Machining method for finely boring stand and finely bored stand thereof

A processing method and machine base technology, which is applied in the field of machine base fine boring and machine base fine boring processing, can solve the problems that the overall dimensional accuracy and runout accuracy of the machine base cannot meet the requirements of product drawings, uneven turning stress distribution, machine base shape and To solve problems such as heavy weight, achieve the effects of saving alignment time, improving dimensional accuracy and roughness accuracy, and improving the stability of the machine base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

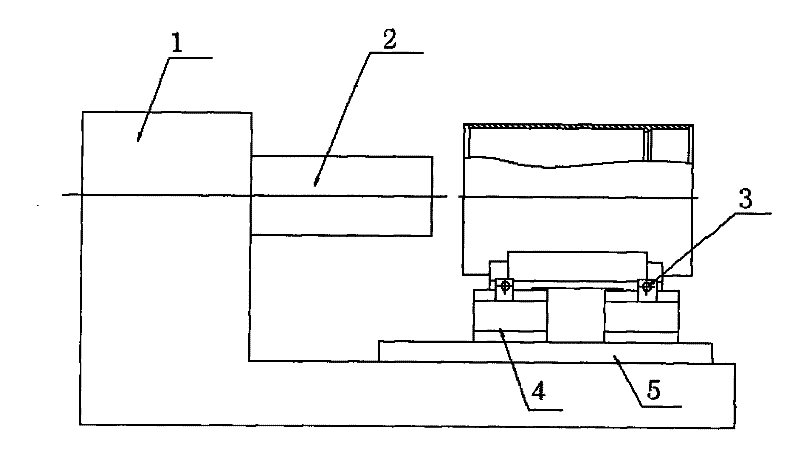

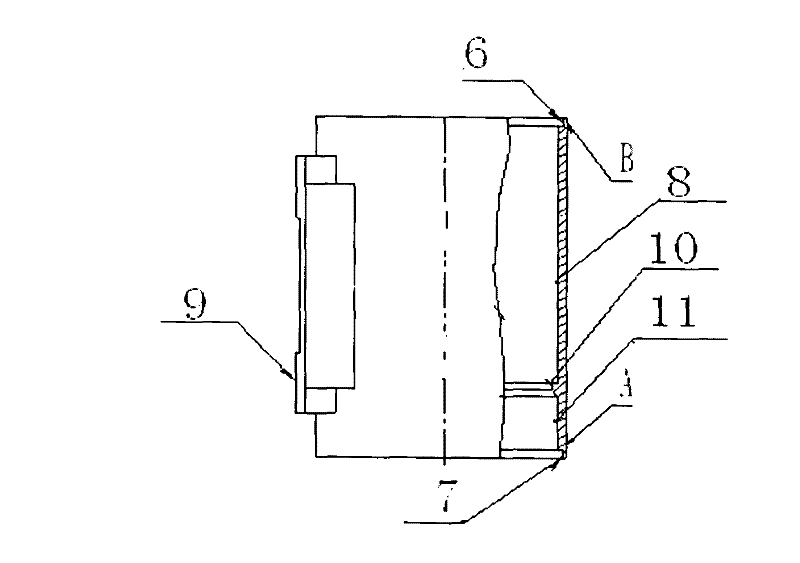

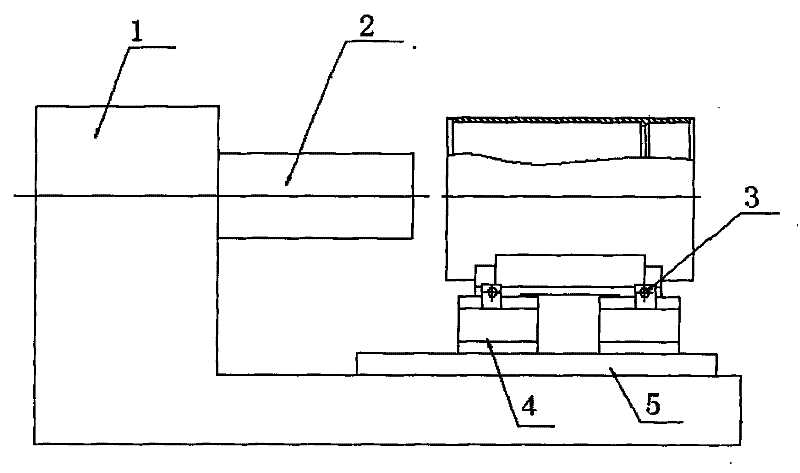

[0020] like figure 1 , figure 2 As shown, the base fine boring includes a boring machine 1, a boring machine head 2, a fine-tuning screw 3, a positioning tire 4 and a boring machine table 5; the machine base part includes a stopper 6, a stopper 7, an iron core 8, a foot plane 9, Block table 10 and empty tool place 11, the specific steps of the machine base fine boring processing method and the machine base fine boring processing method thereof are as follows:

[0021] 1. The machine base is vertically clamped on the vertical lathe in the traditional way, that is, the four-jaw chuck is used to clamp the machine base A, and after alignment, the stop (6) and the iron core of the rough turning machine base 1 mm machining allowance for the end face, 2 mm machining allowance for the diameter of the seam (6), and 1.5 mm machining allowance for the diameter of the iron core (that is, leave the machining allowance for fine boring once to the product drawing size); the machine base is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com