Smelting technology of III grade hot-rolled ribbed bars

The technology of threaded steel bar and process is applied in the field of smelting process of grade III hot-rolled threaded steel bar, which can solve the problems of large loss, high alloying cost, long process flow, etc., so as to reduce production cost, simplify process flow and shorten process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

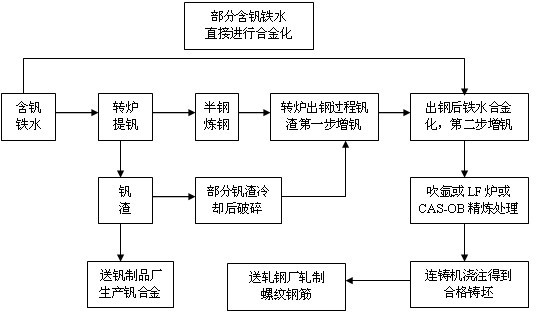

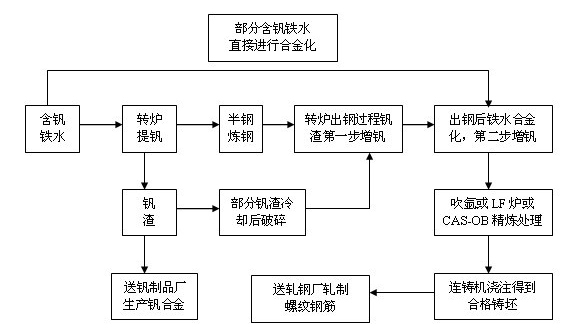

Method used

Image

Examples

Embodiment 1

[0036] Smelting heat 1: This heat smelts ∮6mm HRB400 steel bars, and the lower limit of the internal control of the finished product V is 0.015%. This furnace uses semi-steel steelmaking, the end point of the converter is C: 0.15%, P: 0.025%, S: 0.040%, which meets the requirements for tapping, and then taps. During the tapping process, materials are added in the order of vanadium slag-reductant-silicon-manganese alloy-grained lime-slagging agent, silicon aluminum barium is used as deoxidizer, and the addition amount is 0.2kg / ton of steel, of which the vanadium slag grade is 12.5%. The addition amount is 2kg / ton of steel, the theoretical vanadium addition amount is 0.012%, the reducing agent is aluminum powder, the addition amount is 0.5kg / ton of steel, the addition amount of granular lime is 3kg / ton of steel, and the slag adjustment agent is calcium aluminate Slag agent, its composition range weight percentage is: CaO: 40%, Al 2 o 3 : 20%, SiO 2 ≤10%, the rest are impuriti...

Embodiment 2

[0038] Smelting heat 2: This heat smelts ∮25mm HRB400 steel bars, and the lower limit of the internal control of the finished product V is 0.030%. This furnace uses semi-steel steelmaking, the converter end point C: 0.08%, P: 0.020%, S: 0.035%, which meets the requirements of tapping, and then taps. During the tapping process, materials are added in the order of vanadium slag-reductant-silicon-manganese alloy-grained lime-slagging agent. The deoxidizer uses silicon-aluminum iron, and the addition amount is 0.5kg / ton of steel, of which the vanadium slag grade is 13%. The addition amount is 3.5kg / ton steel, the theoretical vanadium addition amount is 0.020%, the reducing agent is silicon calcium powder, the addition amount is 1kg / ton steel, the granular lime addition amount is 5kg / ton steel, and the slag adjustment agent is calcium aluminate Slagging agent, its composition range weight percent is: CaO: 45%, Al 2 o 3 : 30%, SiO 2 ≤10%, the rest are impurities, and the amount a...

Embodiment 3

[0040] Smelting heat 3: This heat smelts ∮32mm HRB400 steel bars, and the lower limit of the internal control of the finished product V is 0.035%. This furnace uses semi-steel steelmaking, the converter end point C: 0.03%, P: 0.010%, S: 0.033%, which meets the requirements of tapping, and then taps. During the tapping process, materials are added in the order of vanadium slag-reductant-silicon-manganese alloy-grained lime-slagging agent. The deoxidizer uses silicon-aluminum-calcium-barium, and the addition amount is 1.5kg / ton of steel, of which the vanadium slag grade is 13%. , the addition amount is 3.5kg / ton of steel, the theoretical vanadium addition amount is 0.020%, the reducing agent is silicon-calcium powder, the addition amount is 1kg / ton of steel, the addition amount of granular lime is 6kg / ton of steel, and the slag adjustment agent is calcium aluminate It is a slagging agent, and its composition range by weight percentage is: CaO: 45%, Al 2 o 3 : 30%, SiO 2 ≤10%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com