Wide-range differential resistance type strain gauge

A differential resistance and large range technology, applied in the field of strain gauges, can solve the problems of different, sacrificing the accuracy of instrument parameters, different initial prestress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

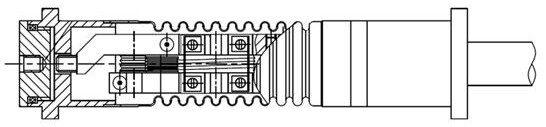

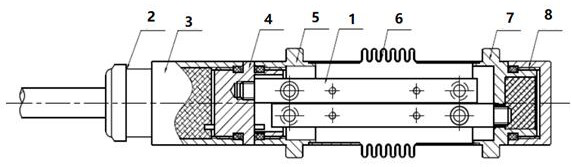

[0026] Such as image 3 As shown, a large-range differential resistance strain gauge includes end components, a protective shell, a tail component and a differential sensing structure 1 connected in sequence. The differential induction structure 1 is fixed in the protective casing, and the front end and rear end of the differential induction structure 1 are respectively connected with the end assembly and the tail assembly.

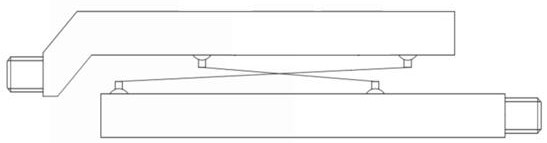

[0027] Such as Figure 4 As shown, the differential induction structure 1 includes a front differential steel wire 11 , a rear differential steel wire 12 , an upper structural member 9 and a lower structural member 10 .

[0028] Both the upper structural part 9 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com