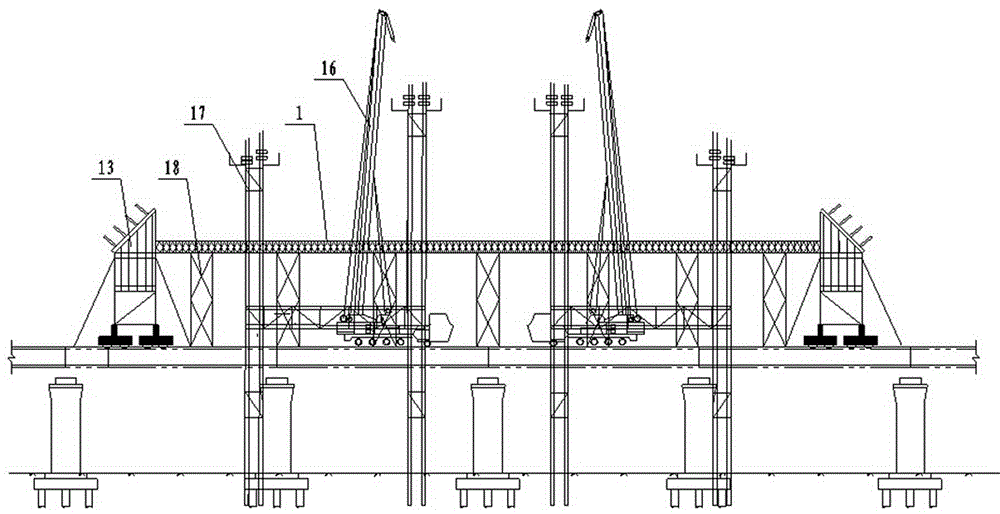

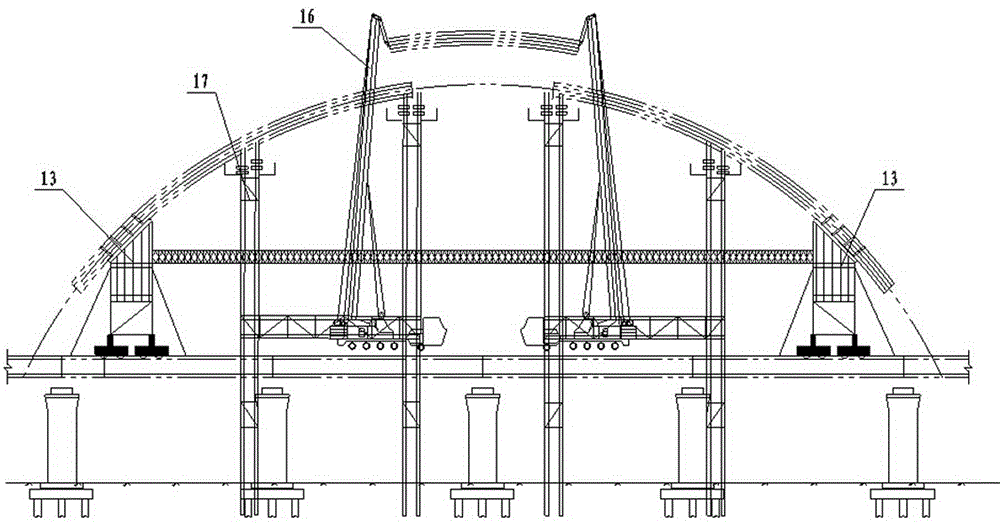

Construction method for continuous tie bar steel tube arch bridge

A steel pipe arch bridge and construction method technology, applied in the direction of arch bridges, bridges, bridge construction, etc., can solve the problems of large safety hazards, long construction period, and difficult construction, and achieve the effects of ensuring construction quality, shortening the construction period, and good reference significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below in conjunction with engineering examples, but it is not used to limit the present invention.

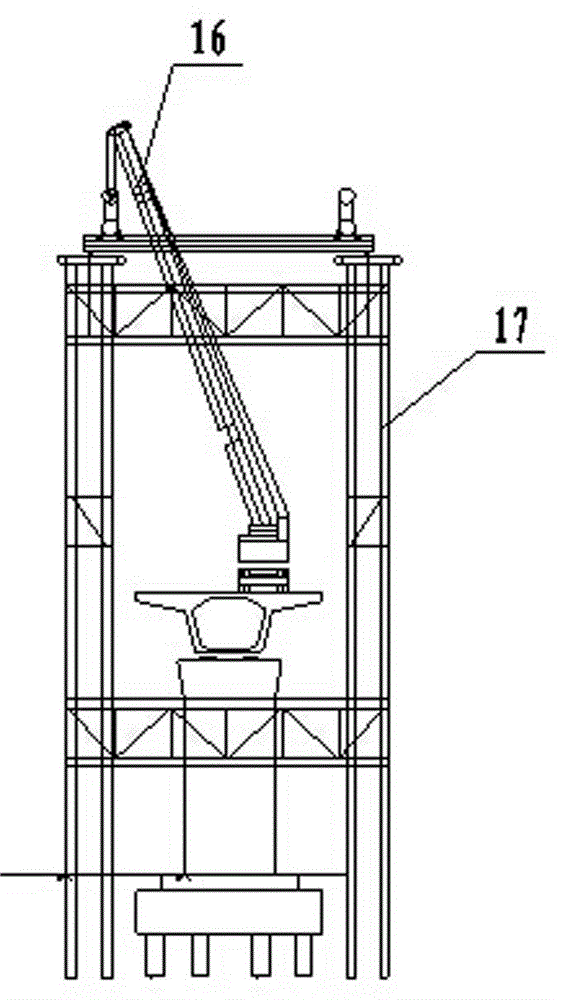

[0036] 1. Project overview: The newly-built Datong-Xi'an Railway Project (74.9+148+128+148+74.9) m ballastless track continuous beam arch bridge is a composite structure of prestressed concrete continuous beam and steel tube concrete arch. This bridge is located in Yangqu Town, Taiyuan City, and crosses Yuantai Expressway, National Highway 208, and Beitongpu Railway in turn. The top width of the main girder is generally 15.8m; the linear change of the top width at the side fulcrum is 12.0m when it is connected with the standard beam of the adjacent span; m; there are 14 transverse diaphragms in total for the main girder, 2 transverse diaphragms with a thickness of 1.5m at the side fulcrums; 4 transverse diaphragms with a thickness of 4.0m at the middle pivot point; The transverse partitions are provided with manholes. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com