Transmission shaft front section straightening mechanism adopting circlip groove to position

A technology of circlip grooves and drive shafts, applied in the field of drive shafts, can solve problems such as spline fit errors, middle fork position errors, and overall runout that do not meet the requirements, so as to meet the requirements of guaranteed runout, real alignment effect, and improvement of actual The effect of mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

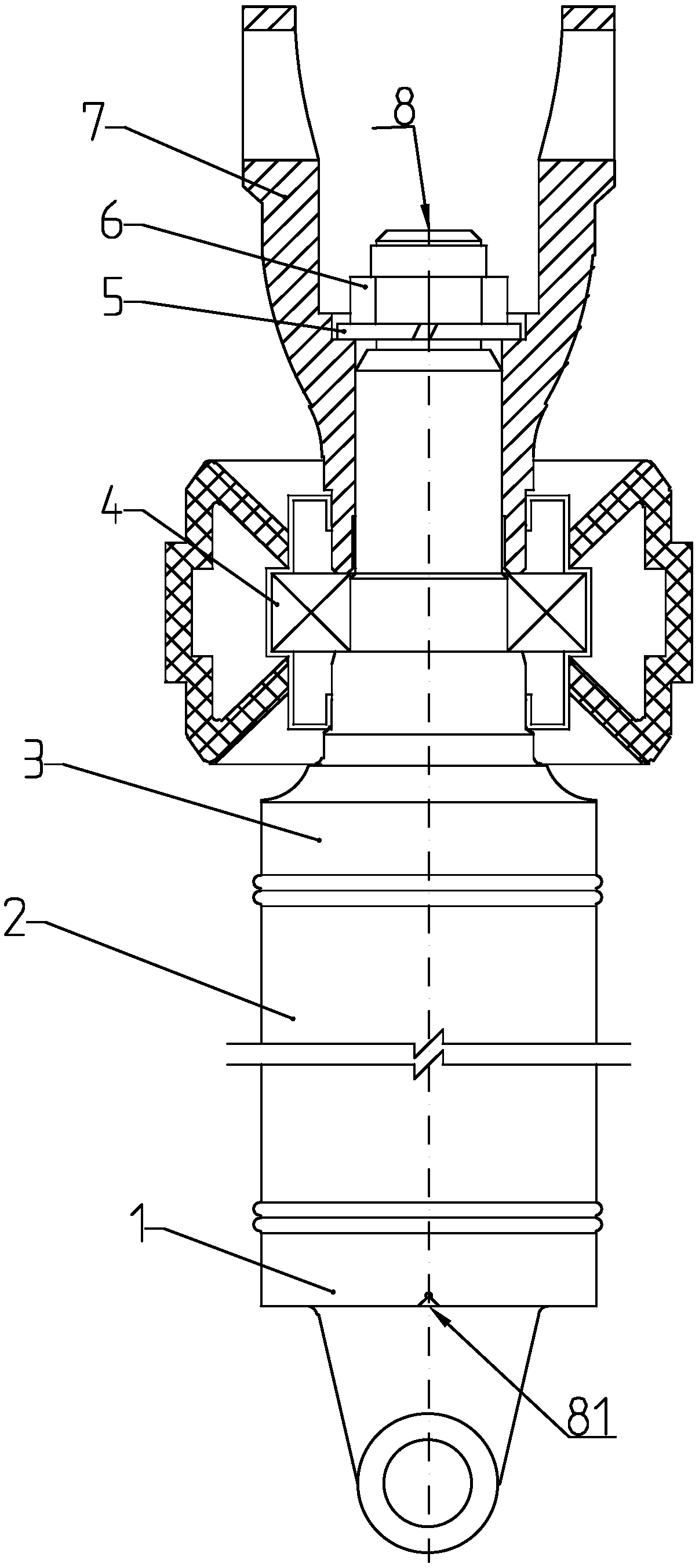

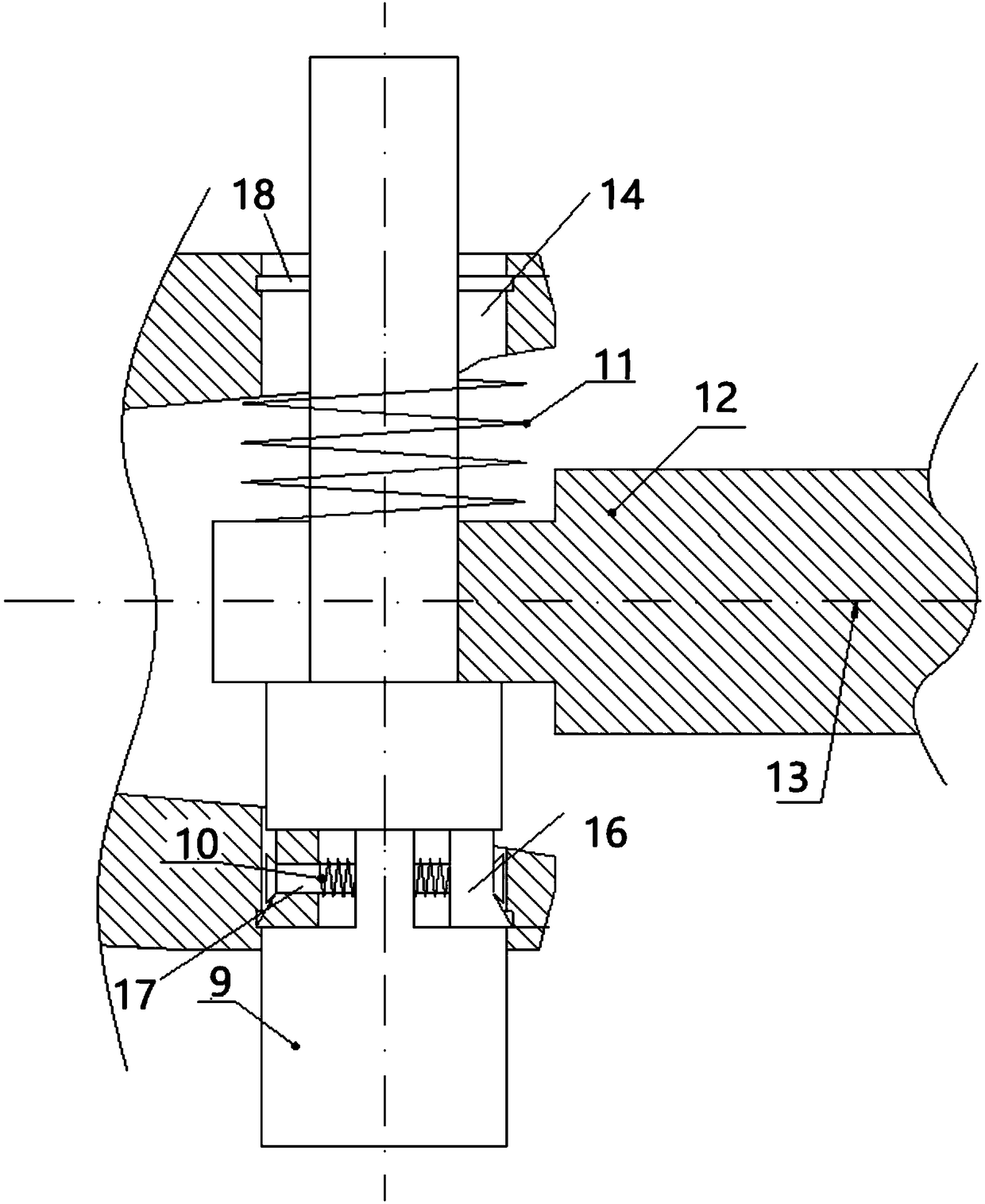

[0016] Embodiment: As shown in the accompanying drawings, the straightening mechanism of the front section of the transmission shaft positioned by the circlip groove mainly includes the mandrel assembly 9, the spring A10, the spring B11, the rotary shaft 12, the ear hole 14, the round hole 15, the tension The opening mechanism 16, the connecting rod 17, the snap ring groove 18, the mandrel assembly 9 is inserted into the ear hole 14, the middle part of the mandrel assembly 9 is inserted into the rotary shaft 12, and a spring B11 is set between the top of the rotary shaft 12 and the ear hole 14 and is set on the core. Outside the rod assembly 9, the mandrel assembly 9 is composed of three sections of cylinders, the top section of the cylinder at the bottom is provided with a platform, and the center of the platform is provided with a circular hole 15. The round hole 15 passes through the connecting rod 17 and the opening mechanism 16 is installed through the connecting rod 17. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com