Semiconductor structure and formation method thereof

A semiconductor and patterning technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as poor quality of target graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It can be known from the background art that even if the self-aligned double patterning process is introduced, the quality of the target pattern formed after etching is still poor, which easily leads to a decrease in the performance and yield of the formed semiconductor structure. The reasons for this are now analyzed in conjunction with a method for forming a semiconductor structure of the invention.

[0017] refer to Figure 1 to Figure 5 , a schematic diagram of the structure corresponding to each step in a method for forming a semiconductor structure is shown.

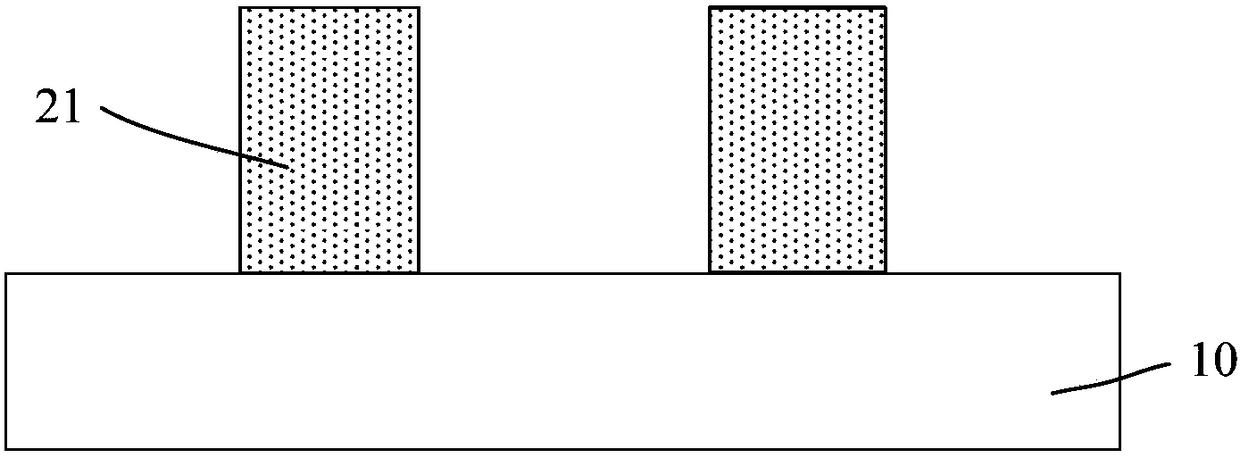

[0018] refer to figure 1 , to provide a material layer 10 to be etched, and a plurality of discrete core layers 21 are formed on the material layer 10 to be etched.

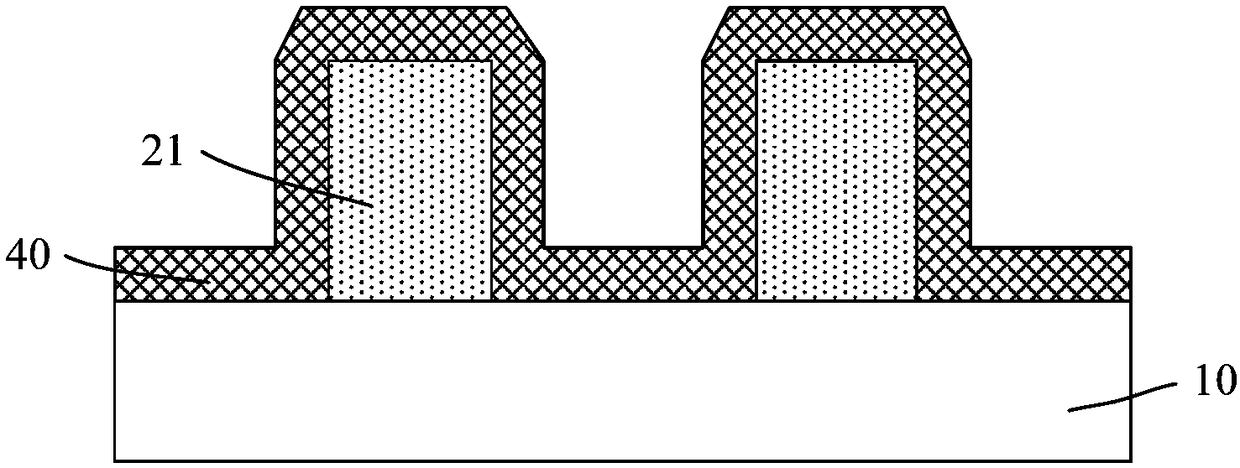

[0019] refer to figure 2 , forming a sidewall film 40 on the top and sidewall surfaces of the core layer 21 and the material layer 10 to be etched.

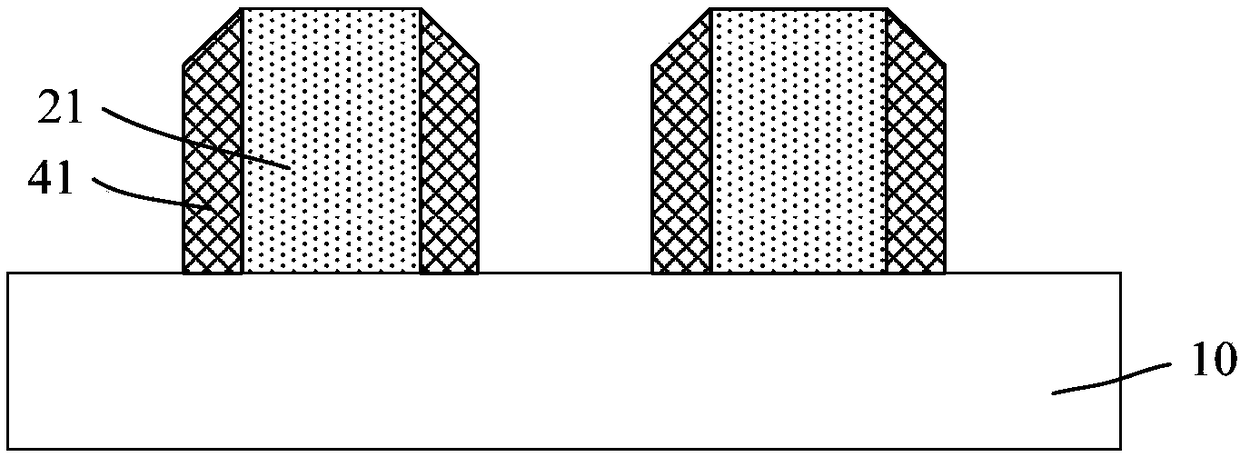

[0020] refer to image 3 , using a maskless etching process to etch the sidewall film 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com