Lifting device for wallboard installation

A lifting device and installation technology, applied in the direction of building, building structure, etc., can solve the problems of limited quantity, uneven wall installation, increase installation cost, etc., achieve strong practicability, small contact area, improve installation quality and The effect of installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

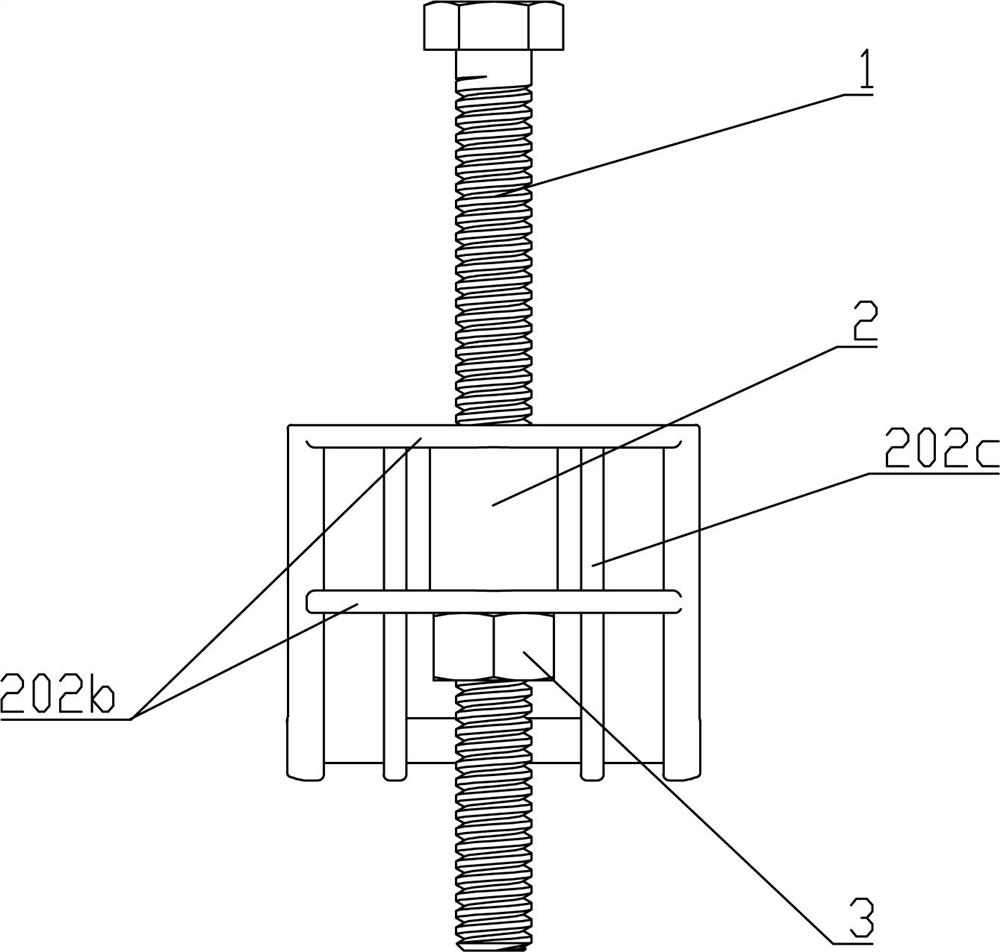

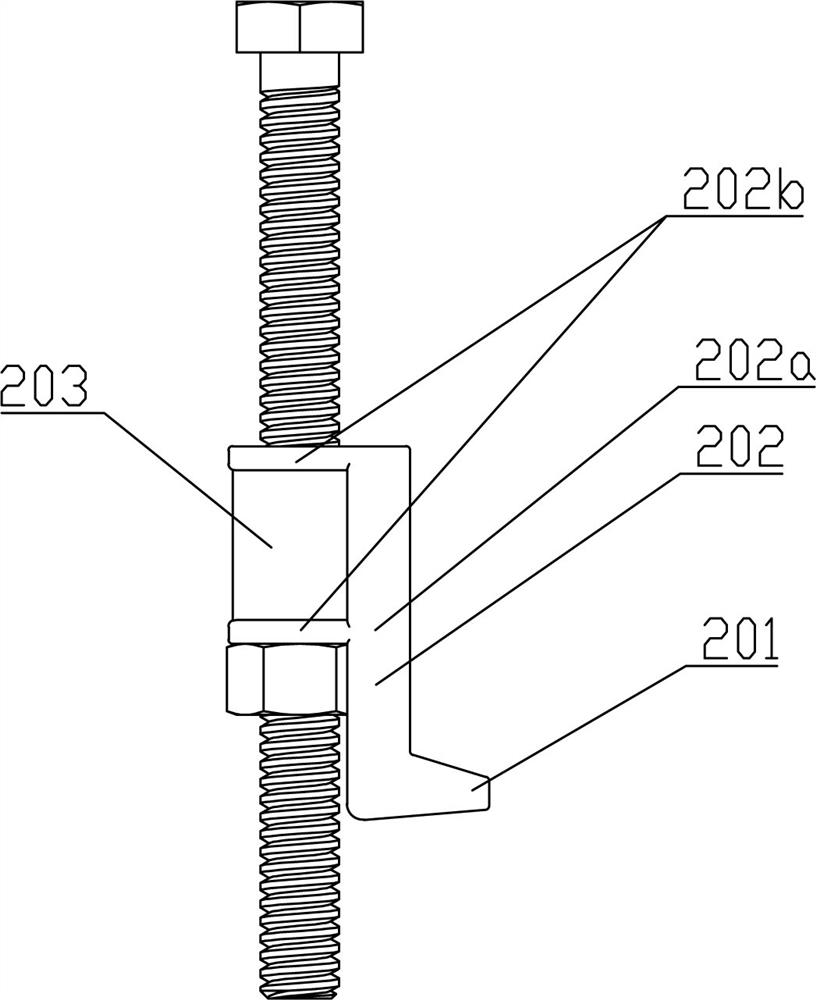

[0028] Embodiment one: if Figure 1-3 As shown, it is only one of the embodiments of the present invention, a lifting device for wall panel installation, including an adjusting member 2 for supporting the wall panel, a screw 1 movably connected with the adjusting member 2, and a screw 1 connected with the screw 1 The nut 3 that is threadedly connected to adjust the lifting height of the wallboard, the adjustment part 2 is provided with a support part 201 for placing the wallboard, a connecting part 202 fixed to the support part 201, and a flexible connection with the screw rod 1 And the adjustment part 203 located above the nut 3 .

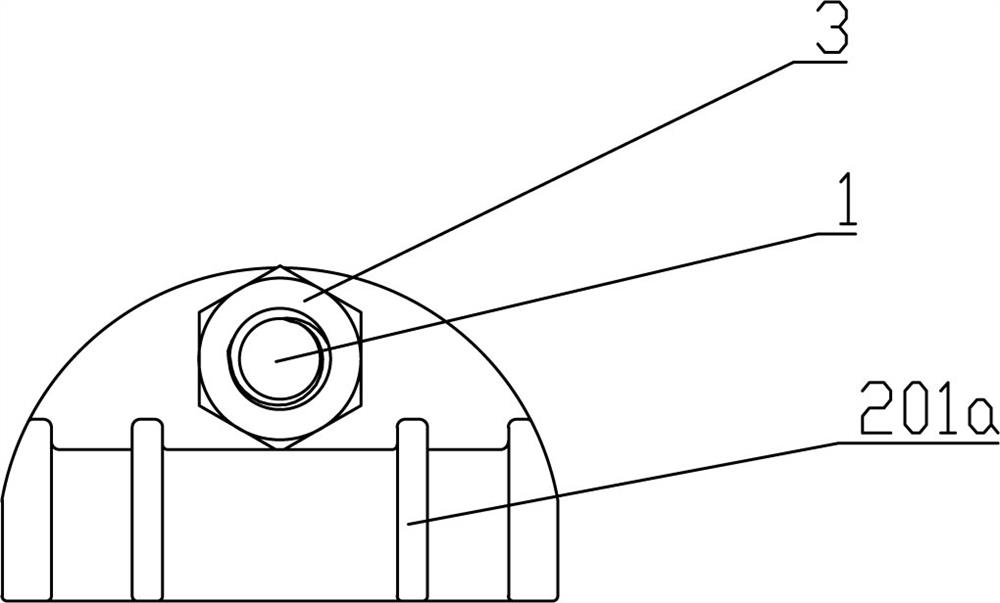

[0029] In the present invention, the upper surface of the supporting part 201 is set as a slope, and the angle between the slope and the lower surface of the supporting part 201 is not more than 30°, and the angle is preferably 20° here. Setting the upper surface of the support part 201 as an inclined plane reduces the contact area between the wa...

Embodiment 2

[0033] Embodiment two: if Figure 1-3 What is shown is only one of the embodiments of the present invention, and on the basis of the first embodiment, the threads on the screw 1 can be set as double threads or single threads. Due to the small helix angle of the single thread, the friction force formed by the screw on the screw 1 and the nut 3 is relatively large, which has good self-locking ability. Twice, due to the increase of the thread lead of the double thread thread, the self-locking ability is reduced, and the single thread is preferred here.

[0034] The lower surface of the supporting part 201 is provided with a first reinforcing rib 201 a to enhance the bearing strength of the supporting part 201 . One side of the first connecting plate 202a is provided with a second reinforcing rib 202c, which not only improves the bearing strength of the first connecting plate 202a, but also saves raw materials, reduces weight, and reduces costs.

[0035] The adjusting hole can b...

Embodiment 3

[0036] Embodiment three: as Figure 1-3 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, a method for using a lifting device for wallboard installation includes the following steps:

[0037] S1: Manually adjust the adjusting part 2 to the height that the wallboard needs to be lifted, and pre-tighten the nut 3;

[0038] S2: placing the wallboard on the upper end surface of the support part 201 of the adjusting part 2;

[0039] S3: Fine-tune the wallboard, adjust the nut 3, and adjust the height of the adjustment part 2 accordingly, until the installation accuracy of the wallboard is met;

[0040] S4: Tighten the nut 3, and take off the device when the wallboard is firmly bonded to the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com