Pressing mold for two-layer edge curling opening sealing of sealed aluminum foil lunch box and opening sealing method

A technology for pressing molds and aluminum foils, which is applied in the field of one-time automatic crimping and sealing of aluminum foil lunch boxes and aluminum foil lunch box lids, can solve the problems of shortening, low aesthetics, secondary pollution of food, etc., and achieves the effect of flat appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples.

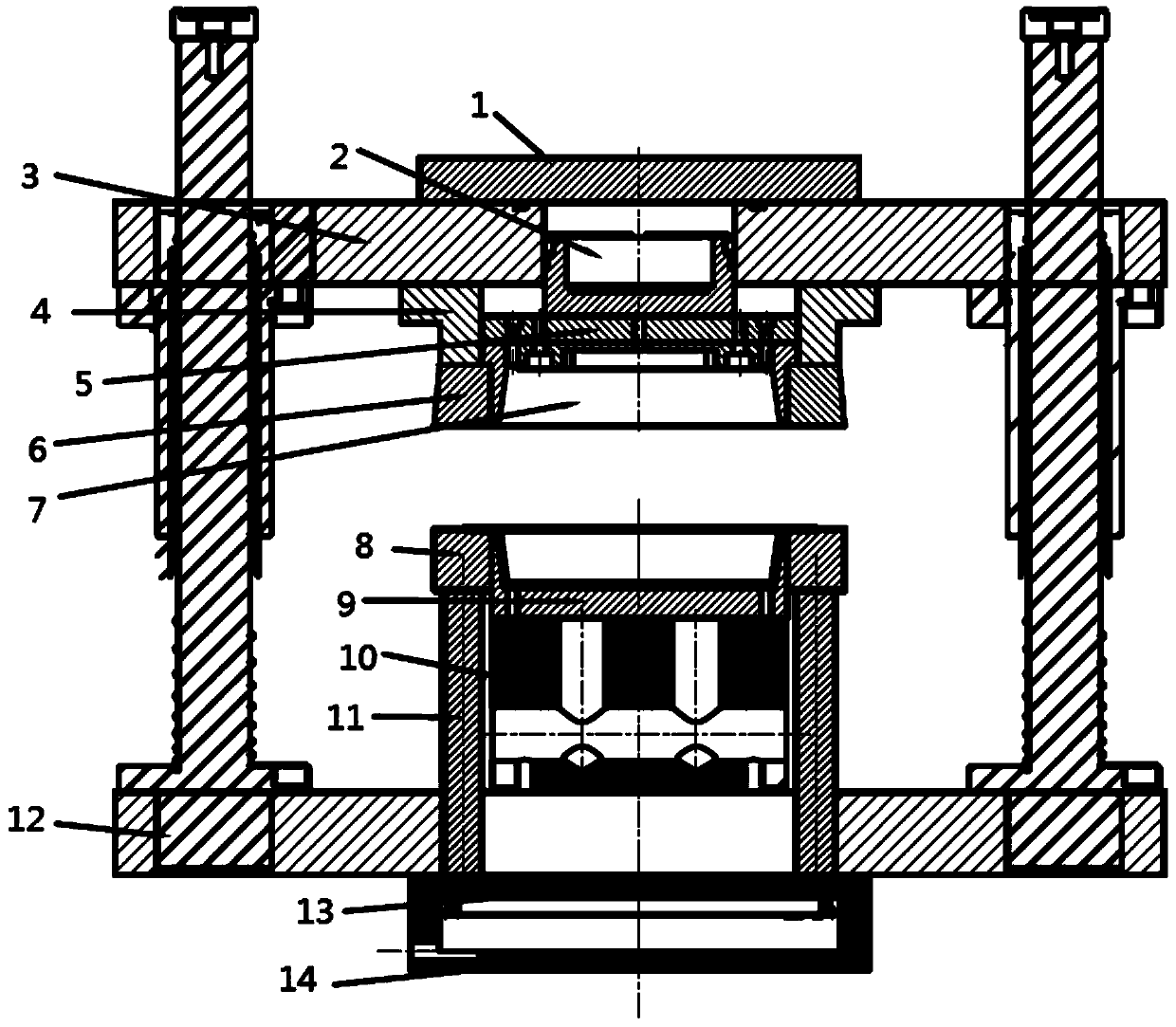

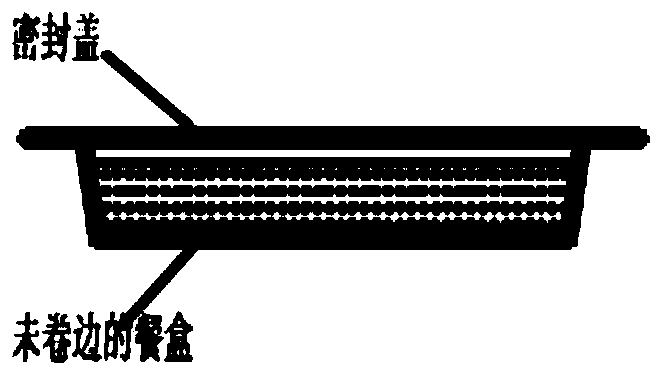

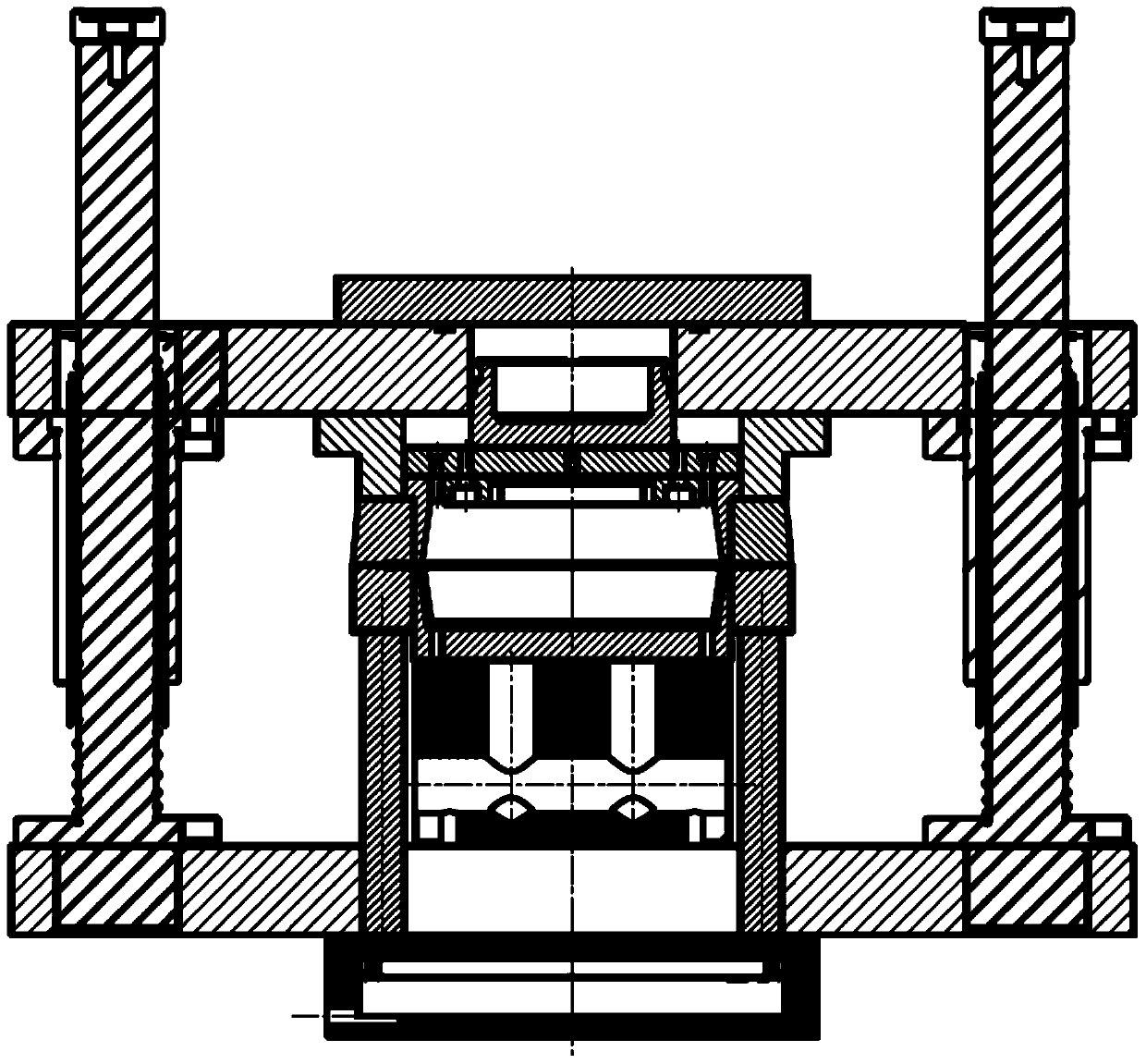

[0029] see Figure 1-11 , a pressing mold for sealing the two-layer crimp seal of an aluminum foil lunch box, comprising: an upper mold part, and the upper mold part includes a loading template 1, an upper template 3, an upper piston 2, an upper notch seat 4, an upper notch 6, Upper die 7, upper die mounting plate 5; lower die part, described lower die part comprises lower blank holder ring 8, lower die 9, lower die base 10, lower cylinder 14, lower cylinder push rod 11, lower Template 12; upper and lower mold guiding parts, the upper and lower mold guiding parts include guide posts and guide sleeves; the shape of the upper die 7 is guided with the inner hole of the upper notch 6, and the upper die mounting plate 5 is connected to the upper die 7 from top to bottom , the upper piston 13 acts on the upper die mounting plate 5, the upper notch seat 4 is connected to the upper n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com