Hydraulic expansion type hob edge grinding cutter rod and use method thereof

An expansion-tightening, hydraulic technology, used in milling cutters, grinding workpiece supports, grinding/polishing equipment, etc., can solve problems such as difficulty in ensuring clamping accuracy, and achieve the effect of avoiding installation accuracy problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

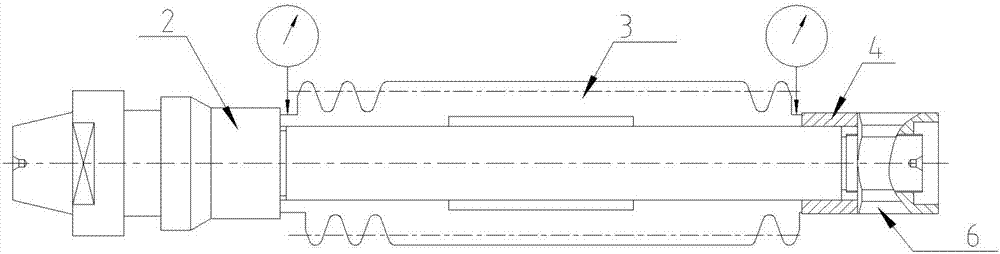

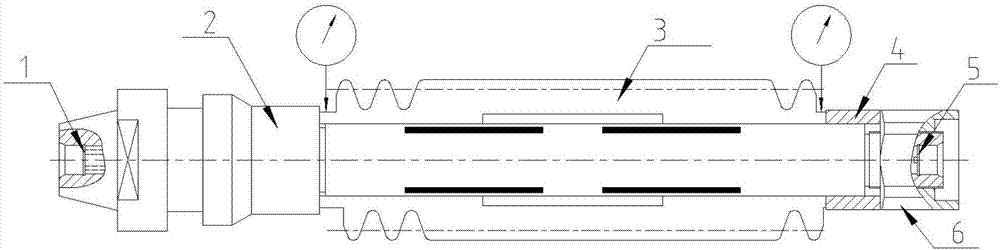

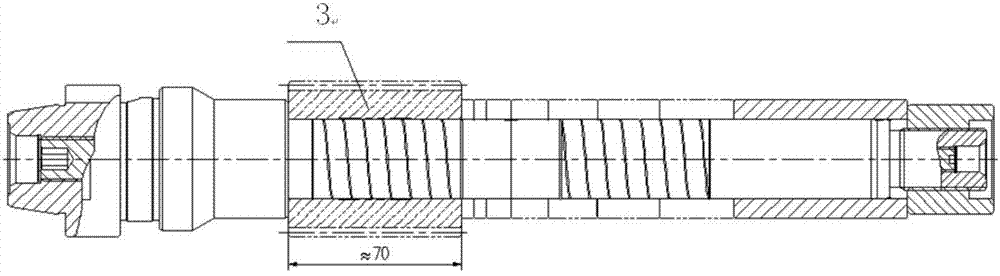

[0028] see figure 2 , the present invention hydraulically tightens the hob sharpening rod, which changes the original clamping method, the cutter rod 2 is filled with liquid, and the front end is provided with a pressure screw 1, and the liquid is squeezed through the pressure screw 1 to make the cutter rod 2 expand , thereby clamping the hob 3 to ensure that the hob is installed securely. The end of the cutter bar 2 is provided with a pressure adjusting screw 5, when the cutter bar 2 wears and the liquid loss in the cutter bar 2 cannot clamp the hob 3, screw in the adjusting screw 5 to make the internal oil pressure enough to clamp the hob 3. The liquid in the cutter bar 2 is arranged in sections, which can meet the installation requirements of hobs of different lengths and ensure the strength. The present invention is also equipped with adjusting washers of differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com