Eccentric adjusting cutter base of numerical control lathe

An eccentric adjustment, CNC lathe technology, applied in the direction of tool clamps, etc., can solve the problem that the Y axis of the CNC lathe cannot be adjusted, and achieve the effect of shortening the alignment time, improving processing efficiency and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

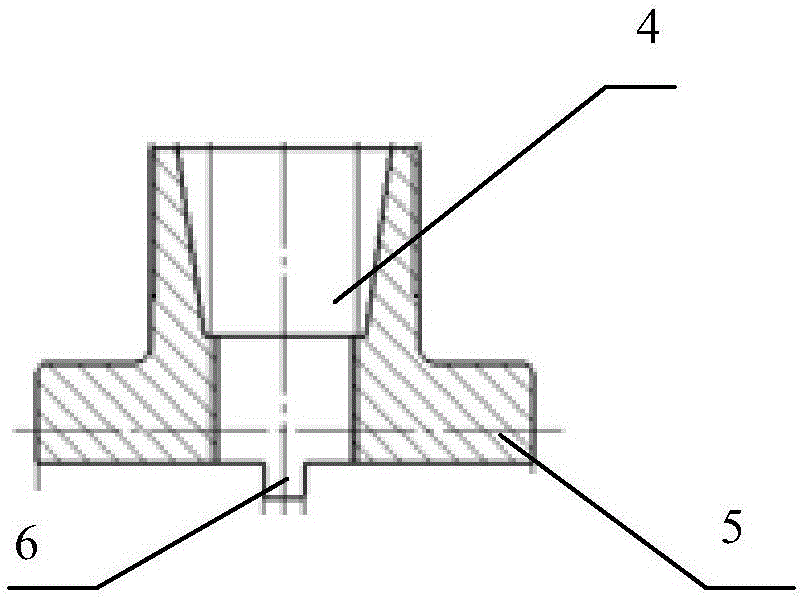

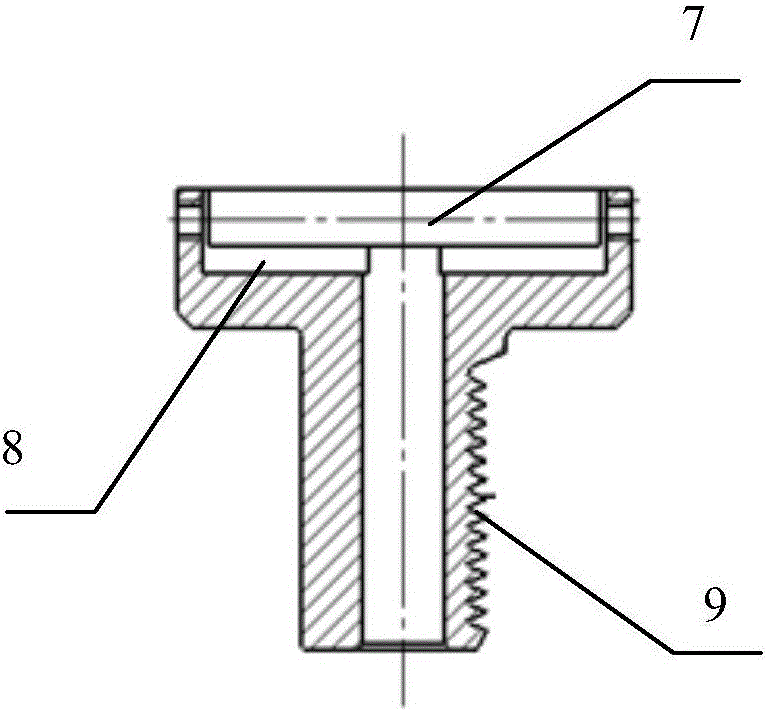

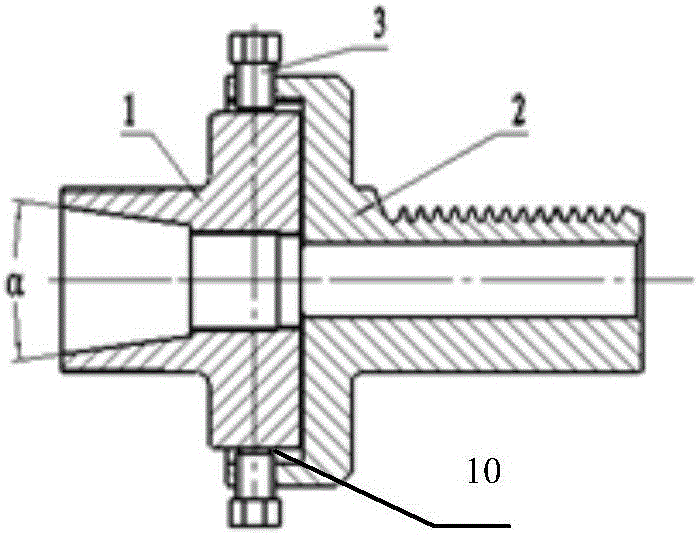

[0017] see figure 1 , 2 , 3, 4, the structure of the specific embodiment of the present invention includes an upper knife seat 1 and a lower knife seat 2, the center of the head of the upper knife seat 1 is provided with an upper cavity 4, and the shape of the upper cavity 4 is adapted to the shape of the circlip chuck. Through the external thread and taper, different specifications of circlips can be clamped, so as to clamp different drill bits, milling cutters, reamers, etc. The center of the lower knife seat 2 is provided with a lower cavity 7 that can place the upper knife seat base 5. There is a gap 10 between the inner edge of the lower cavity 7 and the outer edge of the upper knife seat base 5 to ensure the adjustment of the Y axis. An adjustment screw 3 is provided on the knife seat 2 corresponding to both sides of the lower cavity 7, and the whole screw 3 can be adjusted in the Y-axis direction. Upper knife base 5 is provided with upper threaded hole 11, and lower k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com