Vacuum sealer and bag-cutting type sealing method

A vacuum sealing and sealing technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of inconvenient use, troublesome use, complex structure, etc., achieve convenient bag cutting, reduce operation steps, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The bag cutting and sealing method of vacuum sealing machine comprises the following steps,

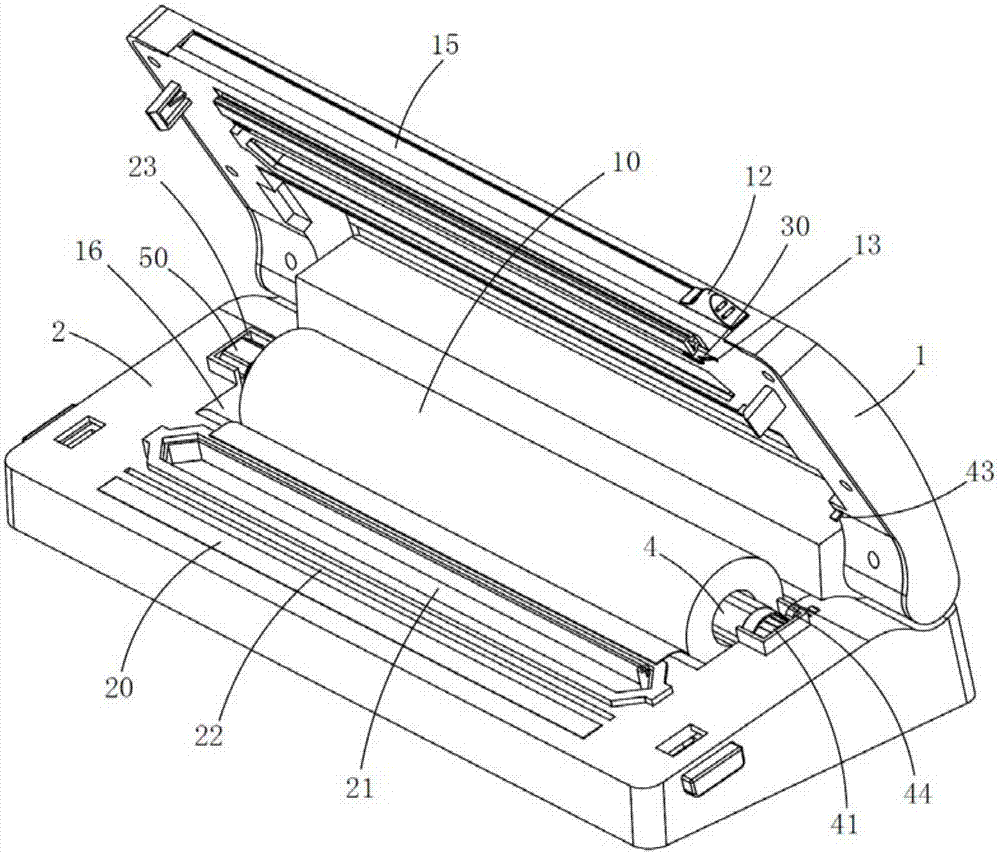

[0049] 1), the roll-shaped vacuum packaging bag roll 10 is fixed on the automatic rewinding shaft 4, and then the two ends of the automatic rewinding shaft 4 are respectively installed in the shaft body installation chambers 23 on both sides of the vacuum sealing machine, so that the vacuum packaging bag roll 10 is stored in the bag storage chamber 16 of the vacuum sealing machine;

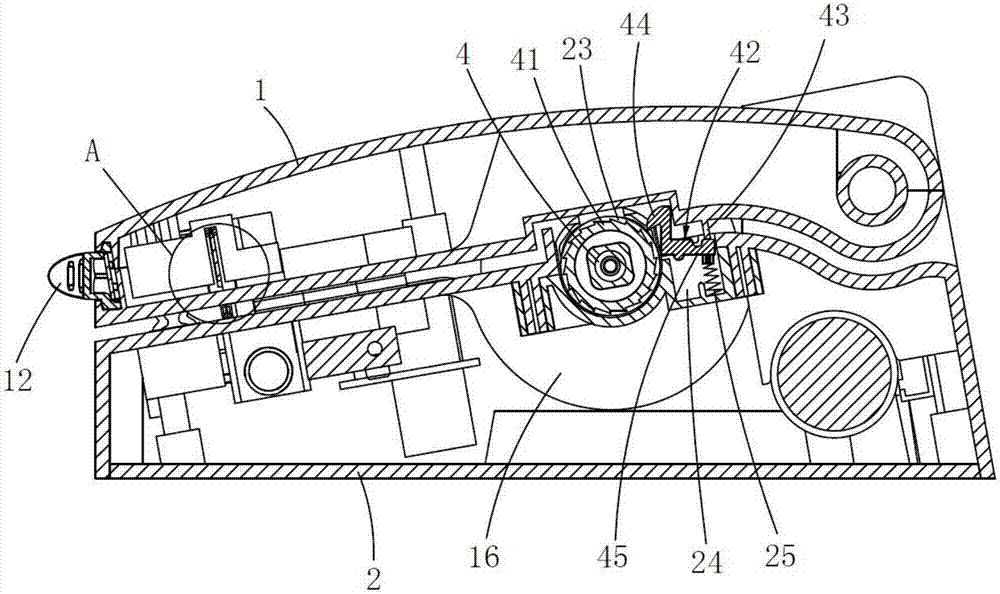

[0050] 2) Pull the vacuum packaging bag roll 10 out of a bag body of appropriate length, the bag body spans the top surface of the cover 2 and is pulled out to the outside of the vacuum sealing machine, and the position where the bag body needs to be cut is located on the lower cover 2 On the side of the vacuuming groove 21 for vacuuming, the automatic rewind shaft 4 rotates when the bag is pulled out, and the part generated when the automatic rewind shaft 4 is rotated by the elastic rewind mechani...

Embodiment 2

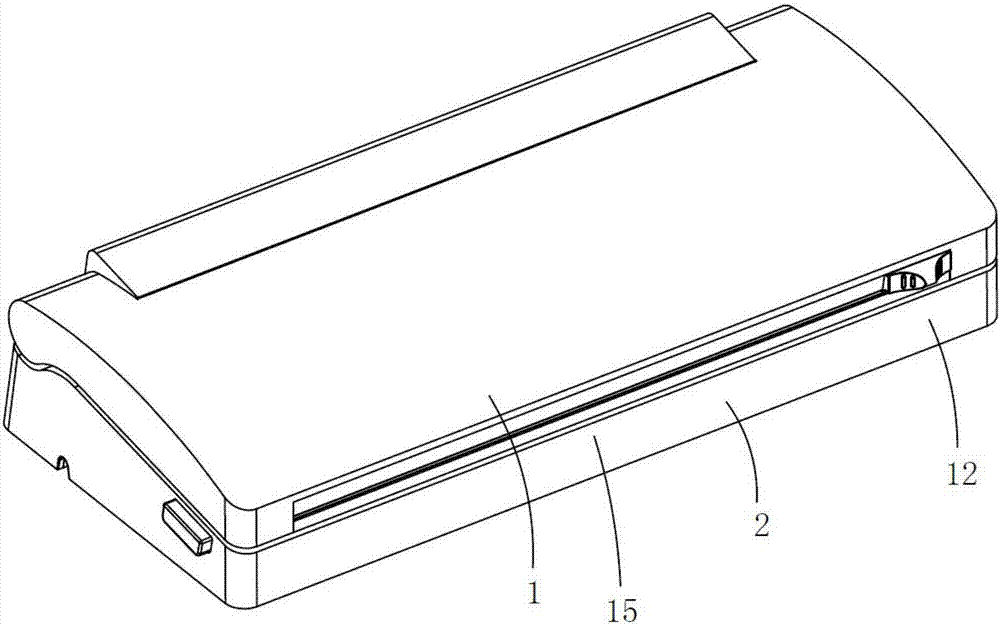

[0059] vacuum sealer, Figures 1 to 10 As shown, it includes an upper cover 1 and a lower cover 2, the upper cover 1 is rotatably installed on the lower cover 2, the upper cover 1 is slidably provided with a cutter device 3, and the front side of the upper part of the lower cover 2 is provided with a heat-sealing strip 20 and a vacuuming groove 21. The upper cover 1 or the lower cover 2 is provided with a bag storage room 16 for storing the roll-shaped vacuum packaging bag roll 10, and a detachable automatic rewinding shaft 4 is rotatably installed in the bag storage room 16, which is used to be arranged in series In the shaft cavity in the middle of the roll-shaped vacuum packaging bag volume 10, the automatic rewinding shaft can be taken out, and the end of the automatic rewinding shaft 4 is equipped with an elastic rewinding mechanism and an elastic one-way locking mechanism. The elastic rewinding mechanism is used to drive the automatic rewinding mechanism. The reel 4 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com