Circulating winnowing machine

A technology of circulating air and air suction duct is applied in chemical instruments and methods, solid separation, and separation of solids from solids by air flow. Avoid heat loss and save the effect of dust removal equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

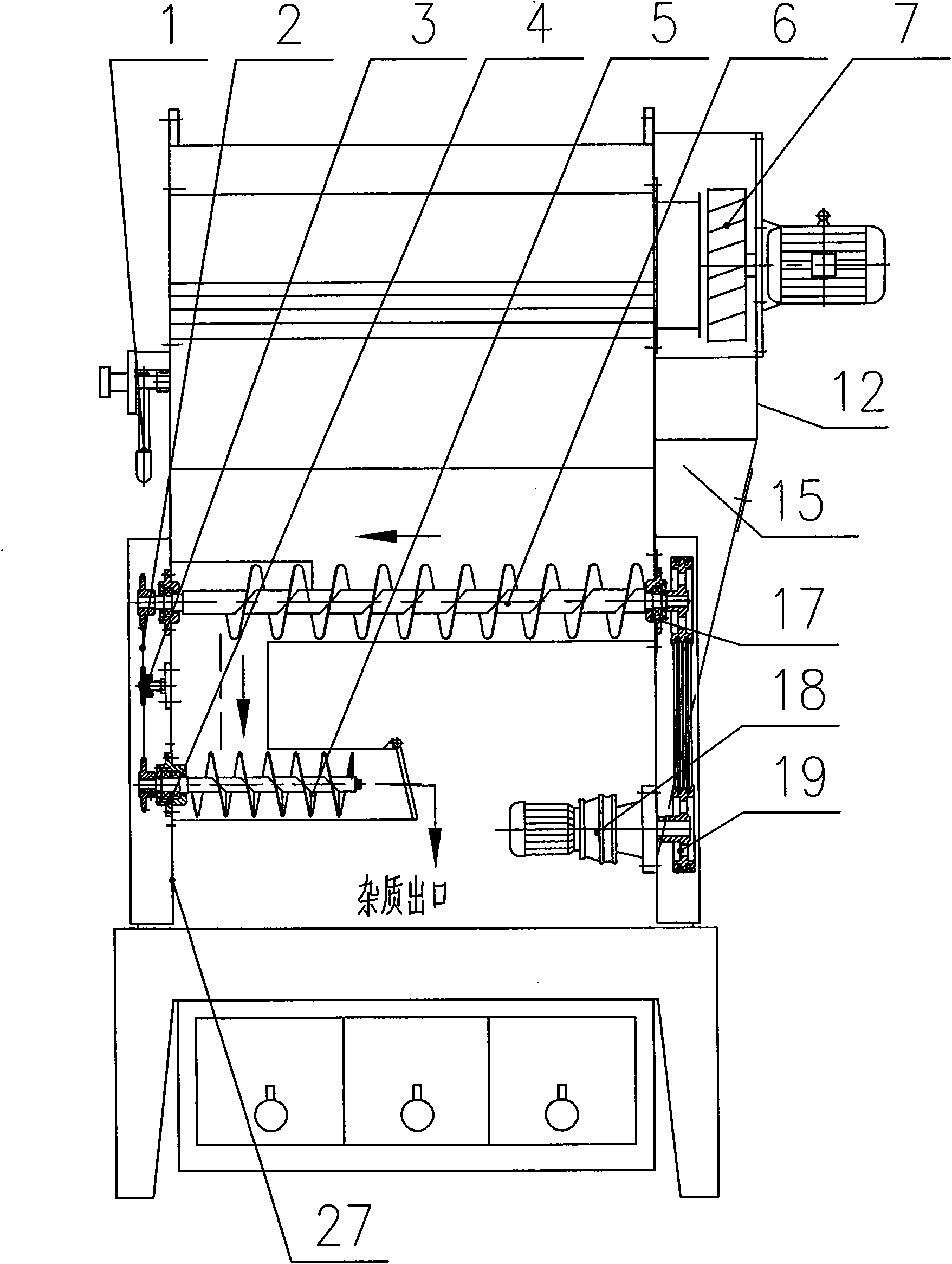

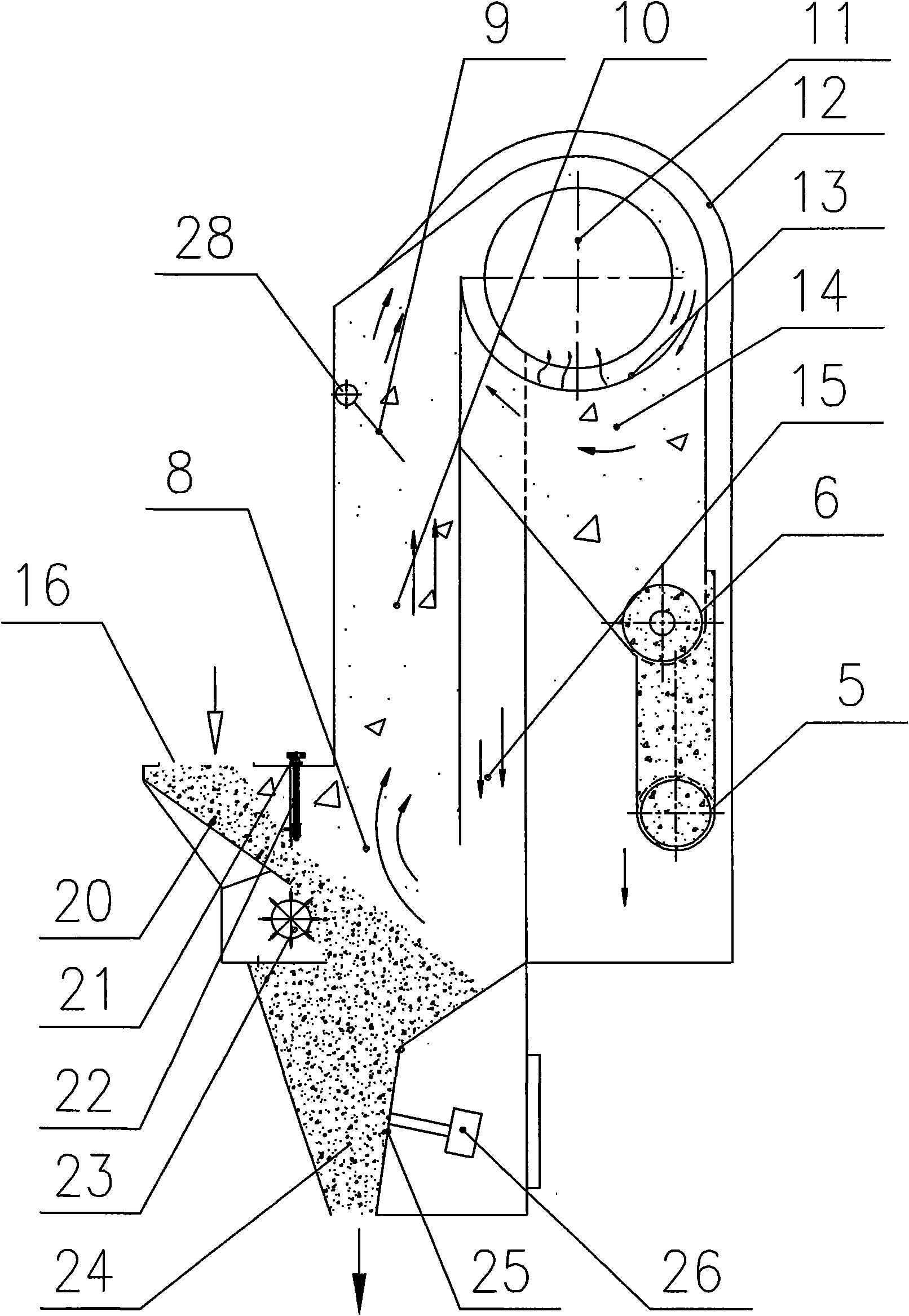

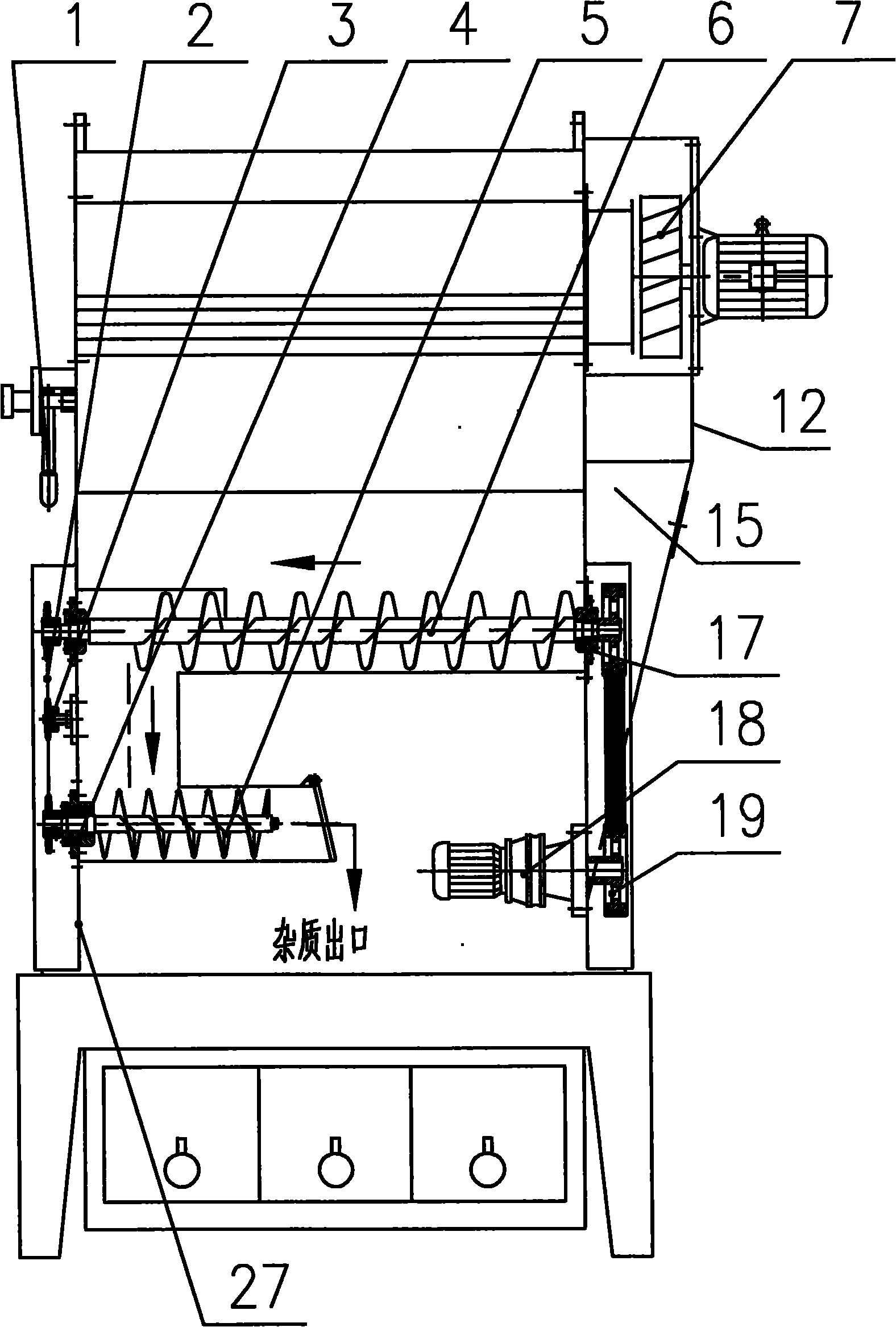

[0022] Such as figure 1 , 2 As shown, it is a circulating air separator, including a frame 27 , the rear end of the frame 27 is provided with a feed port 16 and a discharge port 24 , and the discharge port 24 is arranged below the feed port 16 . At least one screed plate 20 is fixedly connected in the frame 27 , each screed plate 20 is arranged at the feed inlet 16 respectively, and the left and right ends of each screed plate 20 are respectively arranged on the left and right sides in the frame 27 . Insert door 22 is also arranged in frame 27, and the left and right ends of insert door 22 are respectively arranged on the left and right sides of frame 27, and at least two nuts are welded on the side upper end of insert door 22, and an adjusting bolt 21 is inserted in each nut. , the other end of each adjusting bolt 21 is respectively inserted on the frame 27 and is equipped with a hexagonal star handle. In the frame 27, a leveling roller 23 is also arranged, and the leveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com