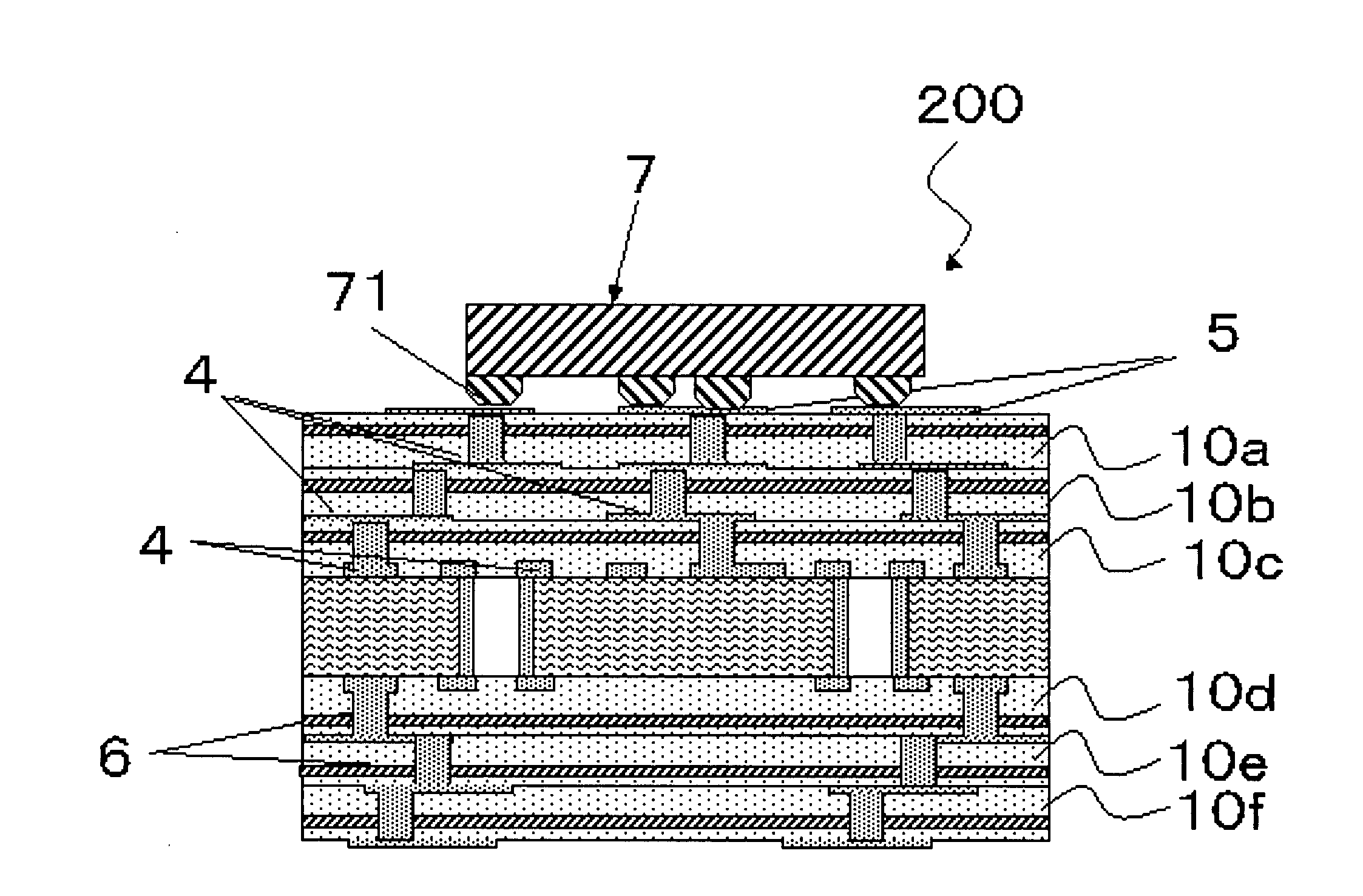

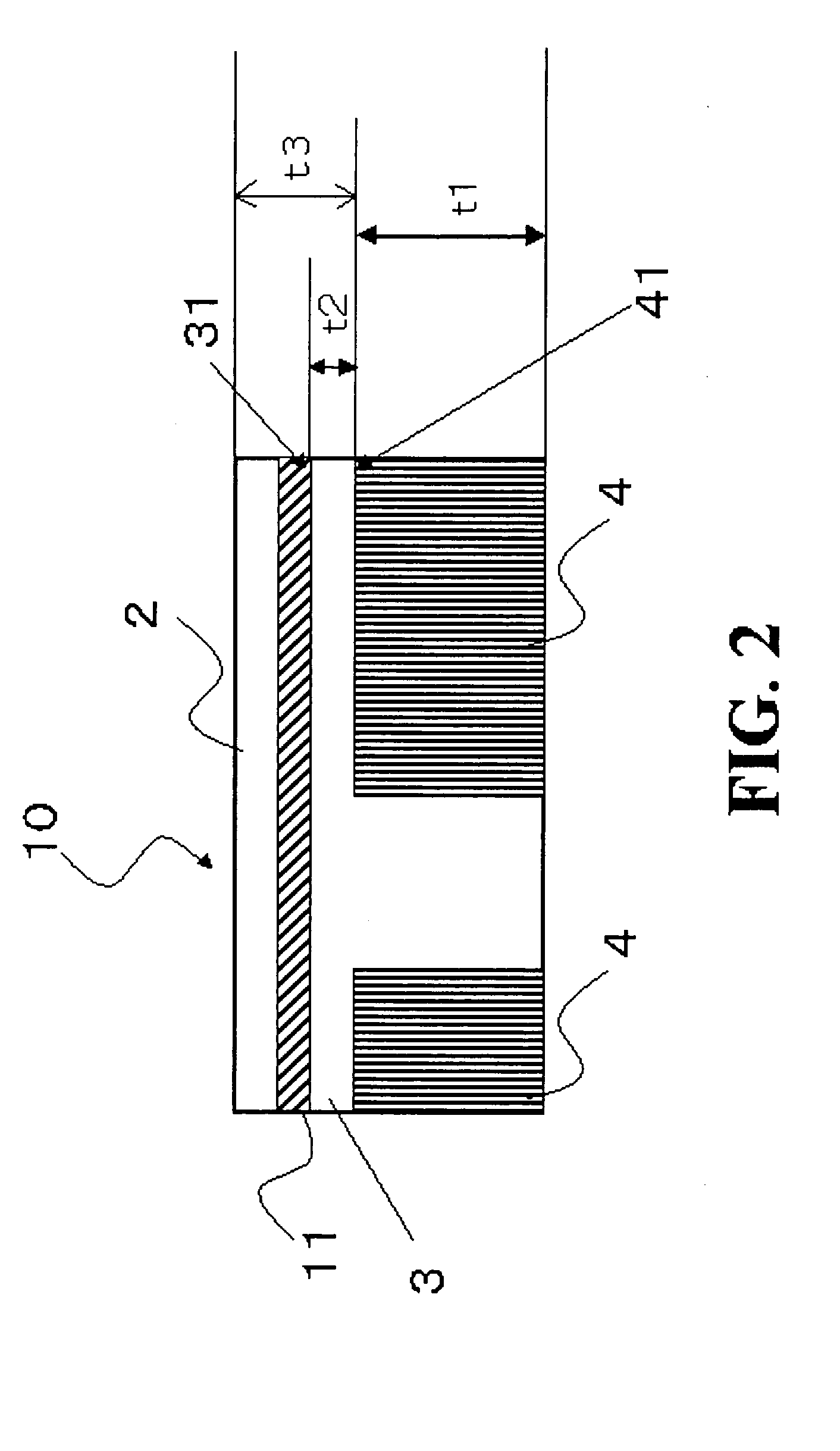

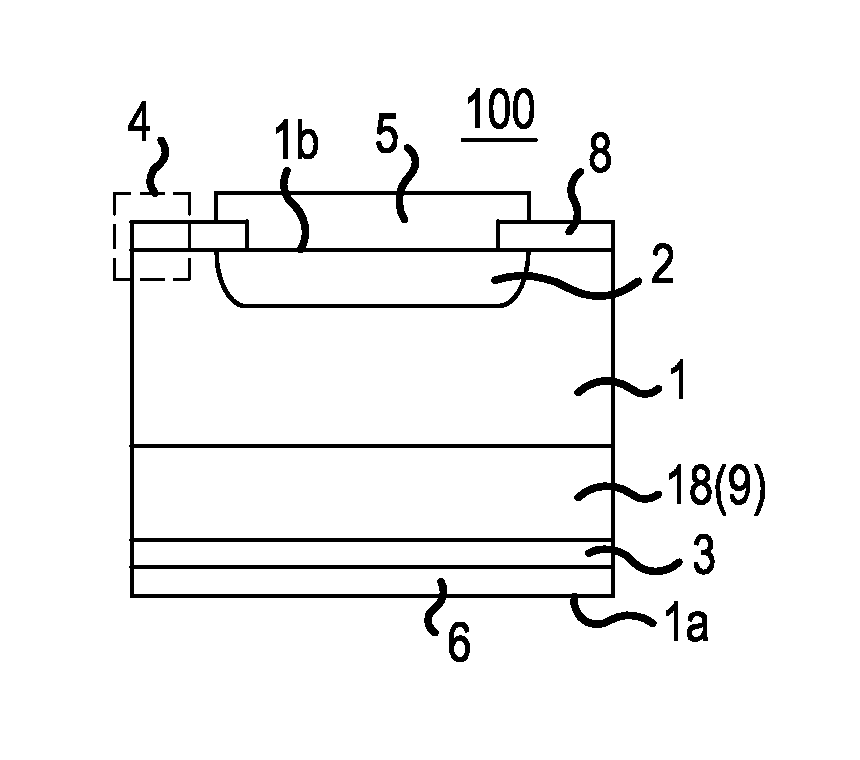

Prepreg, Method for Manufacturing Prepreg, Substrate, and Semiconductor Device

InactiveUS20090302462A1Reduce thicknessAppropriate amountSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A prepreg which can meet a demand for thickness reduction is provided. The prepreg has first and second resin layers having different applications, functions, capabilities, or properties, and allows an amount of a resin composition in each of the first and second resin layers to be set appropriately depending on a circuit wiring portion to be embedded into the second resin layer. Further, a method for manufacturing the above prepreg, and a substrate and a semiconductor device having the prepreg are also provided. The prepreg according to the present invention includes a core layer including a sheet-shaped base member and having one surface and the other surface which is opposite to the one surface, the first resin layer provided on the one surface of the core layer and formed of a first resin composition, and the second resin layer provided on the other surface of the core layer and formed of a second resin composition, wherein at least one of a requirement that a thickness of the first resin layer is different from that of the second resin layer and a requirement that a constitution of the first resin composition is different from that of the second resin composition is satisfied.

Owner:SUMITOMO BAKELITE CO LTD

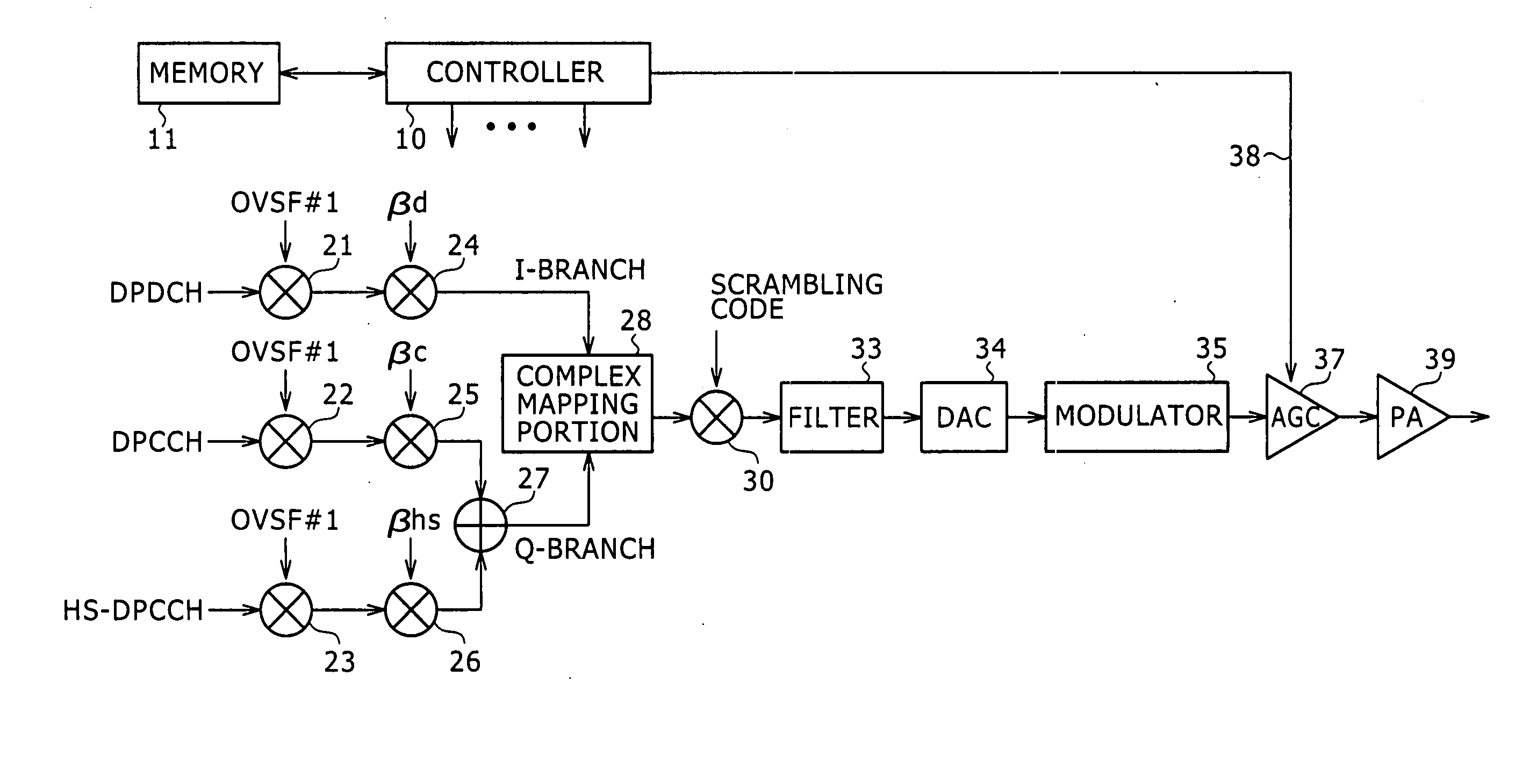

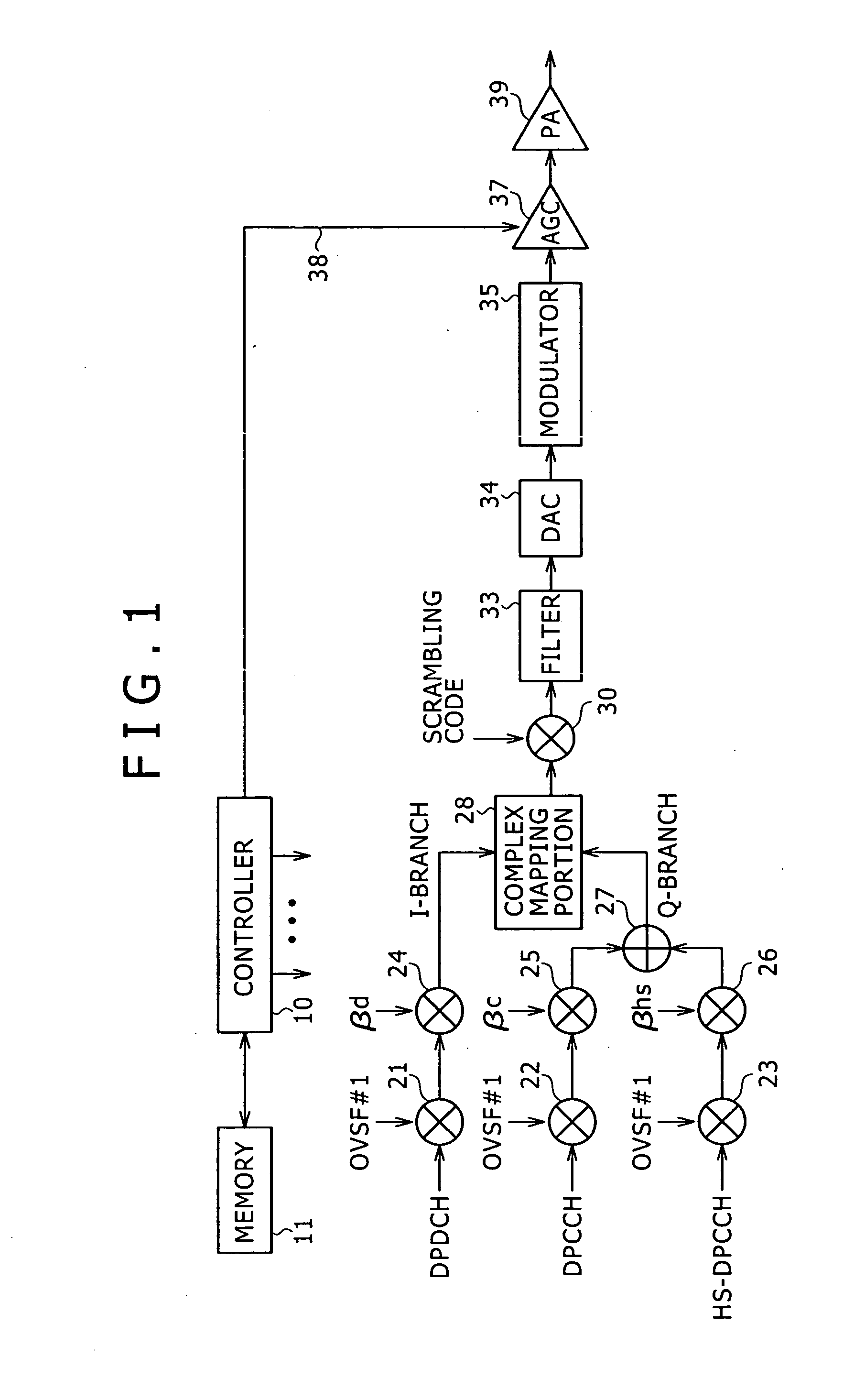

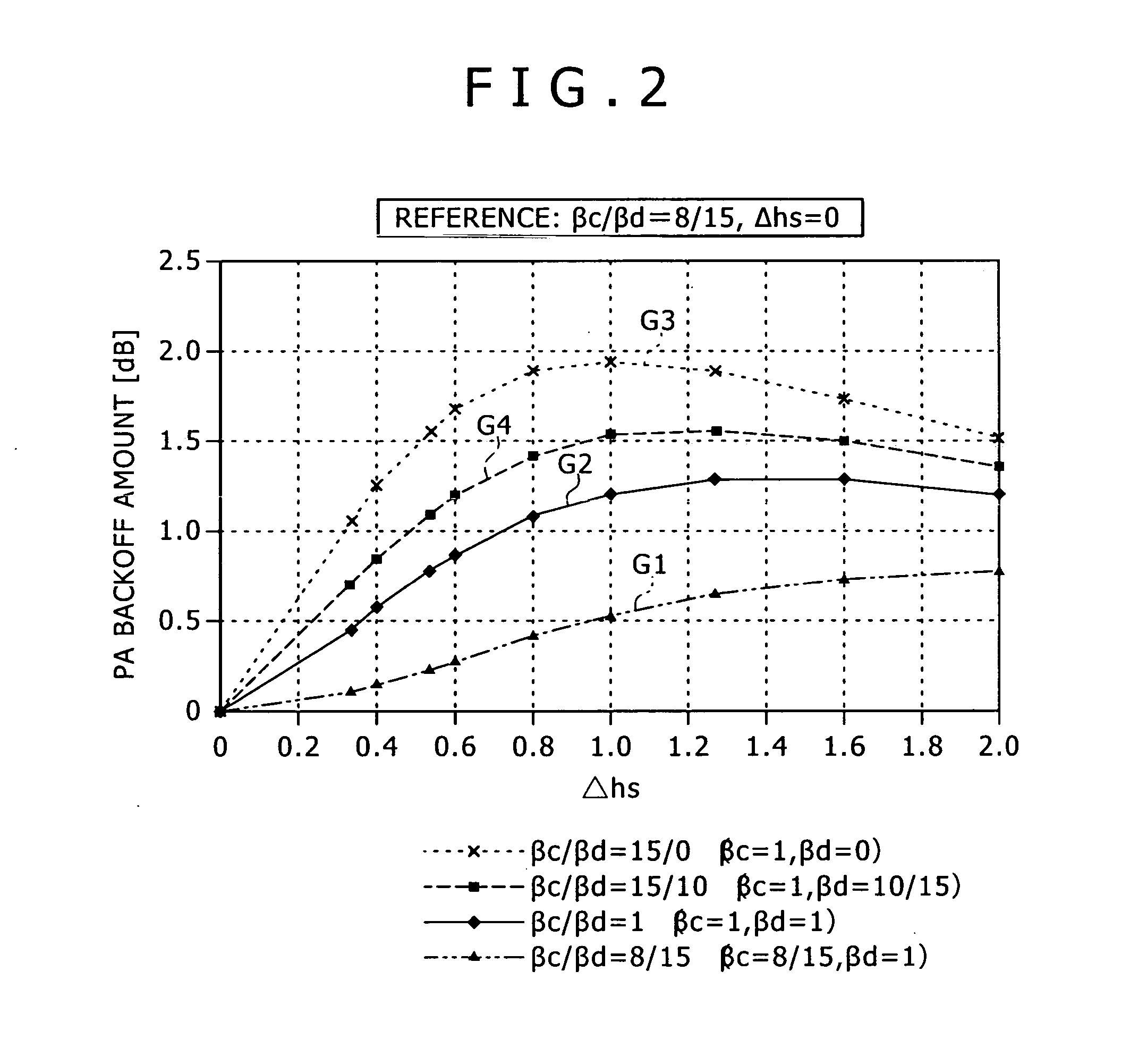

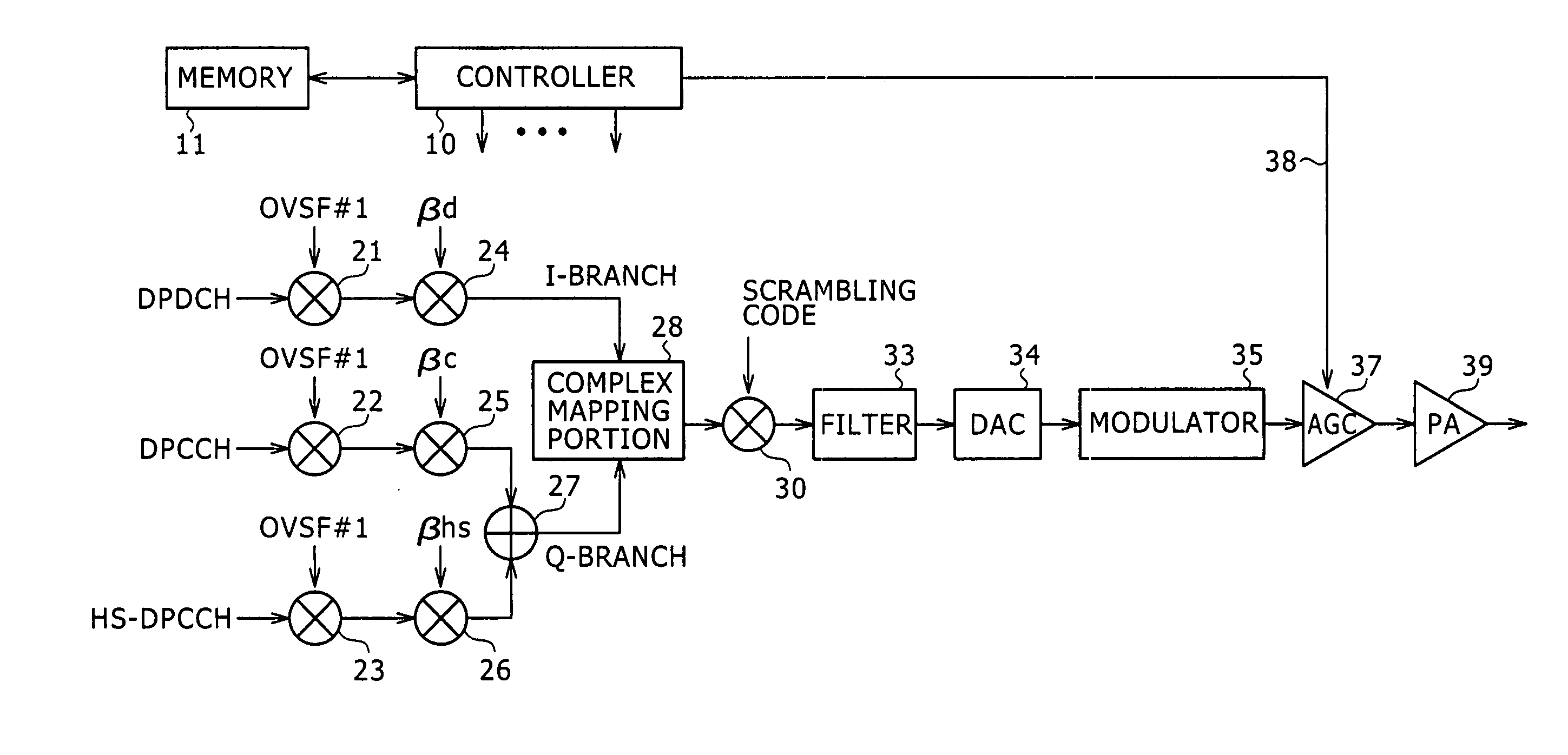

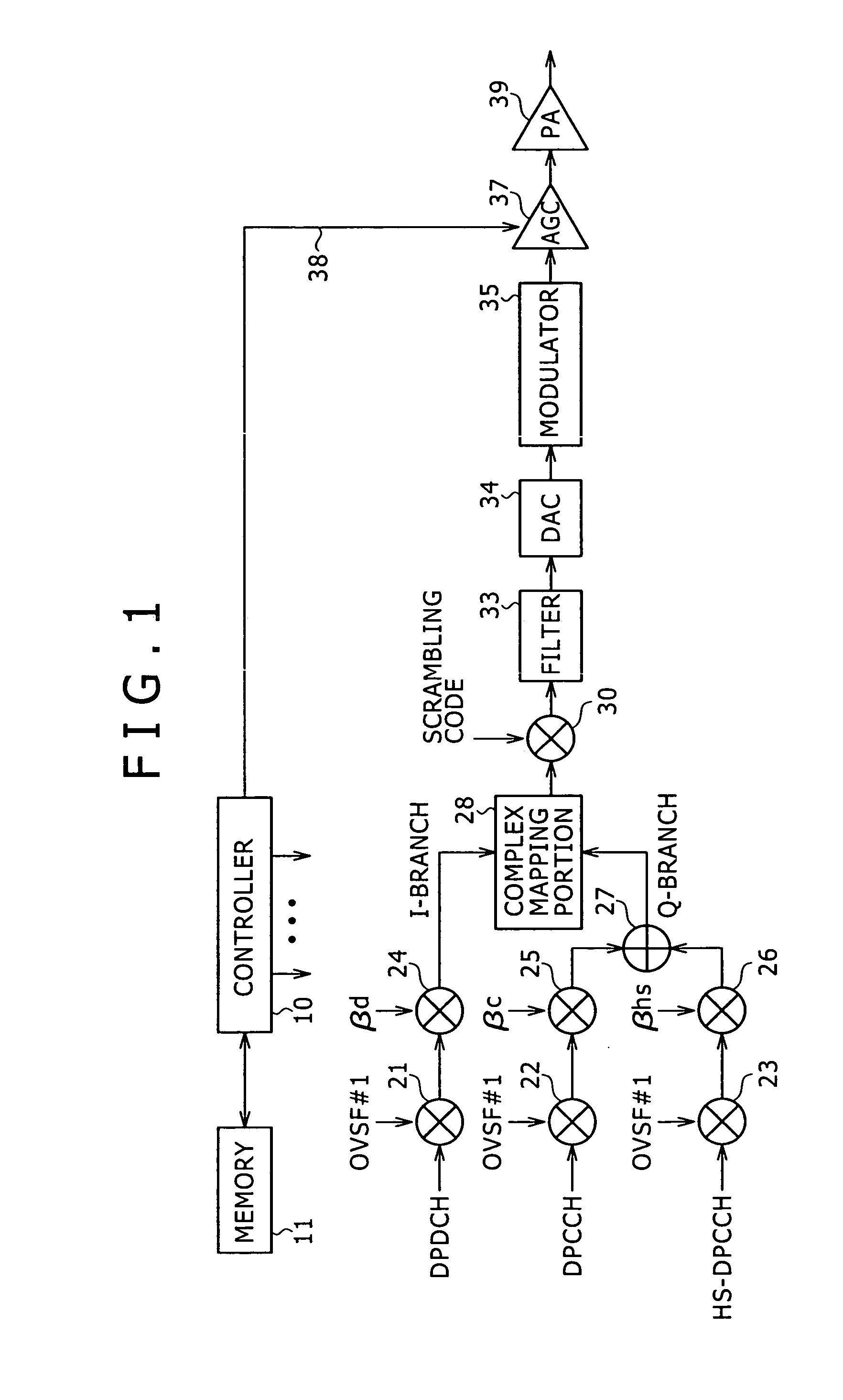

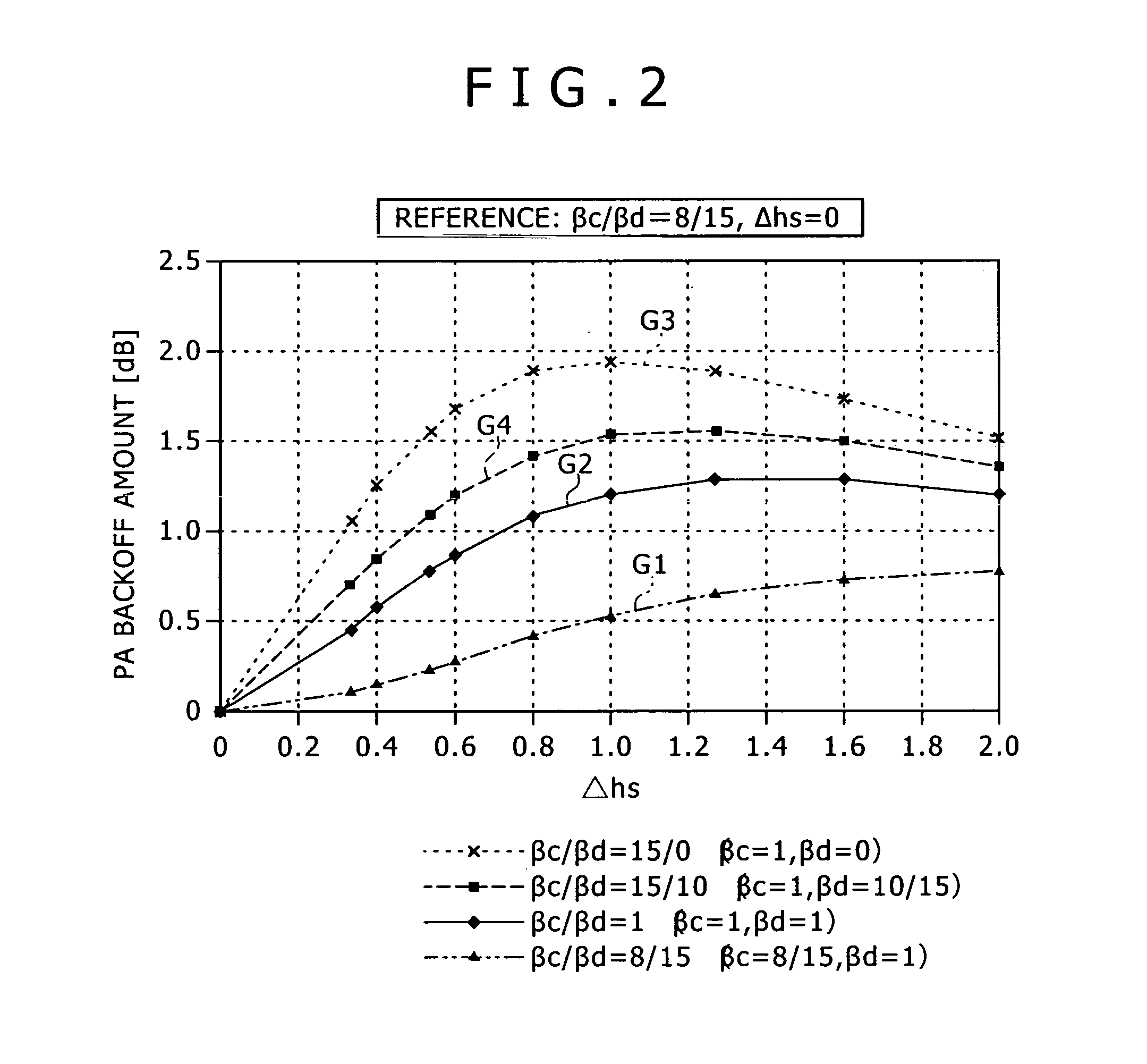

Transmission power control method and device

ActiveUS20060217088A1Enlarge scopeSolve the power is smallPower managementEnergy efficient ICTPower controlEngineering

Disclosed is a method and an apparatus for controlling transmission electric power capable of minimizing a decrease in the amount of maximum transmission electric power without degrading an adjacent channel leakage power ratio when code-multiplexing additional control information with data and main control information. A mobile device checks values of gain factors βd and βc when performing code multiplexing to transmit signals from channels DPDCH to transmit data, DPCCH to transmit main control information, and HS-DPCCH to transmit additional control information. A maximum transmission electric power is decreased at a plurality of levels based on the check result and a ratio (Δhs) between the gain factors βc and βhs. It may be preferable to check the presence or absence of transmission data instead of the gain factor βd. In this case, when no transmission data is available, the maximum transmission electric power is decreased at a plurality of levels based on Δhs. When transmission data is available, the maximum transmission electric power is decreased at a plurality of levels based on the gain factor βc and Δhs.

Owner:SONY CORP

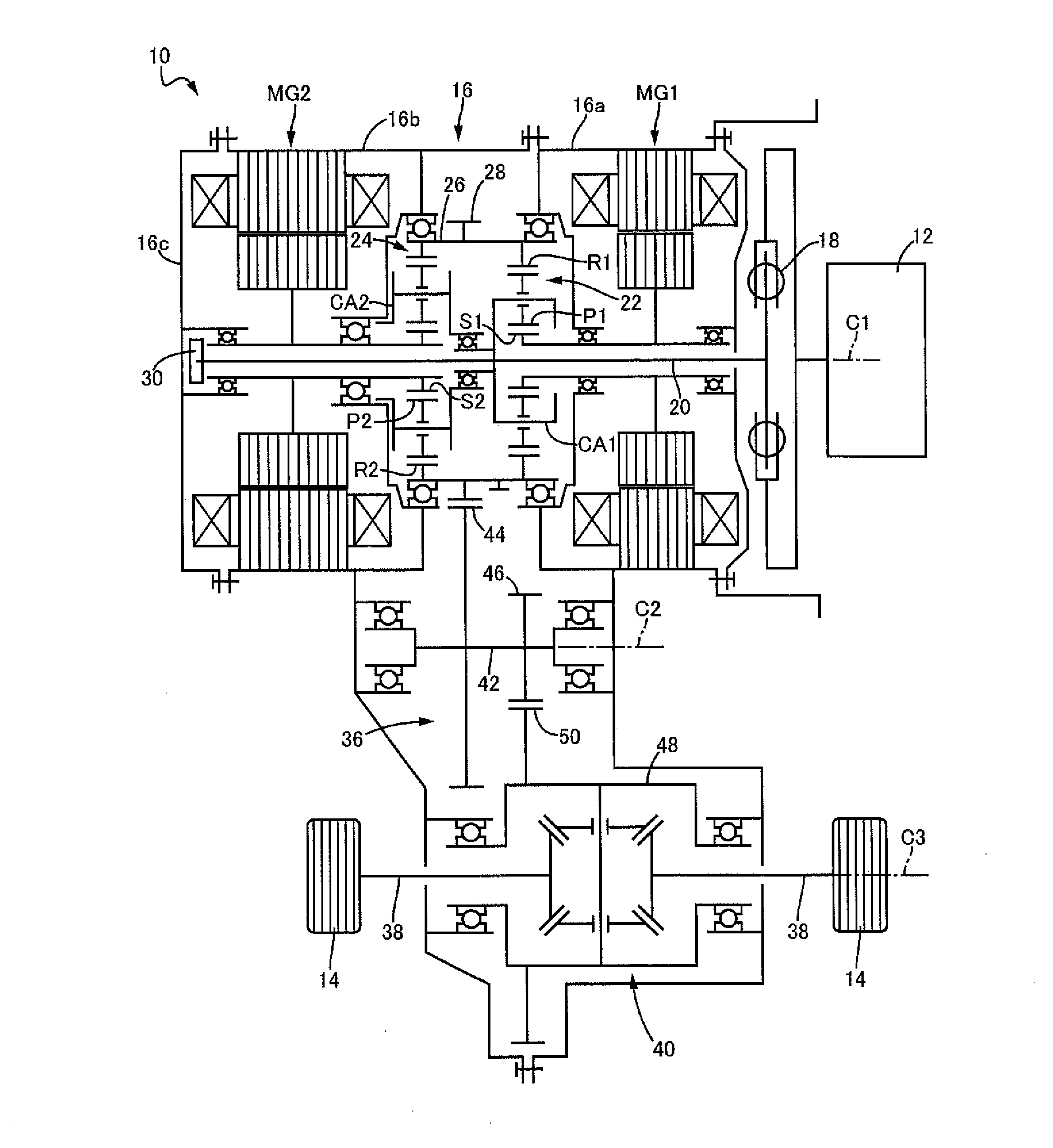

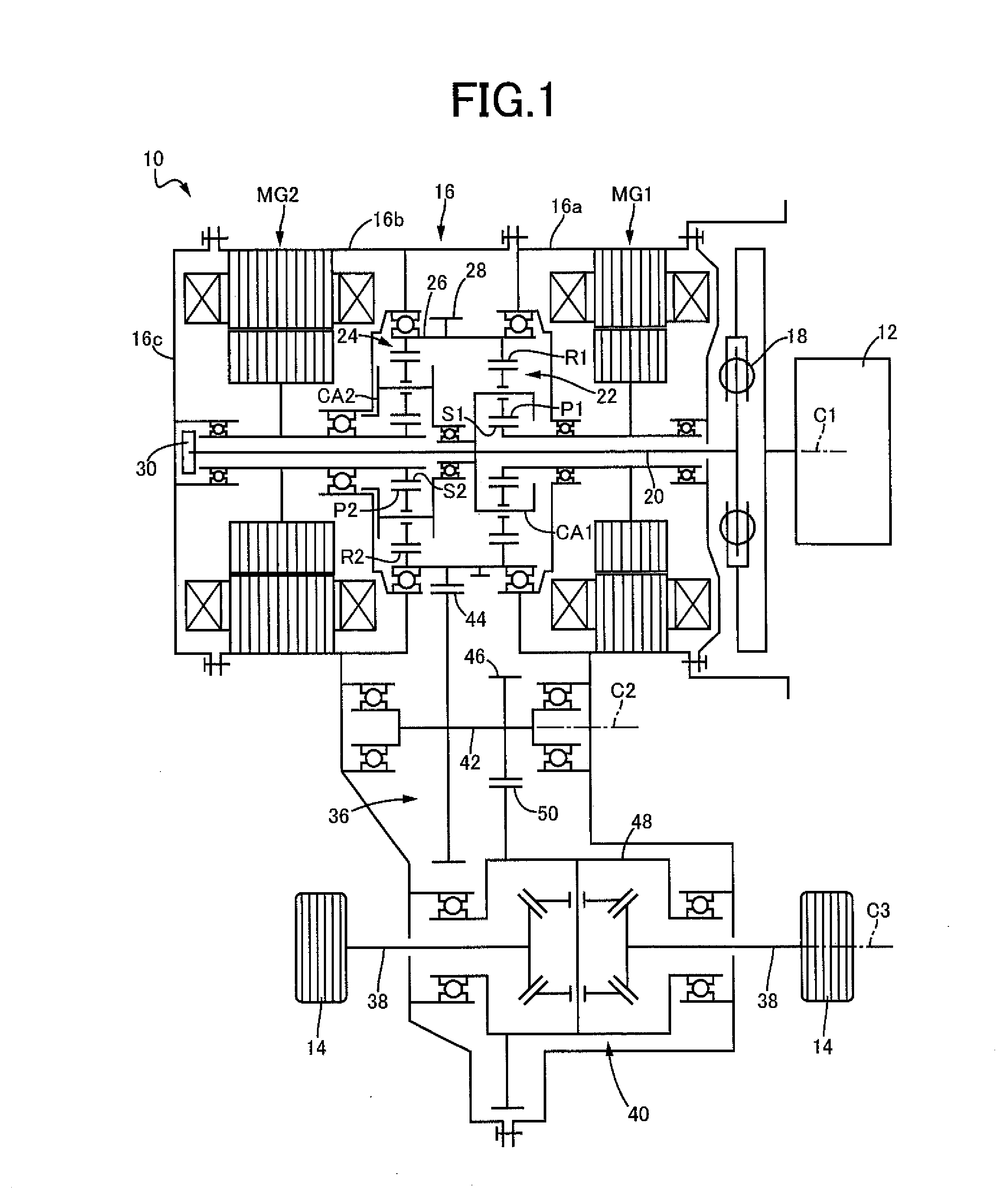

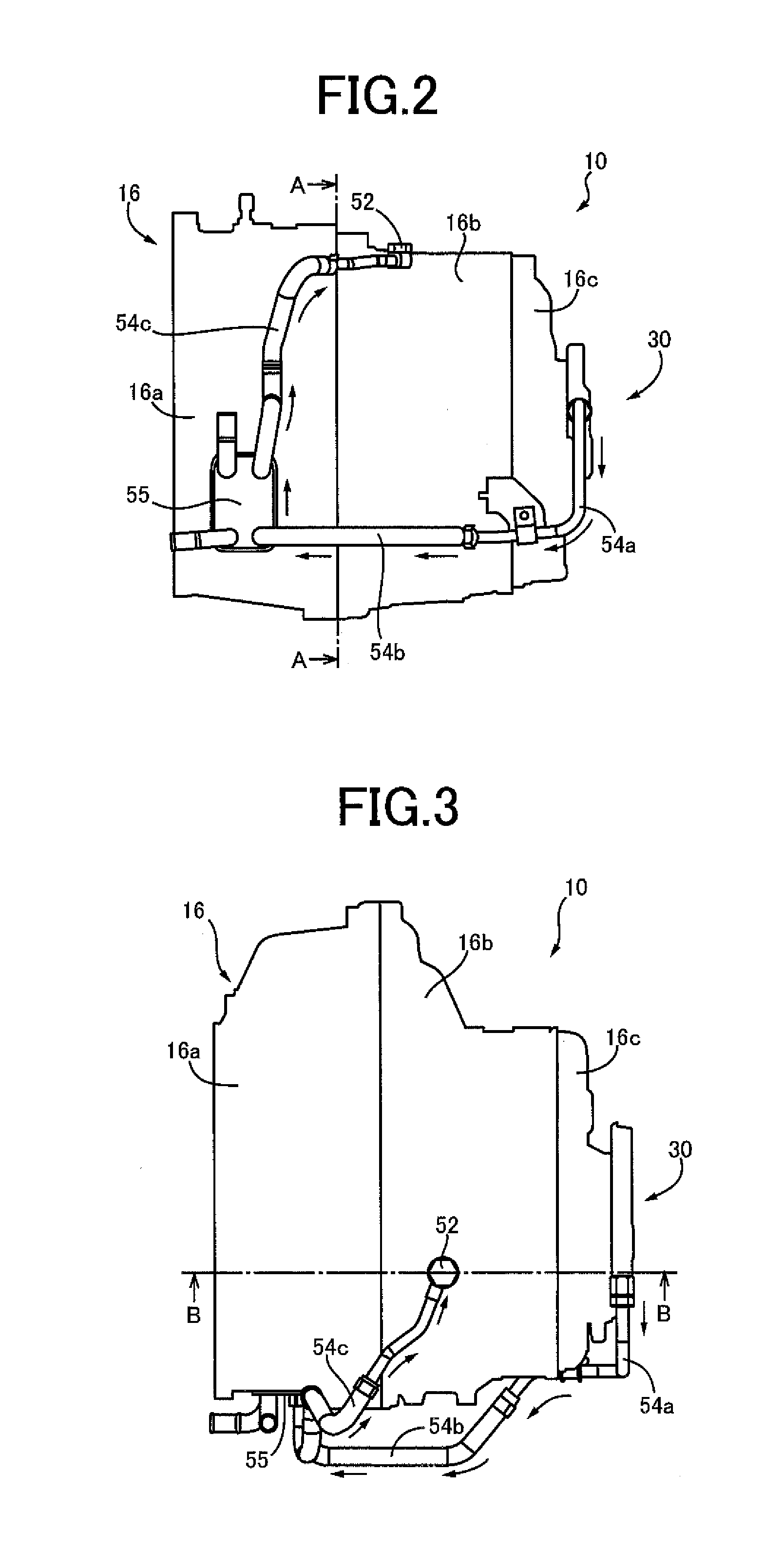

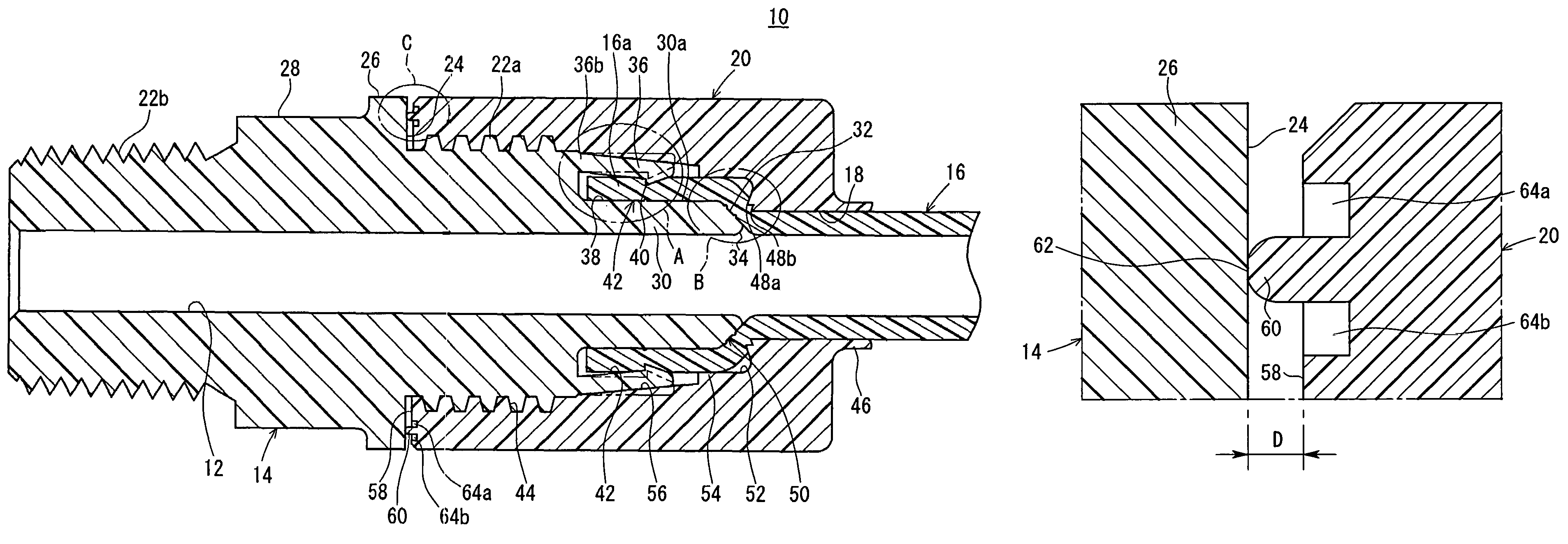

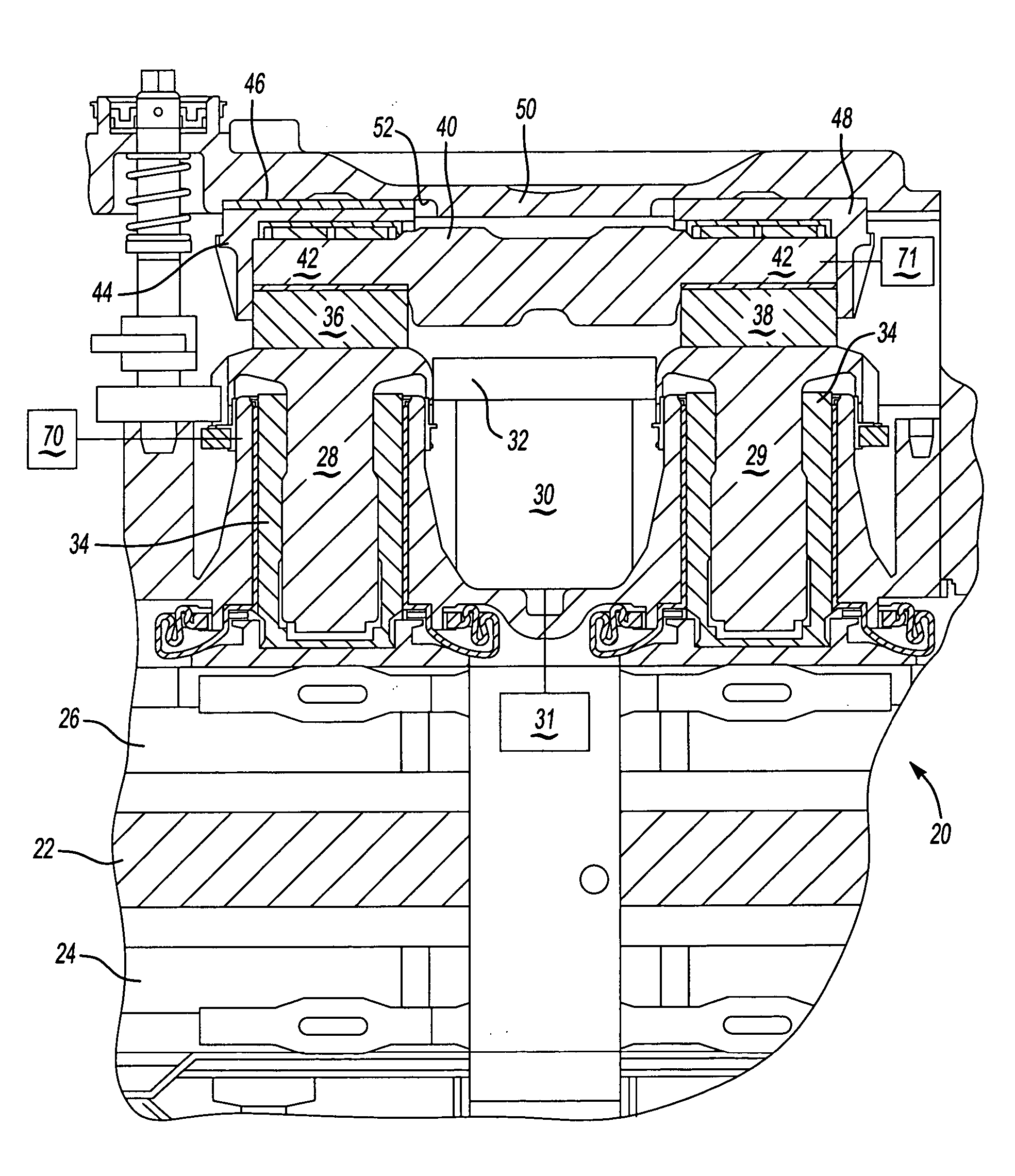

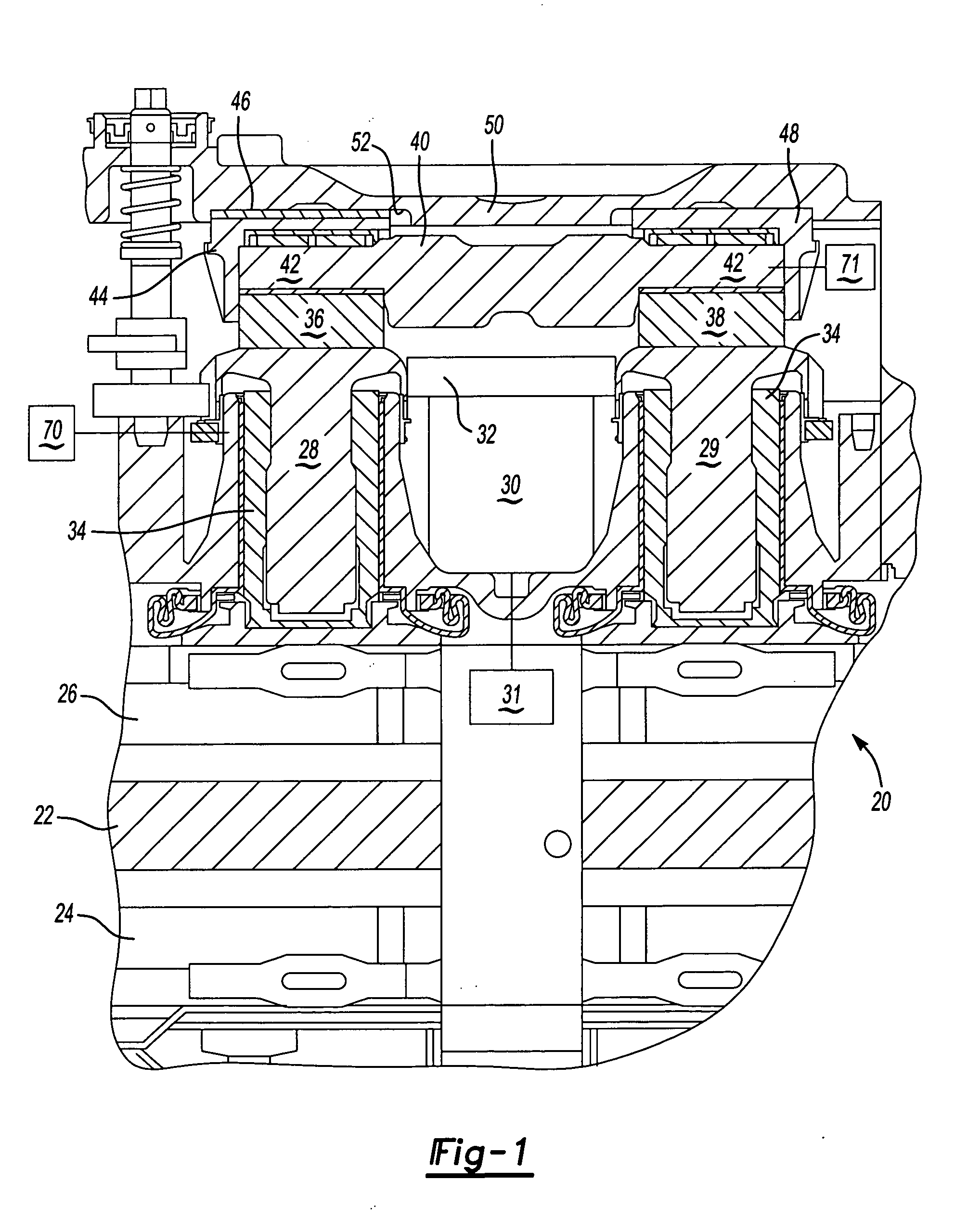

Lubrication device of power transmission device for hybrid vehicle

InactiveUS20140174856A1Supply will become excessiveLow viscosityHybrid vehiclesGear lubrication/coolingHybrid vehicleLubrication

A lubrication device for a hybrid vehicle power transmission device including a gear member, a first electric motor, and a second electric motor within a transaxle case, the lubrication device includes: a first pipe supplying oil forcibly transferred from an oil pump to the second electric motor; an oil passage branched from the first pipe; a first catch tank supplied with oil from the oil passage; a second pipe connected to the first catch tank to supply oil accumulated in the first catch tank to the first electric motor; an oil flow outlet disposed in the first catch tank and located above the second pipe; and a second catch tank disposed vertically beneath the first catch tank to receive oil outflowing from the oil flow outlet.

Owner:TOYOTA JIDOSHA KK

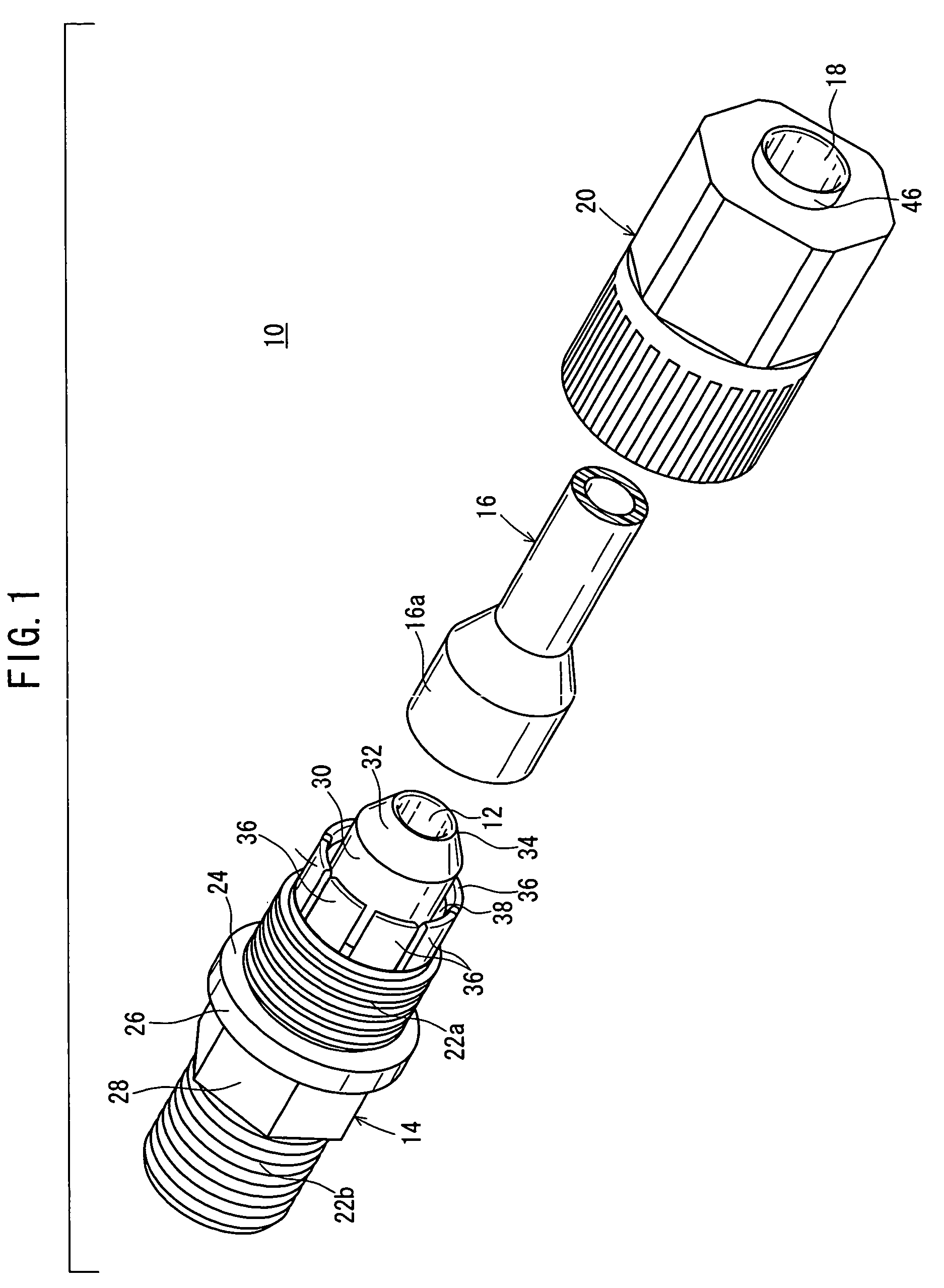

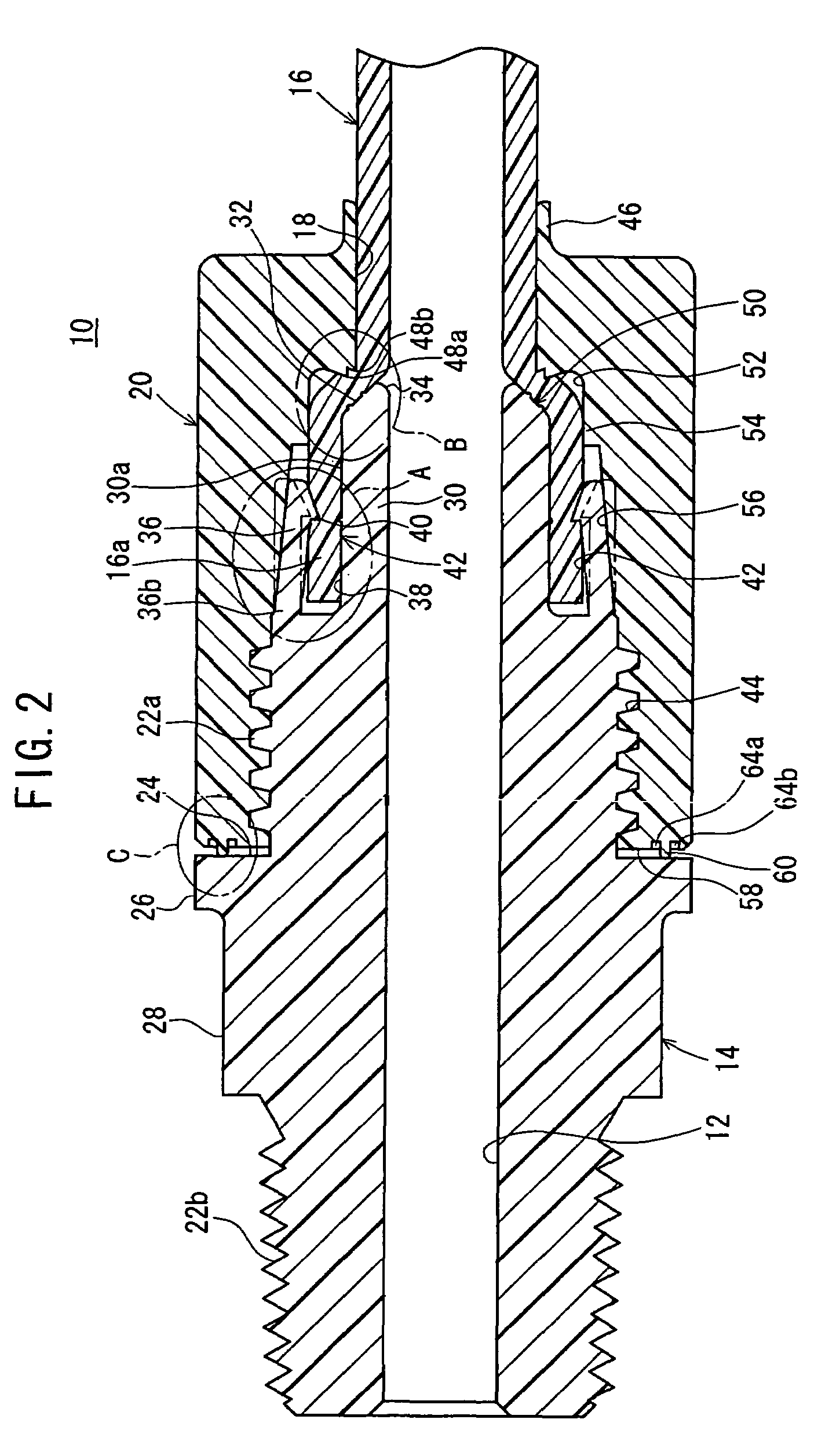

Tube joint

ActiveUS7240925B2Reliably prevent a tube member from being disengaged from a joint bodyAppropriate amountSleeve/socket jointsJoints with sealing surfacesColletEngineering

A tube joint comprises a nut member which connects a tube to a joint body, collet sections which fasten the tube by fastening pawls for being pressed radially inwardly by a pressing section of the nut member to bite into an outer circumferential surface of a diametrally expanded section of the tube, and an annular projection which abuts against an annular step of the joint body and which regulates a screwing amount of the nut member on the joint body.

Owner:SMC CORP

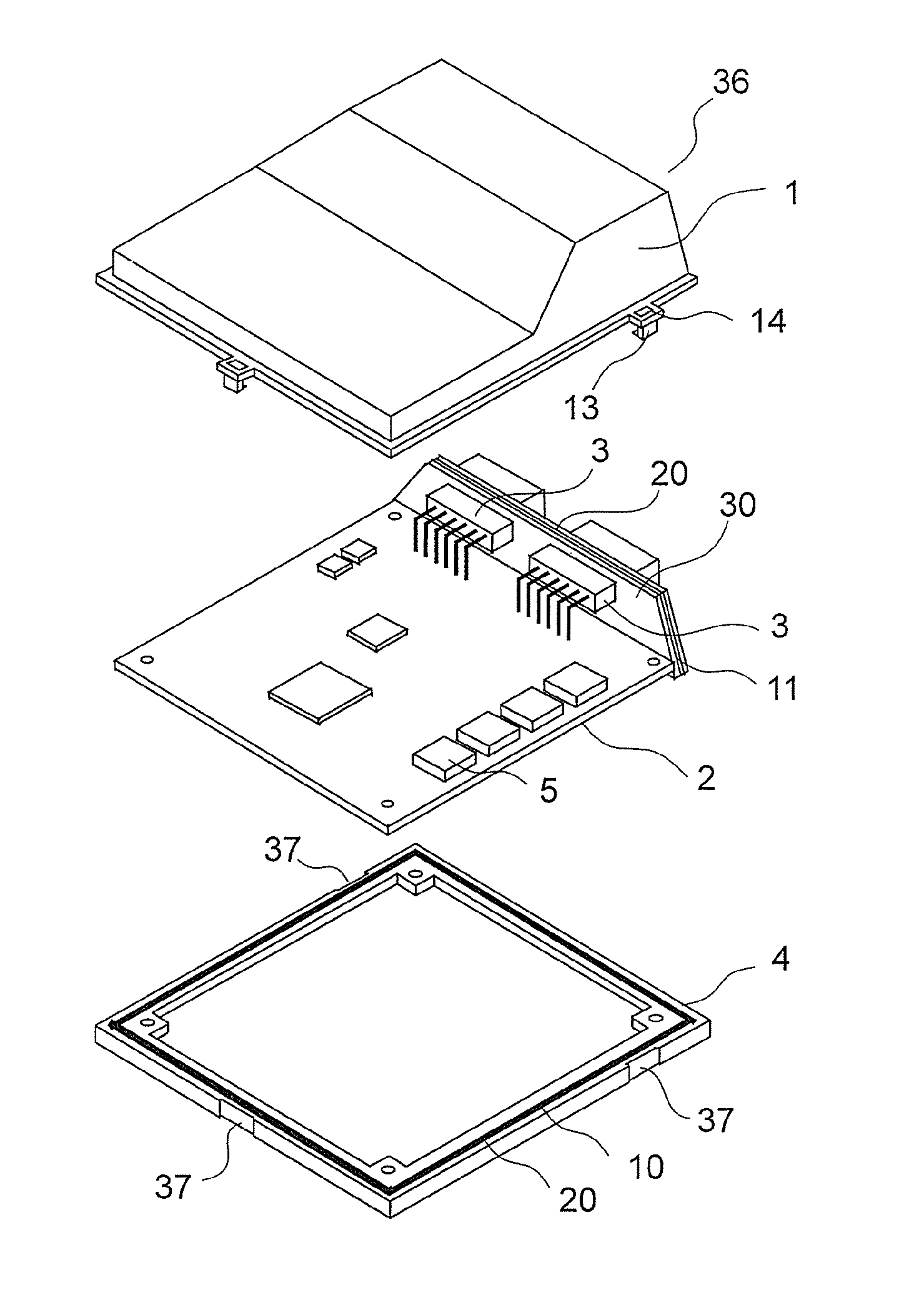

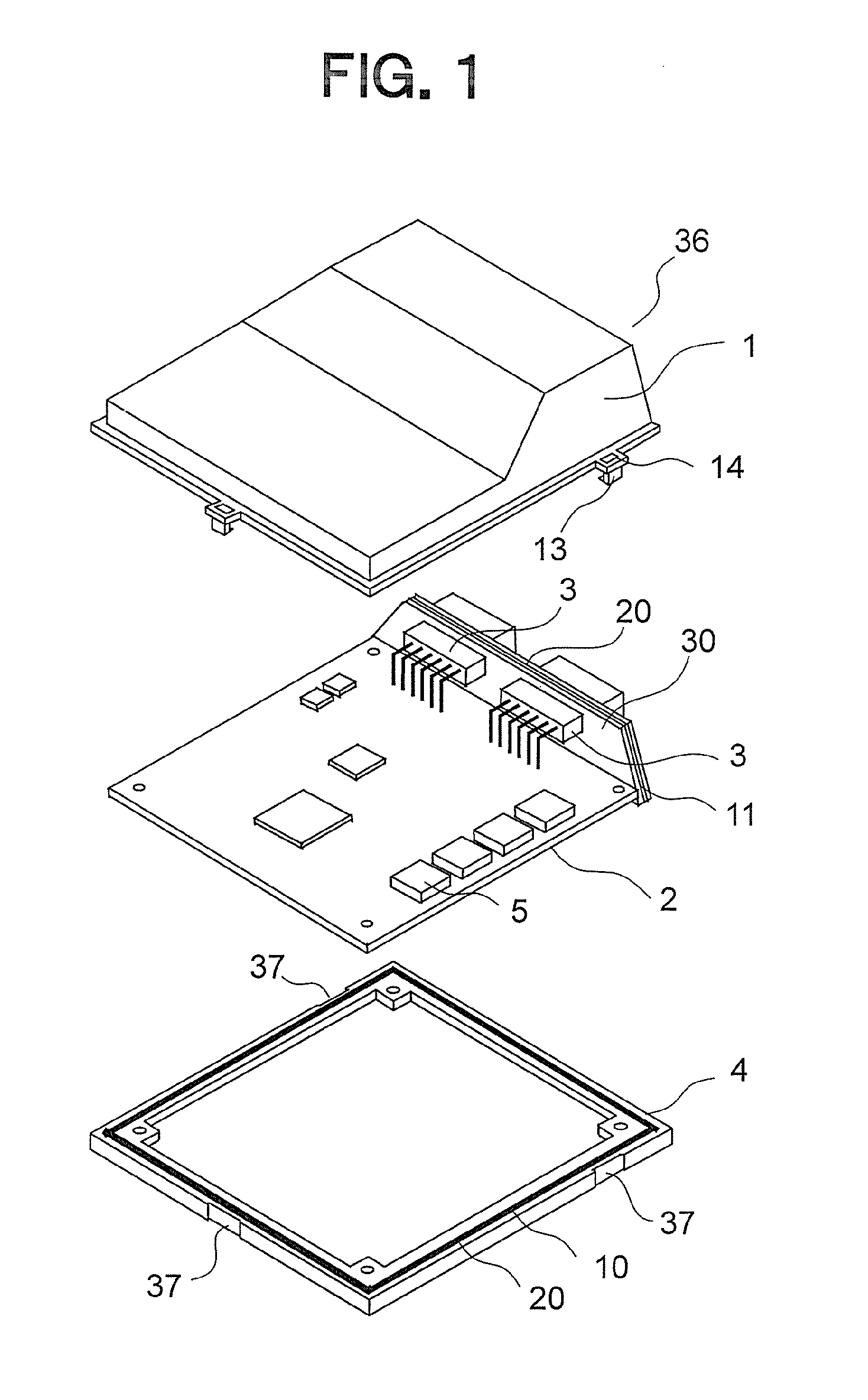

Electronic controller

ActiveUS20130120943A1High possibility of air leakageReject ratio can be reducedSolid-state devicesSupport structure mountingElectronic circuitEngineering

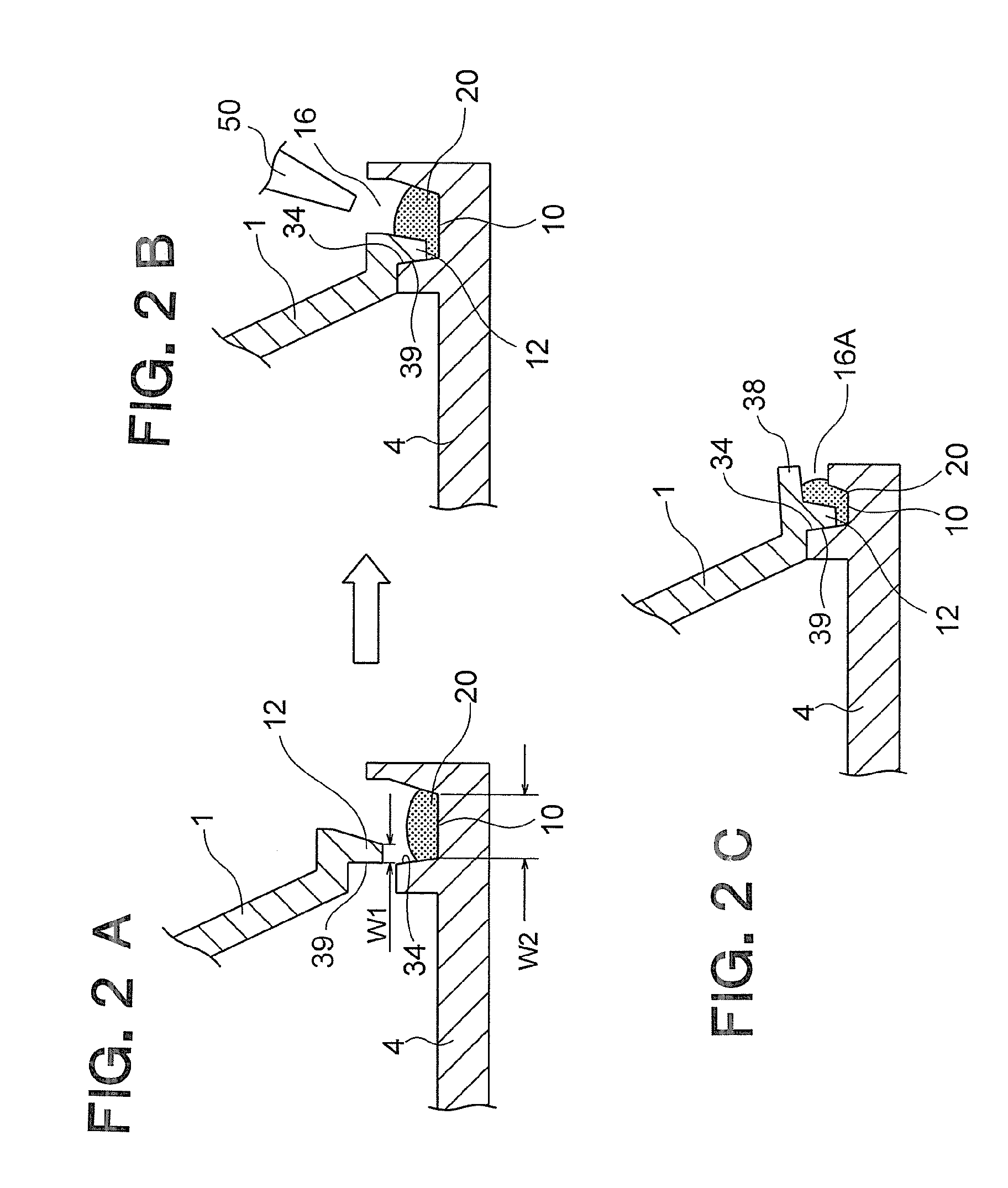

Provided is an electronic controller which enables visual identification of a portion applied with a small amount of a sealing material, which has a high possibility of air leakage from an area in which a joint is to be established. The electronic controller includes: an electronic circuit board; and a casing including a cover (1), a base (4), and a lid sealed with a sealing material (20) applied to surfaces thereof at which the cover (1), the base (4), and the lid are to be joined together. An area in which the cover (1), the base (4), and the lid are to be joined together is provided with a space (16) thereto for enabling an application state of the sealing material (20) to be observed with a naked eye.

Owner:MITSUBISHI ELECTRIC CORP

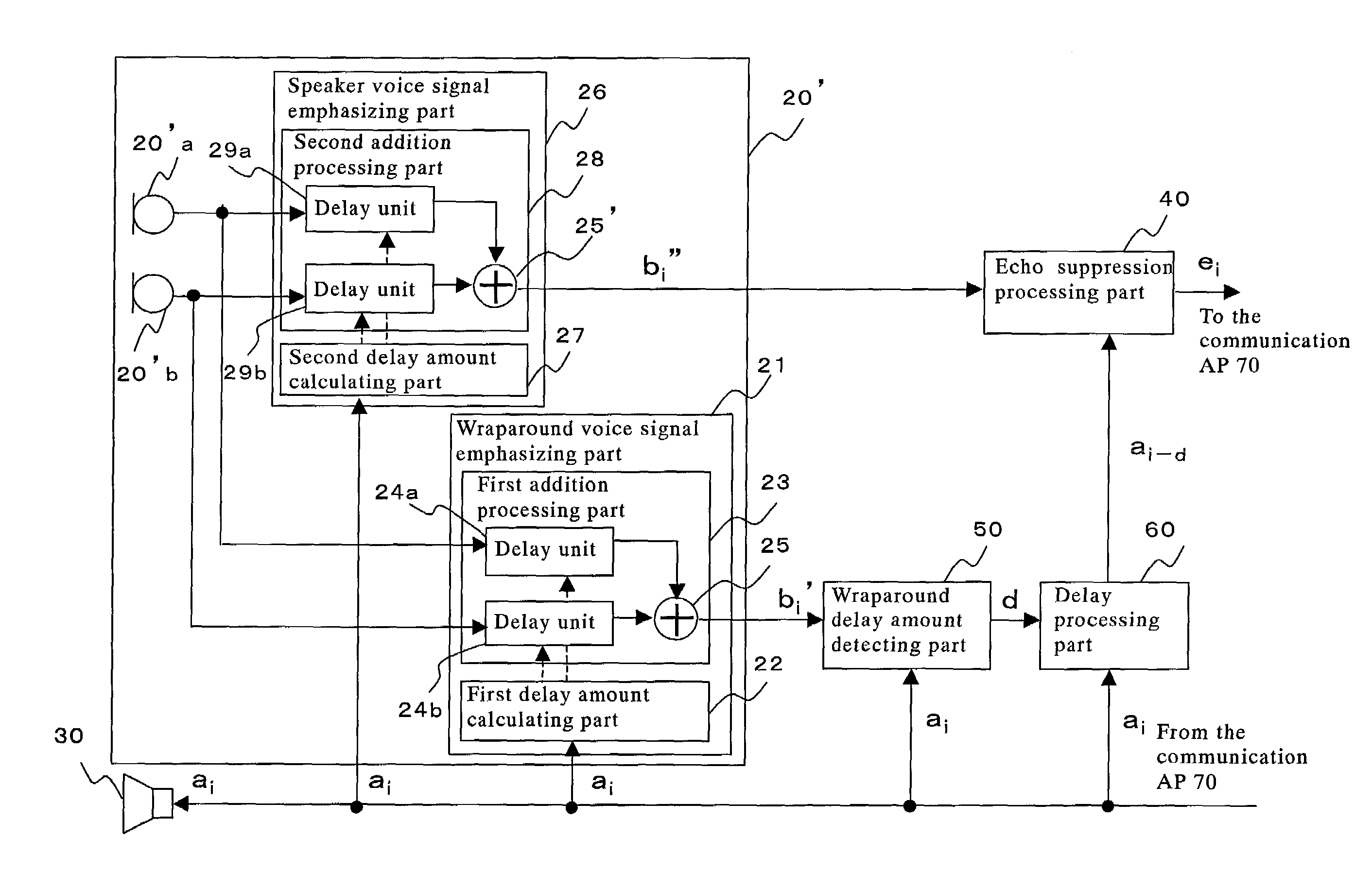

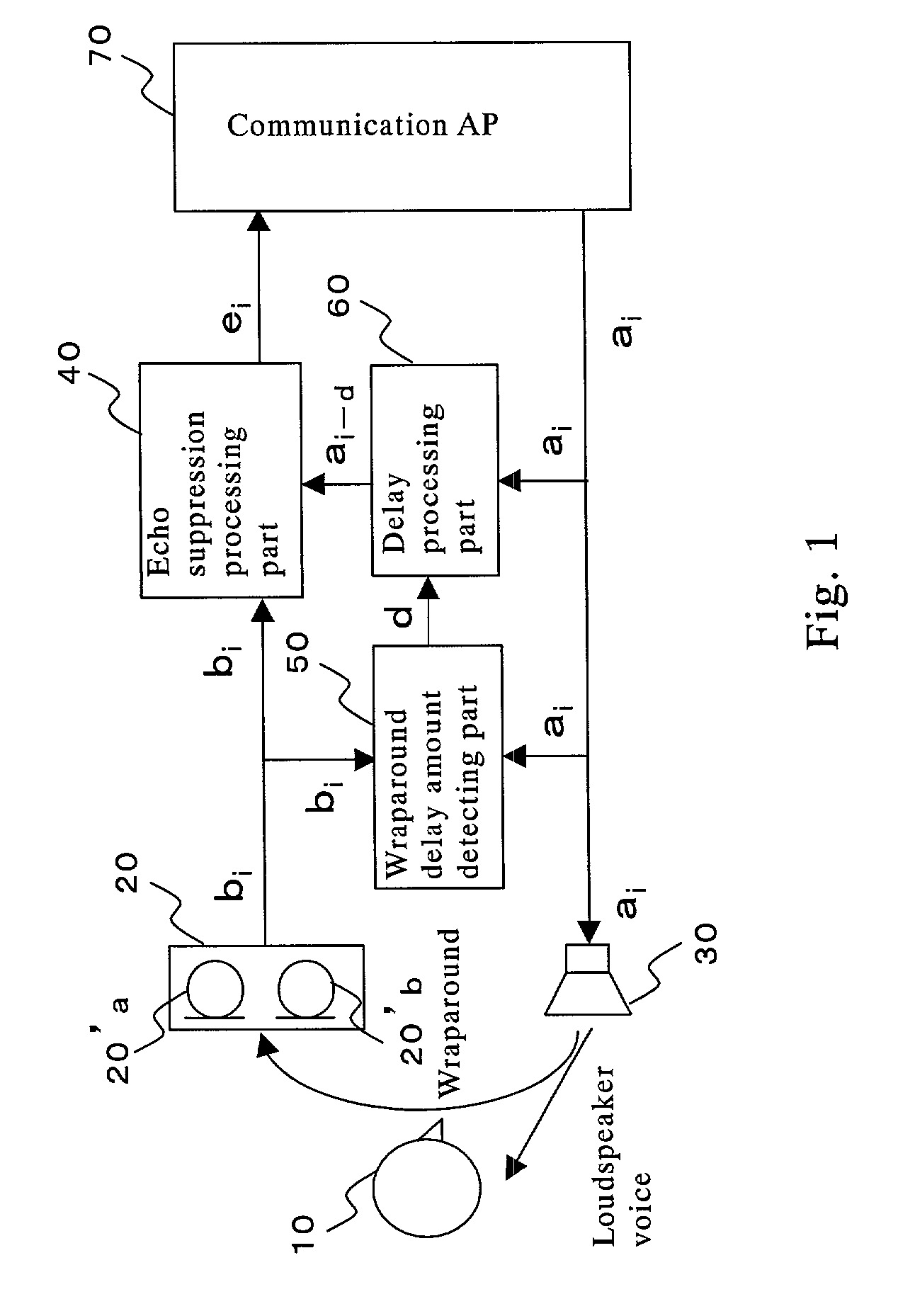

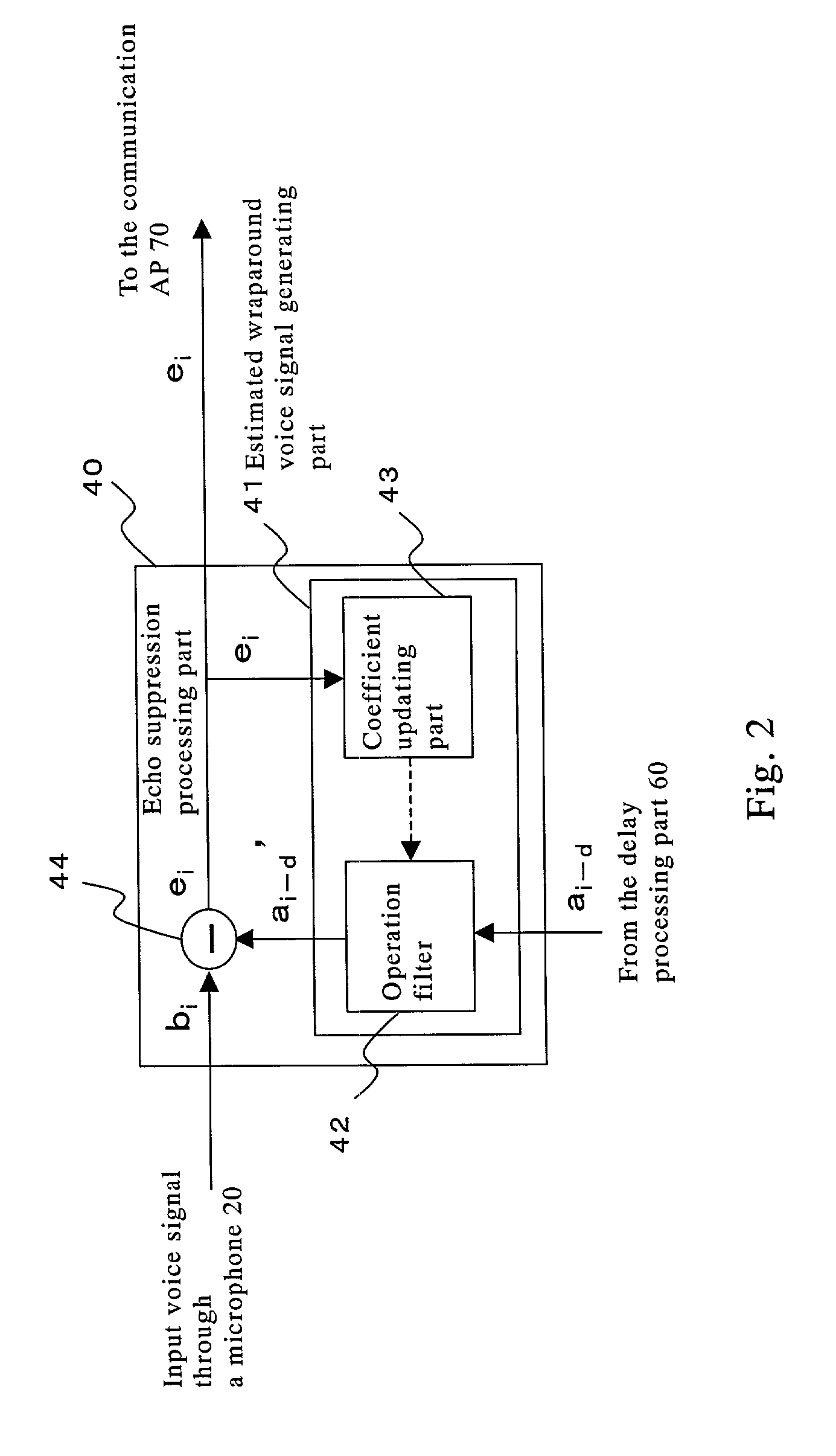

Echo cancellation processing system

InactiveUS7035398B2Improve accuracyHigh maintenance performanceTwo-way loud-speaking telephone systemsSubstation speech amplifiersAdaptive filterHandling system

A wraparound delay amount detecting part calculates a cross-correlation r(k) from an output speech signal “ai” supplied to a loudspeaker and an input speech sigal “bi” inputted through a microphone array to obtain a delay amount “d” of a wraparound speech signal. The delay processing part generates a speech signal “ai-d” obtained by delaying the output speech signal “ai” by the delay amount “d”. Even if there is a change in delay amount due to the variation in environment, appropriate delay processing can be conducted by the delay processing part. In an adaptive filter, an estimated wraparound speech signal ai-d′ is generate from the speech signal “ai-d” subject to delay processing. A subtracter subtracts the estimated wraparound speech signal ai-d′ from the input speech signal “bi” to generate an echo cancellation signal “ei”. A coefficient updating part updates the coefficient of the adaptive filter.

Owner:FUJITSU LTD

Transmission power control method and device

ActiveUS7324828B2Solve the power is smallAppropriate amountEnergy efficient ICTPower managementMultiplexingEngineering

Disclosed is a method and an apparatus for controlling transmission electric power capable of minimizing a decrease in the amount of maximum transmission electric power without degrading an adjacent channel leakage power ratio when code-multiplexing additional control information with data and main control information. A mobile device checks values of gain factors βd and βc when performing code multiplexing to transmit signals from channels DPDCH to transmit data, DPCCH to transmit main control information, and HS-DPCCH to transmit additional control information. A maximum transmission electric power is decreased at a plurality of levels based on the check result and a ratio (Δhs) between the gain factors βc and βhs. It may be preferable to check the presence or absence of transmission data instead of the gain factor βd. In this case, when no transmission data is available, the maximum transmission electric power is decreased at a plurality of levels based on Δhs. When transmission data is available, the maximum transmission electric power is decreased at a plurality of levels based on the gain factor βc and Δhs.

Owner:SONY CORP

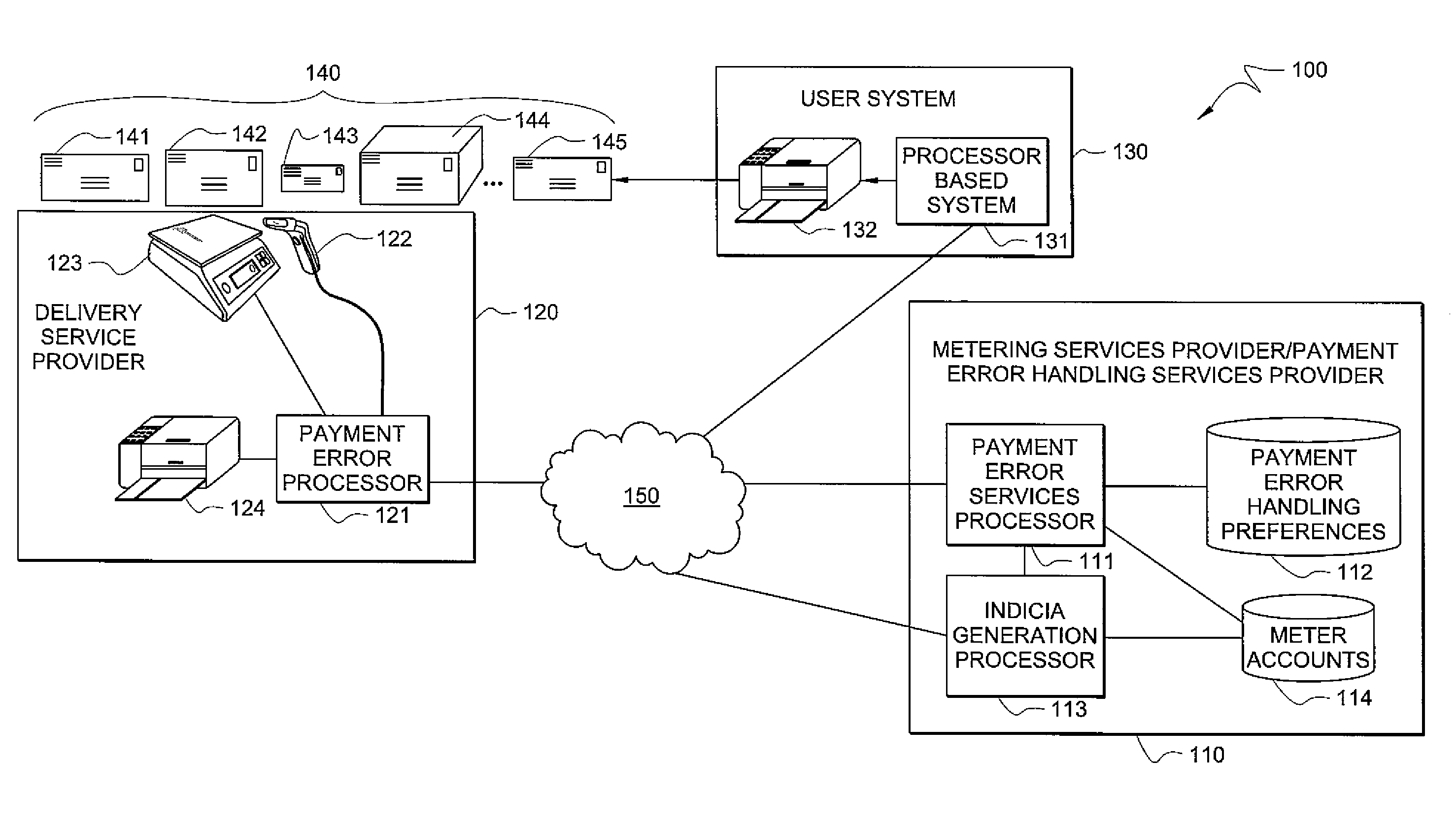

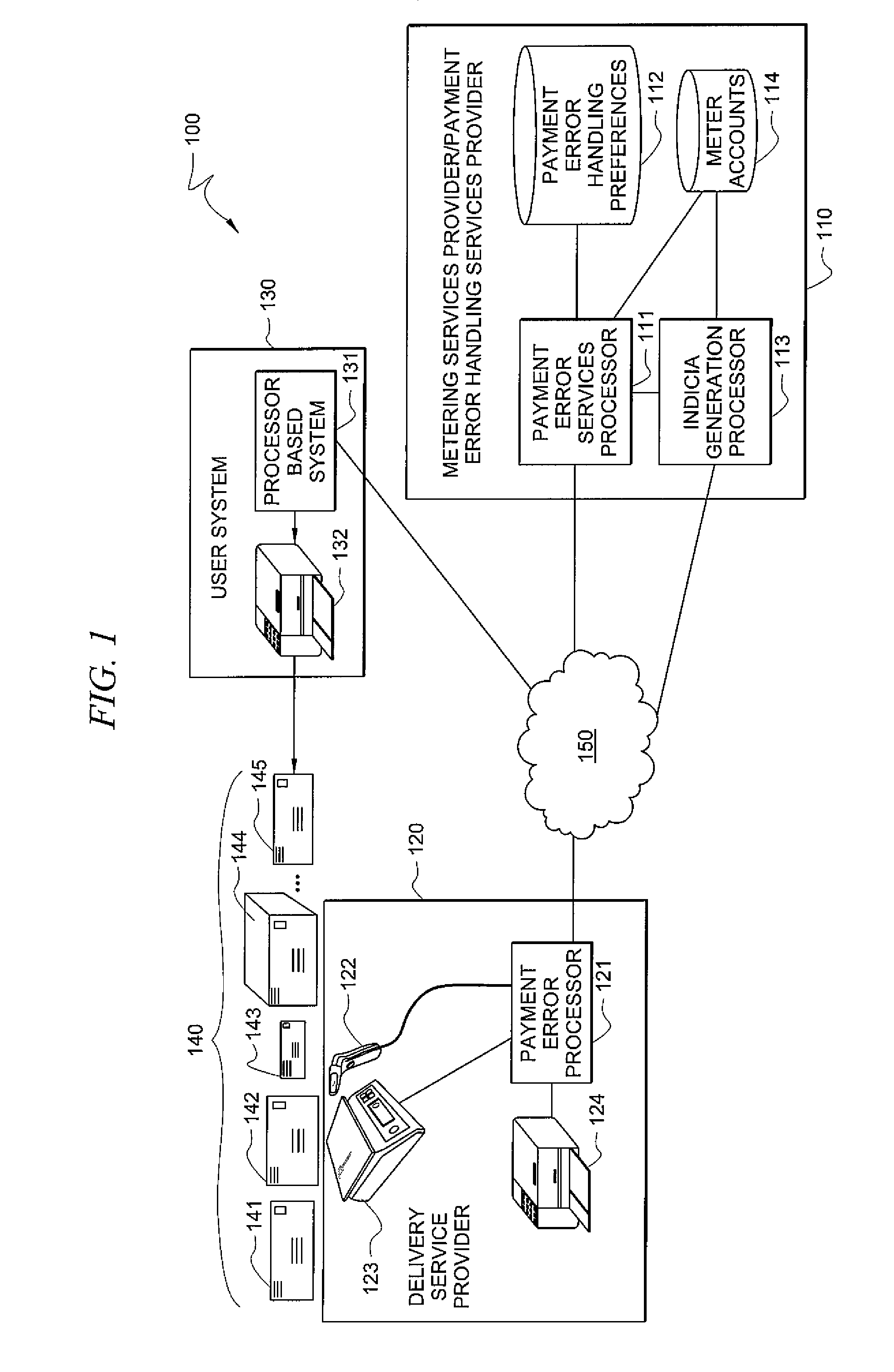

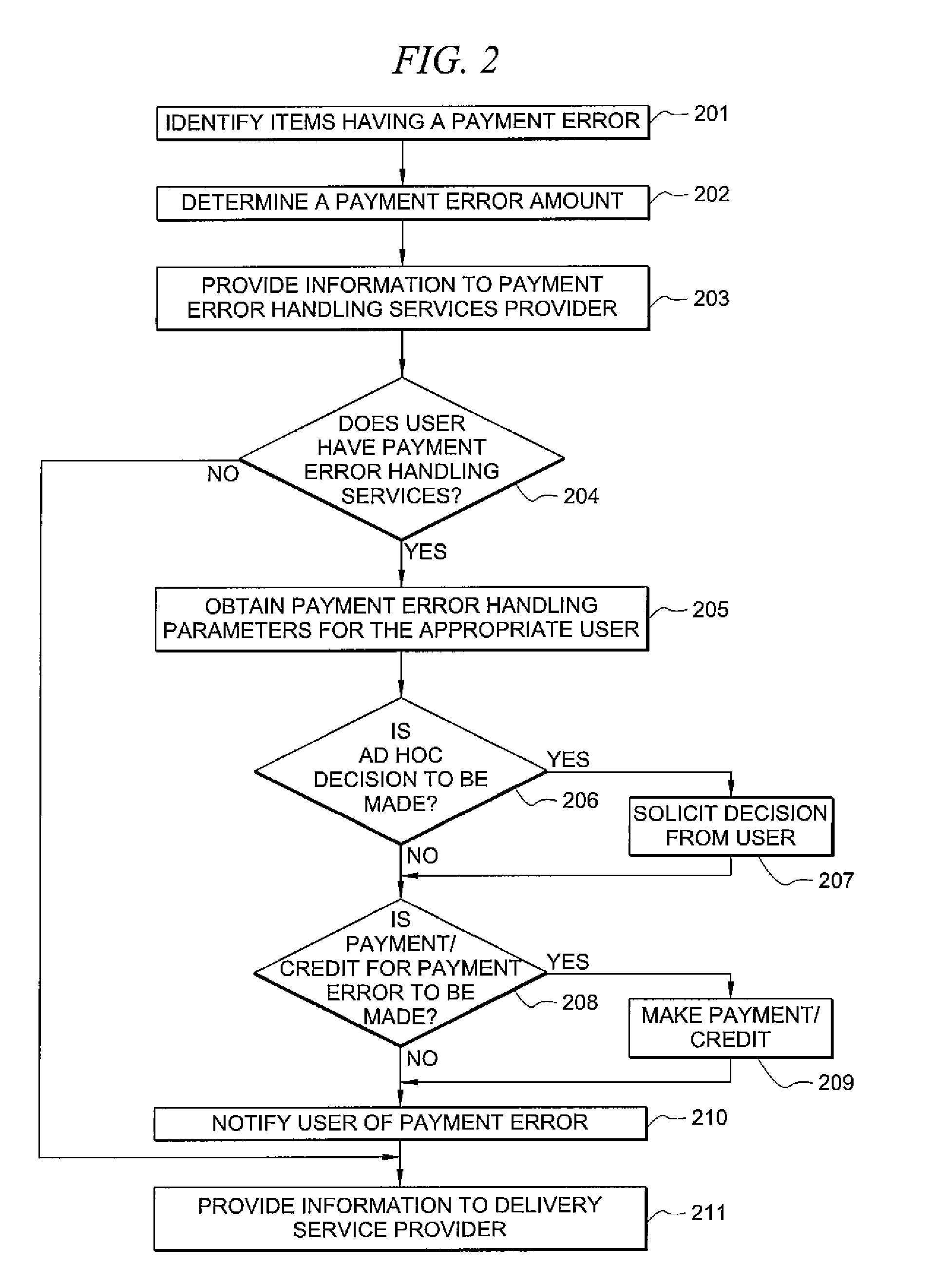

System and method for handling payment errors with respect to delivery services

ActiveUS8612361B1Facilitate subsequent processingDelay in delivery of the itemPayment architectureFranking apparatusPaymentService user

Systems and methods which provide processing of payment errors with respect to delivery services in accordance with user preferences are disclosed herein. According to embodiments, a delivery service user provides information with respect to how payment errors with respect to delivery services provided to the user are to be handled to facilitate electronic and / or automated processing of such payment errors. A user may authorize payment shortages on the user's behalf, may request notification for an ad hoc determination as to how the shortage is to be handled, or may elect to have postal items returned in the case of payment shortage. Various levels of payment error handling services may be provided with respect to users. Detailed information, such as statistics with respect to users' payment errors, the numbers and types of payment errors, user's preferences in handling payment errors, etcetera, may be provided.

Owner:AUCTANE INC

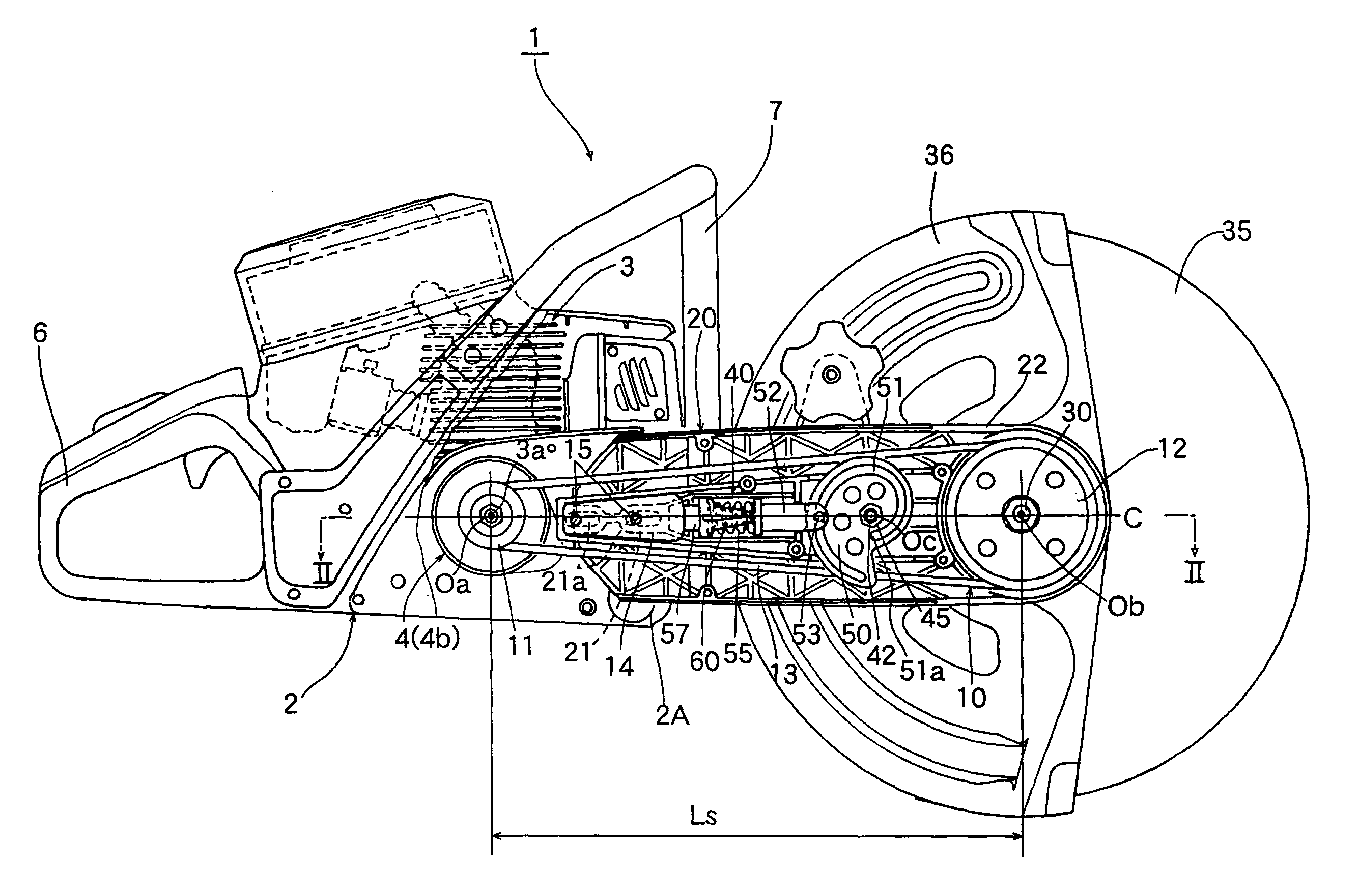

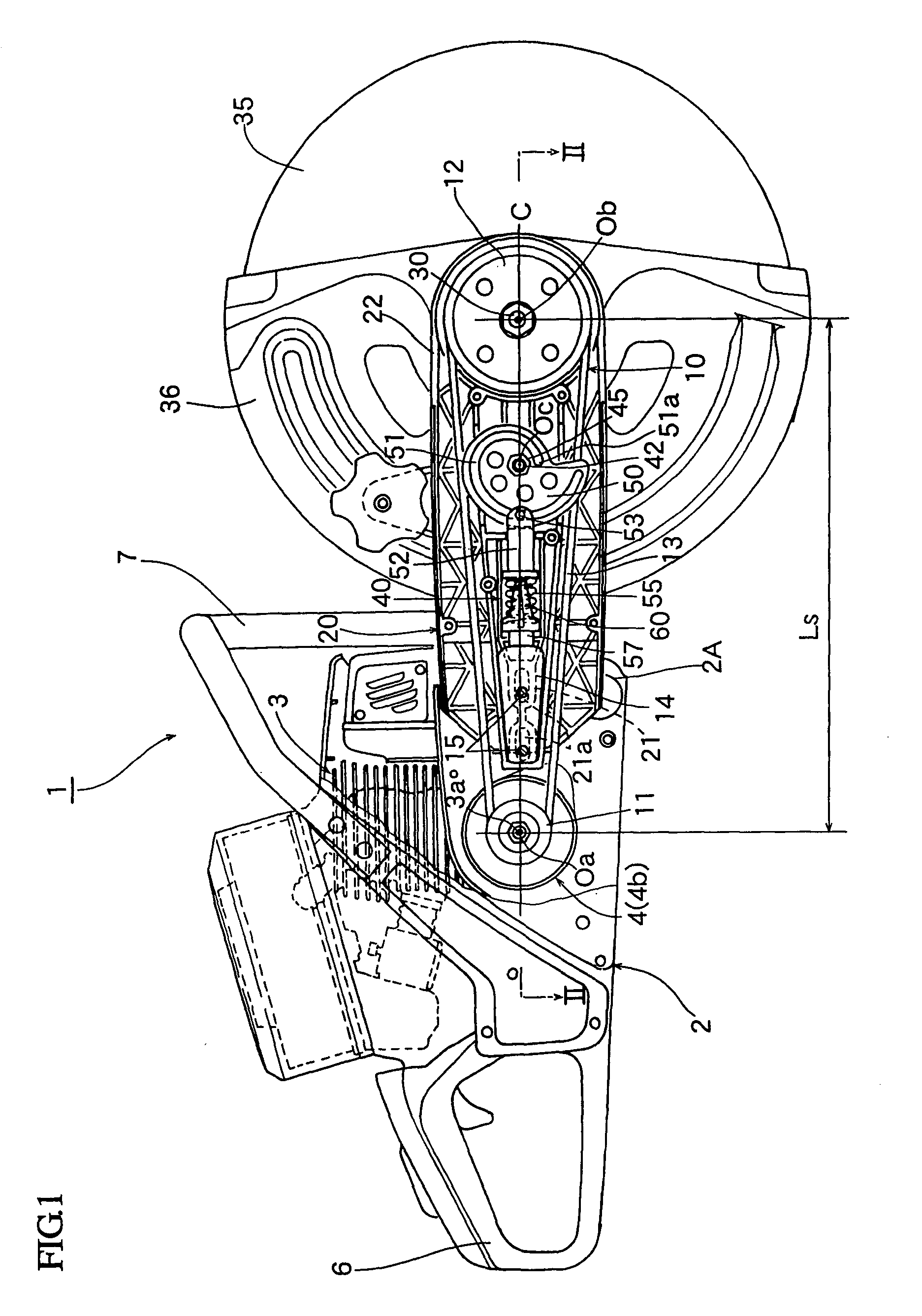

Power transmission device and portable power working machine provided with the same

InactiveUS7101295B2Simple structureEasily and swiftly and appropriately alteringMetal sawing devicesGearingRotational axisPortable power

A power transmission device is disclosed which is capable of easily, swiftly and appropriately altering the distance between the axes of a pair of transmission wheels such as pulleys, enabling an endless belt to be kept under constant and appropriate tension without necessitating a tension roller. This power transmission device comprises an endless belt wound around a pair of transmission wheels; and a cam-type adjusting mechanism which is interposed between a driving side supporting member and a driven side supporting member and configured to adjust a distance between the axes of the wheels. This cam-type adjusting mechanism comprises a supporting shaft secured to either the driving side supporting member or the driven side supporting member and disposed parallel to the rotational axes of the wheels; and a cam rotatably secured via a manipulating boss member to the supporting shaft.

Owner:KIORITZ

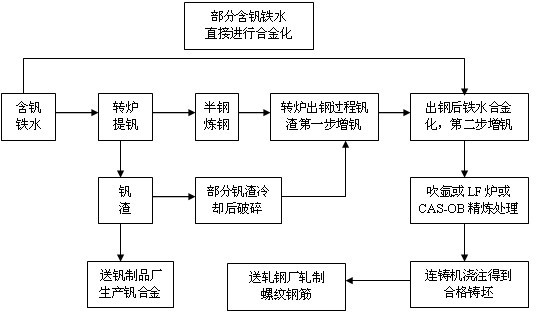

Smelting technology of III grade hot-rolled ribbed bars

InactiveCN102304604AHigh strengthMeet the seismic requirementsManufacturing convertersSlagShock resistance

The invention relates to a smelting technology of III grade hot-rolled ribbed bars. The invention belongs to the technical field of steel smelting. The technical scheme of the invention is that: vanadium-containing molten iron is adopted as a raw material; a vanadium increasing process in a bar production procedure is divided into two steps that: first, during a steel producing procedure, vanadium slag extracted from the vanadium-containing molten iron is added, and vanadium elements are reduced and added into molten steel, such that first-step vanadium increasing is carried out; second, when steel is discharged from a converter, vanadium-containing molten iron is directly poured into the ladle, such that second-step vanadium increasing is carried out. During the process, the vanadium elements in the vanadium-containing molten iron are directly converted into the vanadium elements in the vanadium-containing molten steel. The vanadium alloyed raw materials (the vanadium slag and the vanadium-containing molten iron) are internal materials sourced from a steel refinery. With the composite vanadium increasing method, a problem of high cost in the production process of the III grade hot-rolled ribbed bars is solved. The produced ribbed bars satisfy both the performance requirement and the shock resistance requirement. With the method, direct and highly efficient utilization of rare resources is realized, the technology process is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:HEBEI IRON AND STEEL

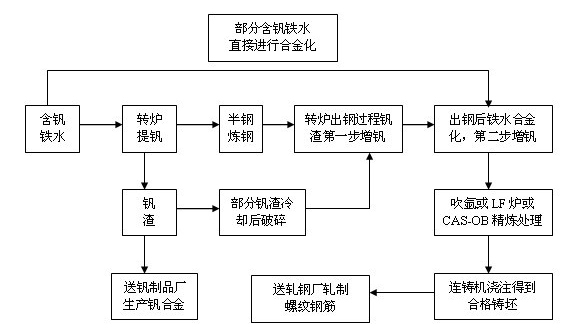

Method and apparatus for resistance variable material cells

InactiveUS7030405B2Increase chanceFast switching speedSolid-state devicesSemiconductor/solid-state device manufacturingSulfurChalcogenide glass

The present invention is related to methods and apparatus to produce a memory cell or resistance variable material with improved data retention characteristics and higher switching speeds. In a memory cell according to an embodiment of the present invention, silver selenide and a chalcogenide glass, such as germanium selenide (GexSe(1−x)) are combined in an active layer, which supports the formation of conductive pathways in the presence of an electric potential applied between electrodes. Advantageously, embodiments of the present invention can be fabricated with relatively wide ranges for the thicknesses of the silver selenide and glass layers.

Owner:MICRON TECH INC

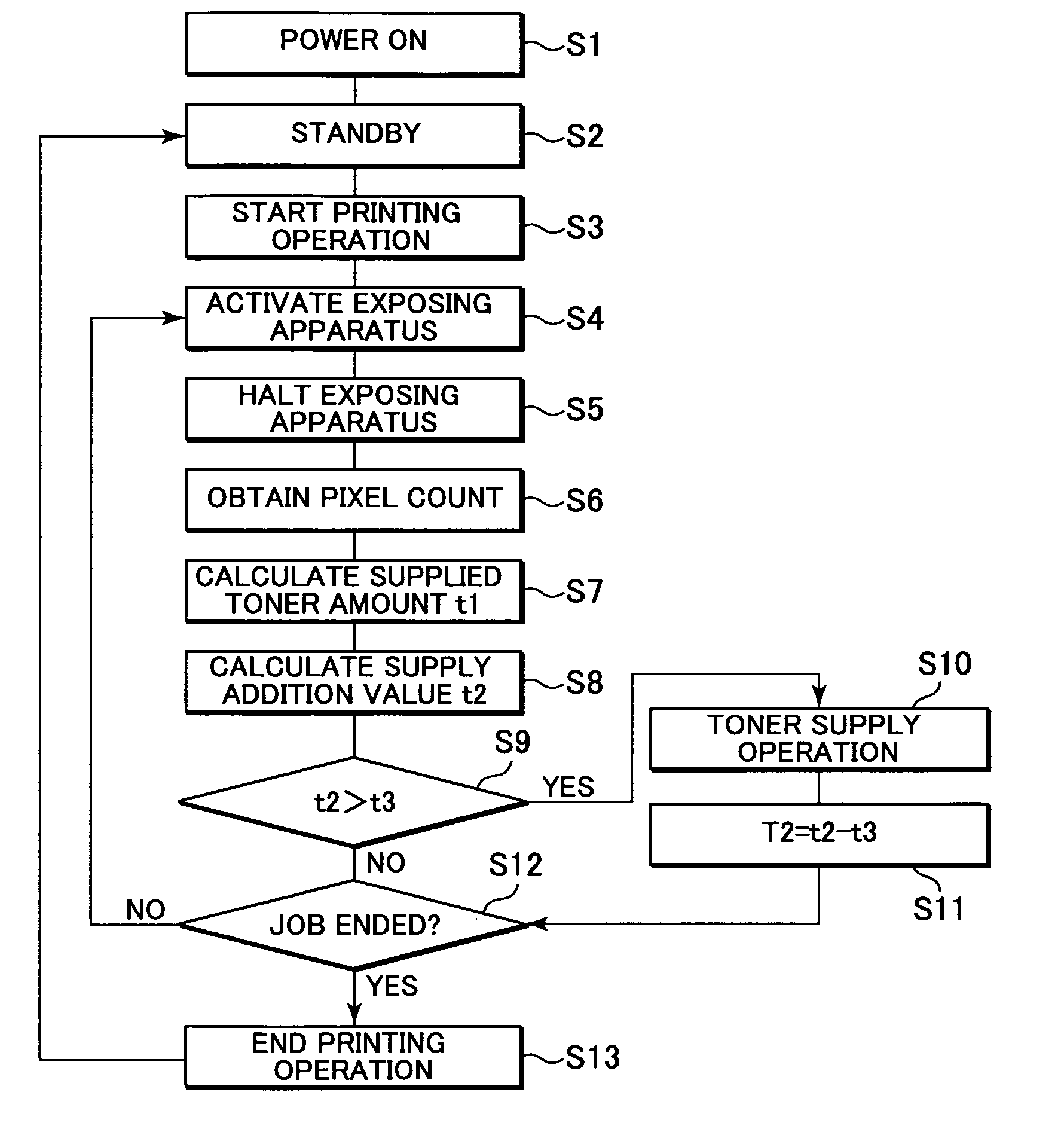

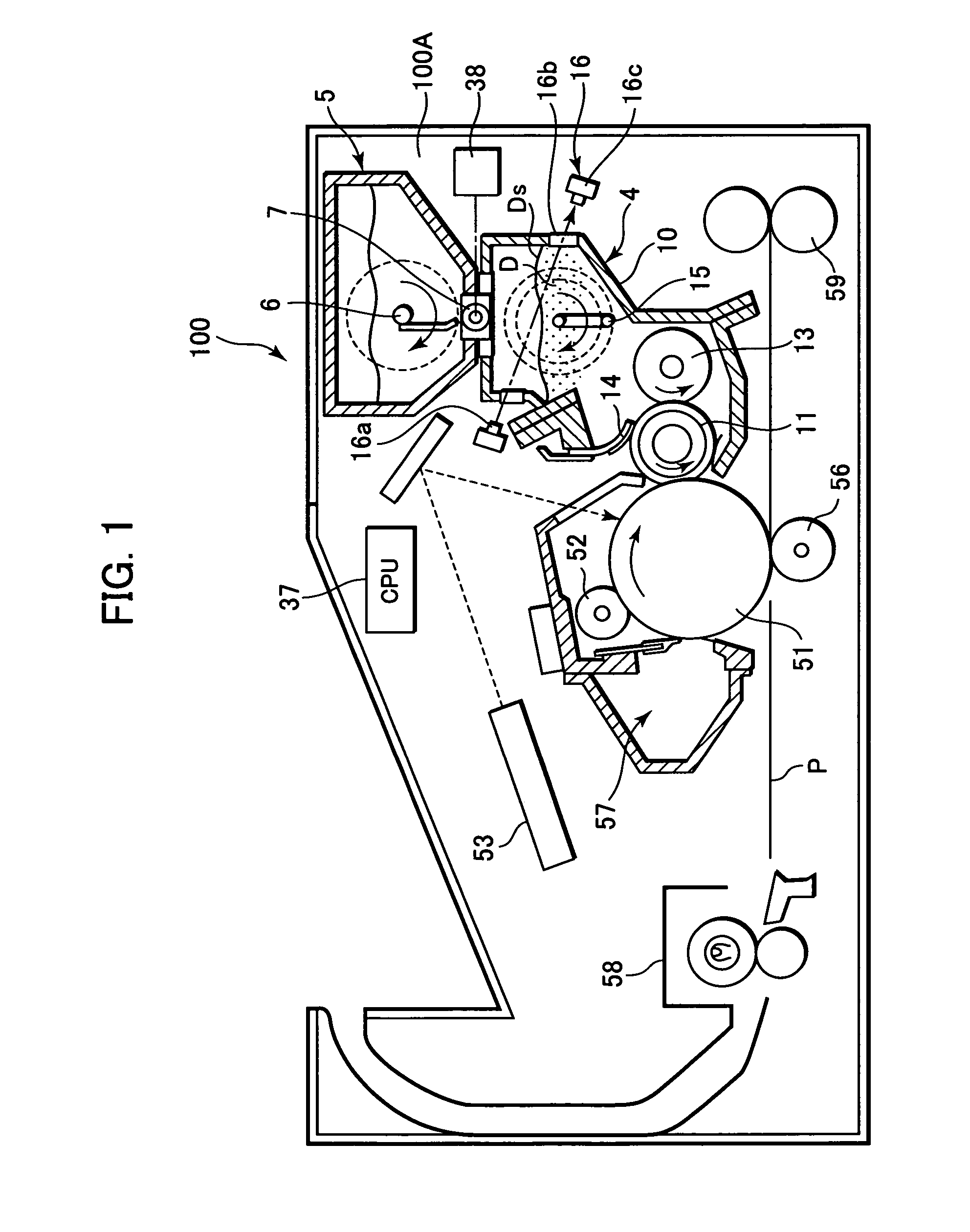

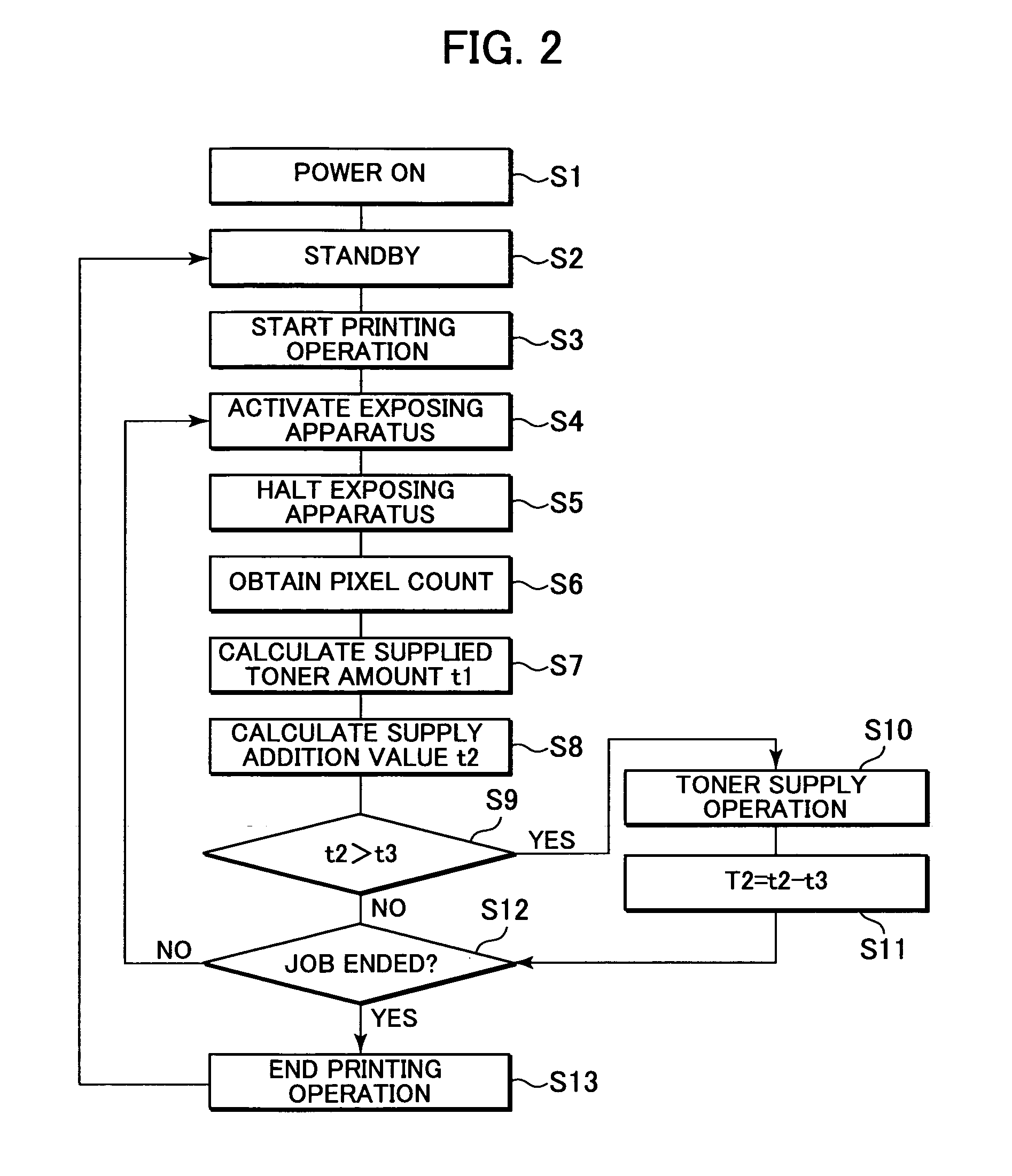

Image forming apparatus, cartridge, storage device and developer supplying method

ActiveUS20060263106A1Reduce in quantitySatisfactory agitation and chargingElectrographic process apparatusImage formationProcess engineering

An image forming apparatus is provided which includes a developing apparatus configured to form a developer image; a supply apparatus configured to supply developer to the developing apparatus; a detector configured to detect an amount of developer consumed during an image forming process; and a controller configured to perform an addition calculation for the amount of developer consumed, and for employing a value obtained by the addition calculation and a supply threshold value to determine whether developer should be supplied to the developing apparatus, wherein the controller sets the supply threshold value in accordance with an operating state of the developing apparatus.

Owner:CANON KK

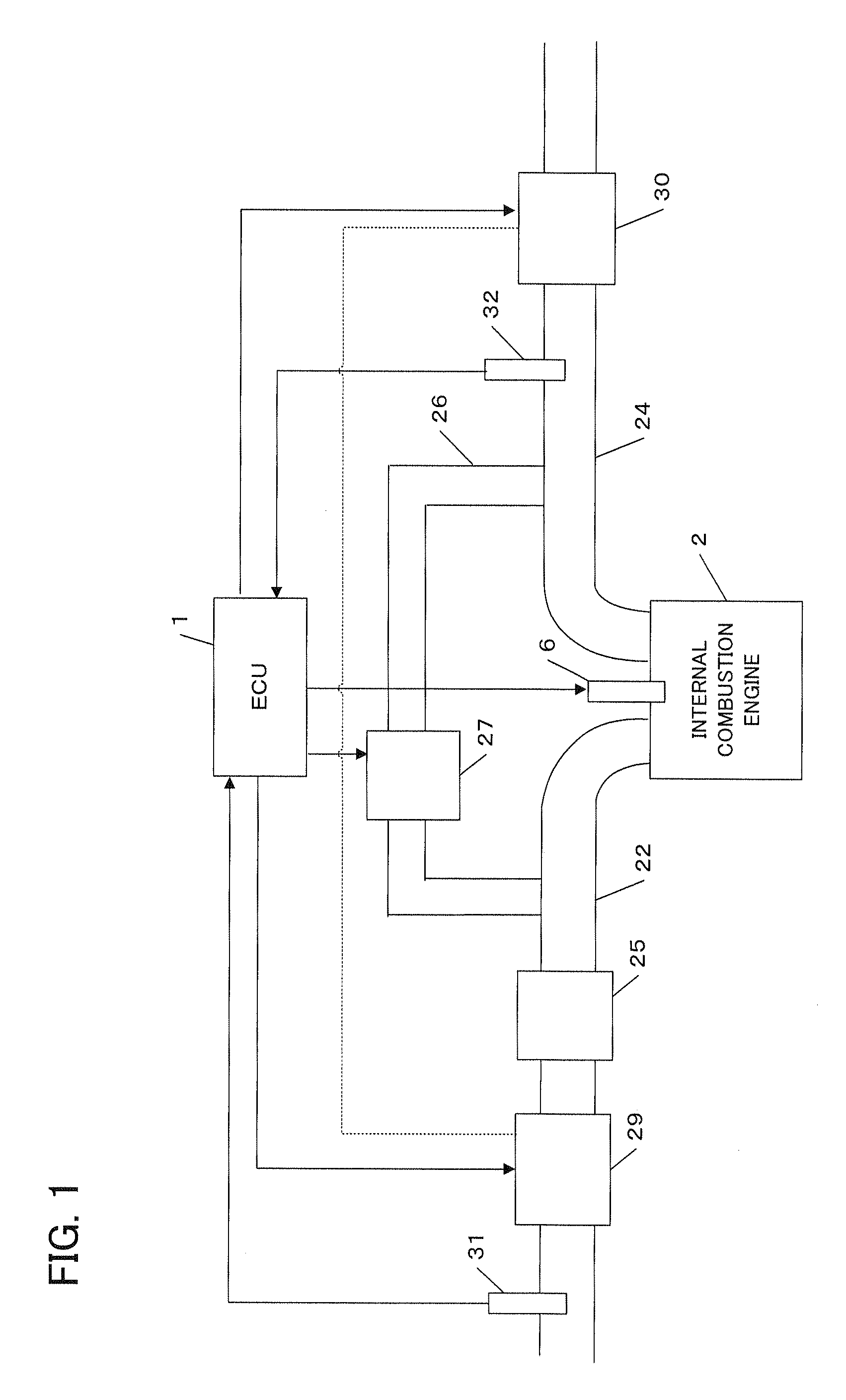

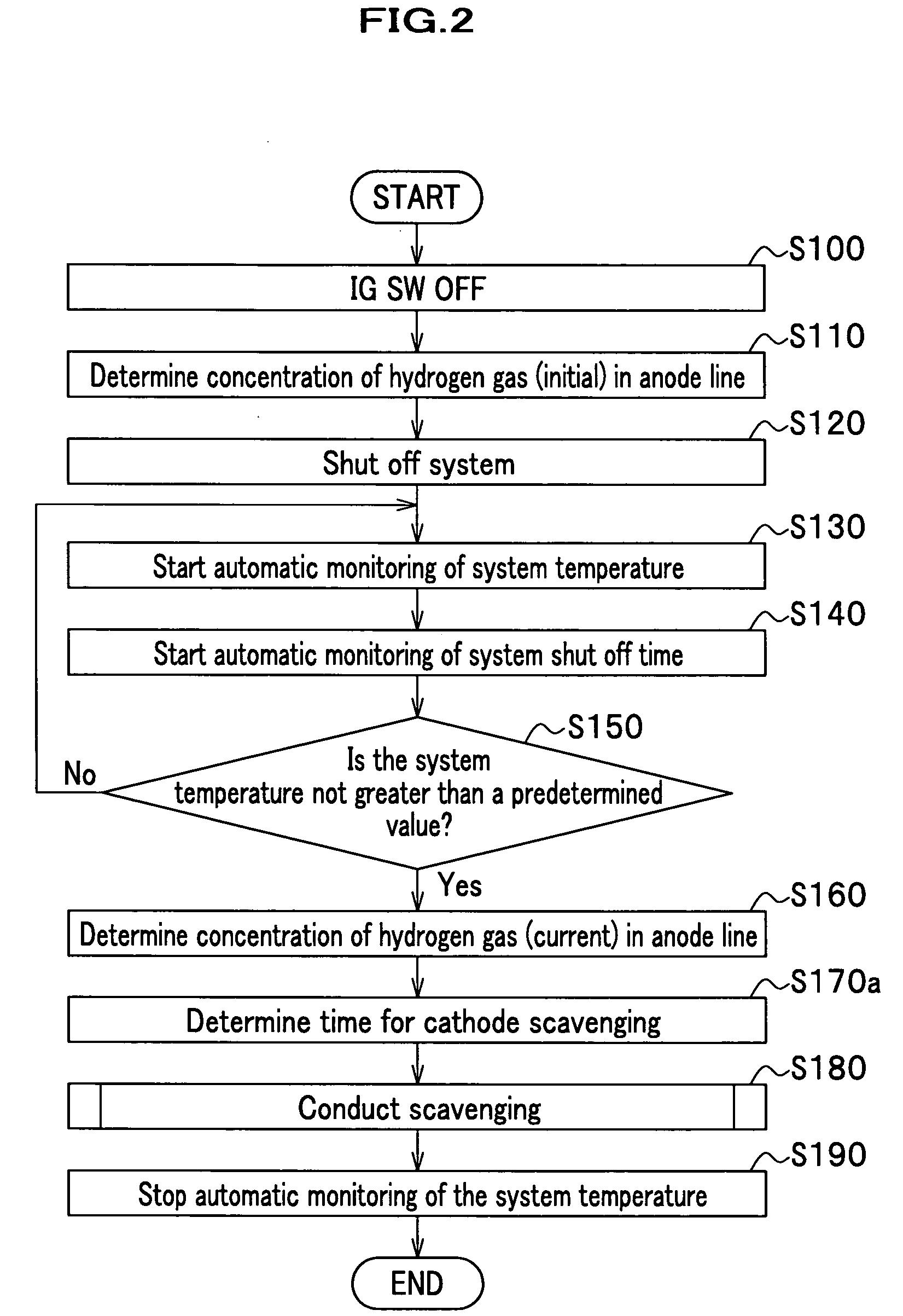

Fuel cell system and method

ActiveUS20070026277A1Reduce power consumptionAppropriate amountFuel cell heat exchangeSolid electrolyte fuel cellsAutomotive engineeringOff time

A fuel cell system and a method for scavenging it are provided. The fuel cell system includes a fuel cell, a fuel gas passage, an oxidant gas passage, a communicating passage, a communicating valve, a monitoring device, a valve controller, a scavenging device and a computing device. The monitoring device monitors a state transition of the fuel cell after a termination of power generation. The valve controller opens the communicating valve when a signal indicative of the state transition meets a predetermined criterion. The scavenging device includes a first scavenging device for the oxidant gas passage, and a second scavenging device for the fuel gas passage. The computing device computes an amount of the oxidant gas required for scavenging according to a system shut off time. The scavenging device conducts scavenging with the amount of the oxidant gas obtained by the computing device.

Owner:HONDA MOTOR CO LTD

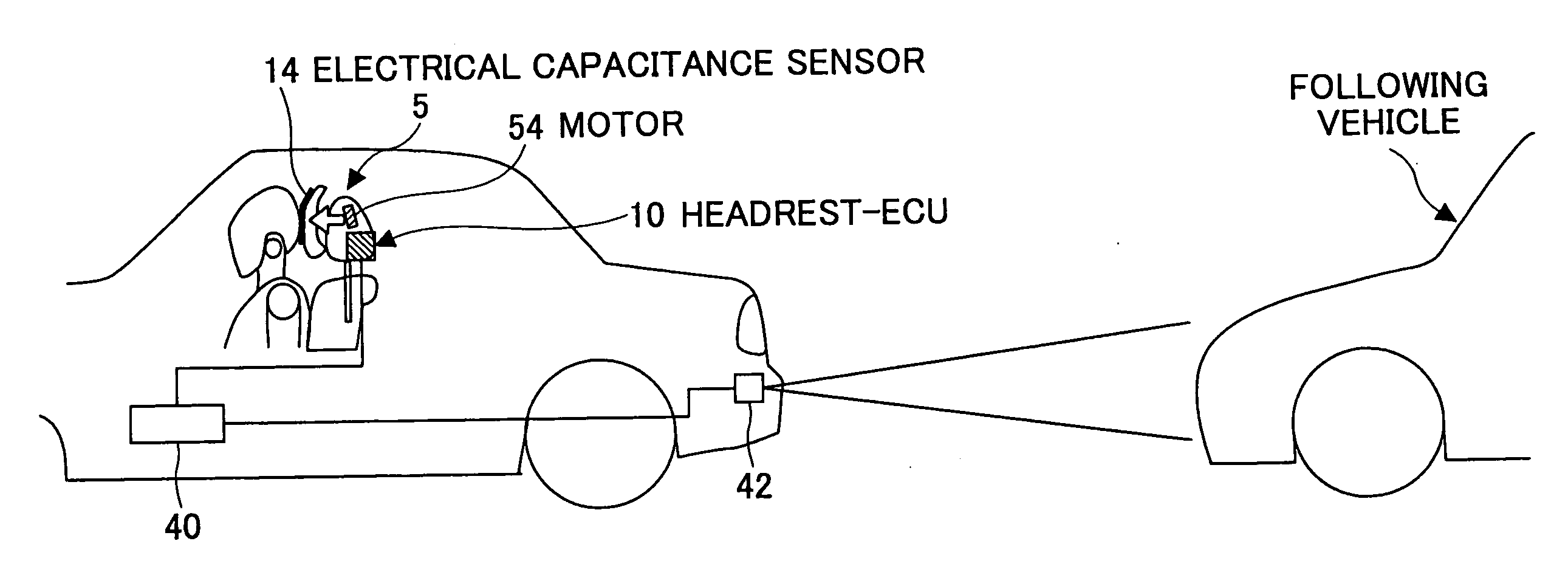

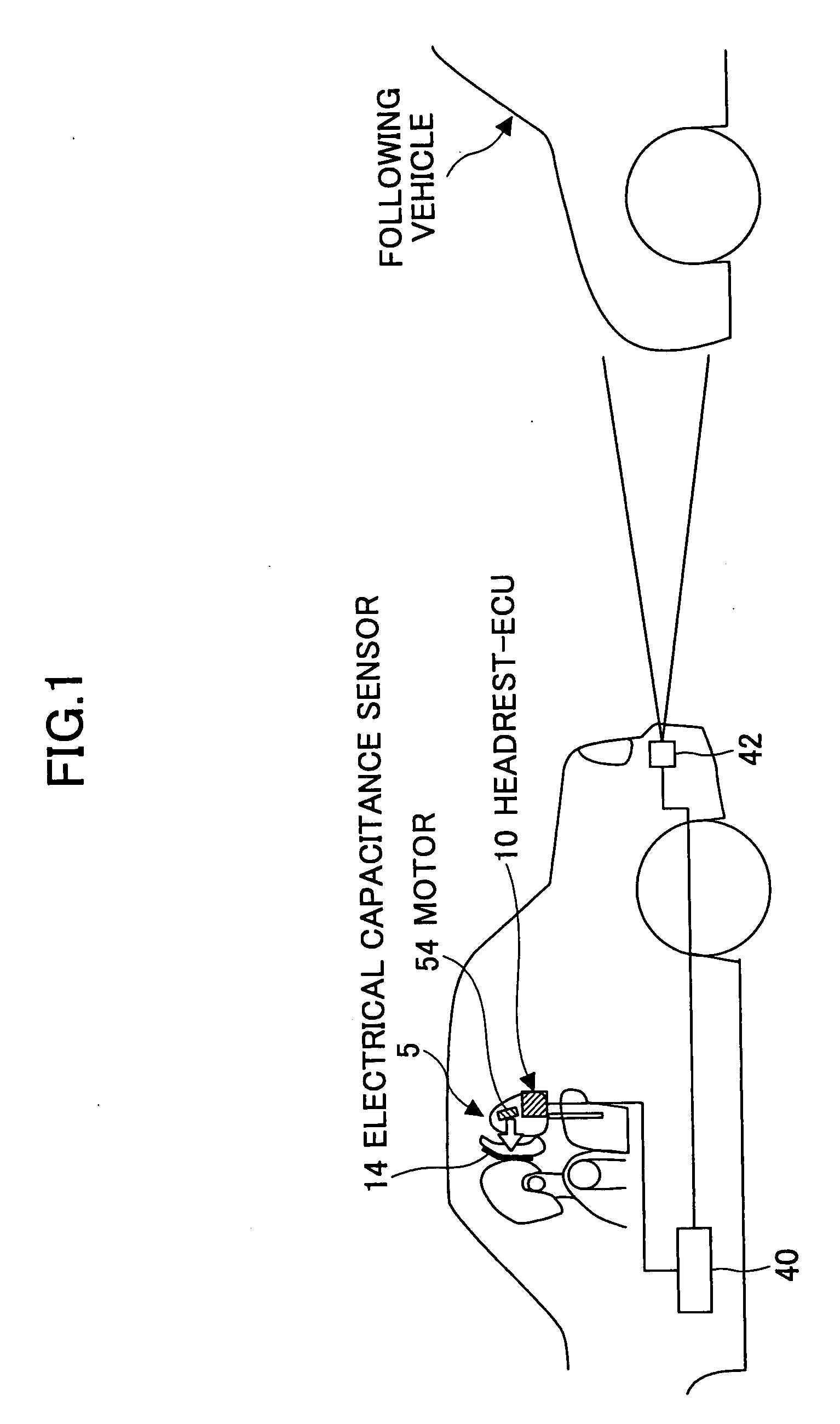

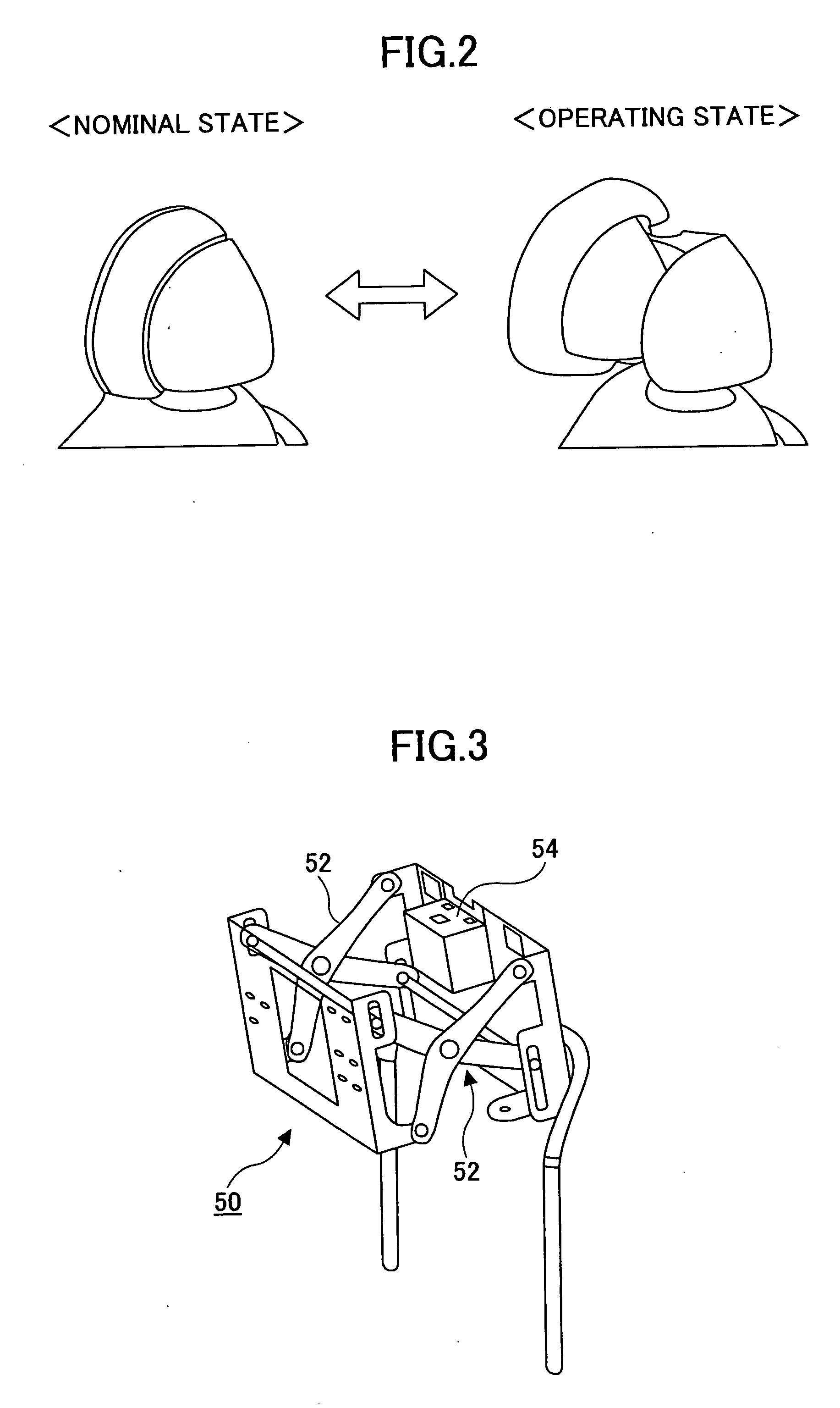

Occupant Protection Device

InactiveUS20080004775A1Appropriate amountVehicle seatsDigital data processing detailsActuatorCapacitance transducer

A vehicle occupant protection device comprising a headrest configured to be movable forward with respect to a vehicle, and an actuator configured to implement the forward movement is disclosed. The device is configured to protect a vehicle occupant by operating the actuator to move the headrest forward in a pre-crash stage in the course of an object crashing into the vehicle from backside of the vehicle. The headrest is provided with an electrical capacitance sensor. The device is configured to control an amount of the forward movement of the headrest according to a variation manner of electrical capacitance, which electrical capacitance is detected by the electrical capacitance sensor when the headrest moves forward.

Owner:TOYOTA JIDOSHA KK

Semiconductor device and method for producing semiconductor device

ActiveUS9276071B2Limited amountIncrease spawn rateSemiconductor/solid-state device manufacturingSemiconductor devicesGeneration rateProton implantation

Hydrogen atoms and crystal defects are introduced into an n− semiconductor substrate by proton implantation. The crystal defects are generated in the n− semiconductor substrate by electron beam irradiation before or after the proton implantation. Then, a heat treatment for generating donors is performed. The amount of crystal defects is appropriately controlled during the heat treatment for generating donors to increase a donor generation rate. In addition, when the heat treatment for generating donors ends, the crystal defects formed by the electron beam irradiation and the proton implantation are recovered and controlled to an appropriate amount of crystal defects. Therefore, for example, it is possible to improve a breakdown voltage and reduce a leakage current.

Owner:FUJI ELECTRIC CO LTD

Force sensor for vehicle brake application

ActiveUS20050103580A1Good indicationLimited amountAxially engaging brakesBraking action transmissionControl powerEngineering

A force sensor is incorporated into a disc brake, and is operable to sense the point of force application increase during application of the disc brake. The force will increase sharply once the brake pad initially contacts the rotor. The sensor is able to determine the point of this force increase, and provide this information to a control. The control powers an electric motor for providing electric motor adjustment of the position of the piston which drives the brake pad, to compensate for wear. In a preferred embodiment, the sensor includes a protective cover with a thin anvil between the cover and the sensor. The anvil is operable to transmit the force, and limit the force applied, to protect the sensor.

Owner:ARVINMERITOR TECH

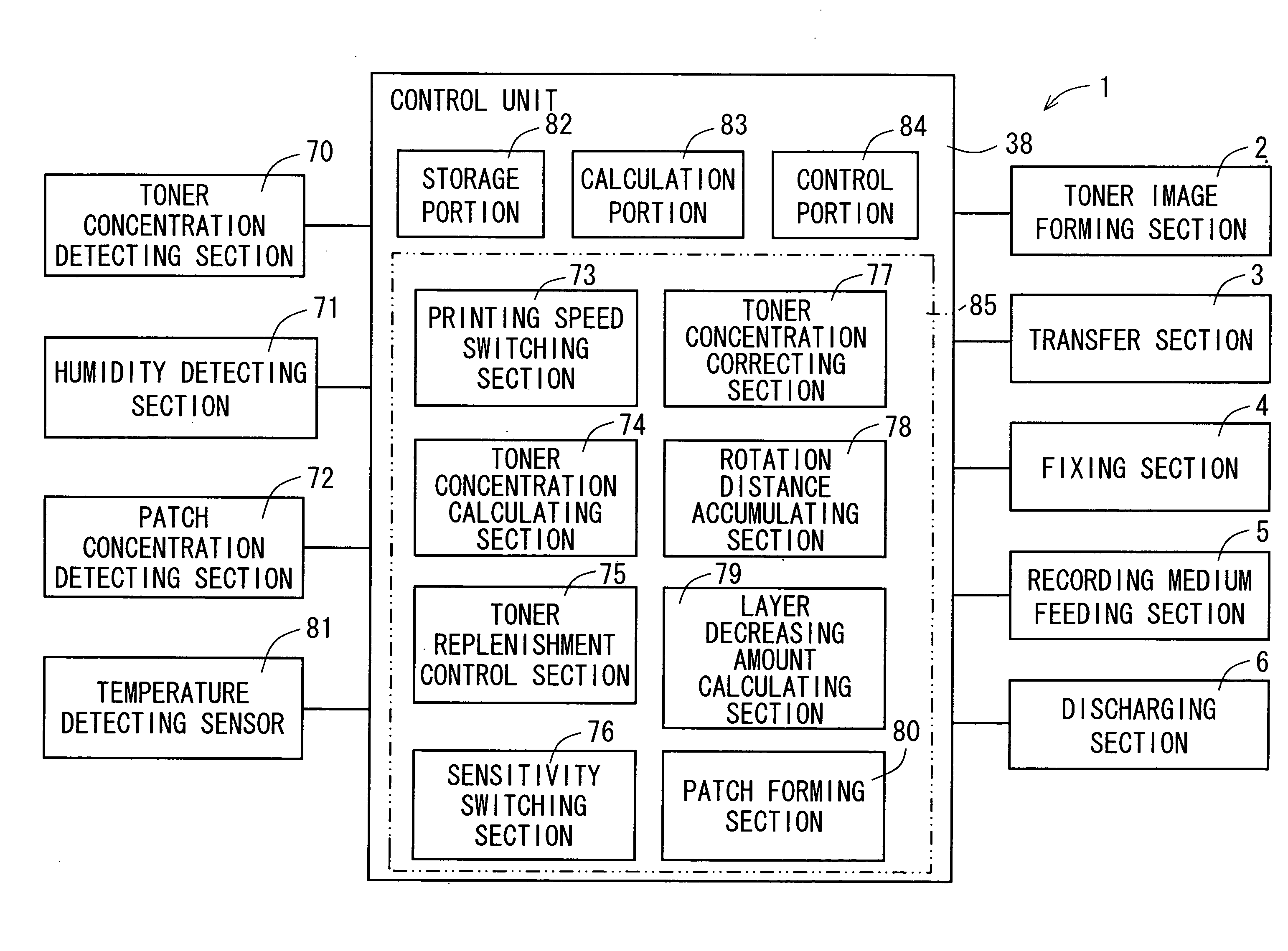

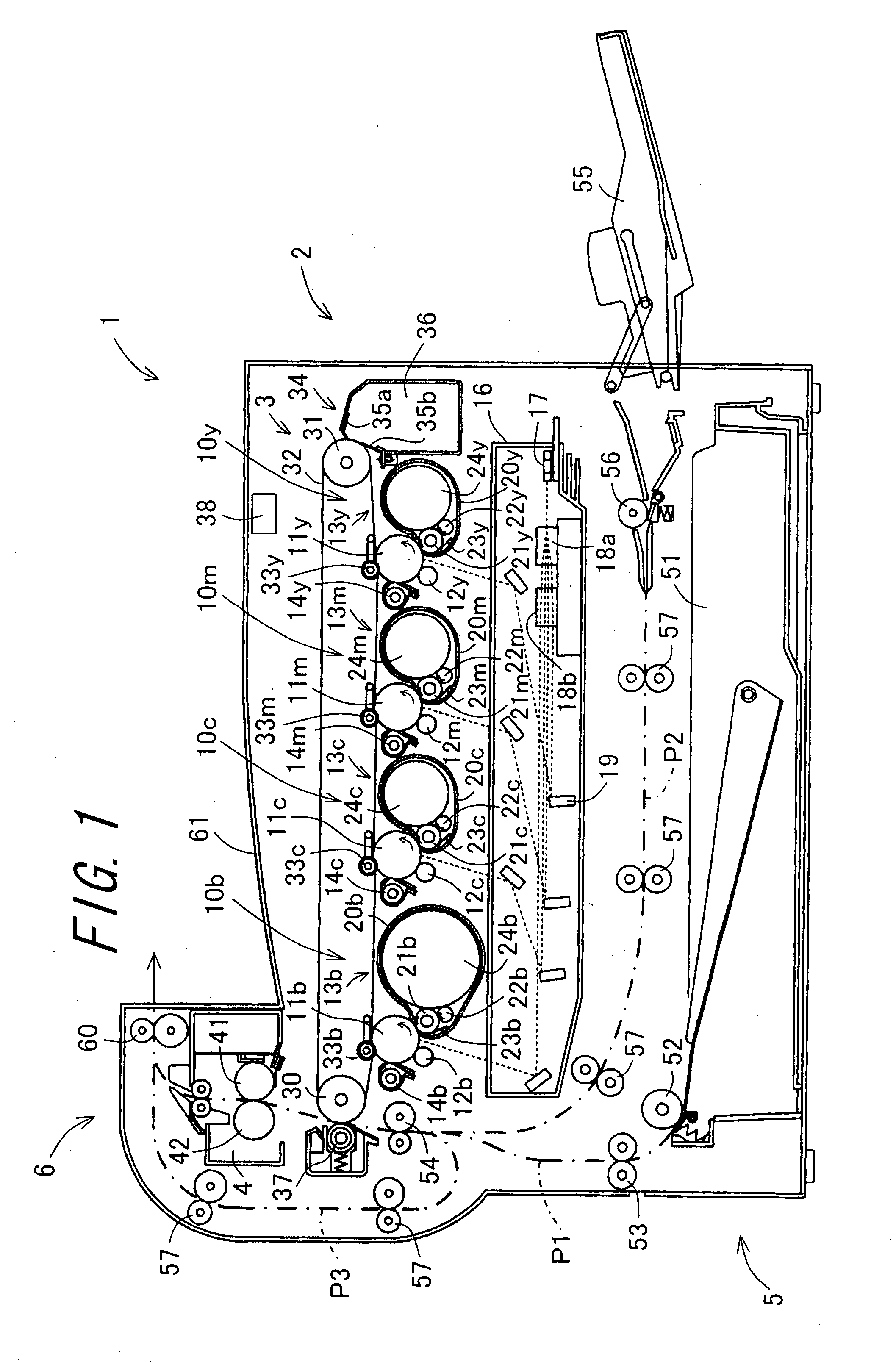

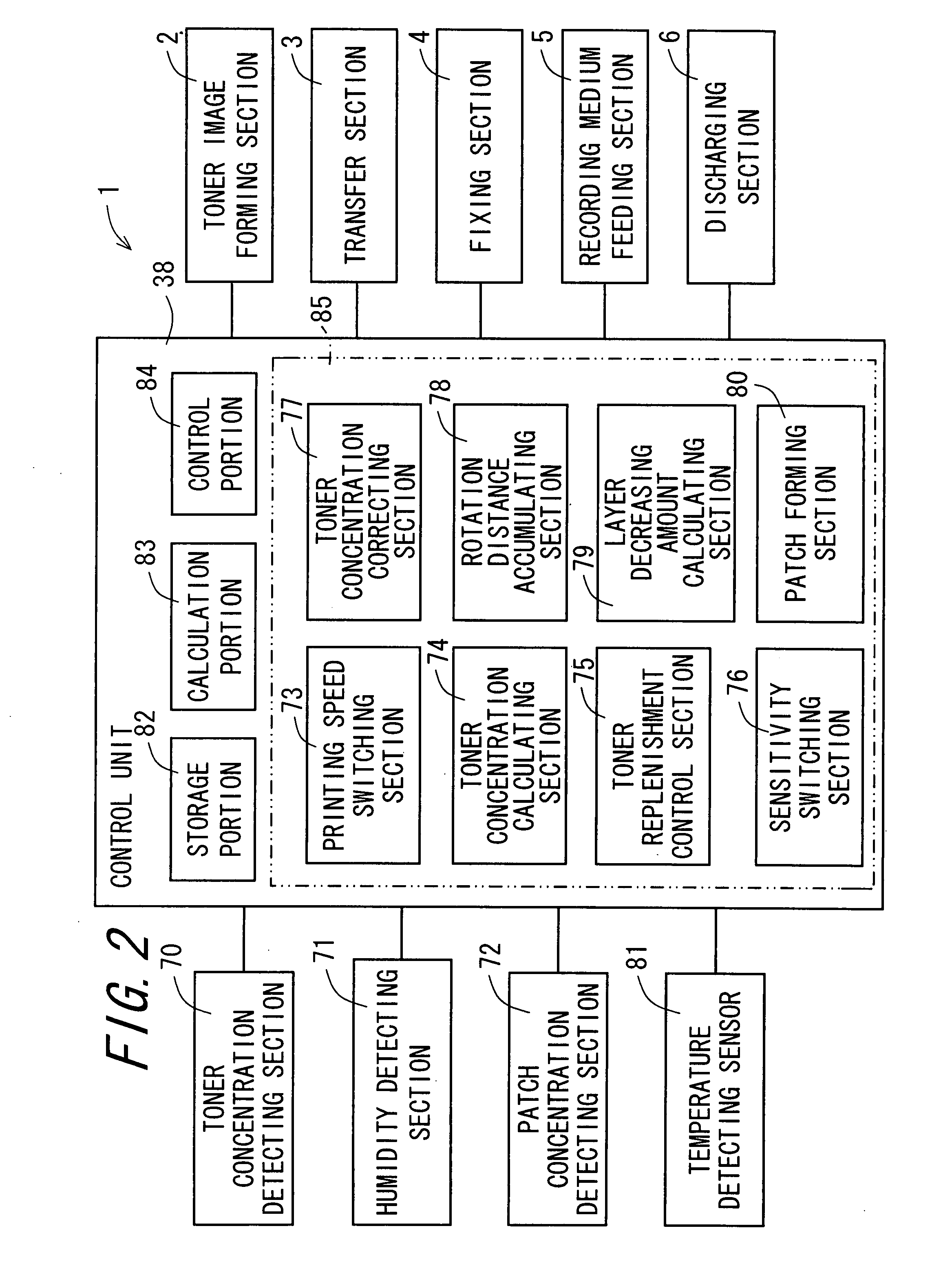

Image forming apparatus

InactiveUS20080124108A1Accurate operationAccurate valueElectrographic process apparatusImage formationEngineering

Owner:SHARP KK

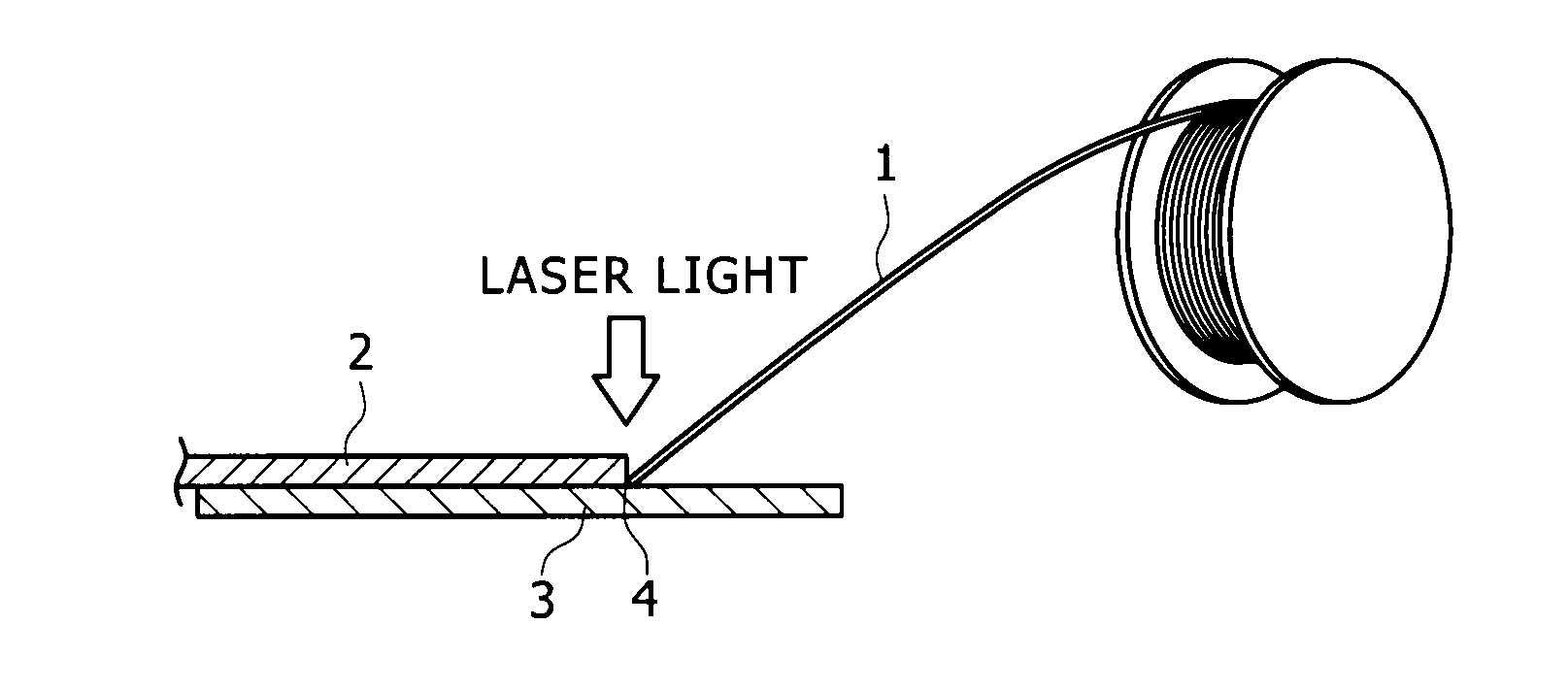

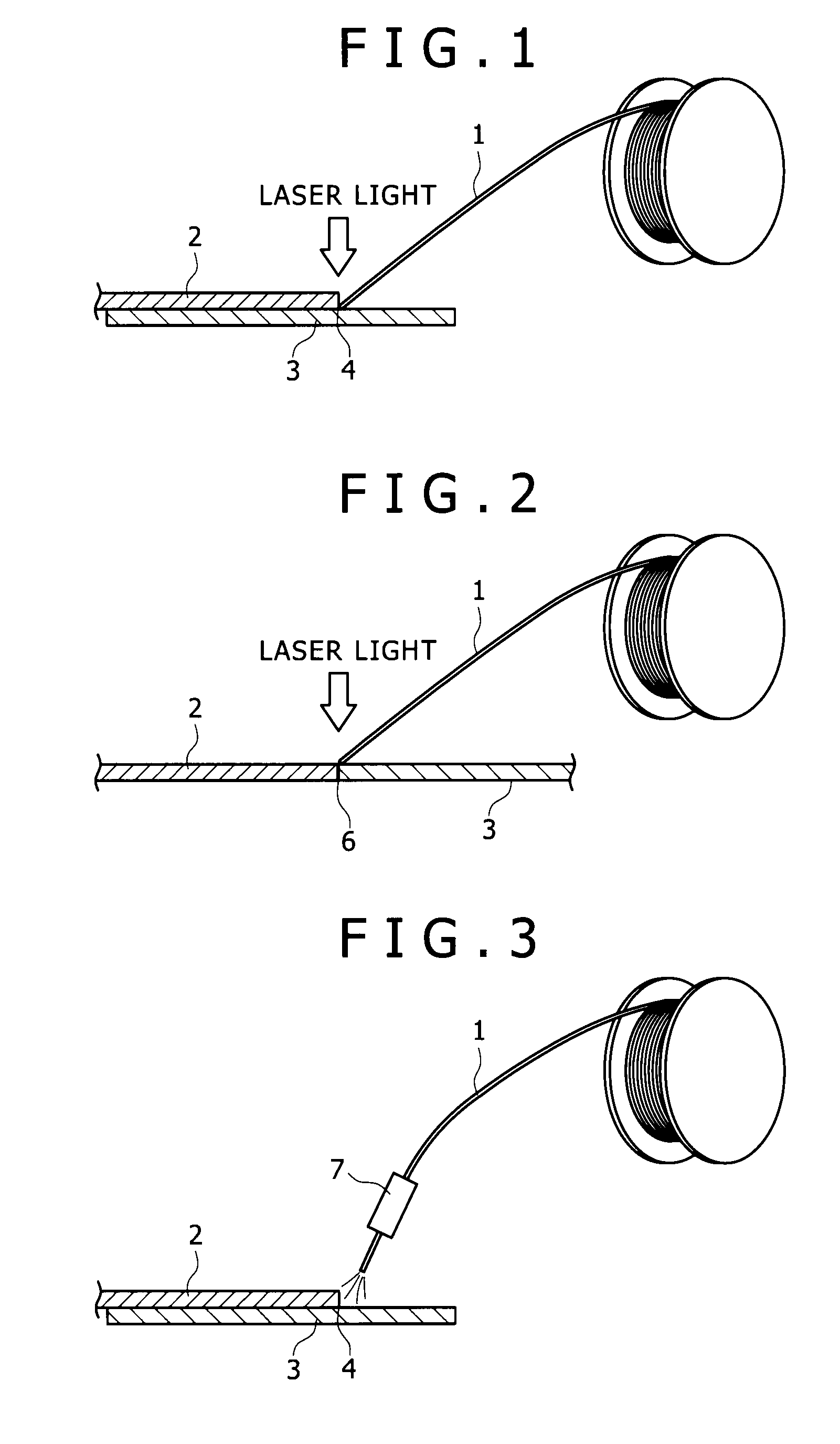

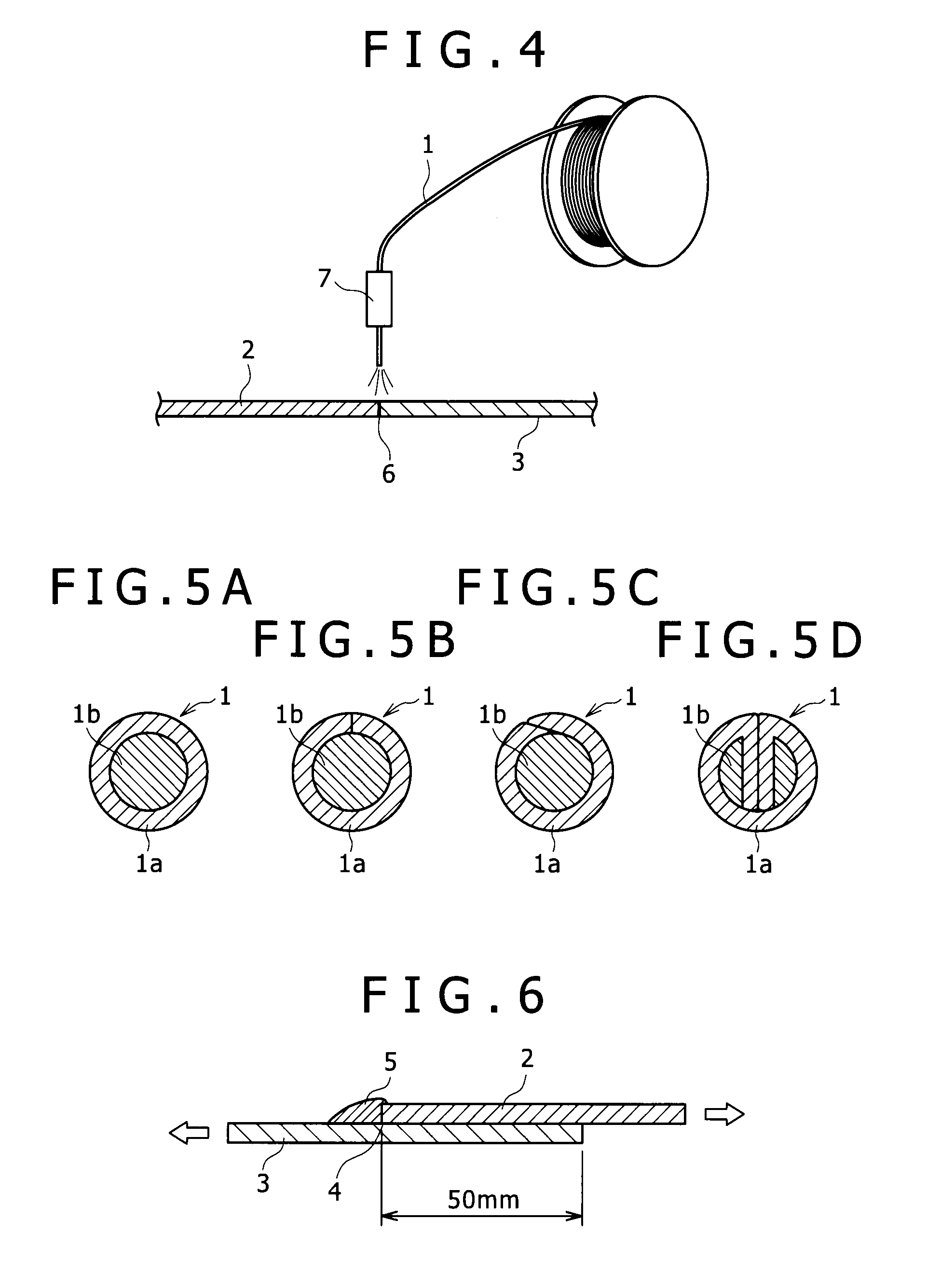

Flux-cored wire for welding different materials, method for laser welding of different materials and method for mig welding of different materials

ActiveUS20120074111A1Appropriate amountImprove joint strengthArc welding apparatusVehicle componentsFluorideUltimate tensile strength

There are provided a flux-cored wire for welding different materials, a method for laser welding of different materials and a method for MIG welding of different materials which can improve tensile shear strength of a welded joint portion and peeling strength of a welded portion interface in welding aluminum or an aluminum alloy material and a steel material. The flux-cored wire has a cylindrical sheath comprising an aluminum alloy which contains Si in an amount of 1.5 to 2.5% by mass and Zr in an amount of 0.05 to 0.25% by mass, with the remainder being aluminum and inevitable impurities, and a flux filling inside this sheath and containing cesium fluoride in an amount of 20 to 60% by mass, and the packing fraction of the flux being 5 to 20% by mass of the total mass of the wire.

Owner:KOBE STEEL LTD

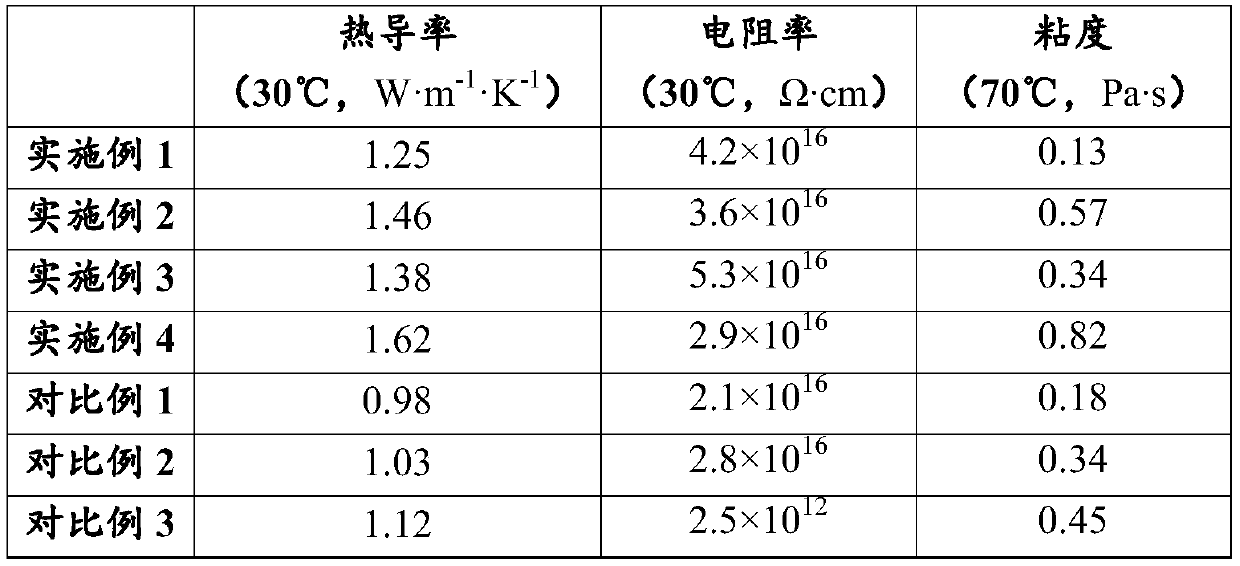

Epoxy resin thermally conductive insulating material and preparation method thereof

ActiveCN110016205AImprove thermal conductivityFunction increasePlastic/resin/waxes insulatorsHeat-exchange elementsEpoxyOmega

The invention belongs to the technical field of thermally conductive and insulating materials, and particularly relates to an epoxy resin thermally conductive insulating material and a preparation method thereof. The material includes an epoxy resin basic material, inorganic filler and a curing agent, wherein the inorganic filler is composed of fillers of three different particle sizes. The epoxyresin thermally conductive insulating material has excellent thermal conductivity and insulation performance only through selection of the ratio of three different particle size grading of the inorganic filler, the ratio of the use amount of the filler of different particle sizes and the particle sizes, and no surface-modified inorganic filler is needed, so that the material cost is reduced, and the preparation method of the material is simpler. The thermal conductivity of the material can reach 1.25 W.m<-1>.K<-1> at 30 DEG C, the highest thermal conductivity can reach 1.62 W.m<-1>.K<-1>, theresistivity of the material is 2.9x10<16> omega.cm or above below 30 DEG C, and application requirements of power electronic transformers, saturation resistors and other high insulation scenes can bemet fully.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Fuel control for internal combustion engine

InactiveUS8340887B2Deterioration of combustionDeterioration of of emissionElectrical controlInternal combustion piston enginesExternal combustion engineIgnition timing

A fuel injection control for an internal combustion engine is provided. Fuel is injected into a cylinder of the internal combustion engine. The fuel injection is divided into main injection and pilot injection in advance of the main injection. An actual compression ignition timing is detected based on a combustion state in the cylinder. A fuel injection timing of the main injection is controlled based on the actual compression ignition timing. An amount of heat release based on the pilot injection is computed. A fuel injection amount of the pilot injection is corrected based on the computed heat release amount.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com