Semiconductor structures and methods of forming them

A semiconductor and patterning technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as poor target pattern quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It can be seen from the background art that even if a self-aligned double patterning process is introduced, the quality of the target pattern formed after etching is still poor, which easily leads to a decrease in the performance and yield of the formed semiconductor structure. The reason is analyzed in conjunction with an inventive method for forming a semiconductor structure.

[0017] refer to Figure 1 to Figure 5 , shows a schematic structural diagram corresponding to each step in a method for forming a semiconductor structure.

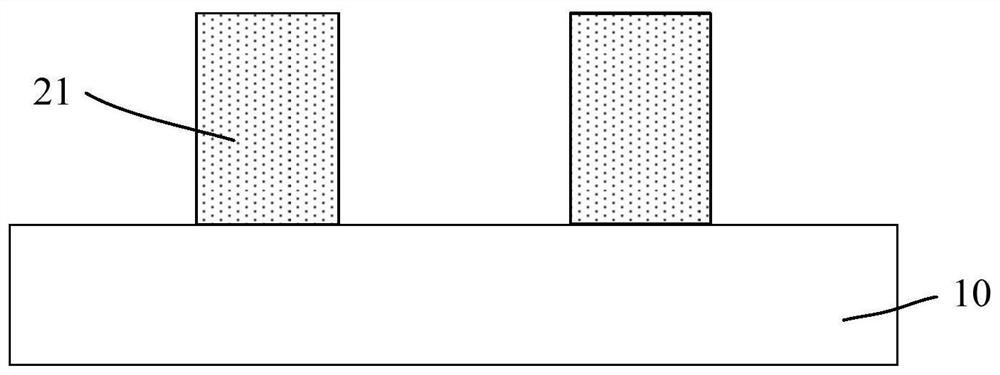

[0018] refer to figure 1 , providing a material layer 10 to be etched, and a plurality of discrete core layers 21 are formed on the material layer 10 to be etched.

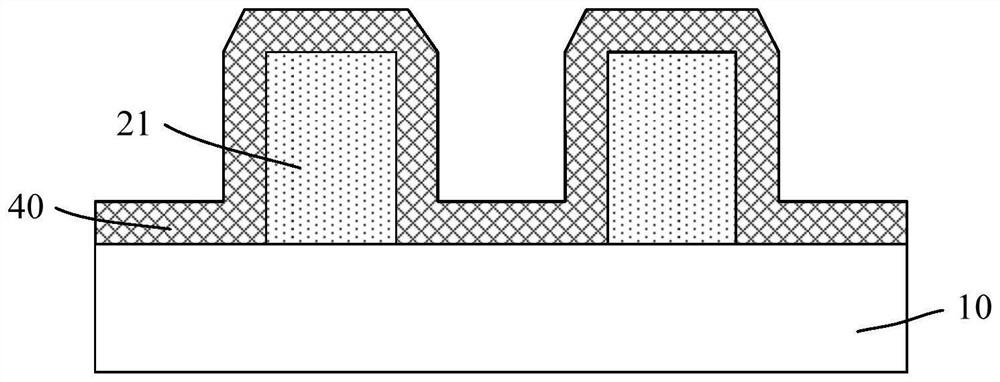

[0019] refer to figure 2 , forming a sidewall film 40 on the top and sidewall surfaces of the core layer 21 and the material layer 10 to be etched.

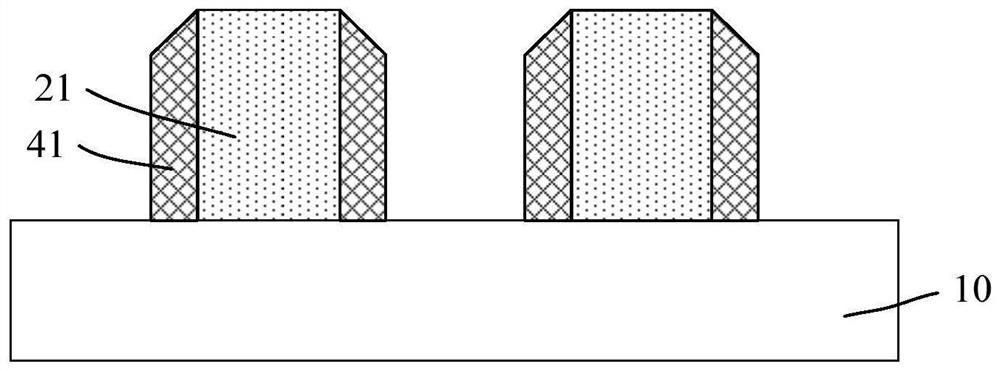

[0020] refer to image 3 , using a maskless etching process to etch the sidewall film 40 (such as figure 2 ), remove the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com