High-strength aluminum alloy for additive manufacturing and preparation method of high-strength aluminum alloy powder

An additive manufacturing, aluminum alloy technology, applied in the field of high-strength aluminum alloy and its powder preparation, can solve the problems of high hot cracking tendency, low tensile and fatigue properties, sample cracks, etc., and achieve easy engineering Application, good fluidity, dense tissue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

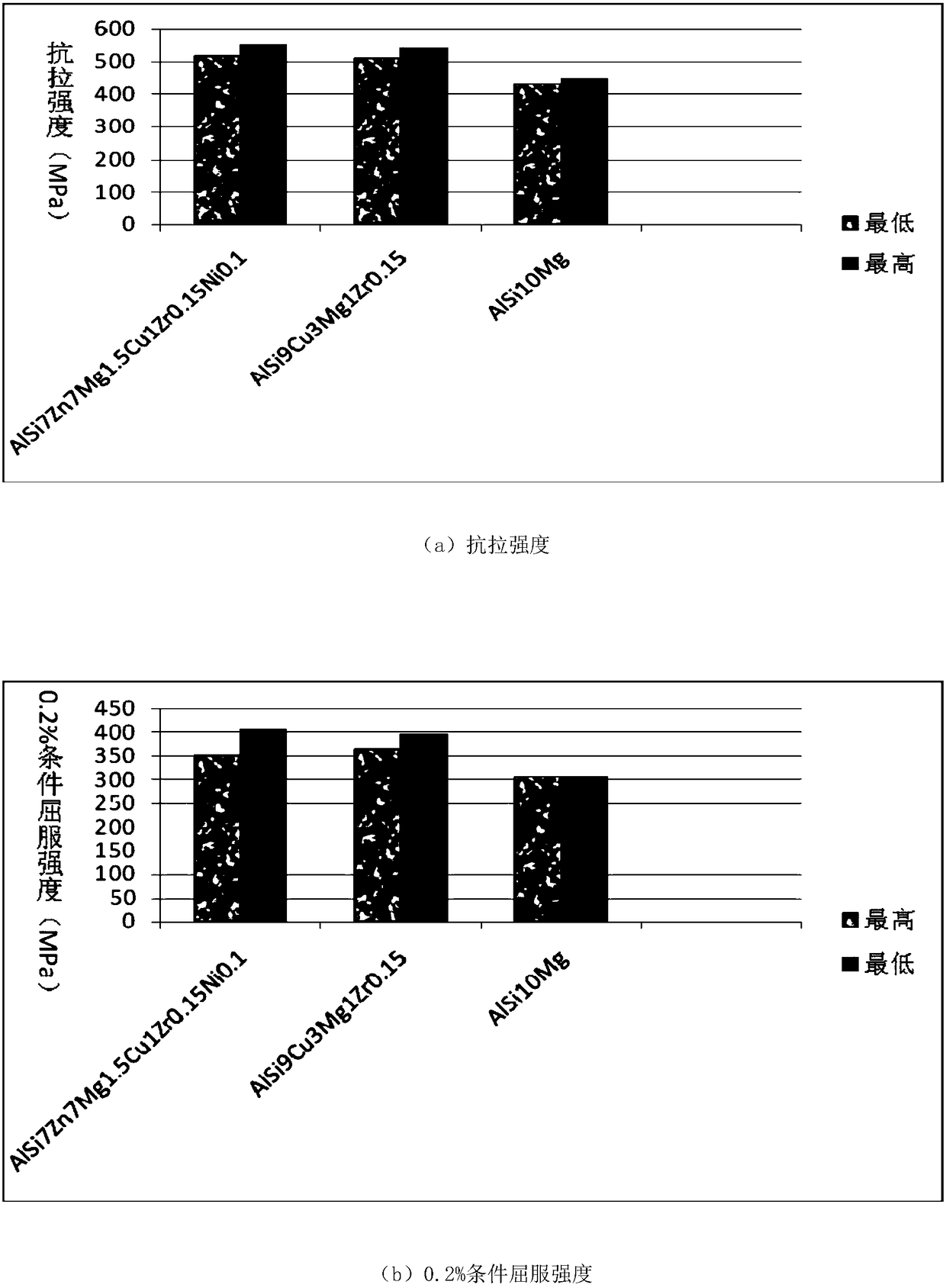

[0047] Table 1 shows the tensile properties and elastic modulus at room temperature of the additively manufactured samples of the aluminum alloy powder of Example 1 in different states.

[0048] Table 1 Room temperature tensile properties and elastic modulus (XY direction) of additively manufactured samples of Al-Si-Zn-Mg-Cu-Ni-Zr aluminum alloy powder in different states

[0049]

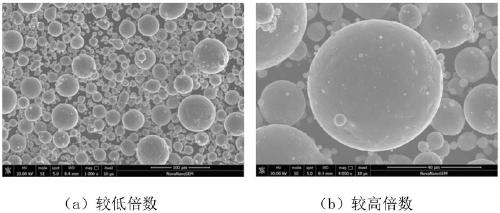

[0050] High-strength aluminum alloy powder for additive manufacturing with the above components by gas atomization process, such as figure 1 shown, and then sieved to select powders with a particle size of 10–60 μm for selective laser melting additive manufacturing. The additive manufacturing was carried out on the BLT-S200 selective laser melting equipment, and the test rod of Φ13×80mm was prepared. Some of the test bars were annealed at 120°C / 2h, 120°C / 24h, 165°C / 2h, 175°C / 2h, and 185°C / 2h.

[0051] According to the regulations of HB5143-1996, process the above-mentioned manufactured and ann...

Embodiment 2

[0053] Table 2 shows the tensile properties and elastic modulus at room temperature of the additively manufactured samples of the aluminum alloy powder of Example 2 in different states.

[0054] Table 2 Room temperature tensile properties and elastic modulus (XY direction) of additive manufacturing samples of Al-Si-Cu-Mg-Zr aluminum alloy powder in different states

[0055]

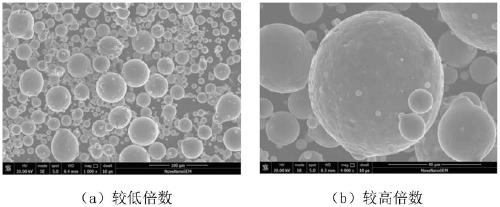

[0056] The high-strength aluminum alloy powder for additive manufacturing with the above components is used in the gas atomization process, and then sieved, and the powder with a particle size of 10-60 μm is selected for selective laser melting additive manufacturing. The additive manufacturing was carried out on the BLT-S200 selective laser melting equipment, and the test rod of Φ13×80mm was prepared. Some of the test bars were annealed at 120°C / 2h and 177°C / 2h respectively.

[0057] According to the regulations of HB5143-1996, process the above-mentioned manufactured and annealed test bars into Φ5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com