Special-shaped steel pipe

A steel pipe and heterosexual technology, which is applied in the field of P-type high-strength heterosexual steel pipes, can solve the problems of low production efficiency and poor workmanship, and achieve the effects of saving materials, ensuring workmanship, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

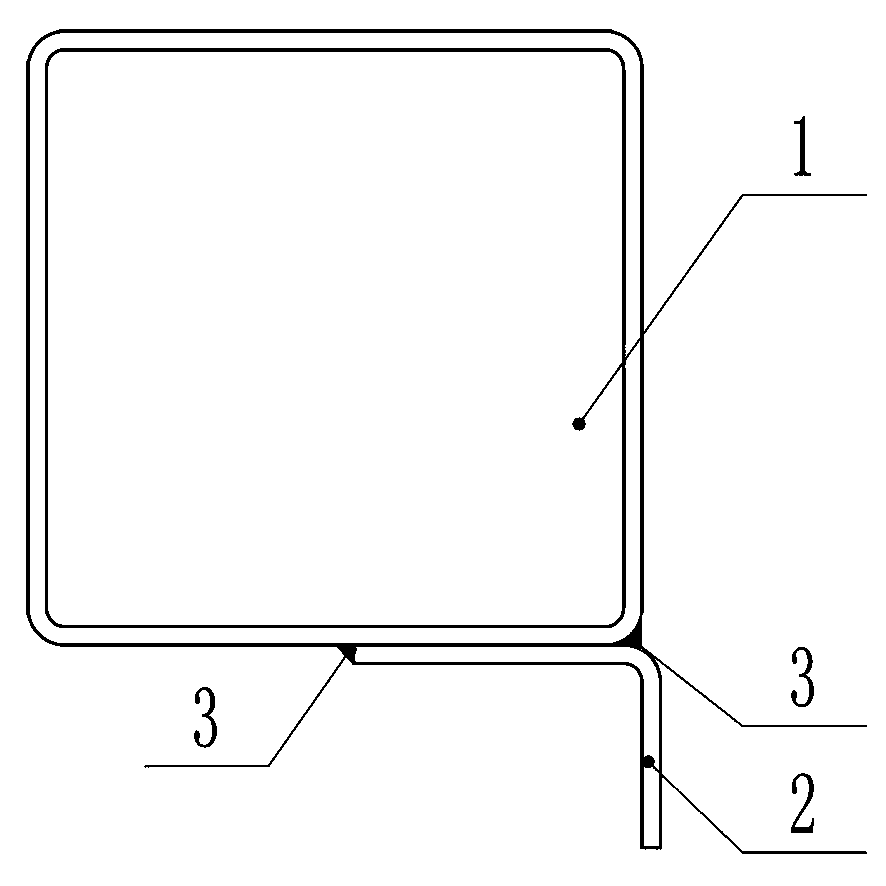

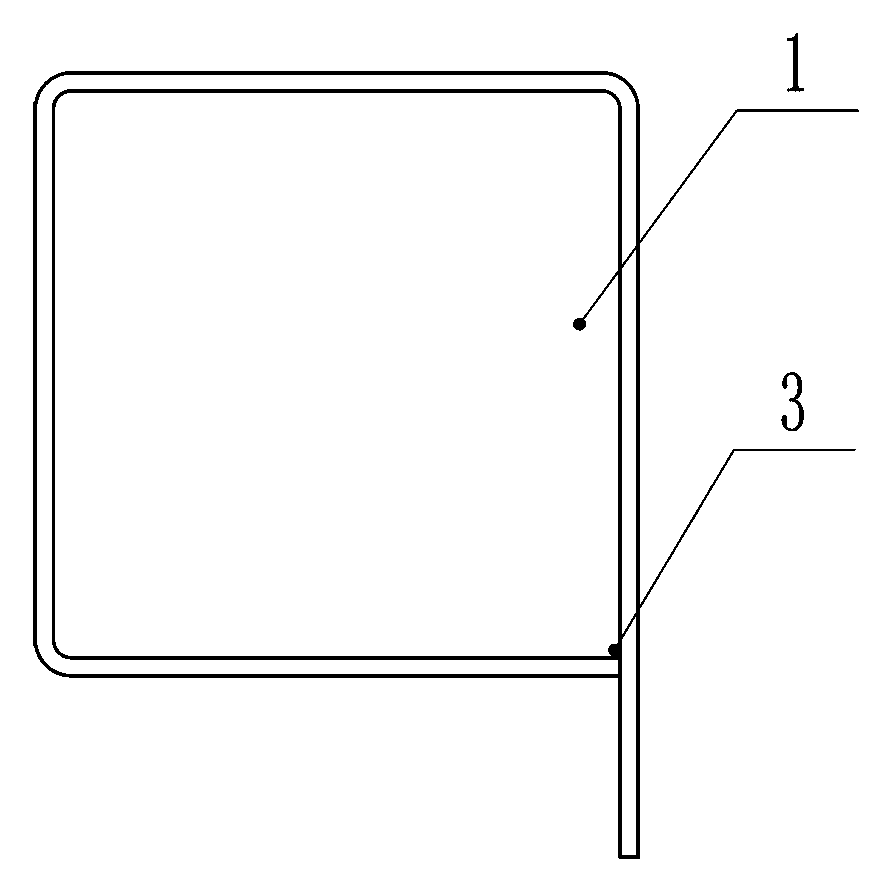

[0014] Such as figure 2 As shown, a kind of heterosexual steel pipe, the heterosexual steel pipe is an integral structure, its cross-section is P-shaped, the P-shaped is that one side of the rectangular pipe 1 whose main body is hollow is extended vertically outward for 10 cm, and then stretched Flanging is carried out on the out part to form an approximate P shape.

[0015] In order to reduce the process flow and reduce the production cost, the main body of the heterosexual steel pipe is formed by rolling (or stamping); in order to improve the welding quality, the sealing part of the rectangular pipe of the main part (that is, the welding position 3) adopts The contact welding method welds the seal.

[0016] In the present invention, a P-shaped tube is formed by vertically extending one side of the rectangular tube outward and flanging, which can be widely used as a section material for various parts requiring high sealing performance and matching clearance. Especially in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com