Anti-static environment-friendly coating fabric and preparing method thereof

A coated fabric, an environment-friendly technology, applied in the field of antistatic and environment-friendly coated fabric and its preparation, can solve the problems of no preparation method, poor functionality, no flame retardancy, antistatic and wear resistance of the coated fabric, etc. Good product quality, good color fastness, and the effect of avoiding oven contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

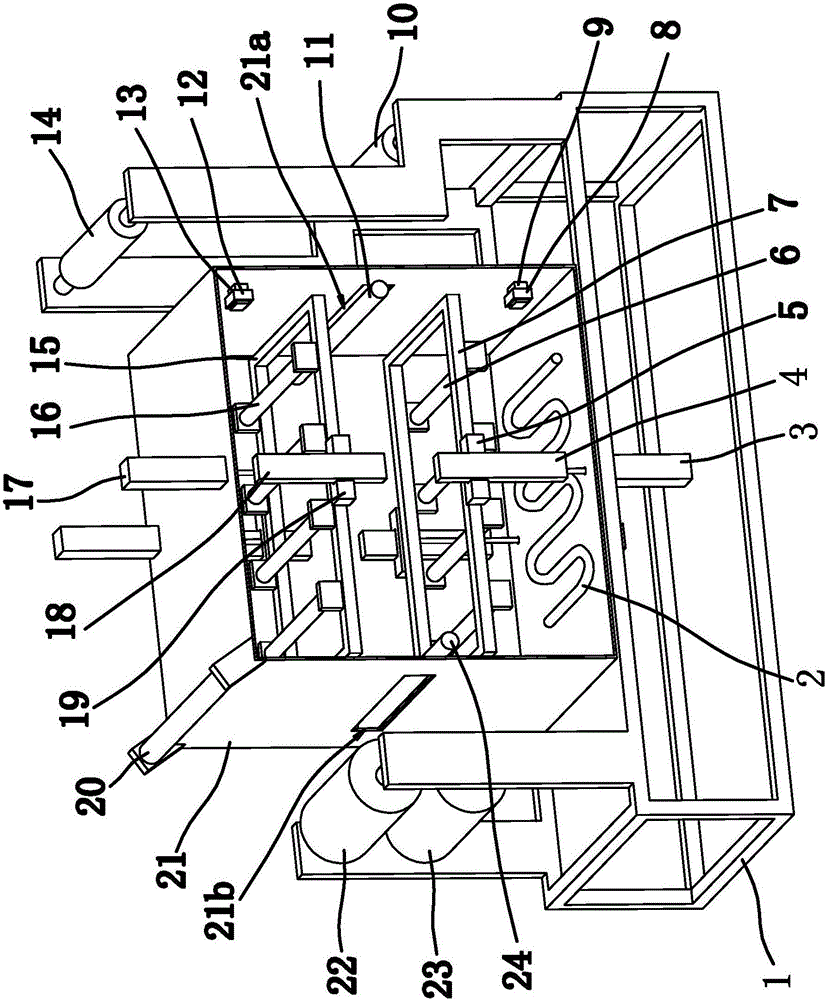

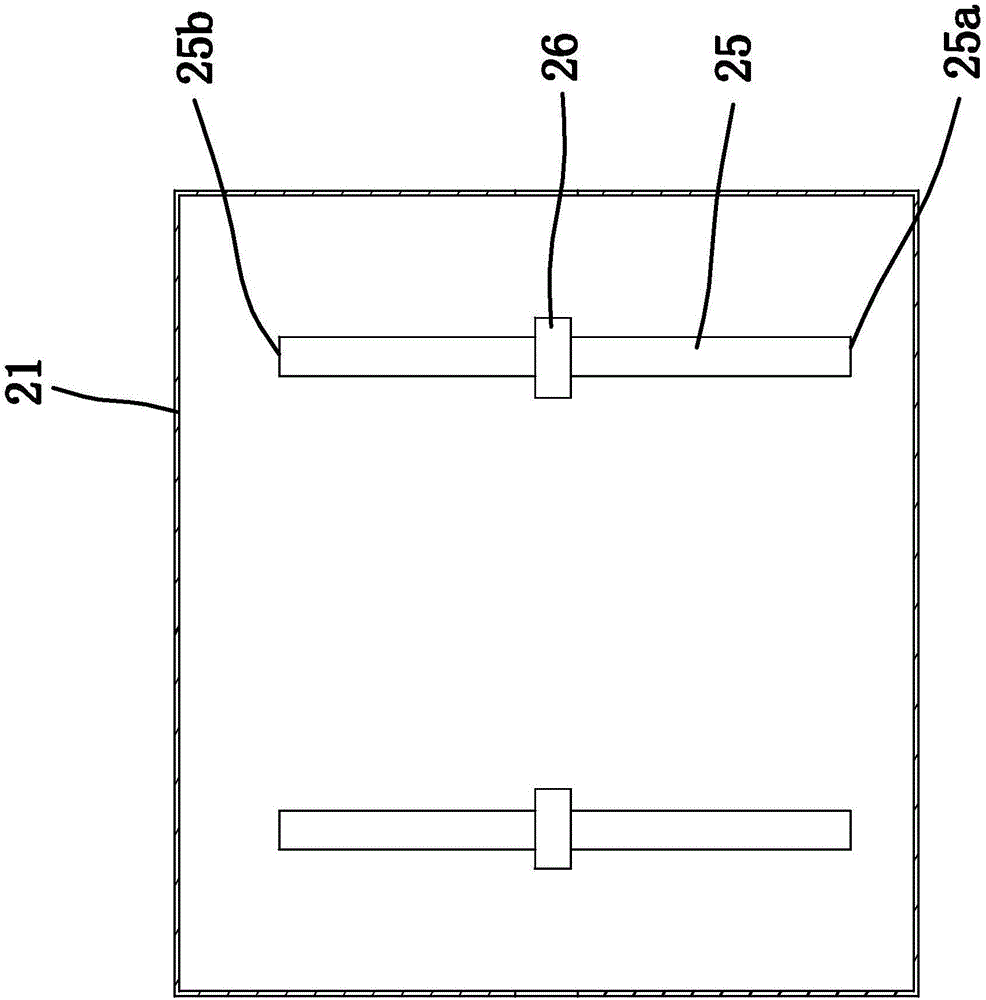

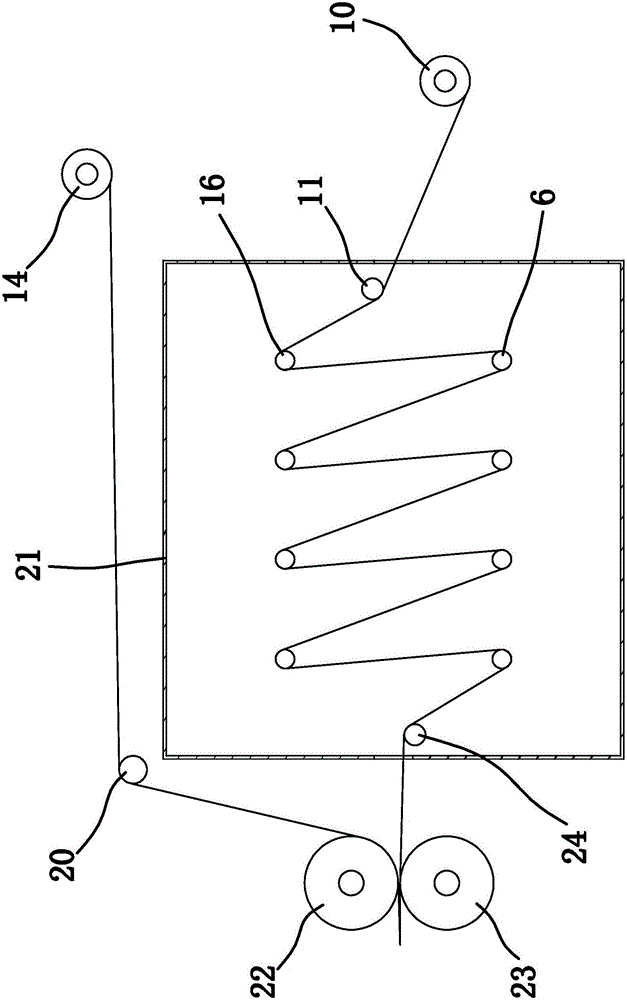

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of the antistatic environment-friendly coated fabric comprises the following steps:

[0051] a. Take the required raw materials by the mass parts of the above components;

[0052] b. Add polyurethane resin, silicone resin, fluororubber and toluene to an ordinary mixer, the stirring time is 10min, and the stirring speed is 300r / min;

[0053] c. Add the cross-linking agent, antistatic agent, magnesium oxide and dyes to the ordinary mixer, the stirring time is 3min, the stirring speed is 100r / min, and the coating liquid is obtained;

[0054] d. Spray the coating liquid evenly on the release paper through an ordinary spray gun, and the spray thickness is 0.12mm;

[0055] e. Put the release paper sprayed with the coating liquid into the ordinary drying equipment to dry, the drying temperature is 90 ℃, and the drying time is 8 minutes, and the reinforcement layer can be obtained;

[0056] f. The base fabric layer and the reinforcing layer are laminate...

Embodiment 2

[0064] The preparation method of the antistatic environment-friendly coated fabric comprises the following steps:

[0065] a. Take the required raw materials by the mass parts of the above components;

[0066] b. Add polyurethane resin, silicone resin, fluororubber and toluene to an ordinary mixer, the stirring time is 12min, and the stirring speed is 350r / min;

[0067] c. Add the cross-linking agent, antistatic agent, magnesium oxide and dyes to the common mixer, the stirring time is 4min, the stirring speed is 120r / min, and the coating liquid is obtained;

[0068] d. Spray the coating liquid evenly on the release paper through an ordinary spray gun, and the spray thickness is 0.126mm;

[0069] e. Put the release paper sprayed with the coating liquid into the ordinary drying equipment to dry, the drying temperature is 100 ℃, and the drying time is 10 minutes, and the reinforcement layer can be obtained;

[0070] f. The base fabric layer and the reinforcing layer are laminat...

Embodiment 3

[0078] The preparation method of the antistatic environment-friendly coated fabric comprises the following steps:

[0079] a. Take the required raw materials by the mass parts of the above components;

[0080] b. Add polyurethane resin, silicone resin, fluororubber and toluene to an ordinary mixer, the stirring time is 15min, and the stirring speed is 400r / min;

[0081] c. Add the cross-linking agent, antistatic agent, magnesium oxide and dyes to the common mixer, the stirring time is 5min, the stirring speed is 150r / min, and the coating liquid is obtained;

[0082] d. Spray the coating liquid evenly on the release paper through an ordinary spray gun, and the spray thickness is 0.18mm;

[0083] e. Put the release paper sprayed with the coating liquid into the ordinary drying equipment for drying, the drying temperature is 110°C, and the drying time is 12 minutes, and the reinforcement layer can be obtained;

[0084] f. The base fabric layer and the reinforcing layer are lami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com