Patents

Literature

42results about How to "Guaranteed leveling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

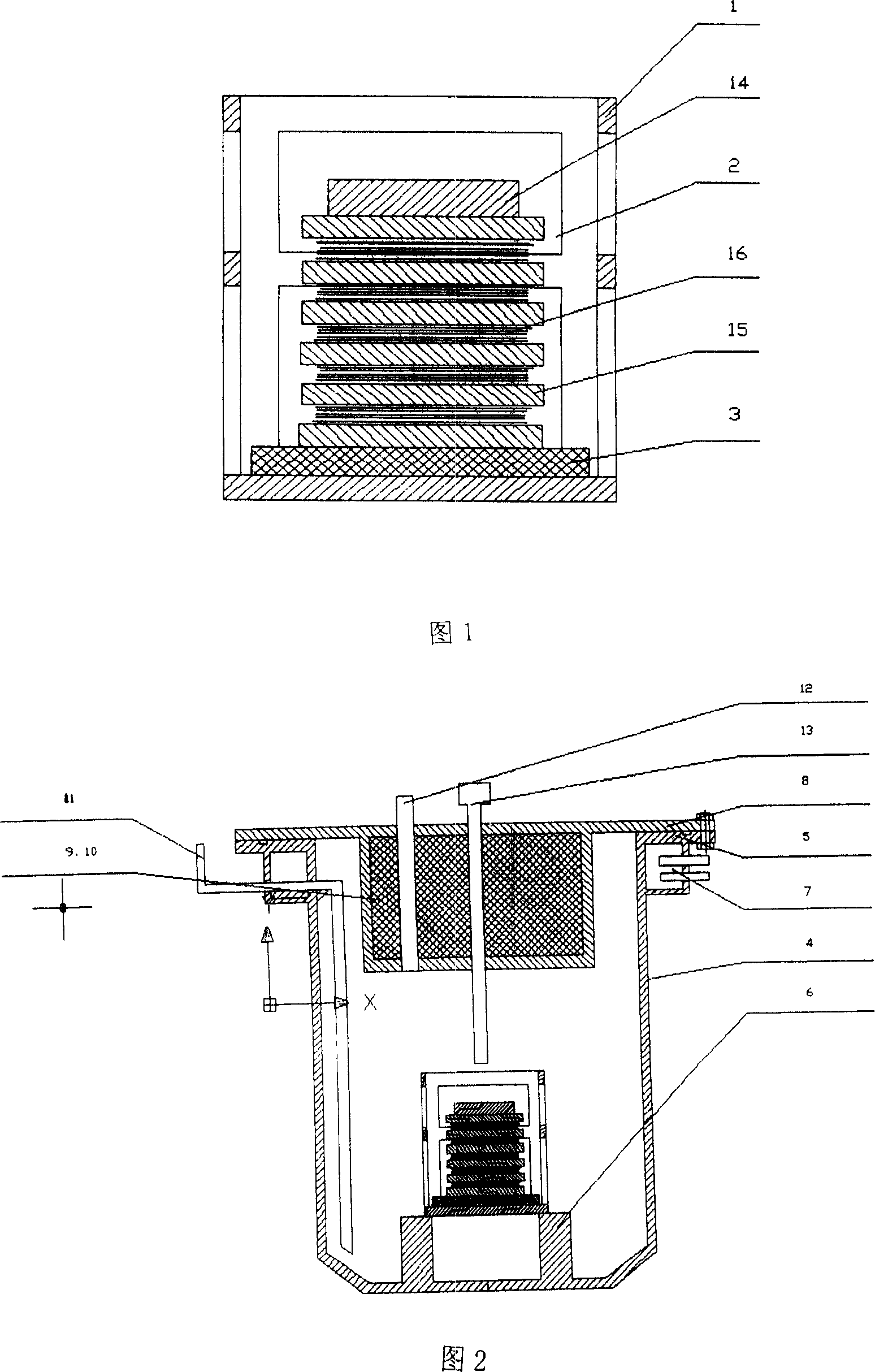

Method for leveling tungsten plate with high straightness

The invention relates to a method for correcting tungsten plate, which comprises it uses the high-temperature molybdenum alloys with high flat degree or TZM alloy as the correct compression block; puts the tungsten plat at the middle of compression block; arranges tungsten block above the top compression block as the weight; then puts them in the steel basket resistant to high temperature; puts at the bottom of correct insulated protective pot with hydrogen gas; then puts the pot in upright resistance furnace to be heated, corrects the pressure and weight of compression block, then cooling to room temperature. The invention uses the correct compression block which will not deform at high temperature, to conform the correct effect. And it uses hydrogen gas and the cooling water sheath to form heating pot to avoid oxidizing tungsten plate.

Owner:WESTERN METAL MATERIAL

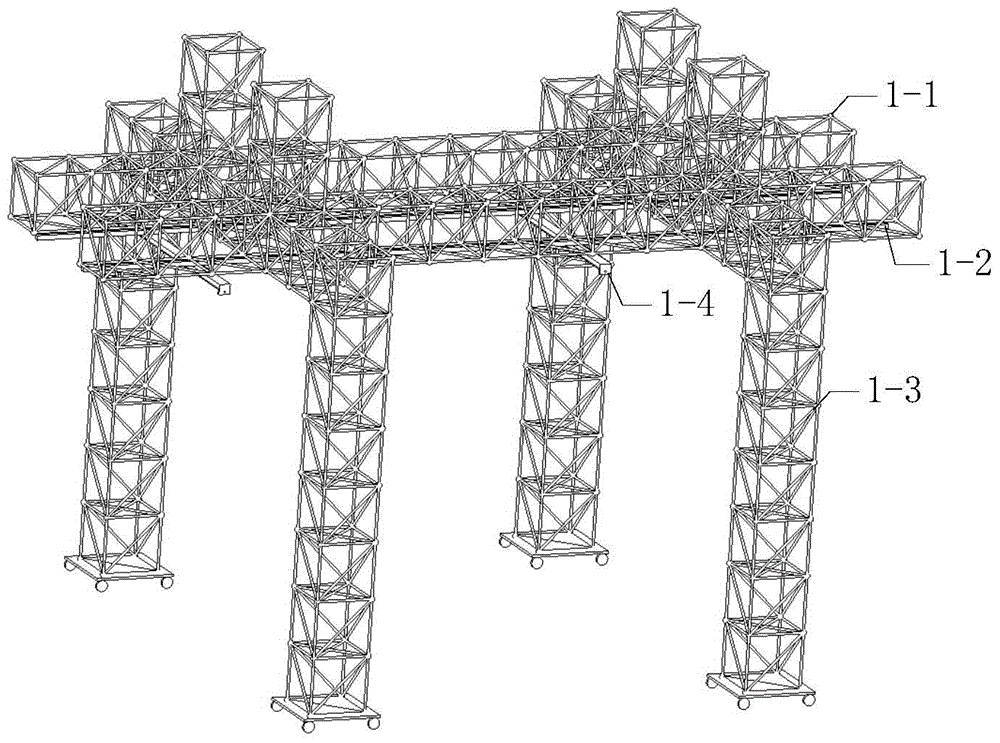

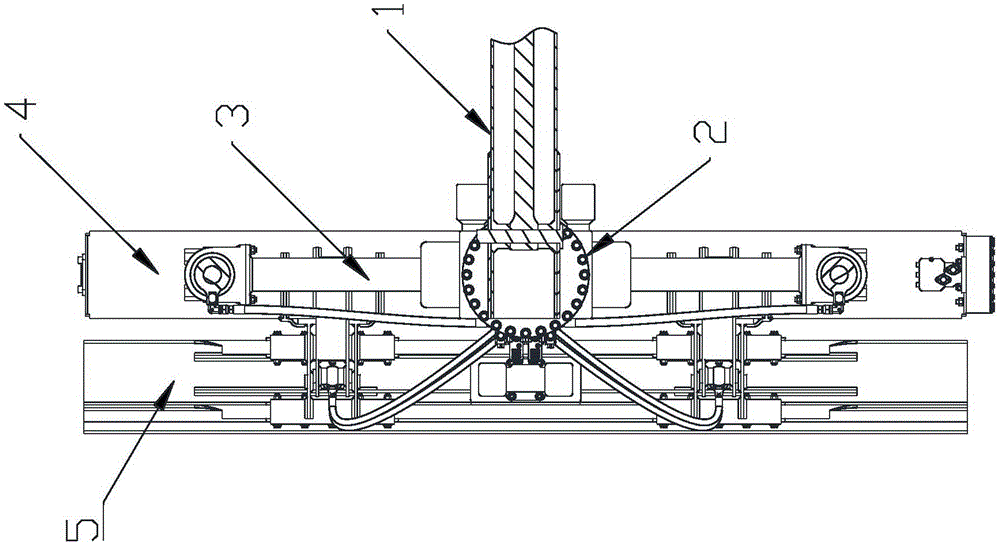

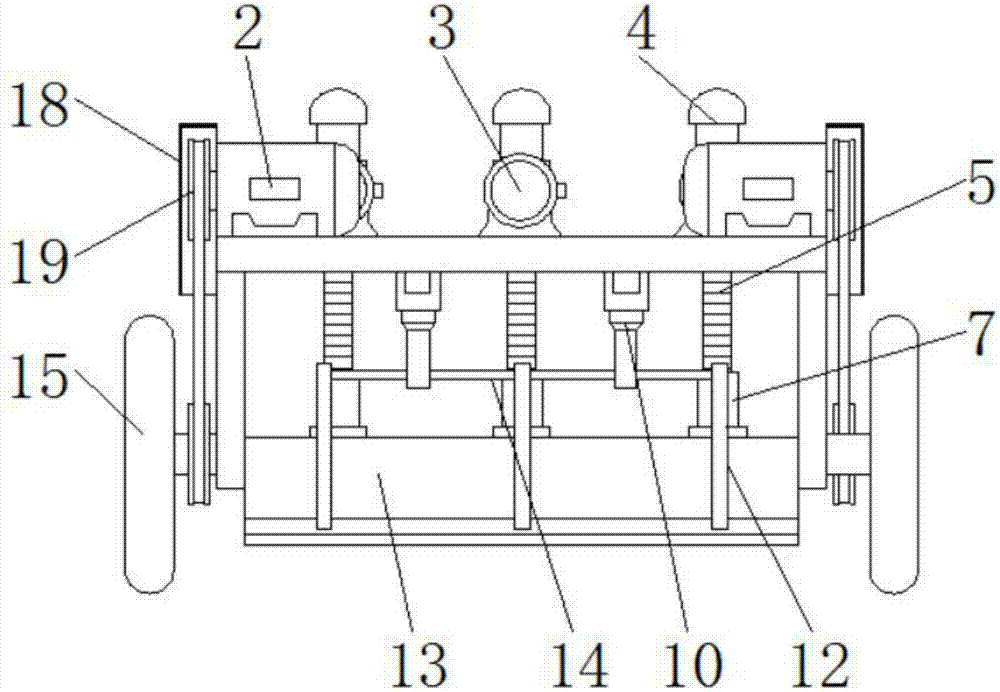

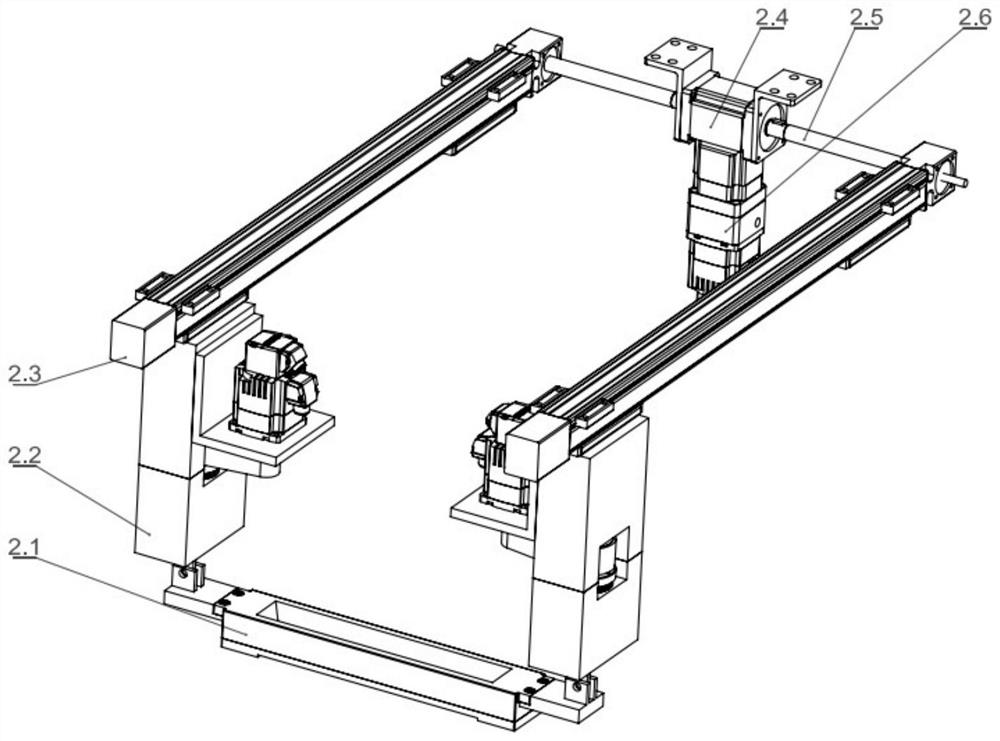

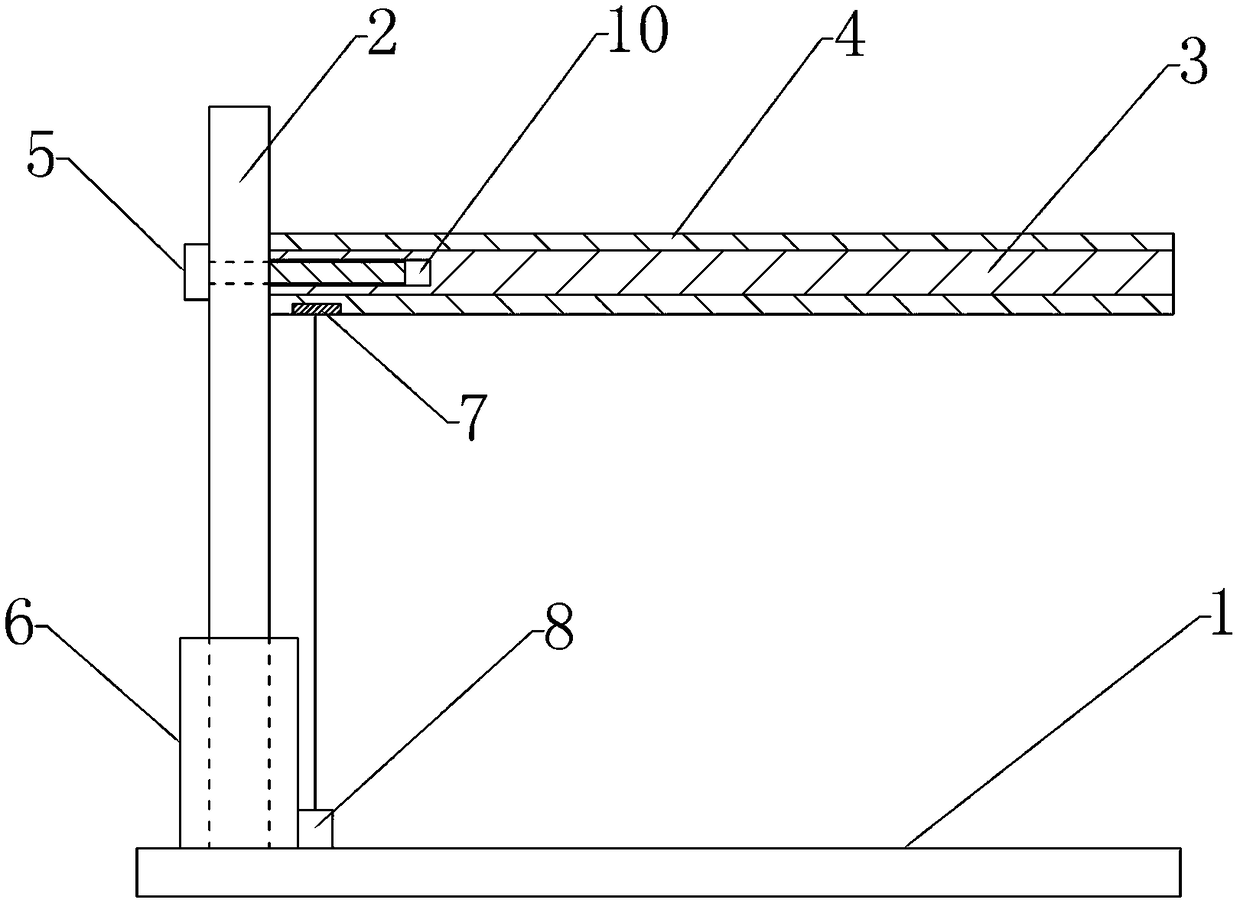

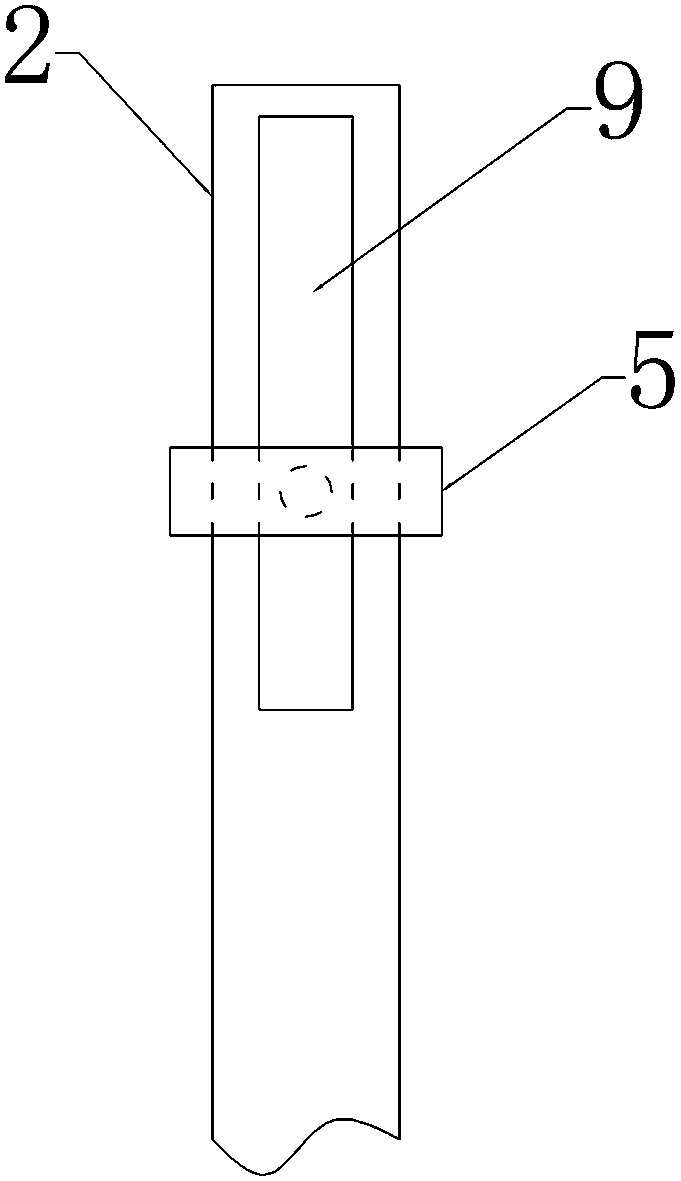

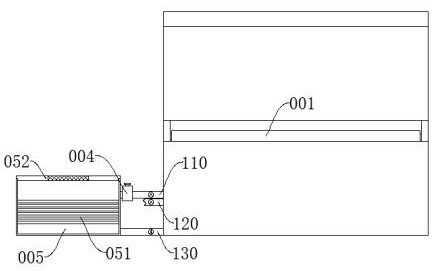

General satellite sun wing expanding frame automatically adjusting levelness

InactiveCN104943877AEliminate wobbleAccurate automatic adjustmentCosmonautic condition simulationsControl systemSatellite

The invention discloses a general satellite sun wing expanding frame automatically adjusting levelness. The general satellite sun wing expanding frame automatically adjusting levelness is composed of a mechanical system and a control system. The mechanical system mainly comprises two upper guide rails, two driving mechanisms, a main beam, a hinged telescopic mechanism and a rigid connection telescopic mechanism. The mechanical system of the sun wing expanding frame is fixed to opposite brackets arranged on the two sides of an infrastructure, and the two upper guide rails are welded to the brackets. The upper guide rails are connected with the main beam. The main beam is driven by the driving mechanisms to move on the upper guide rails, and then the whole system can move in the appointed area. According to the general satellite sun wing expanding frame automatically adjusting levelness, a contact gap and unnecessary constraint are eliminated, a lifting mechanism ascends and descends freely, the clamping phenomenon in the lifting process is eliminated, swinging of a platform is eliminated, the leveling effect and stability of the system are guaranteed, the position of the expanding frame is changed freely, and the expanding frame ascends and descends freely in the height direction, and the accurate and automatic adjustment of 0.04 mm / m of the levelness of the guide rails is achieved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

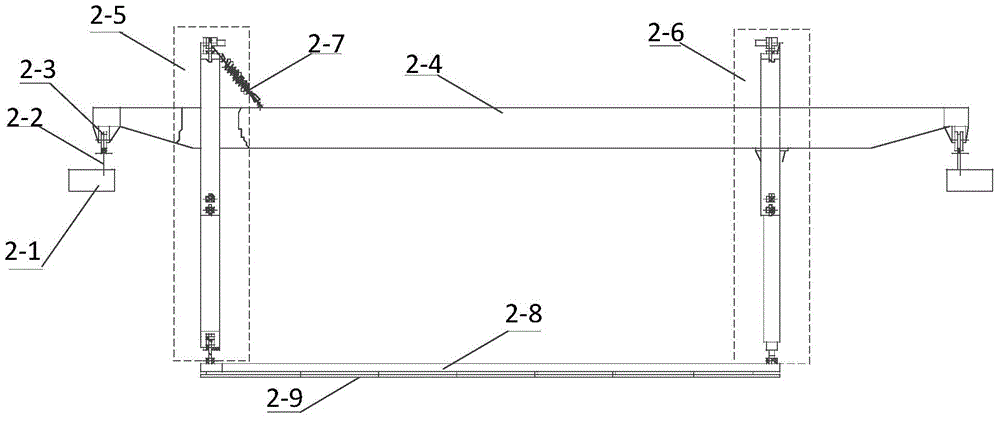

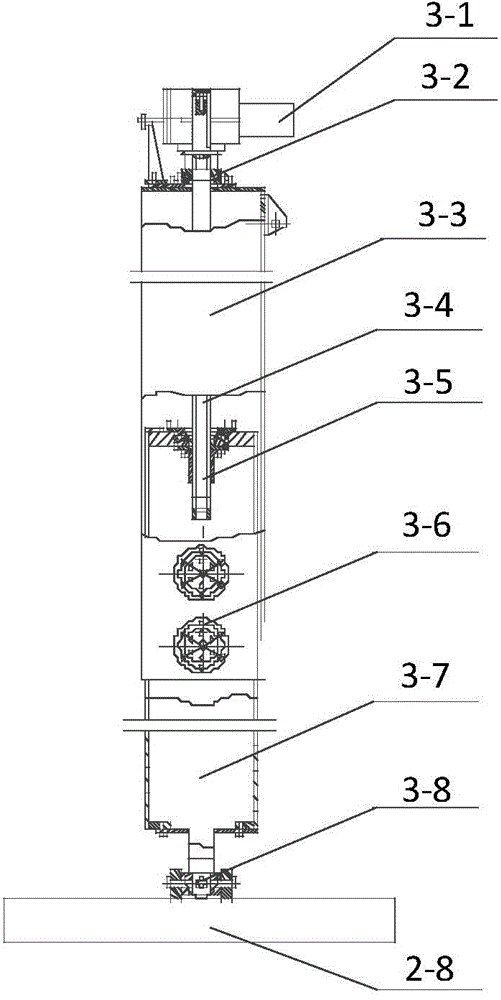

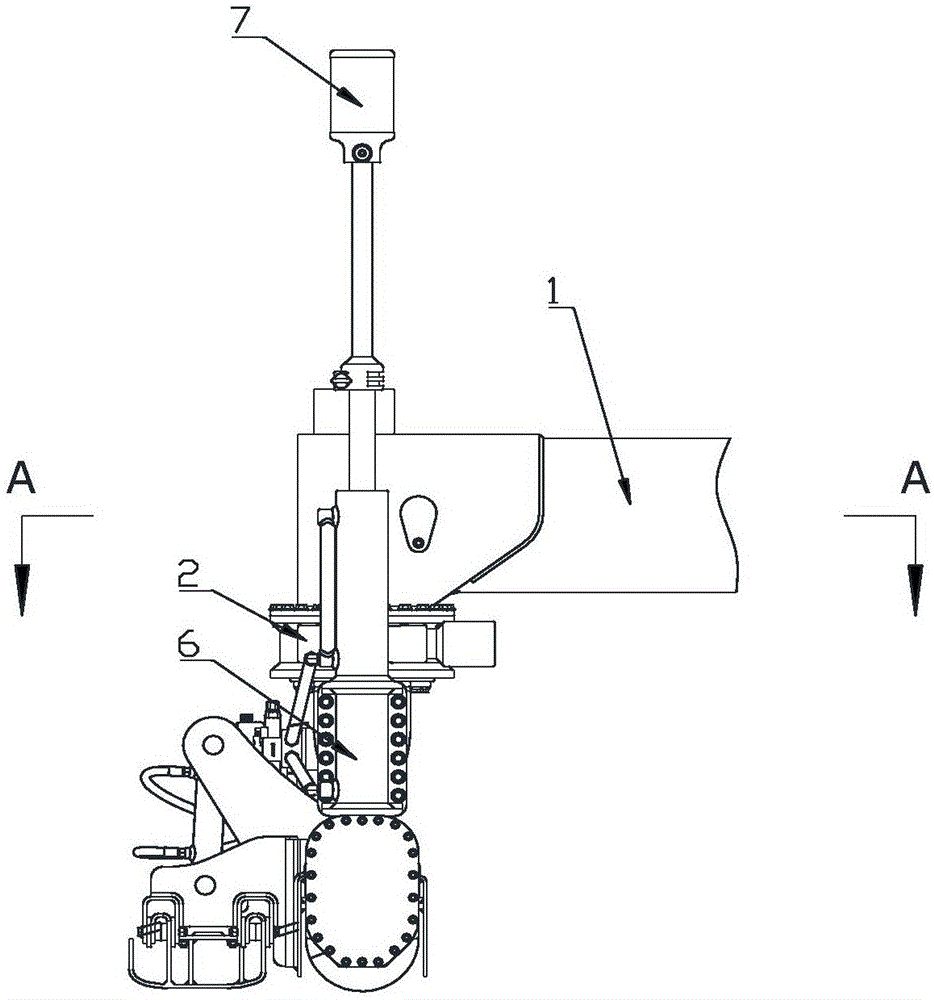

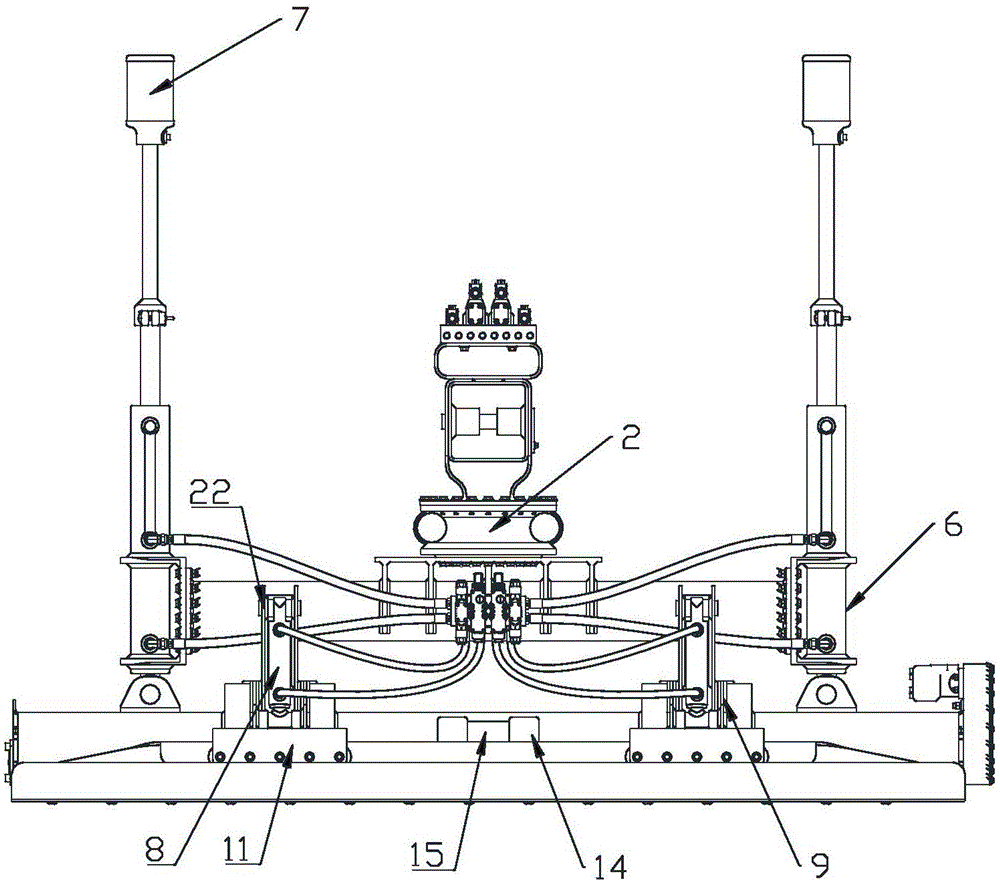

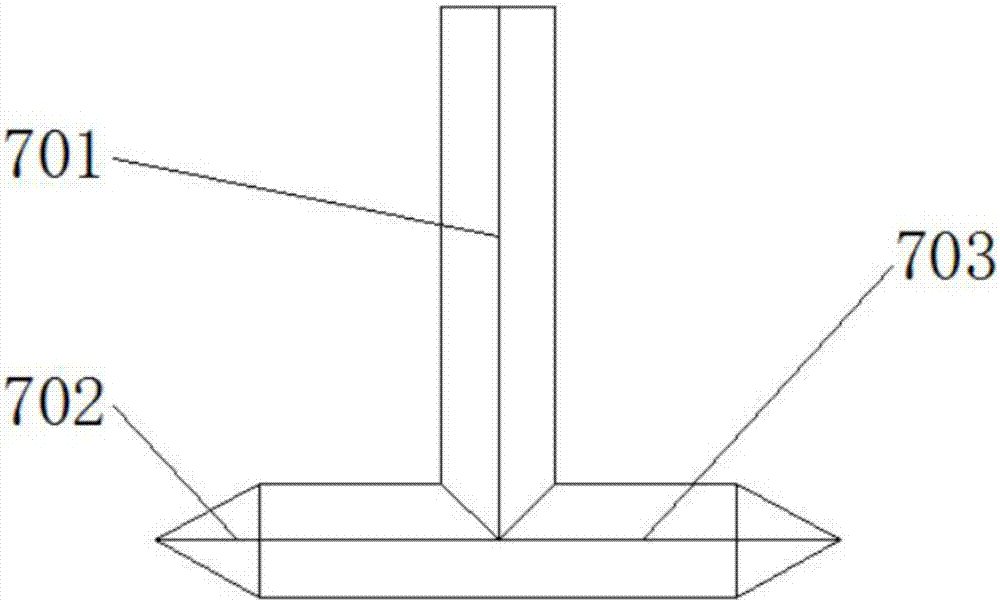

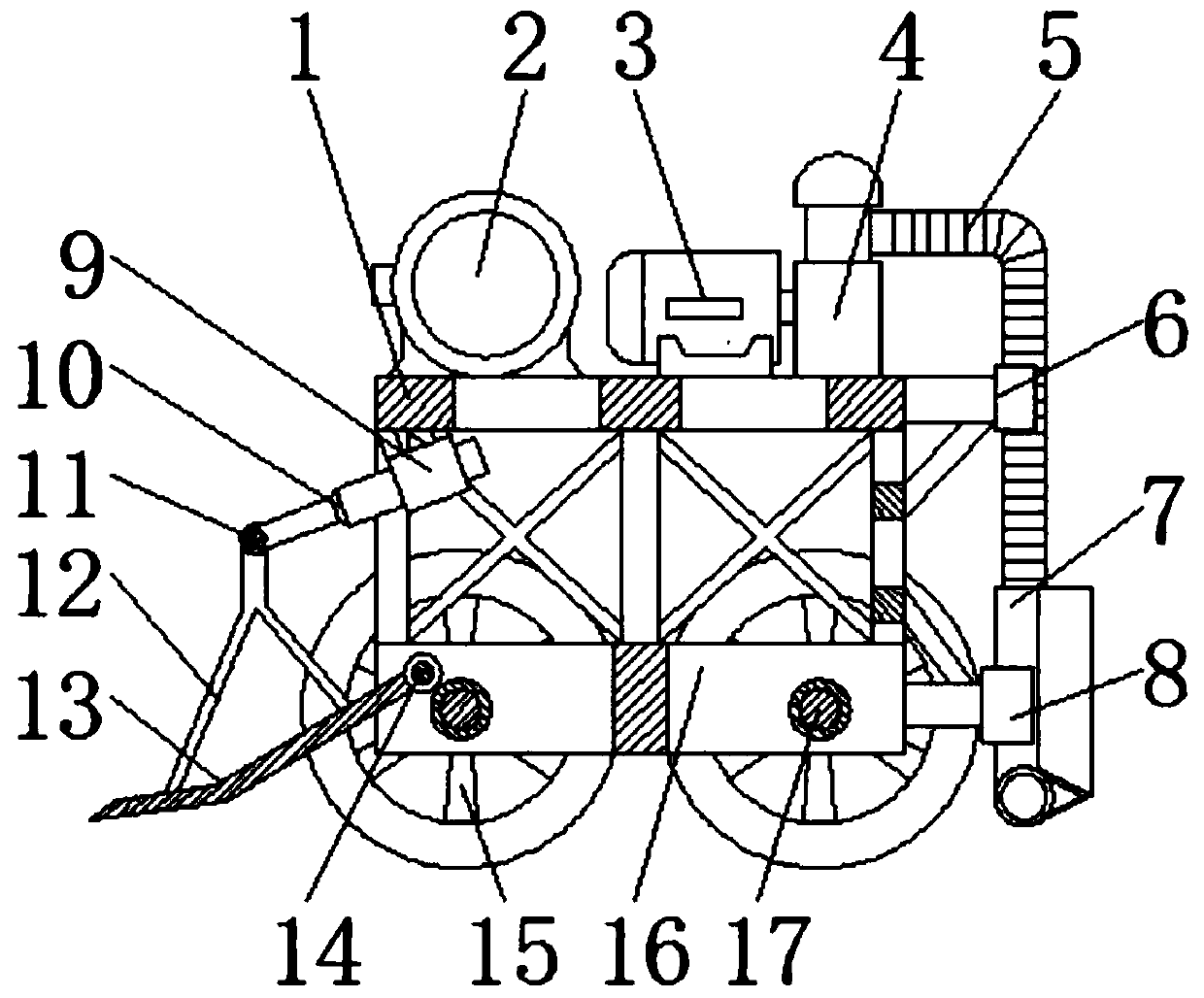

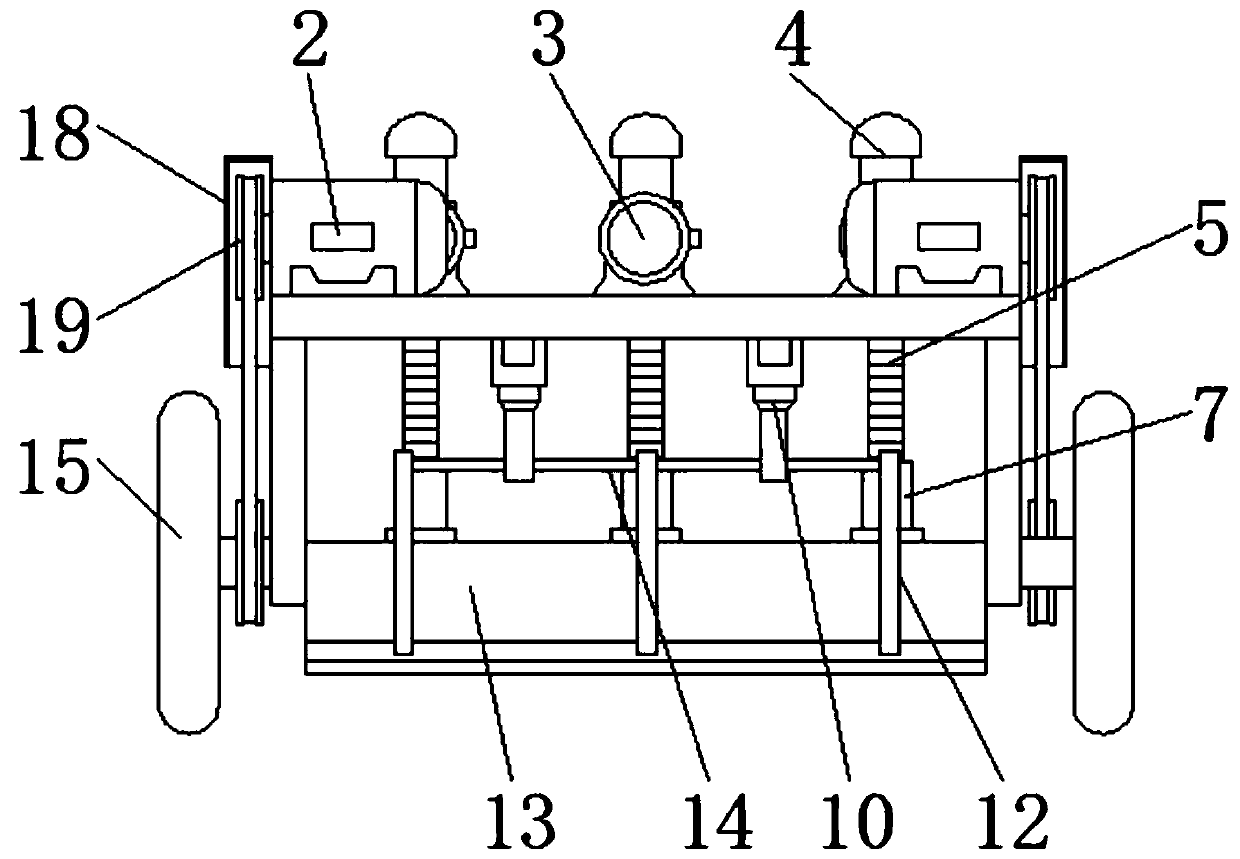

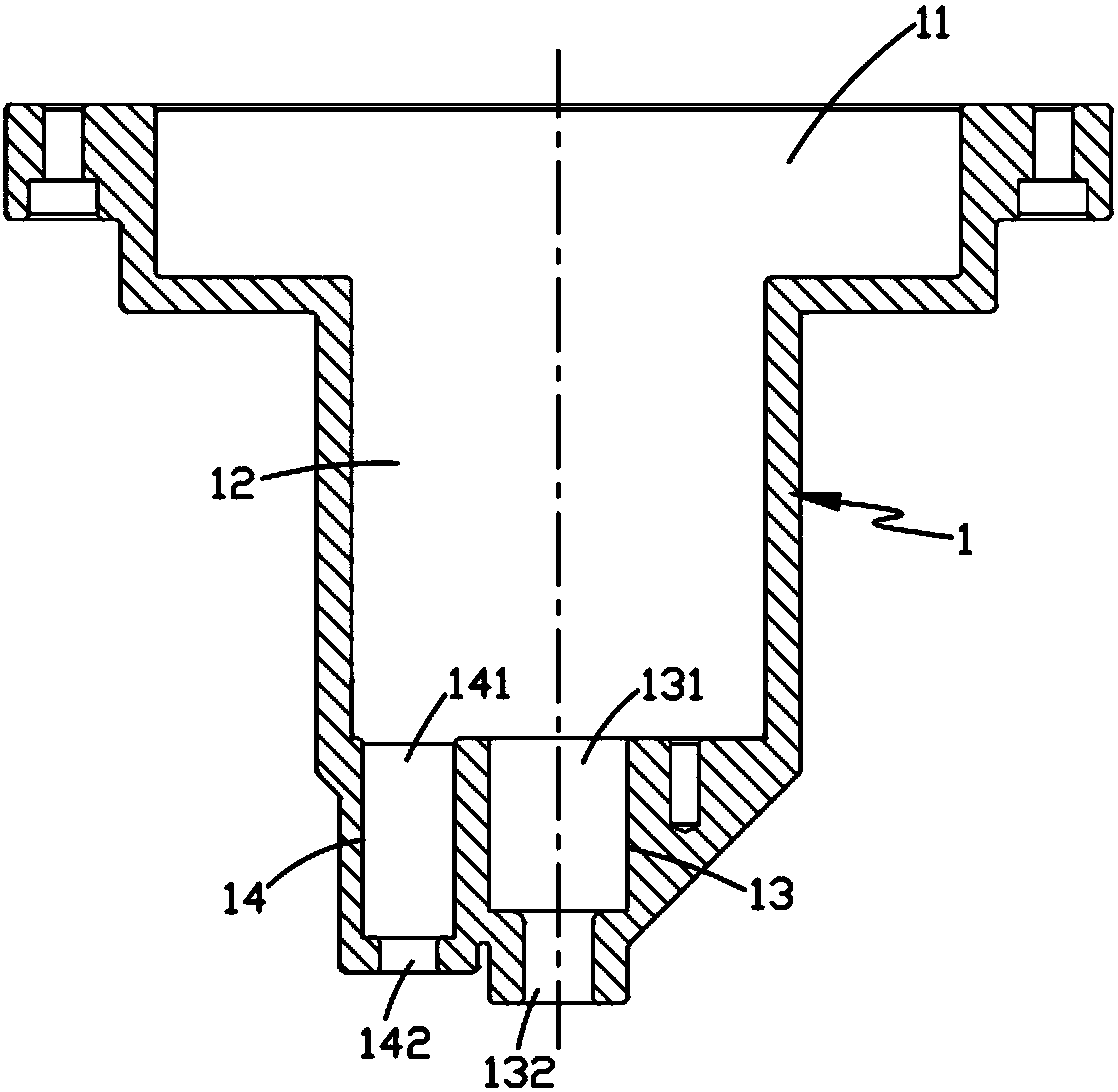

Leveling head

ActiveCN105040963AImproved lifting structureAchieve vertical liftBuilding constructionsEngineeringMechanical engineering

The invention discloses a leveling head which comprises a telescopic beam, a rotary connector, a leveling head transverse beam, a spiral stirring distributing tank and a screeding plate. The telescopic beam, the rotary connector, the leveling head transverse beam, the spiral stirring distributing tank and the screeding plate are sequentially arranged from top to bottom, the rotary connector is arranged below the front end of the telescopic beam, the leveling head transverse beam is horizontally fixedly connected to the lower end of the rotary connector, and the middle of the leveling head transverse beam is fixedly connected with the lower end of the rotary connector; double outlet-rod cylinders are respectively vertically fixedly arranged at two ends of the leveling head transverse beam; the tops of lower piston rods of the double outlet-rod cylinders are movably hinged to the top of the spiral stirring distributing tank; screeding plate lifting cylinders are respectively arranged on two sides of the centers of the side walls of the spiral stirring distributing tank, and piston rods of the screeding plate lifting cylinders downwardly extend; guide plates are respectively arranged on the side walls of the spiral stirring distributing tank, vertical guide grooves are formed in the guide plates, connecting frames are vertically slidably clamped on the guide grooves, the upper ends of the connecting frames are movably hinged to the tops of the piston rods of the screeding plate lifting cylinders, and the bottoms of the connecting frames are fixedly connected with the screeding plate.

Owner:SHANDONG VANSE MECHANICAL TECH CO LTD

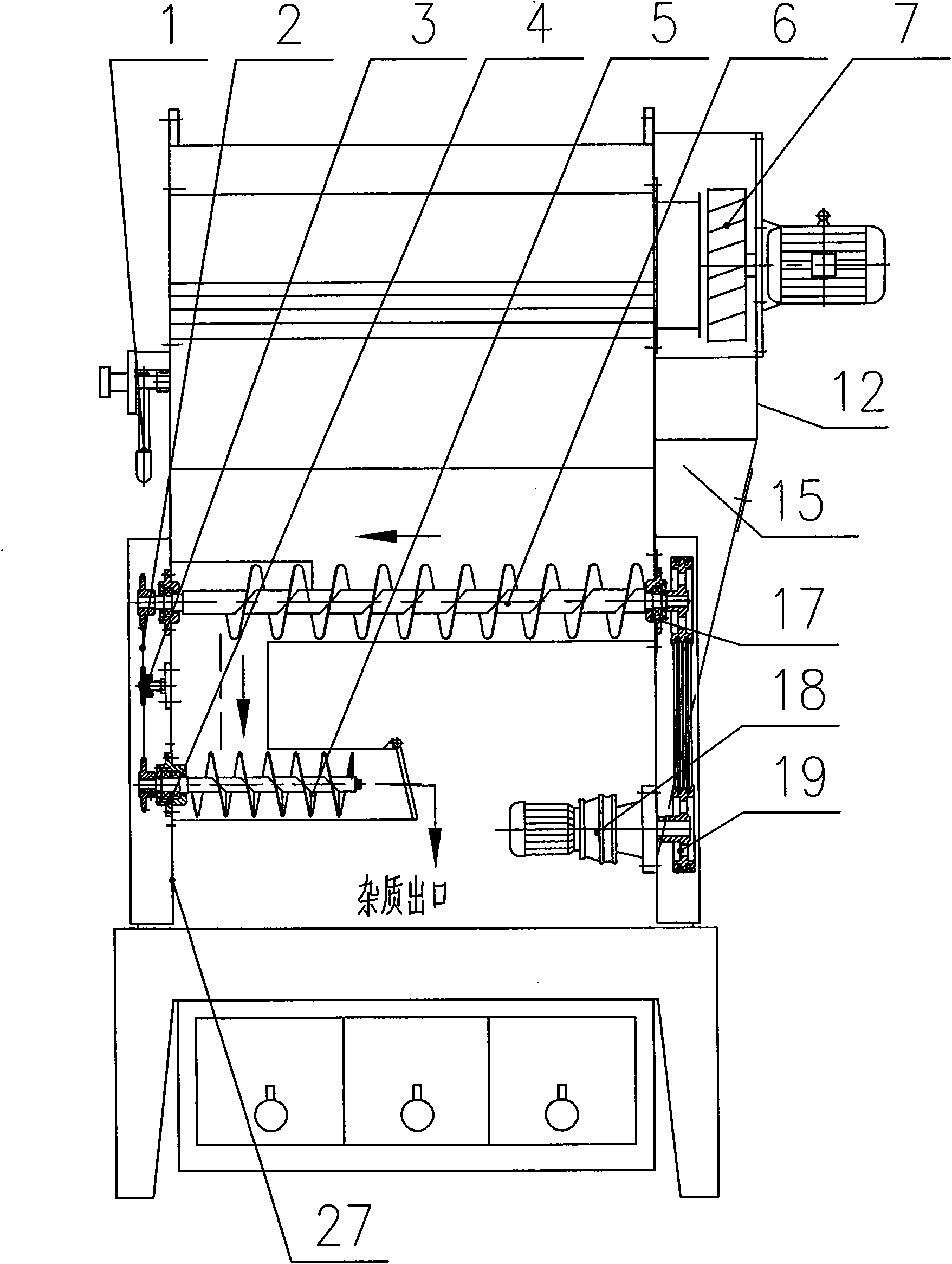

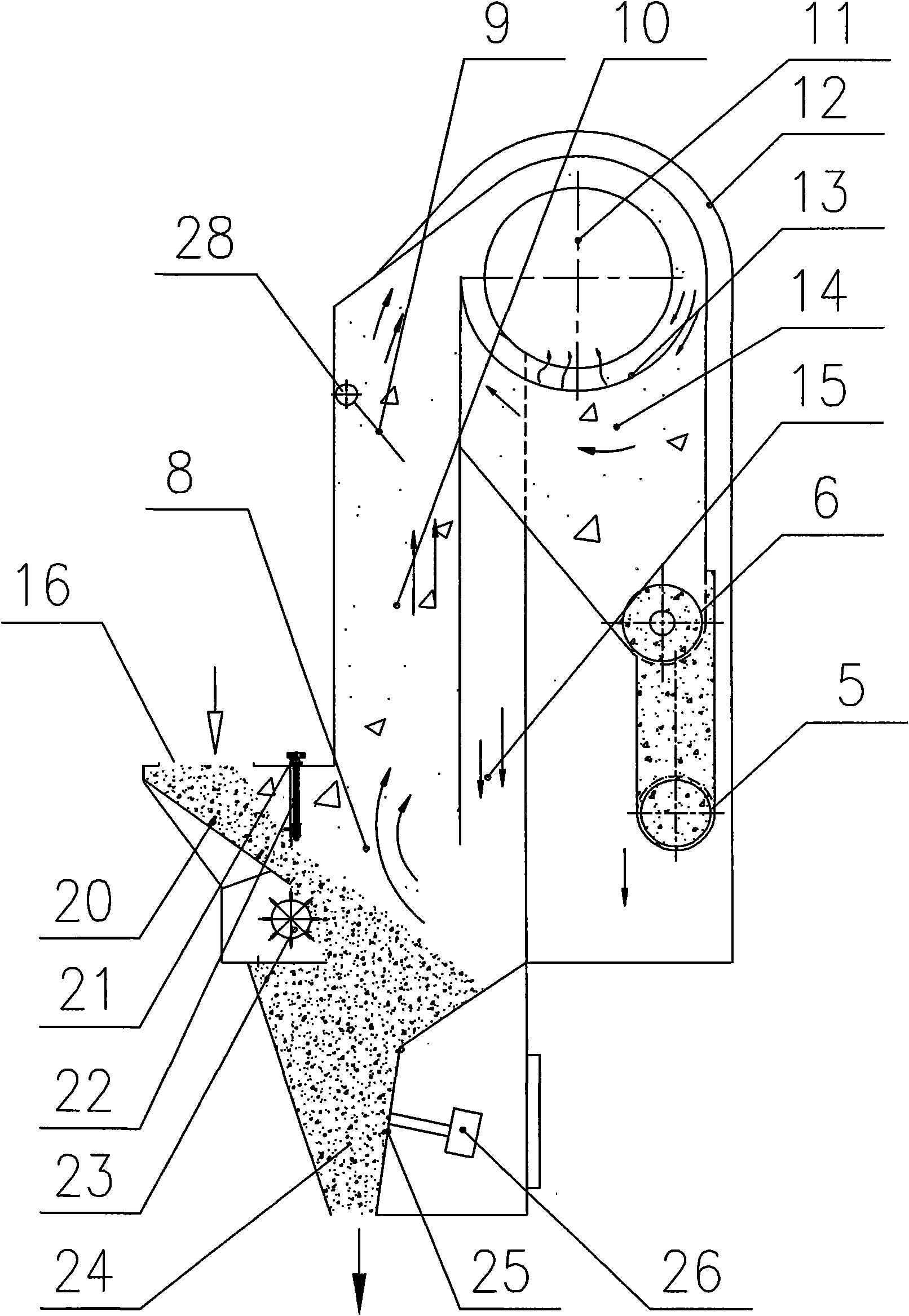

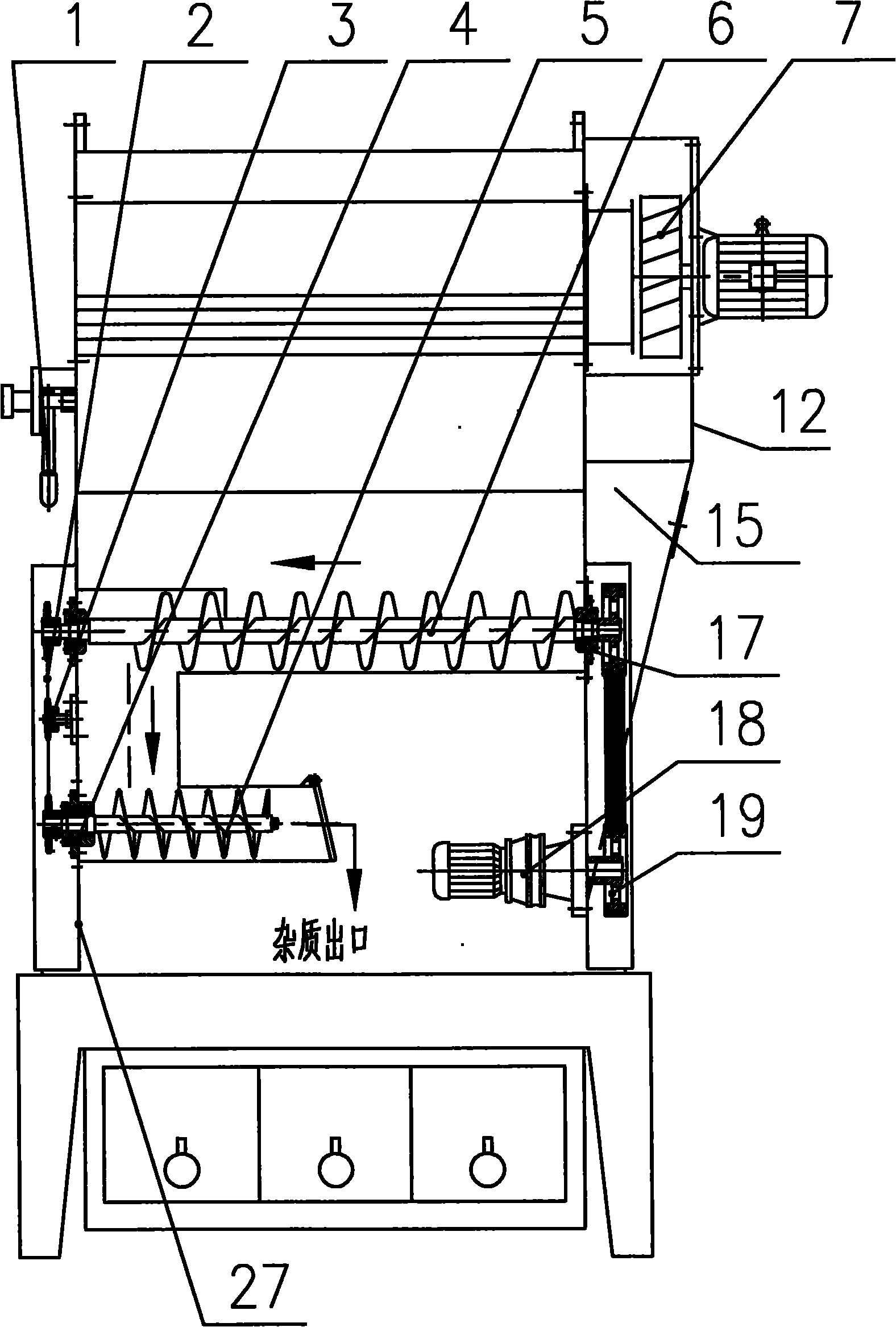

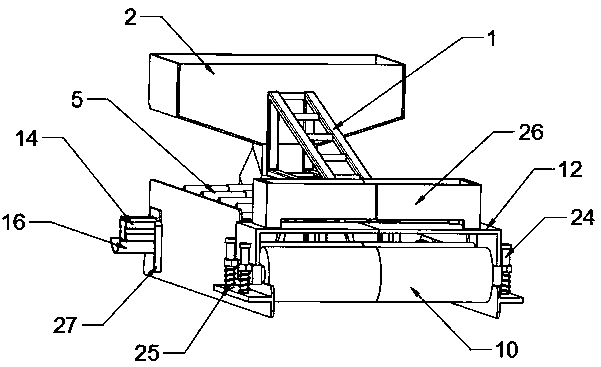

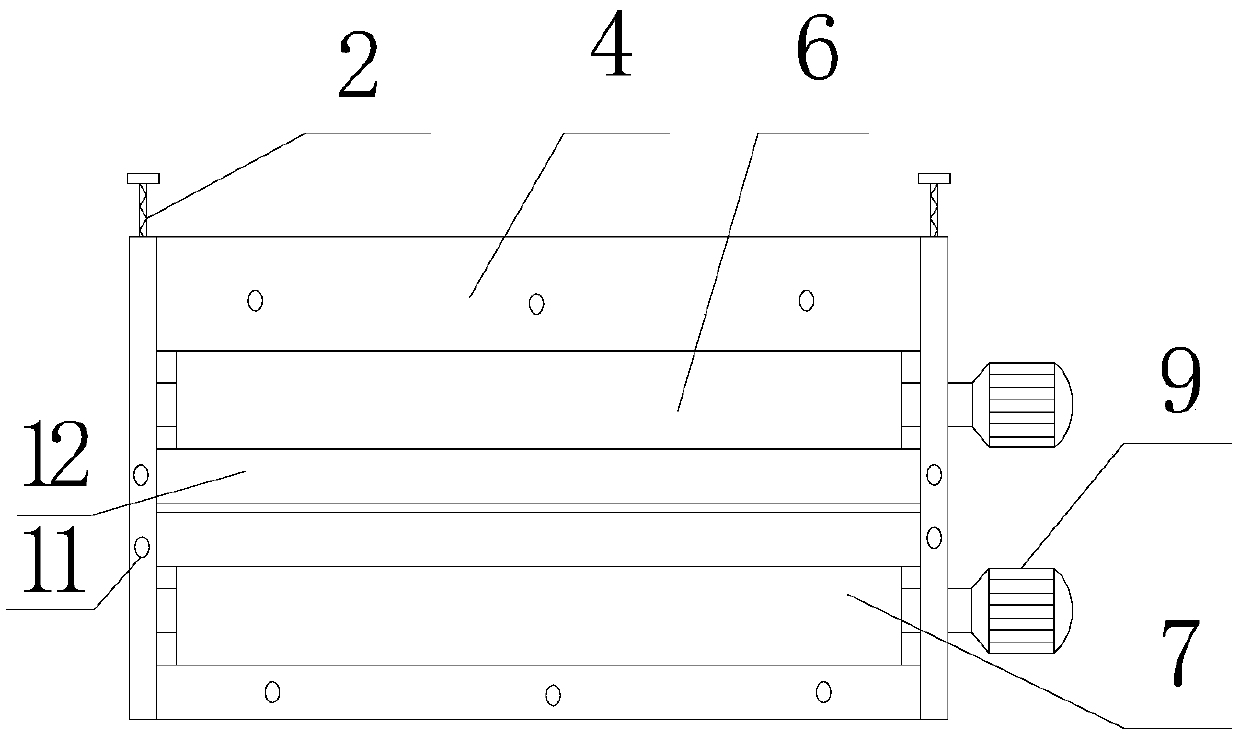

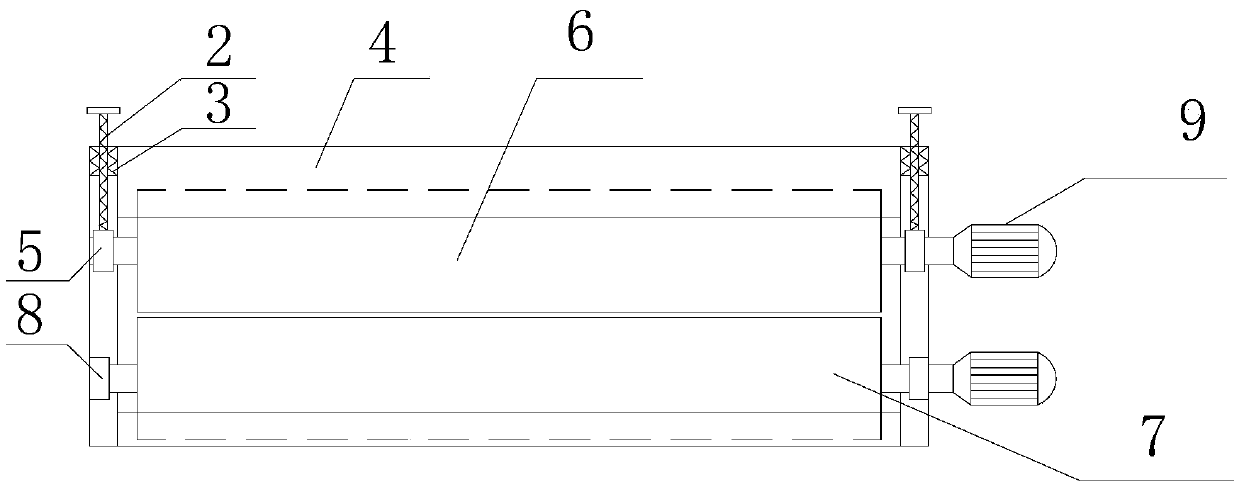

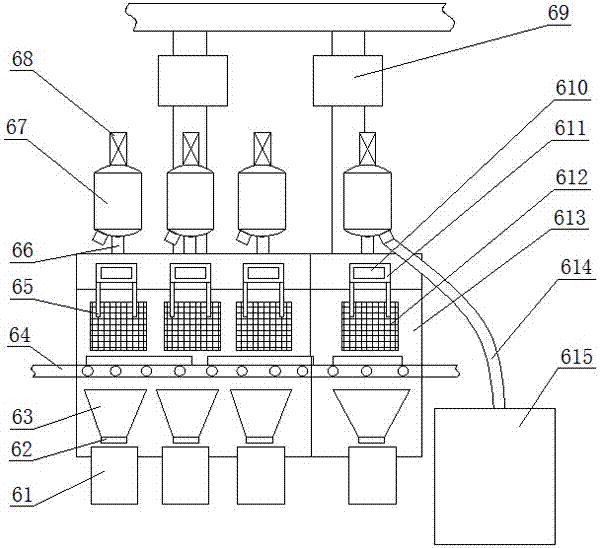

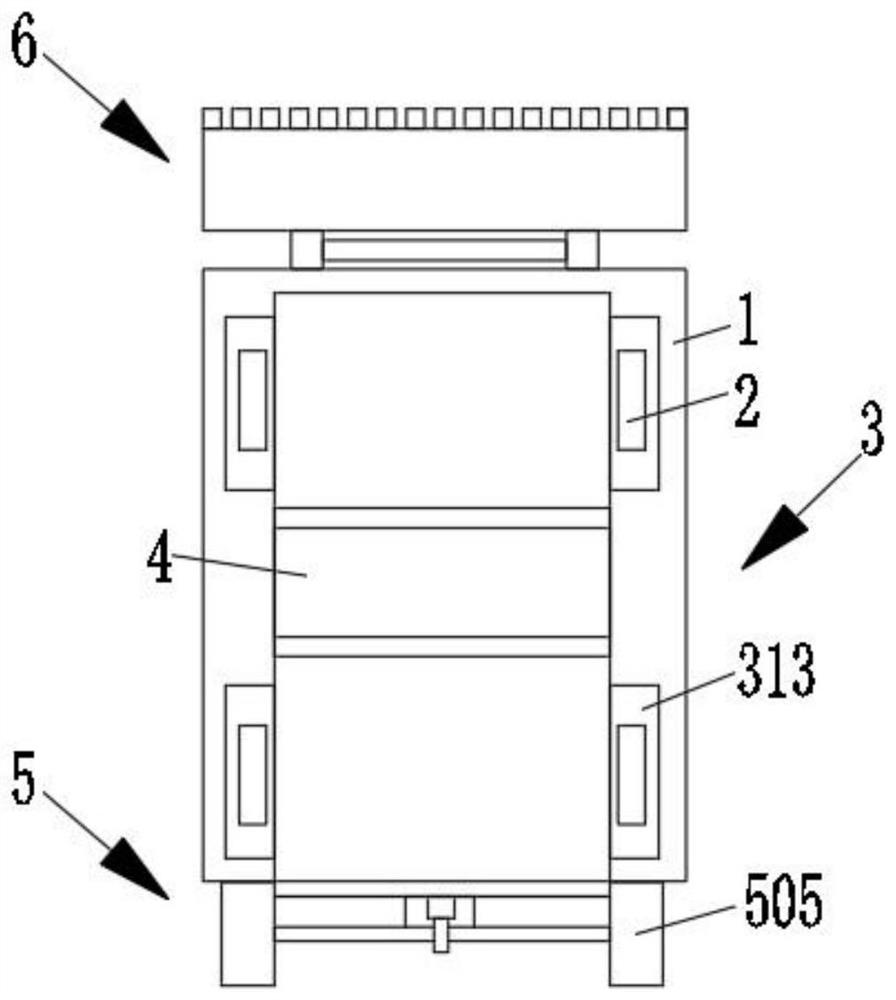

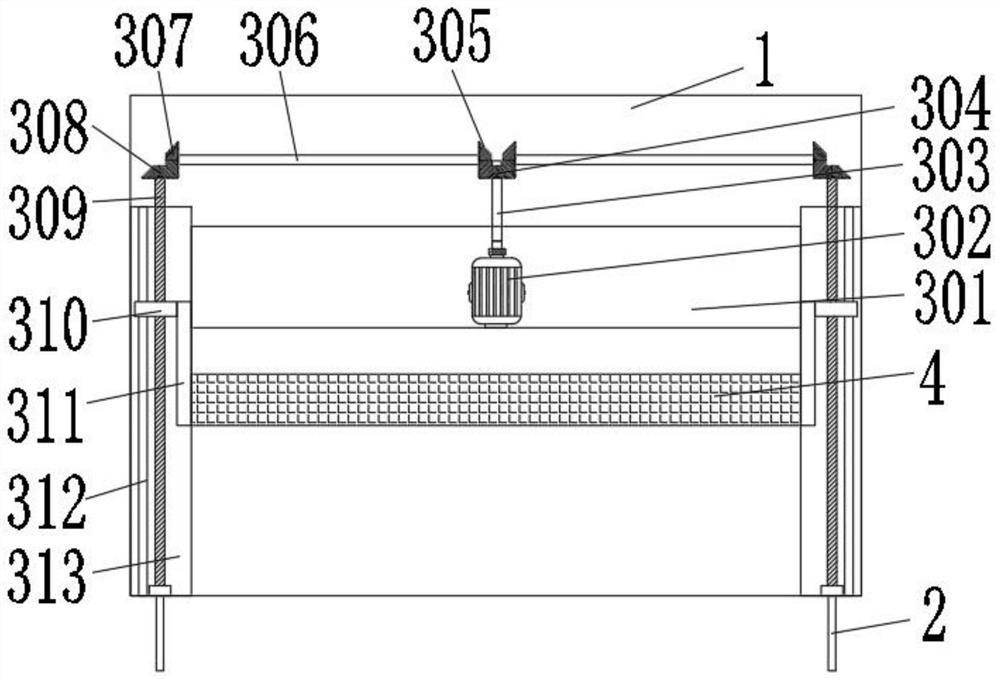

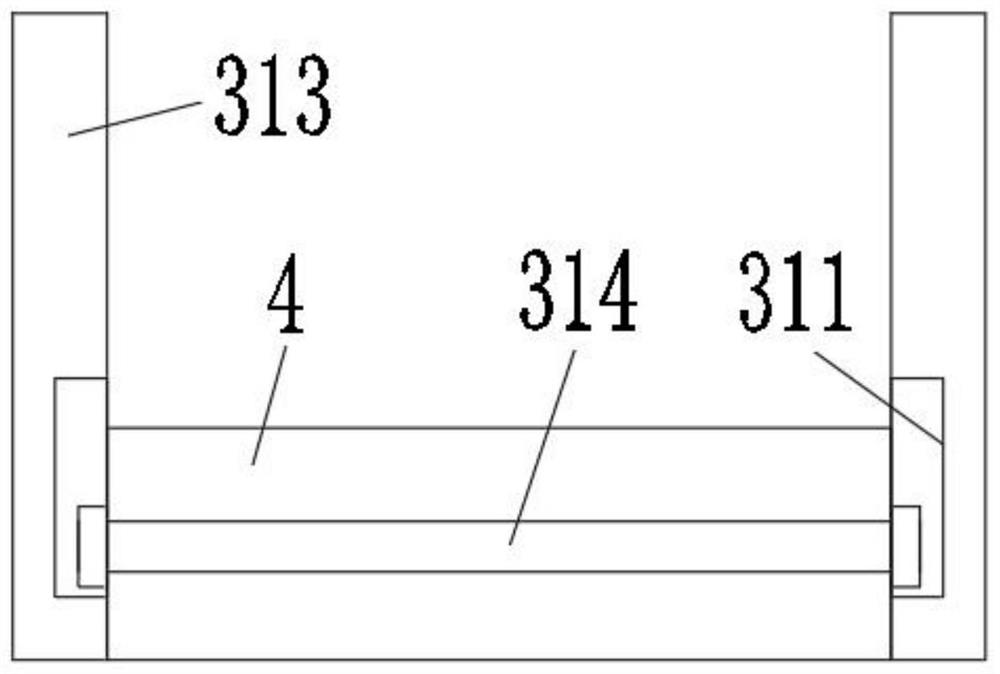

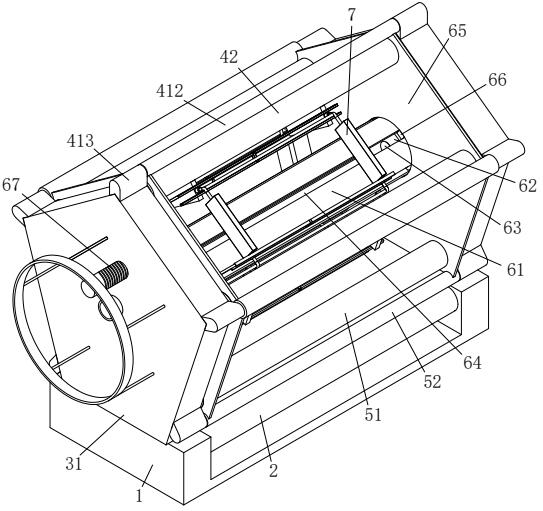

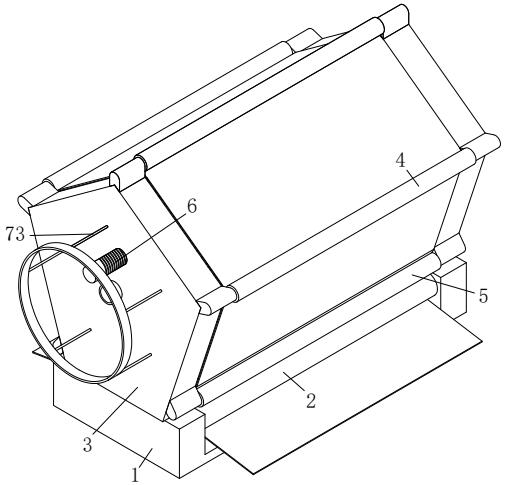

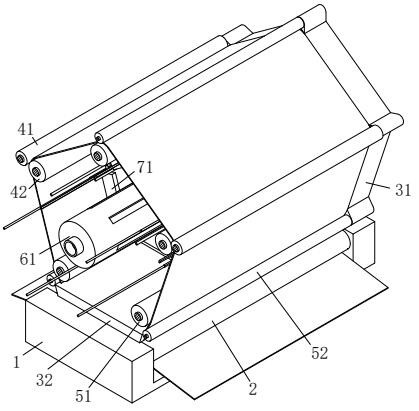

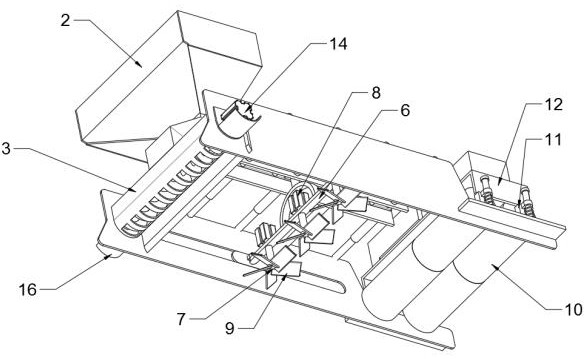

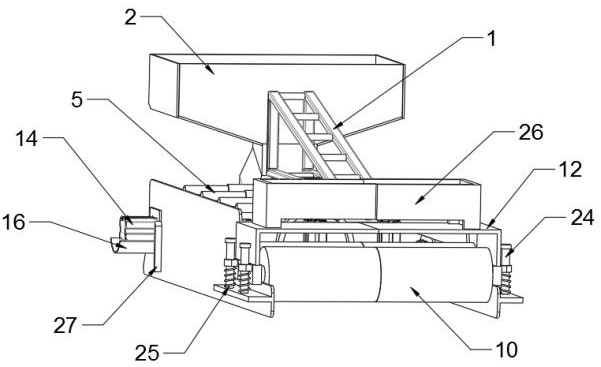

Circulating winnowing machine

InactiveCN101966520ASatisfied with the separation effectGuaranteed craftsmanshipGas current separationEngineeringAirlock

The invention relates to the field of the structure of grain machinery, in particular to a circulating winnowing machine which comprises a stand, wherein a feed port and a discharge port are arranged at the back end of the stand; an air intake channel and a separating zone are arranged in the stand; a separating cartridge is arranged above the separating zone; the separating cartridge is fixedly connected in the stand; a blower is arranged on at least one side of the separating cartridge; the blower is fixedly connected on the stand; a return channel is arranged below the blower outside the stand; the lower end of the return channel is communicated with the air intake channel; a dust chamber is arranged below the separating cartridge; an auger is arranged below the dust chamber; the left end and the right end of the auger are respectively supported on the stand; one end of the auger is connected with a driving device; the other end of the auger is connected with an auger airlock through a chain; the auger airlock is arranged below the auger; one end of the auger airlock is supported on the stand; a pressure valve is hinged in the stand and arranged at the discharge port; and a balancing weight is arranged on the pressure valve. The invention can reduce the impurity content of grain.

Owner:扬州市仙龙粮食机械有限公司

Constructional engineering asphalt paving equipment

The invention discloses constructional engineering asphalt paving equipment. The equipment comprises a mounting frame body. A conveying hopper is fixedly arranged on the mounting frame body; a spreading groove is horizontally arranged in a lower side of the conveying hopper, a spreading scraper is fixedly arranged on one side of the spreading groove, a bidirectional conveying assembly is arrangedin the spreading groove, a plurality of discharging openings are evenly arranged in a lower end surface of the spreading groove, two baffles are vertically and symmetrically arranged on the lower sideof the mounting frame body, and sealing assemblies moving along with the baffles are arranged between the two baffles and the spreading groove; a strip-shaped frame is connected with the mounting frame body and the two baffles through a rotating assembly; and a plurality of flattening cylinders are arranged on the side, away from the spreading groove, of the strip-shaped frame, and telescopic heavy object containing frames are arranged on the upper sides of the flattening cylinders. The asphalt paving equipment can be used for paving asphalt, and comprises three steps of paving, flattening and compacting, in a whole paving process, the asphalt is paved in a constant range through the baffles, manual shoveling is not needed, and meanwhile, the paving range can be freely changed so that theasphalt paving equipment adapts to different pavement widths, and paving is more convenient.

Owner:盐城市恒兴建设工程有限公司

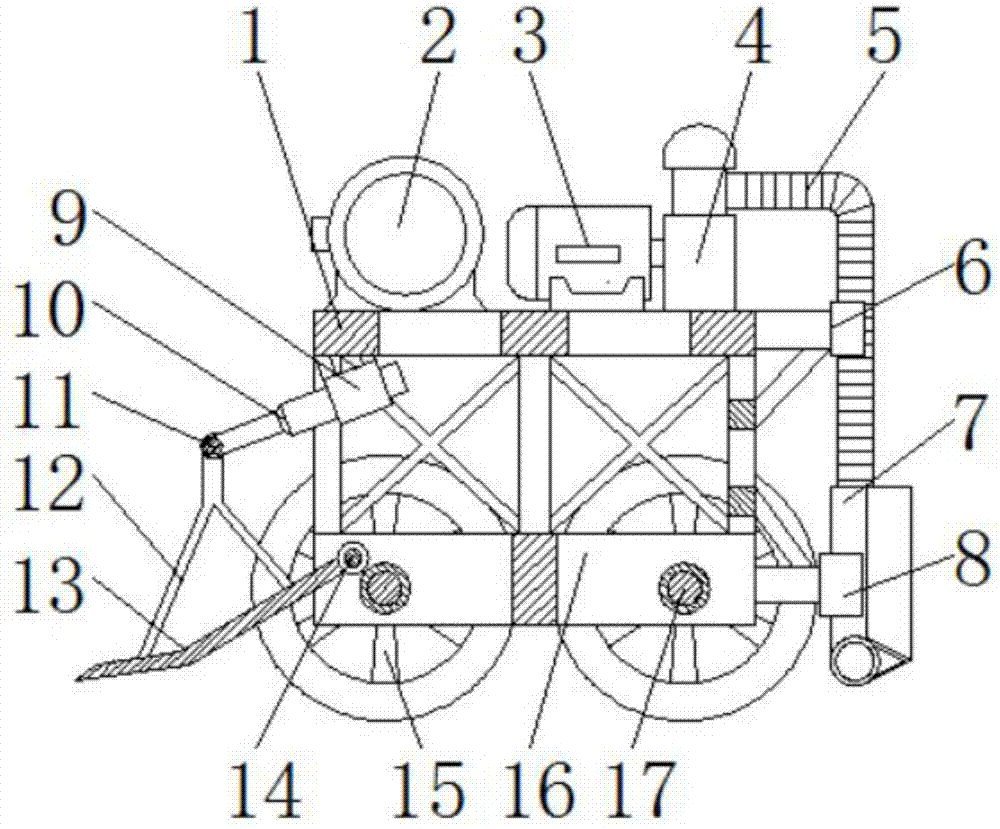

Leveling device for concrete spreading

ActiveCN107217852AQuality assuranceImprove work performanceRoads maintainenceBuilding material handlingWork performanceElectric machinery

The invention discloses a leveling device for concrete spreading. The leveling device comprises a main support, a moving wheel and a protection cover, a first motor is mounted on the upper side of the main support, a second motor is arranged on the right side of the first motor, the middle of a transmission pipe is connected with the main support through an upper fixing support, a vibrating pipe is mounted at the lower end of the transmission pipe, a fixed connecting seat is fixed on the lower side of the main support, a hydraulic rod is mounted on the inner side of the fixed connecting seat, the front end of the hydraulic rod is connected with a trowelling piece through a connecting rod and a fixing rod, a rotating bearing is mounted at the rear end of the trowelling piece, the inner side of the moving wheel is connected with a supporting base through a rotating shaft, and a belt is arranged on the inner side of the protection cover. By arranging a main upper vibrating pipe, a retaining piece and an auxiliary vibrating pipe on the vibrating pipe, the inside of the concrete is enabled to reach a uniform state; the hydraulic rod and the trowelling piece are mounted on the leveling device, so that working performance of the trowelling piece can be improved.

Owner:HUBEI CHANGJIANG ROAD & BRIDGE HLDG

Leveler with safety device and cleaning device

InactiveCN105499311AClean up in timeGuaranteed leveling effectShaping safety devicesCleaning using toolsLeveling effectIndustrial Accident

The invention discloses and provides a leveler with a safety device and a cleaning device. The leveler comprises a leveler body, adjusting screws, adjusting screw nut rails, friction grinding wheel layers, fixed rings, an adjustable rolling shaft, a rolling shaft, fixed grooves, motors, fixed blots, rivets and a safety protection plate. According to the leveler, the friction grinding wheel layers are mounted on an original machine, and dirt and oil stains adhering to two rolling rollers are timely cleaned, so that the leveling effect of the leveler is guaranteed; the dirt and oil stain cleaning work and the leveling work of the leveler are synchronously carried out, so that the downtime wasted due to cleaning is saved while the dirt and oil stain cleaning effect is guaranteed; and, the V-shaped protection plate is mounted on the original machine, so that the industrial accident is effectively prevented while the discharging operation is not influenced.

Owner:XINCHANG ZHONGRUI BEARING FACTORY

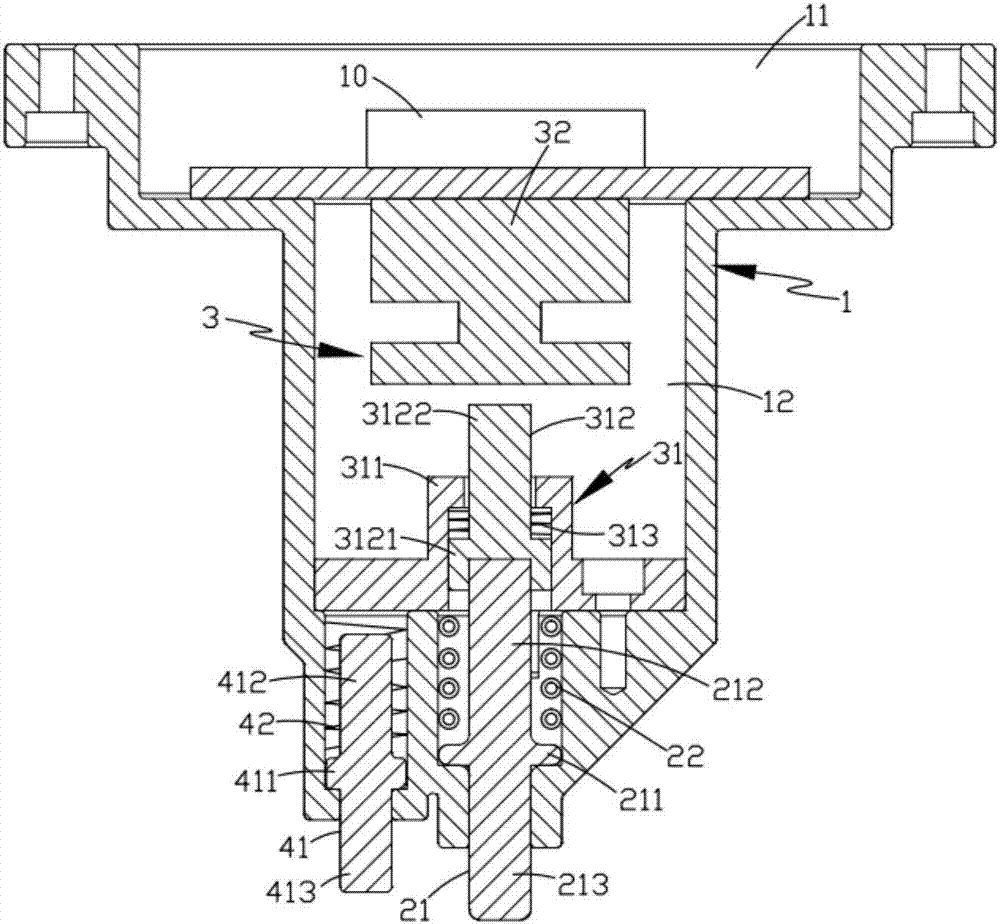

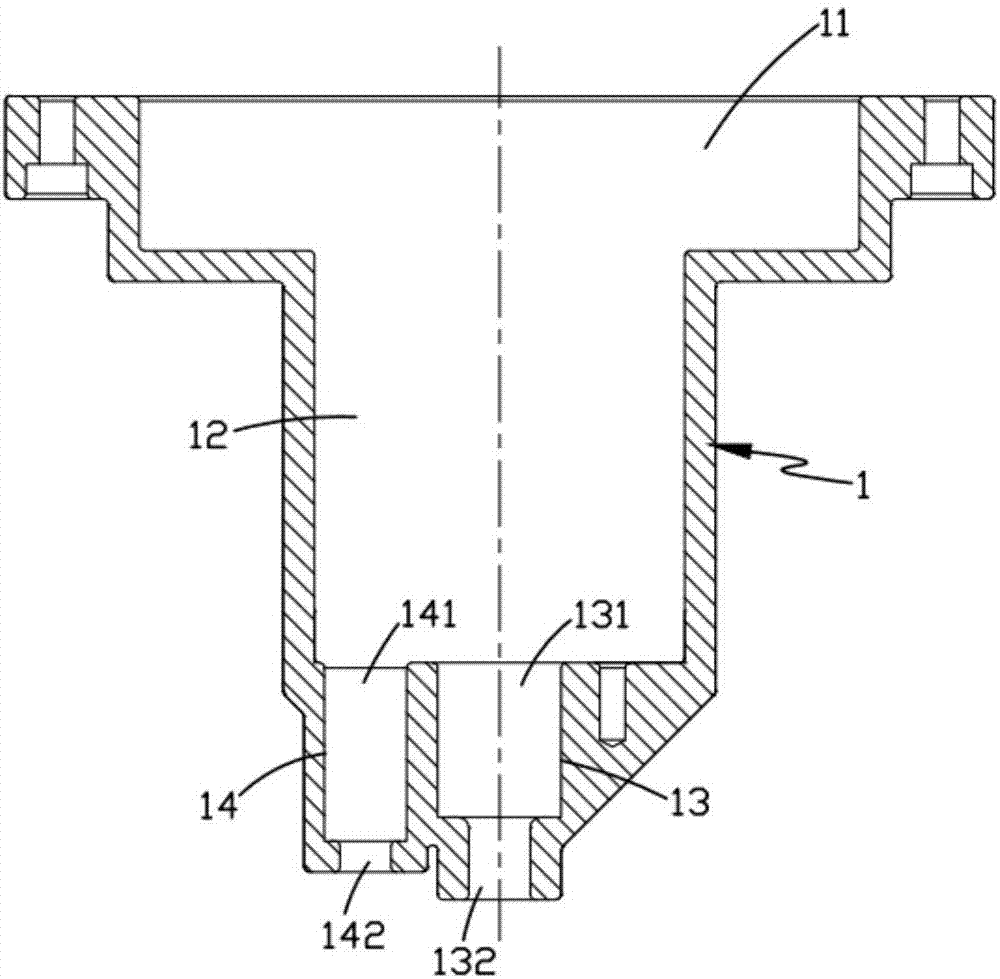

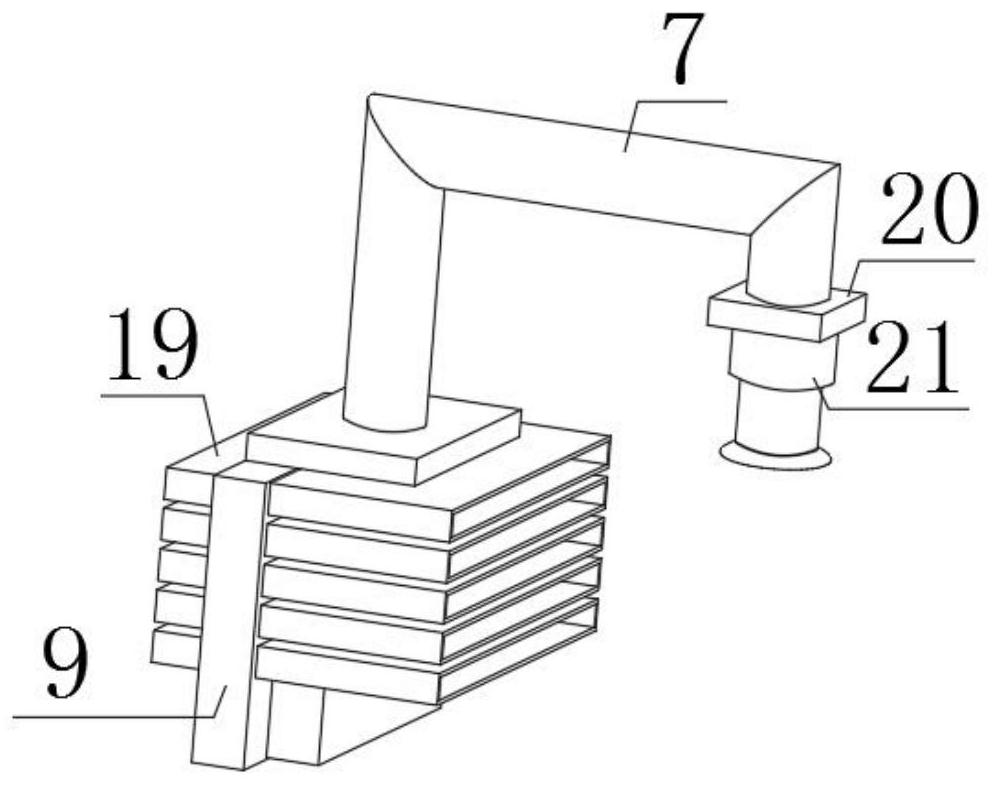

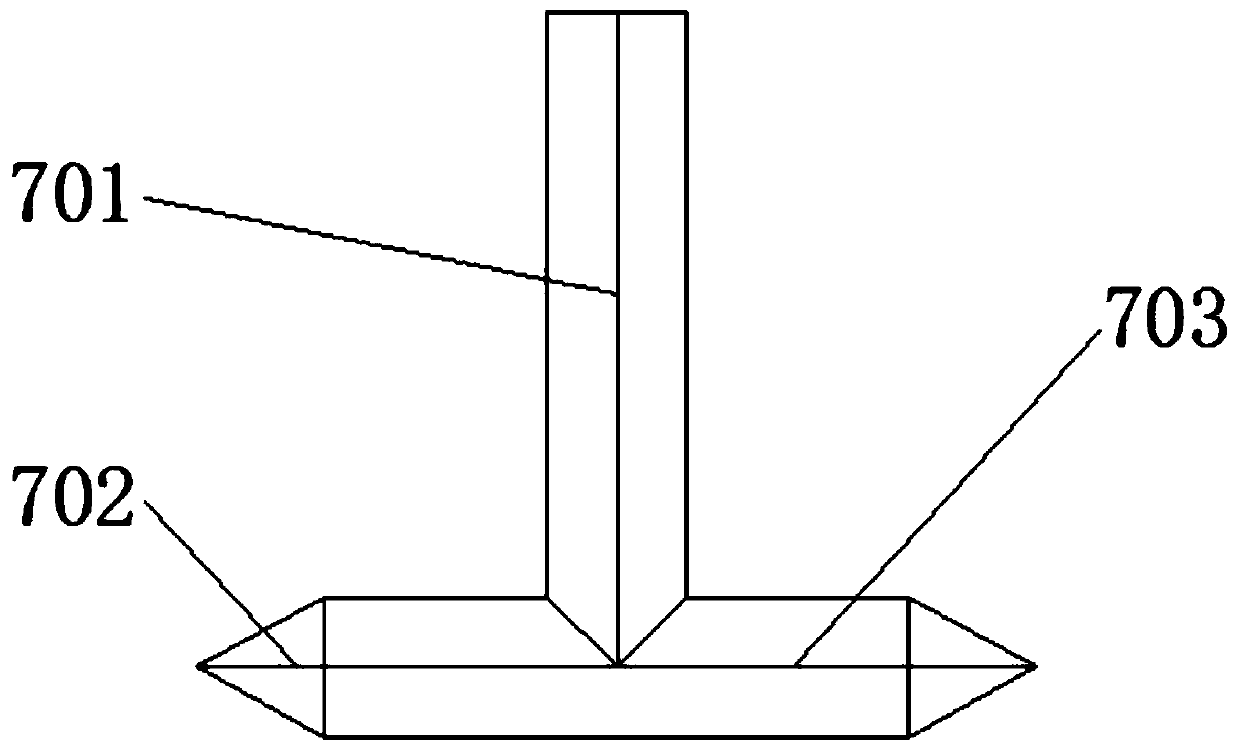

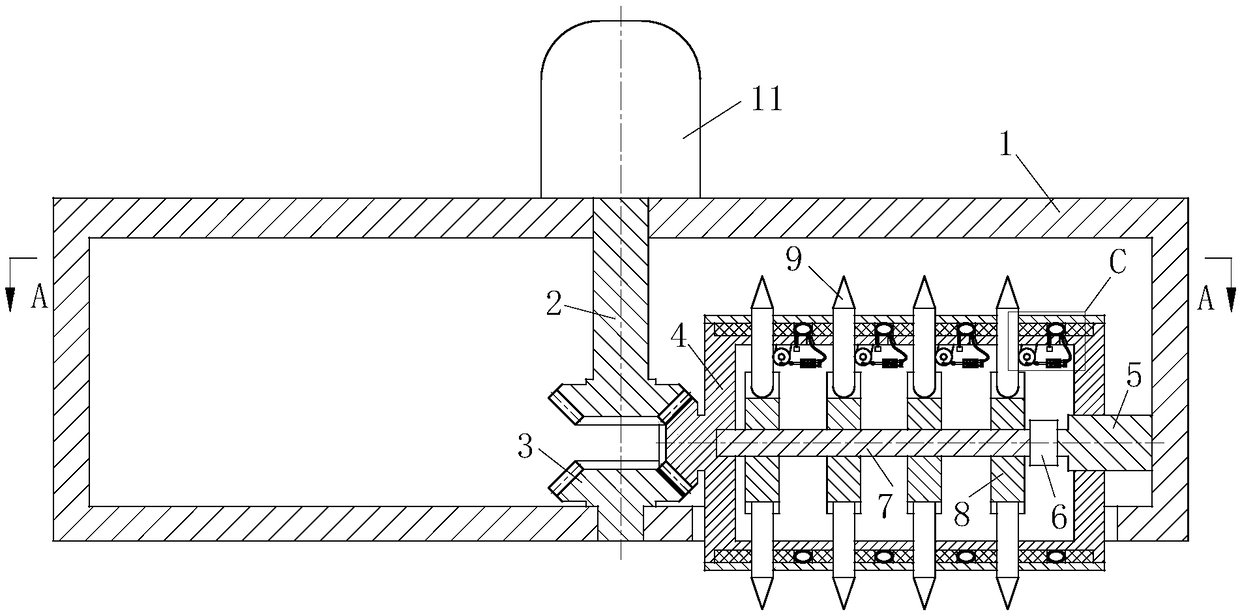

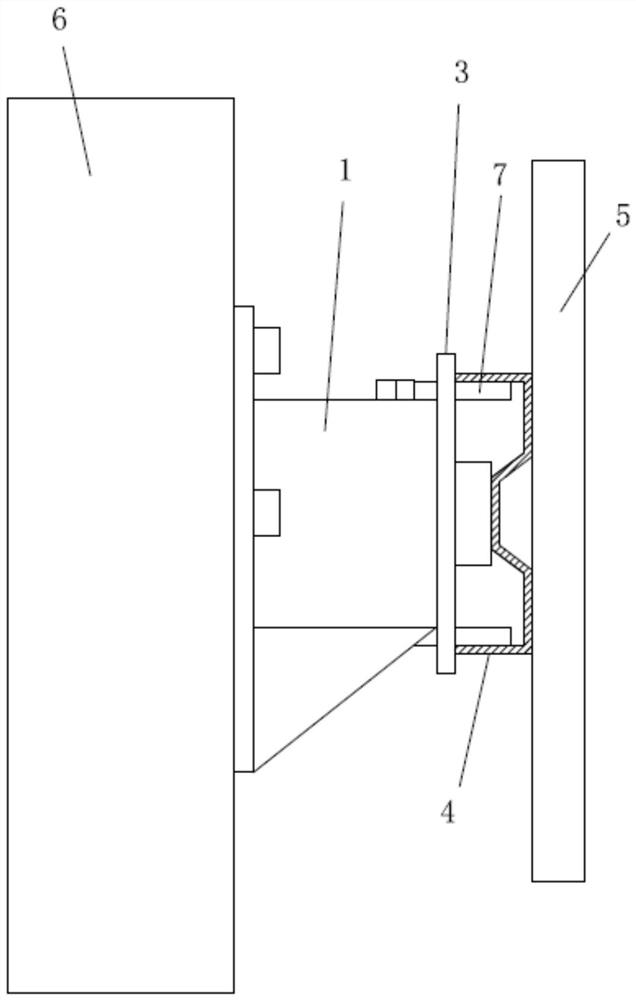

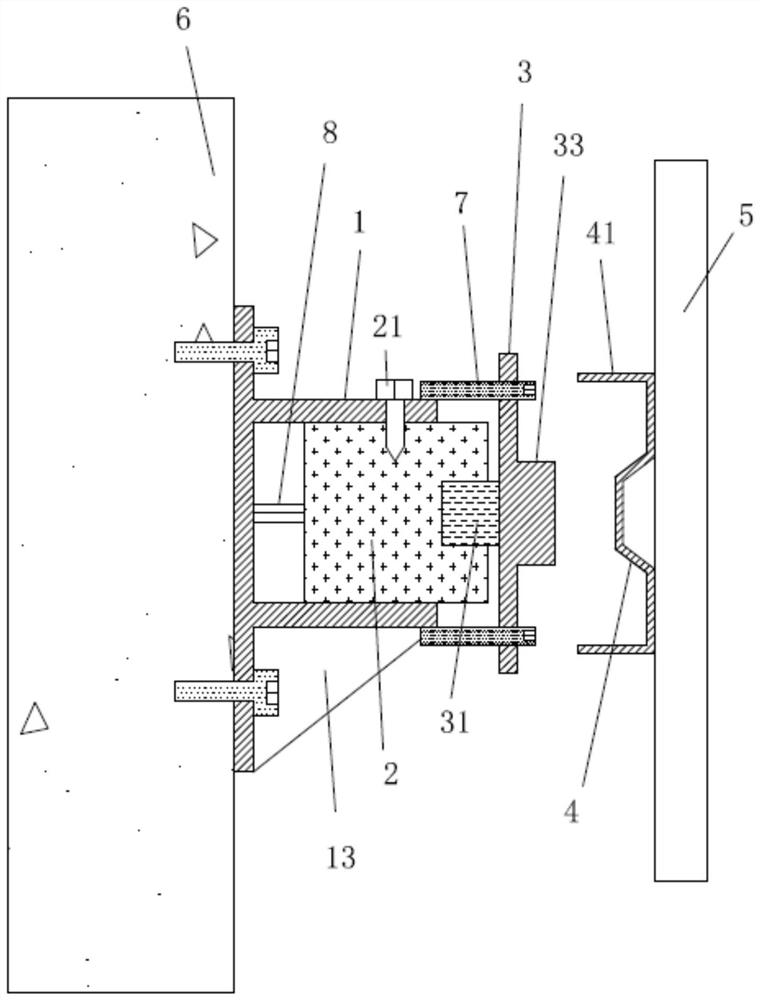

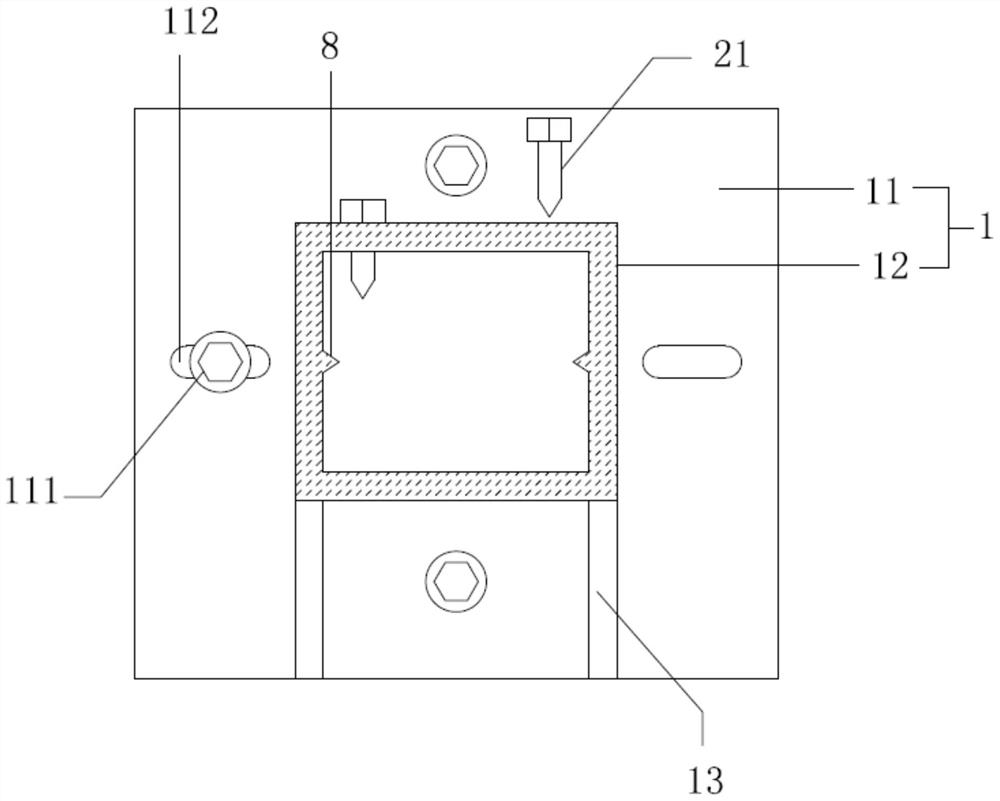

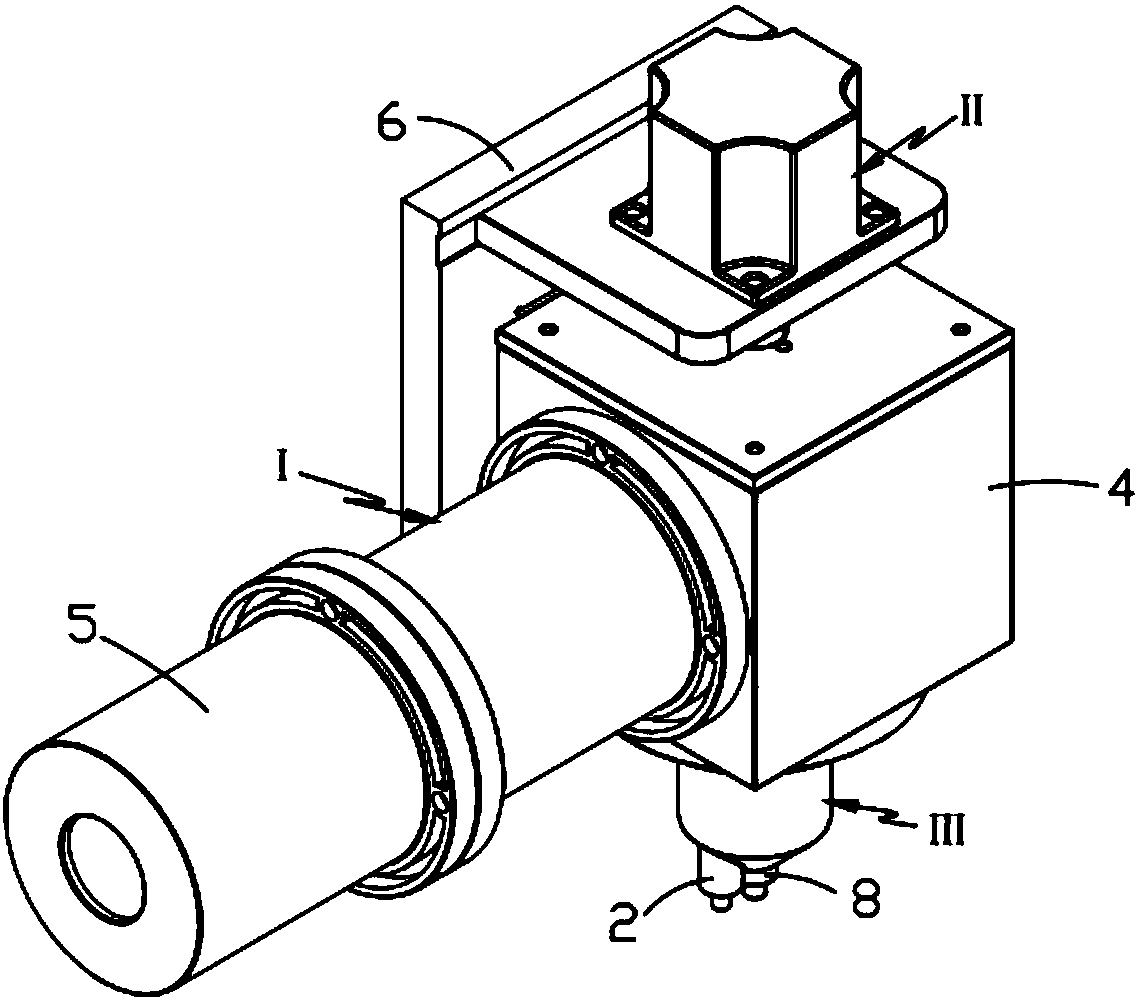

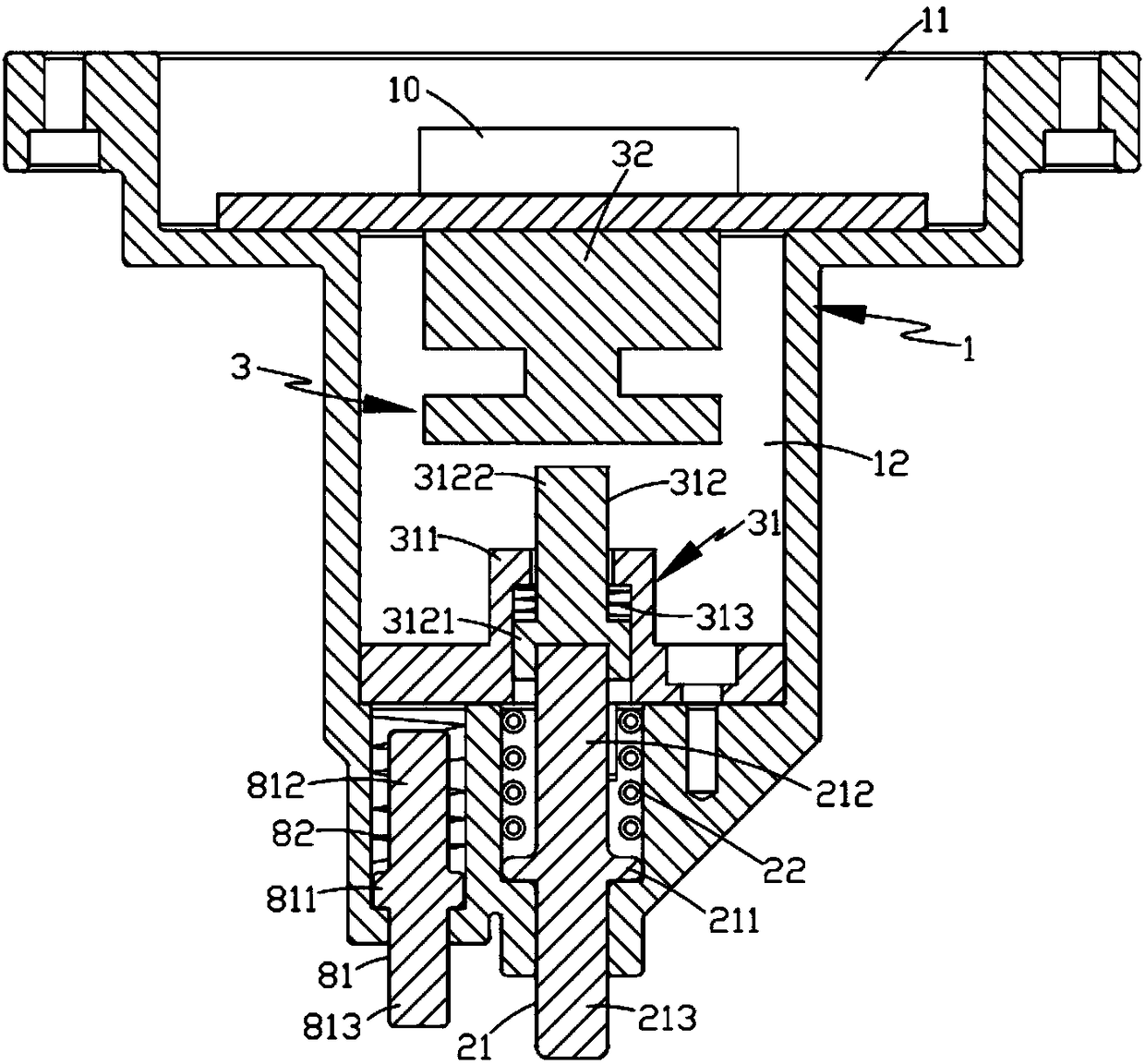

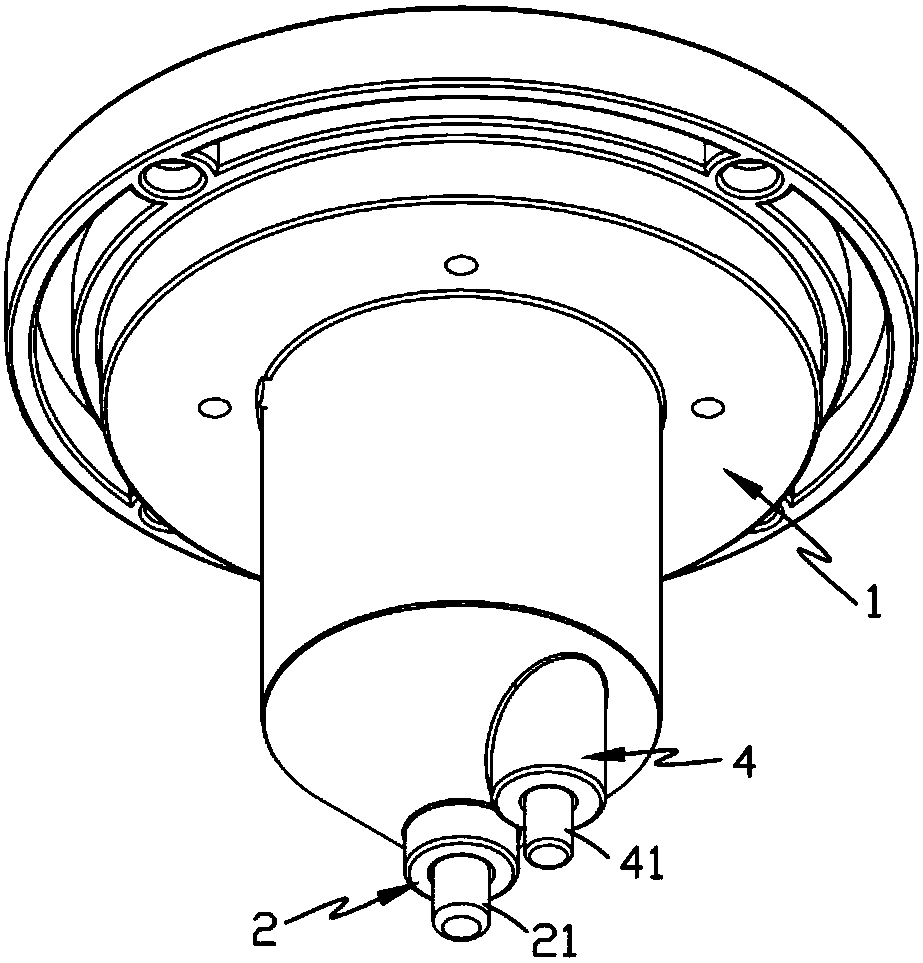

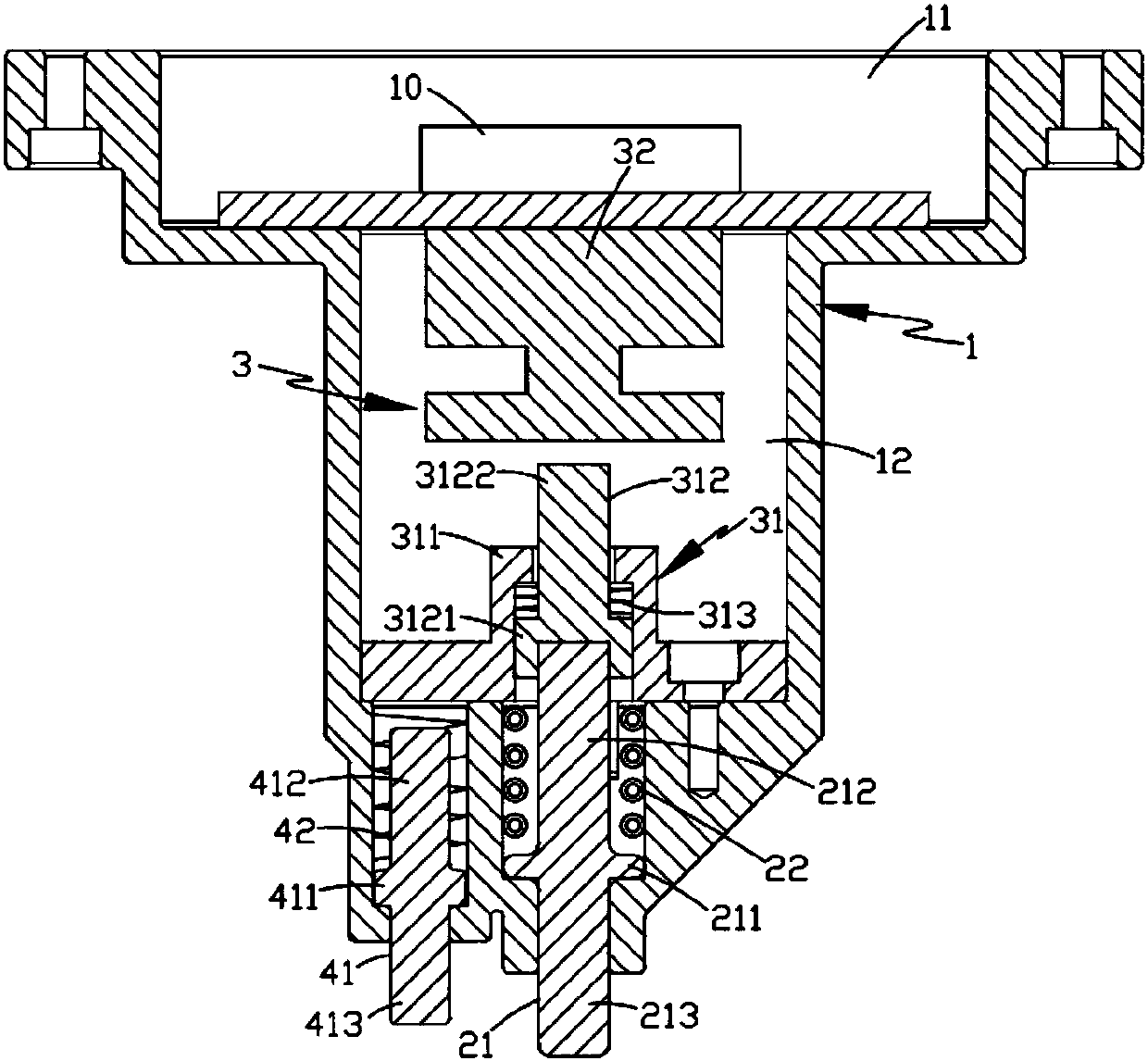

High-frequency welding induction gun head and welding gun with gun head applied

ActiveCN107442918APlay a guiding roleBlock transmission toHigh frequency current welding apparatusMetal working apparatusRobotic armFusion welding

The invention relates to a high-frequency welding induction gun head and a welding gun with the gun head applied. The welding gun comprises a gun body, a drive mechanism and the gun head; the gun head comprises a connection cover and a casing pipe; the gun body comprises a gun head base, a welding assembly and a control assembly; the welding assembly is installed on the front end portion of the gun head base and comprises a magnetic conductive bar and an electromagnetic induction coil surrounding the magnetic conductive bar; the control assembly is arranged on the rear side of the welding assembly and comprises a control unit and a pressure sensor arranged on the rear side of the control unit; the front end of the control unit is in abutting connection with the magnetic conductive bar; and the rear end of the control unit is in non-contact connection with the pressure sensor. Shaping and fusion welding on a post terminal are completed synchronously in the welding process of a storage battery connecting terminal through cooperation of a high-frequency electromagnetic induction heating mode and lifting movement of the gun head, the traditional welding procedure is simplified, and full-automatic and mechanical welding production of the storage battery connecting terminal is easily achieved by being matched with a mechanical arm.

Owner:浙江金麦特自动化系统有限公司

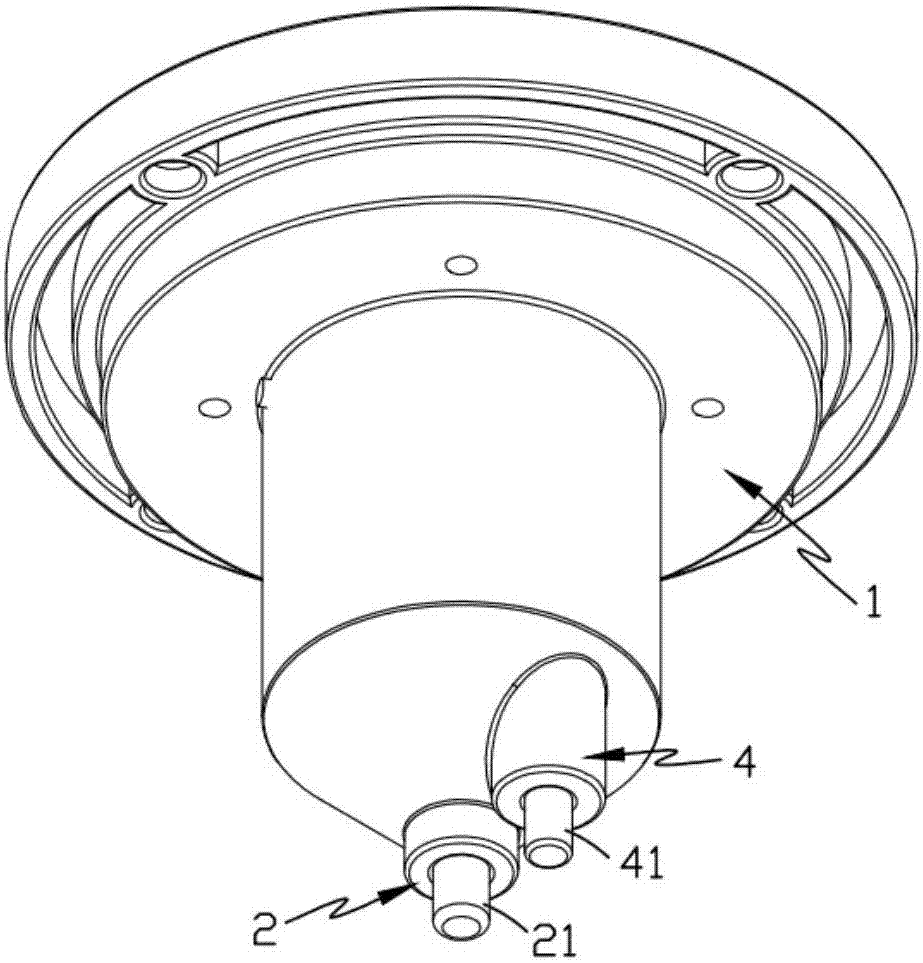

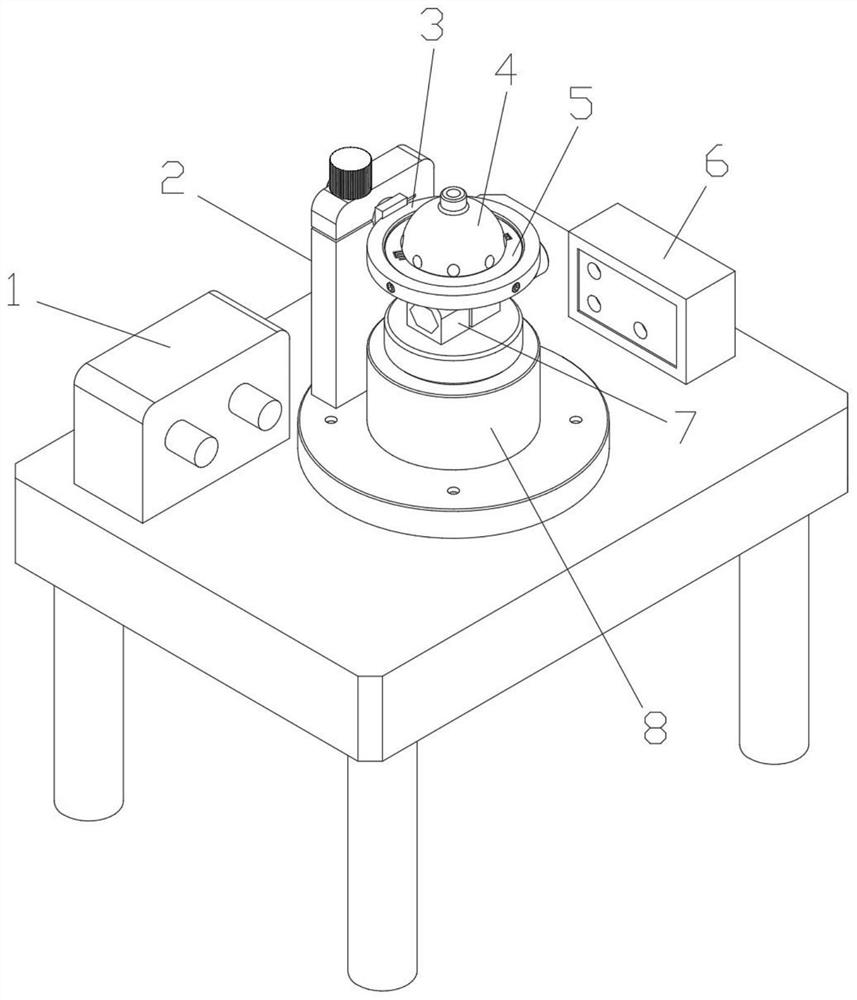

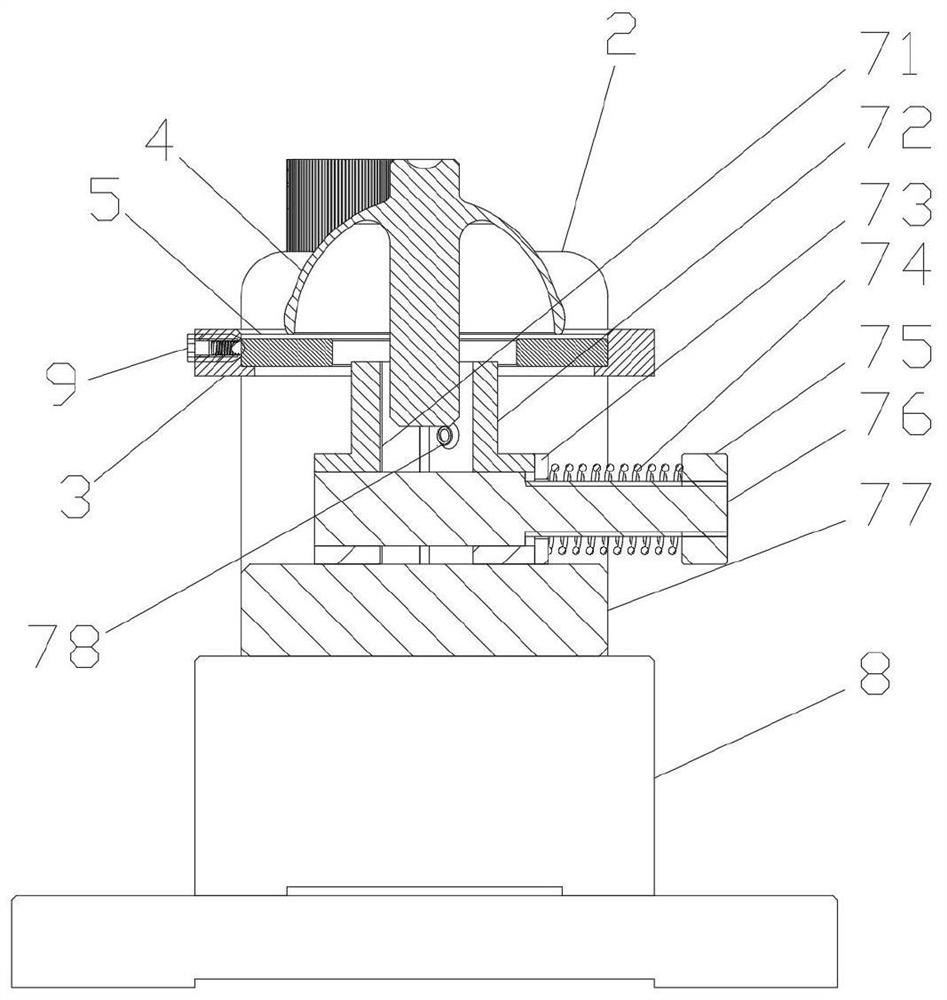

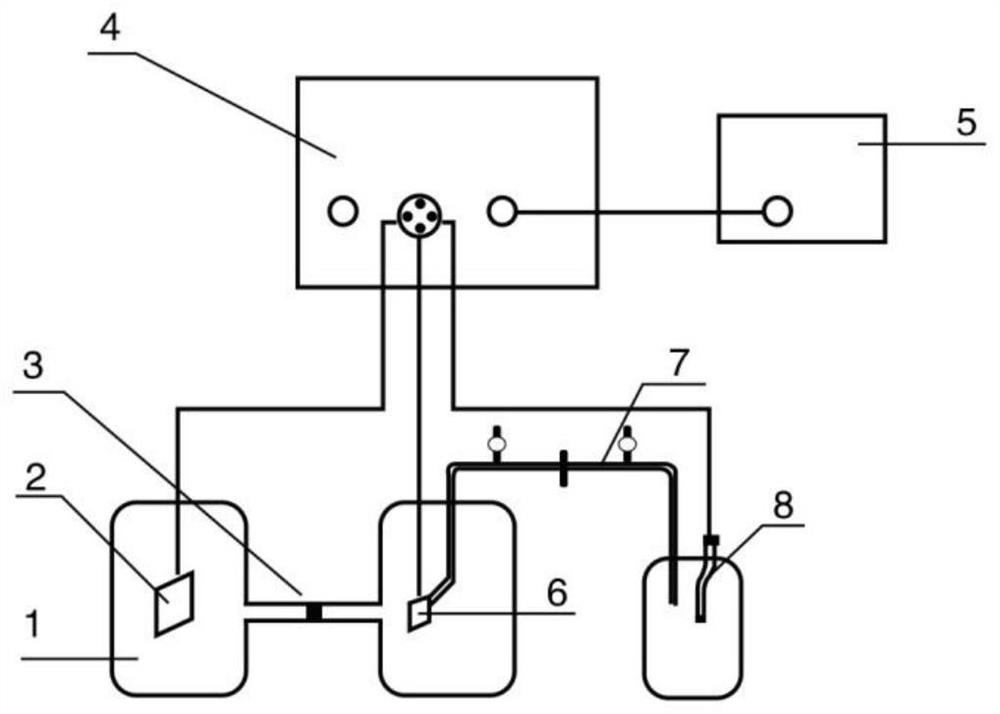

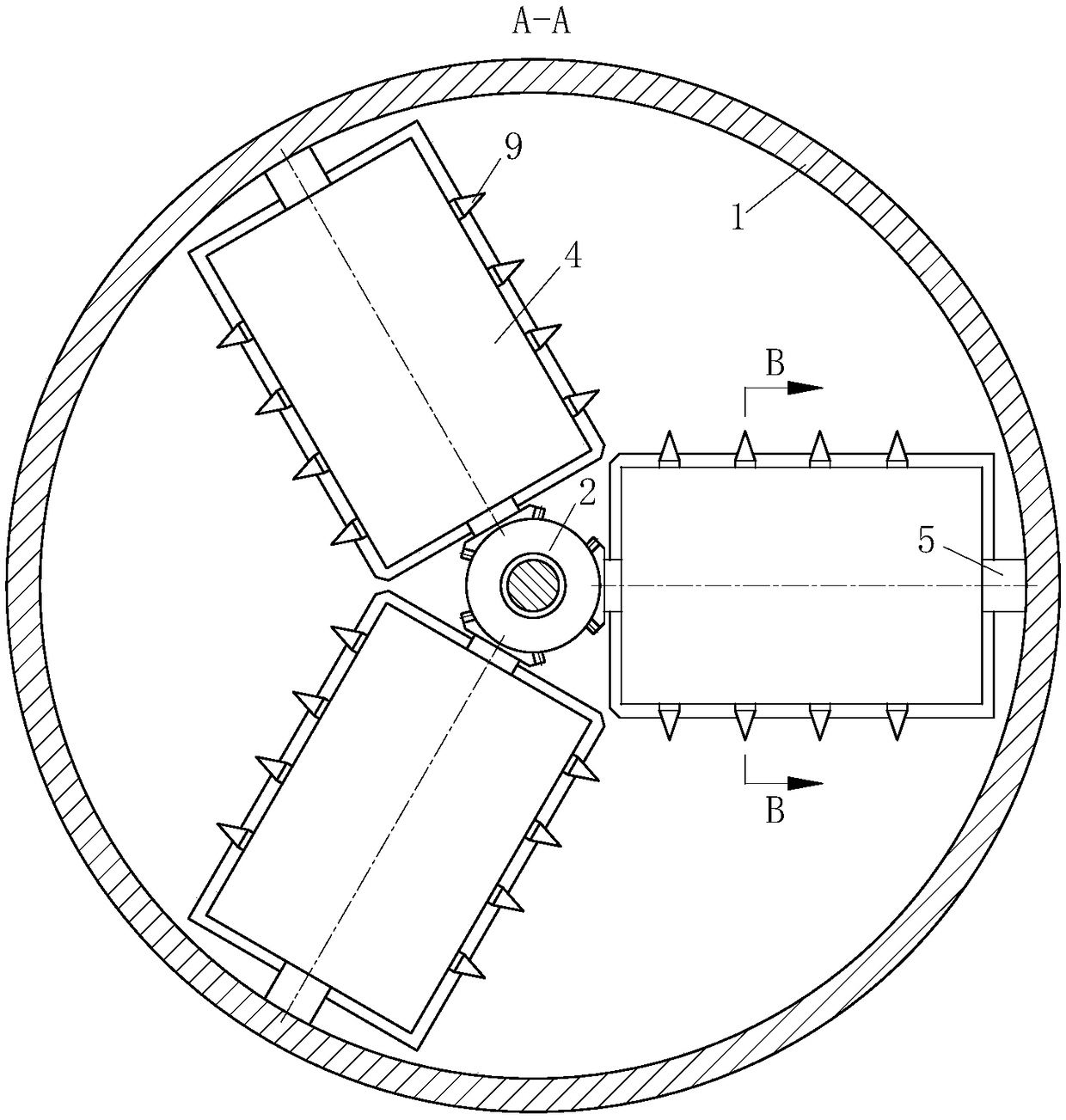

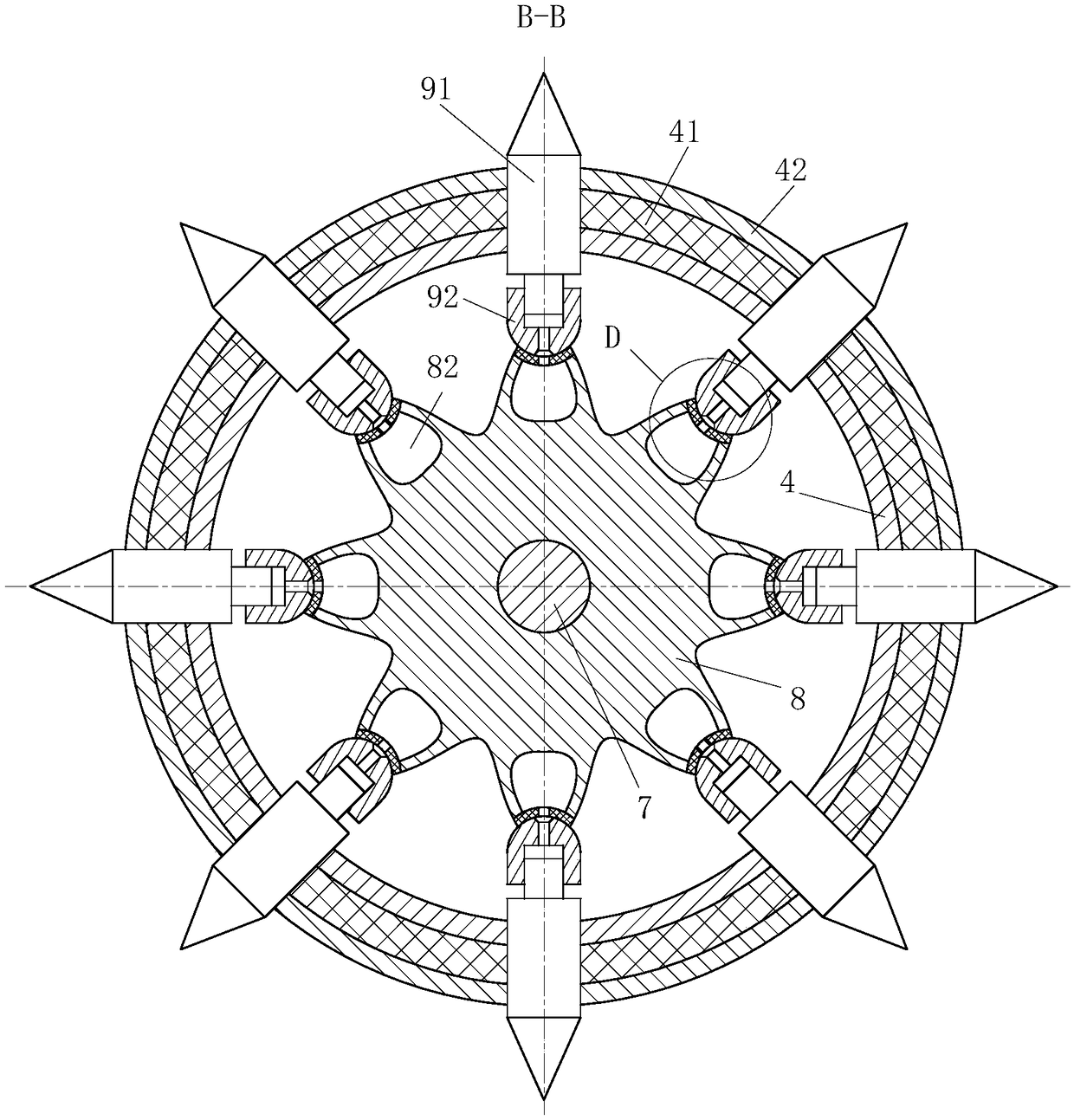

Harmonic oscillator rigid axis identification device and method based on additional electrostatic rigidity principle

ActiveCN112710869AGuaranteed leveling effectThe detection method is simpleAcceleration measurementHarmonic reduction arrangementEngineeringIdentification device

The invention provides a harmonic oscillator rigid shaft identification device and method based on an additional electrostatic rigidity principle. With the harmonic oscillator rigid shaft identification device and method adopted, the position of the rigid shaft of a harmonic oscillator can be accurately identified, so that the leveling effect of the harmonic oscillator can be ensured. The device comprises a rotary table, an electrode holder, comb-shaped electrodes, an electrode holder support mechanism, a signal source and a controller; the electrode holder is of an annular structure; the electrode holder is arranged above the rotary table; an harmonic oscillator supporting rod can penetrate through the electrode holder and is connected with a rotary shaft of the rotary table, so that the lip edge of the harmonic oscillator can be located above the comb-shaped electrodes; the comb-shaped electrodes comprise a comb-shaped direct-current excitation electrode, a comb-shaped alternating-current excitation electrode and a comb-shaped detection electrode which are distributed on the upper end face of the electrode holder in the circumferential direction, and are located bellow lip edge of the harmonic oscillator; the electrode holder support mechanism is arranged on one side of the rotary table and used for supporting the electrode holder; the signal source is connected with the comb-shaped direct-current excitation electrode; and the controller is connected with the comb-shaped alternating-current excitation electrode.

Owner:HUAZHONG PHOTOELECTRIC TECH INST (CHINA SHIPBUILDING IND CORP THE NO 717 INST)

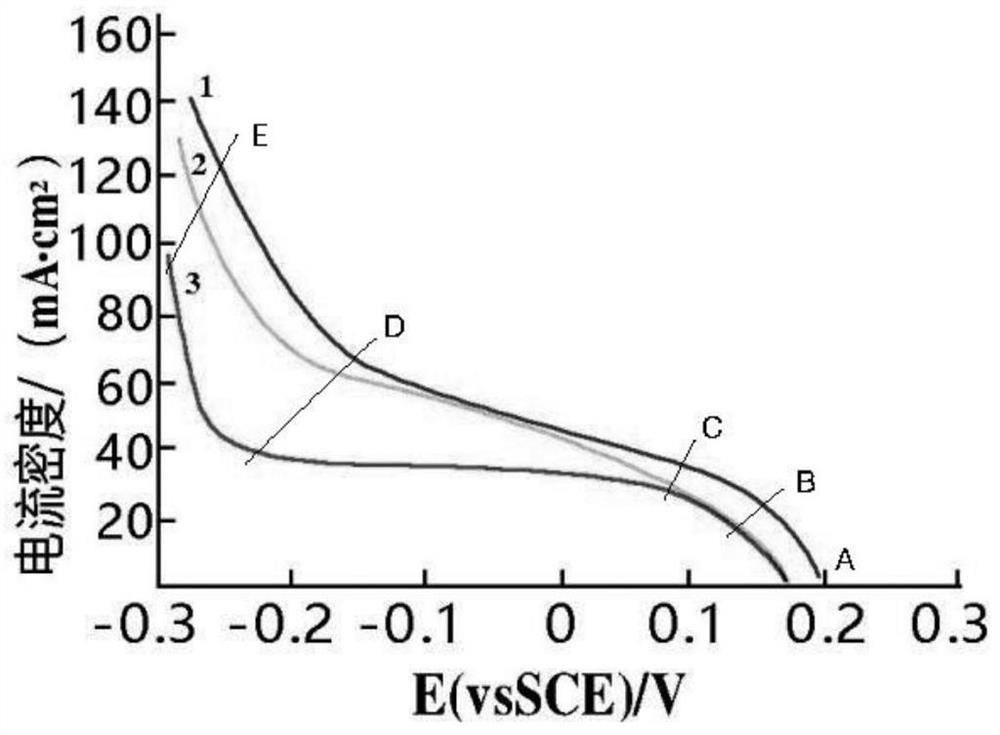

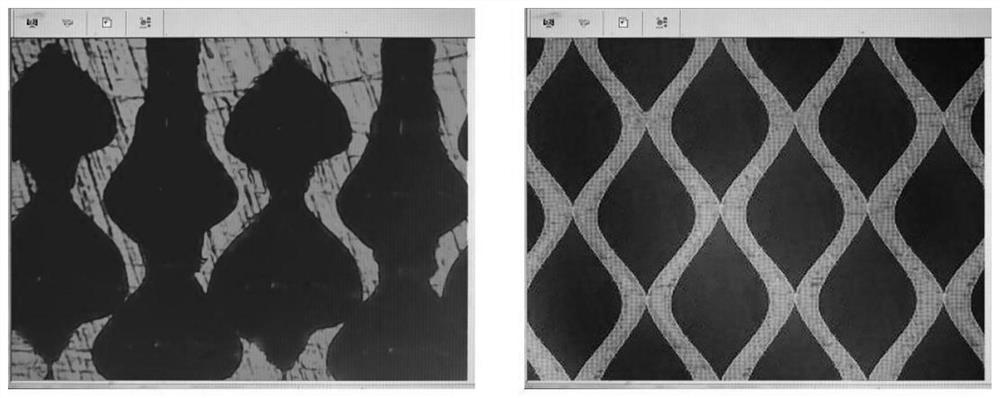

Electronic carving printing gravure alkaline copper plating additive

The invention relates to the technical field of electronic engraving and printing, in particular to an electronic engraving and printing gravure alkaline copper plating additive. Comprising a hardening agent and a leveling agent, and is prepared from the following raw materials in parts by weight: the hardening agent comprises 1-2 parts of M2-mercaptobenzimidazole, 2-4 parts of isothiourea propanesulfonic acid inner salt, 1-2 parts of MOME, 1-3 parts of glycerol and 1-3 parts of dodecylphenol polyoxyethylene ether; the leveling agent is prepared from the following components in parts by weight: 1 to 2 parts of M2-mercaptobenzimidazole, 2 to 6 parts of thiourea, 0.5 to 2 parts of N, N-dimethyl-sodium dithiocarbonyl propane sulfonate, 1 to 4 parts of G-35 polyethyleneimine, 0.5 to 2 parts of diaminourea polymer, 2 to 4 parts of sodium dodecyl benzene sulfate, 0.2 to 1 part of sodium 2-ethylhexyl sulfonate, 2 to 4 parts of disodium ethylene diamine tetraacetate, 1 to 3 parts of sodium dithiodipropane sulfonate and 1 to 2 parts of sodium bicarbonate. The additive disclosed by the invention can be directly used without nickel plating, and a plating layer electroplated by using the additive disclosed by the invention has the advantages of fast bright dipping, good brightness, excellent leveling property, good toughness and good stability.

Owner:三门峡毕昇制版科技股份有限公司

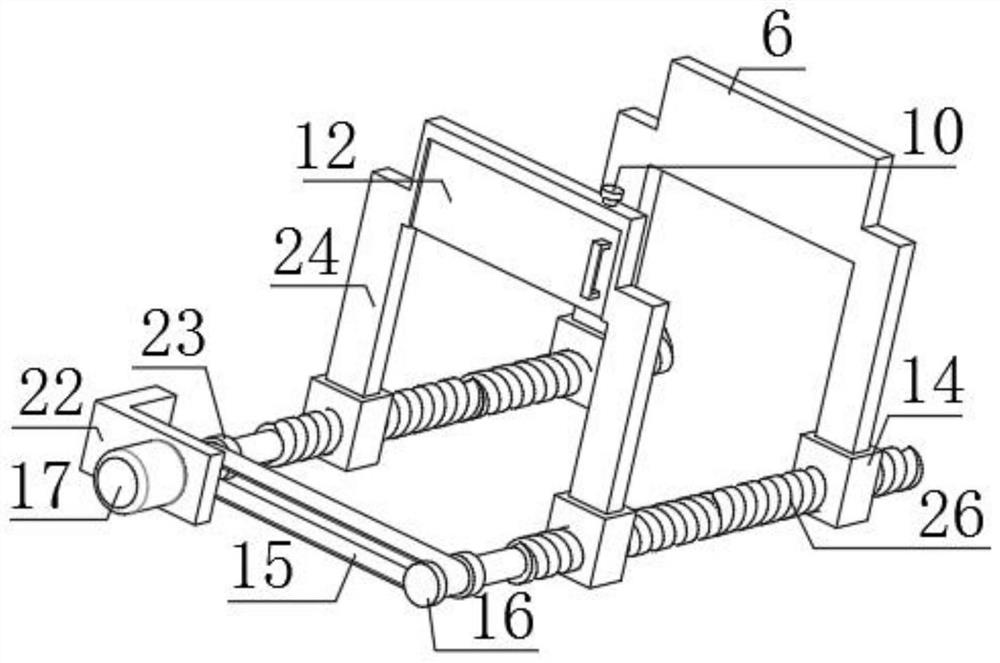

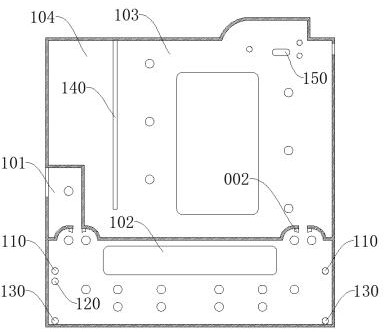

Movable tool for battery pack assembling

InactiveCN112427868AQuality assuranceGuaranteed leveling effectAssembling battery machinesFinal product manufactureElectrical batteryBattery pack

The invention discloses a movable tool for battery pack assembling. The problems that when an existing device used in a battery assembling process has difficulty in automatically aligning a battery pack before fixation, when the battery pack is welded, a situation that battery tabs of finished batteries are not aligned is likely to occur, and the quality is relatively poor need to be solved, so that the following scheme is provided, the movable tool comprises a bottom plate, supporting plates are fixedly connected to the two sides of the outer wall of the top of the bottom plate, the same transverse plate is fixedly connected to the outer walls of the tops of the two supporting plates, and a fixing frame is fixedly connected to one side of the outer wall of the top of the transverse plate.According to the movable tool, a second electric telescopic rod pushes a supporting frame and a push plate to align the batteries on the outer wall of the top of the transverse plate in place, it isguaranteed that the tabs of the batteries are located in the same plane, a first electric telescopic rod drives a base plate at the bottom end of an extension rod to extrude downwards, the aligned andclamped batteries are welded and assembled, and the quality of the finished battery pack is effectively guaranteed.

Owner:湖南电将军新能源有限公司

Cloth leveling device for weaving

PendingCN108930119AAvoid cloggingSolve the problem that easily reduces the leveling effectMechanical cleaningPressure cleaningLeveling effectEngineering

The invention provides a cloth leveling device for weaving. The device of the invention comprises a pedestal, an electric cylinder, sponge, a connecting plate, a pressure plate and a steam leveling plate. The bottom of the electric cylinder is fixed with the pressure plate through bolts. The connecting plate is welded at the left end of the pressure plate. The sponge is glued at the bottom of theconnecting plate. The sponge is arranged at the left end of the pressure plate. The steam leveling plate is welded at the right end of the pressure plate. The sponge, the pressure plate and the steamleveling plate are all installed on the pedestal. With the above design, impurities on cloth are cleared up. The device of the invention is convenient to operate and clean and helps effectively guarantee the leveling effect.

Owner:AOYANG GRP CO LTD

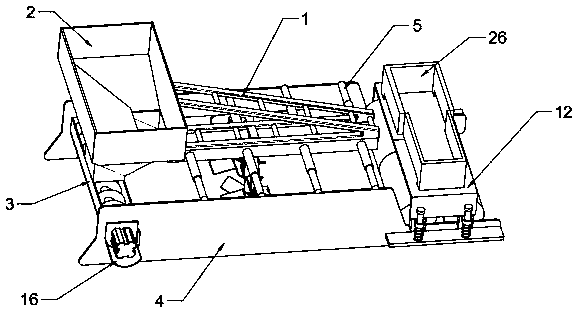

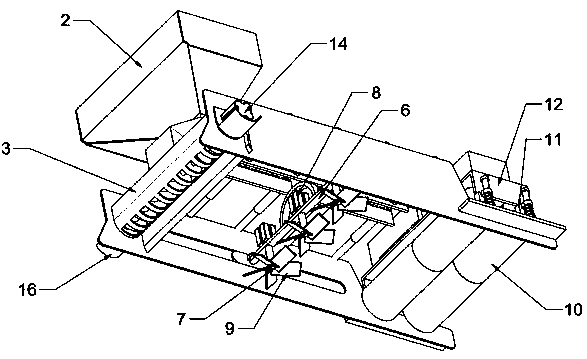

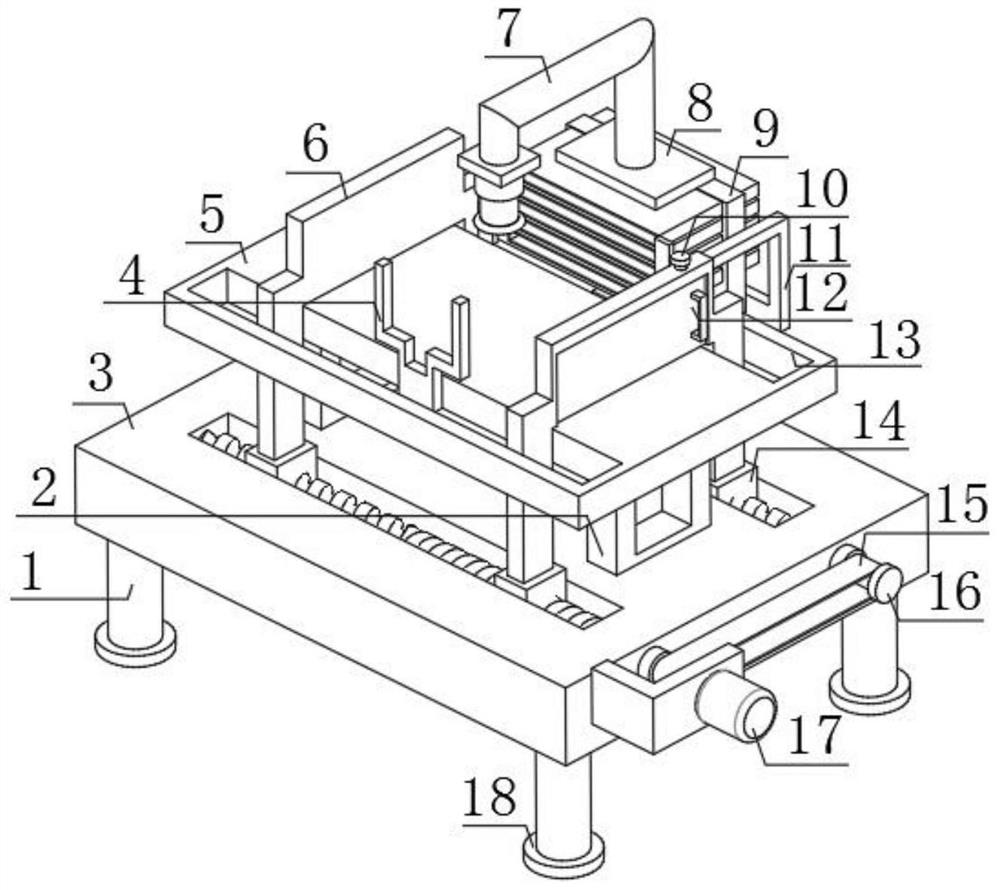

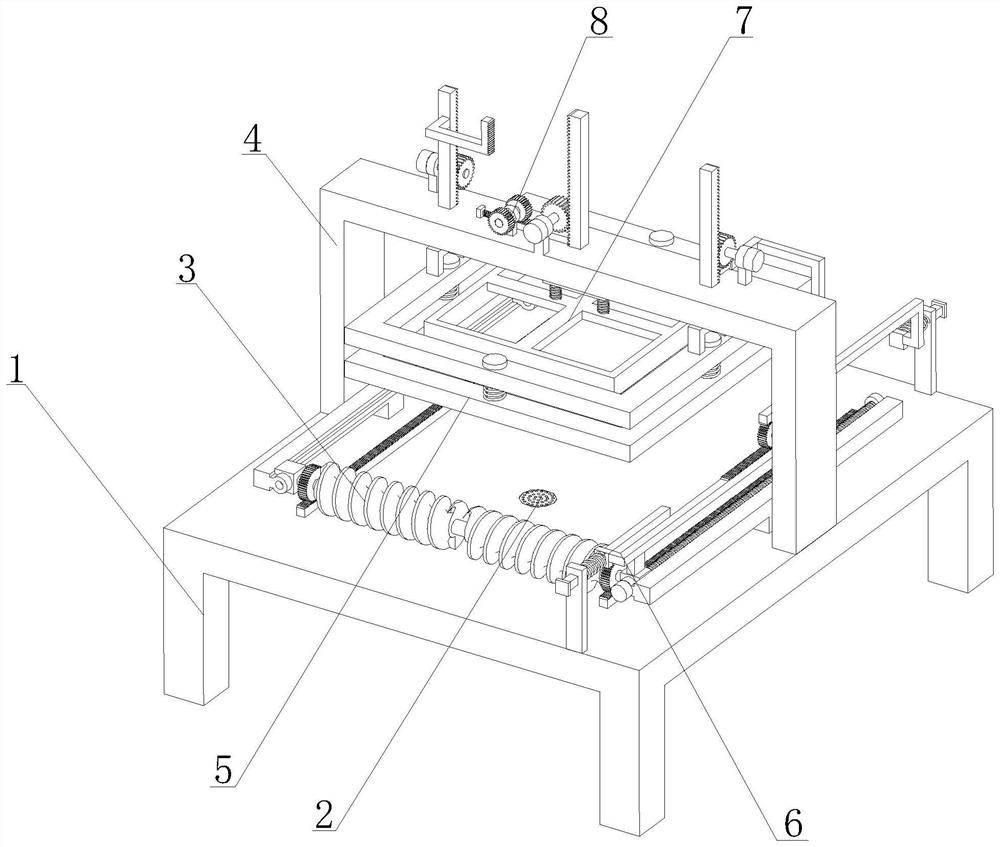

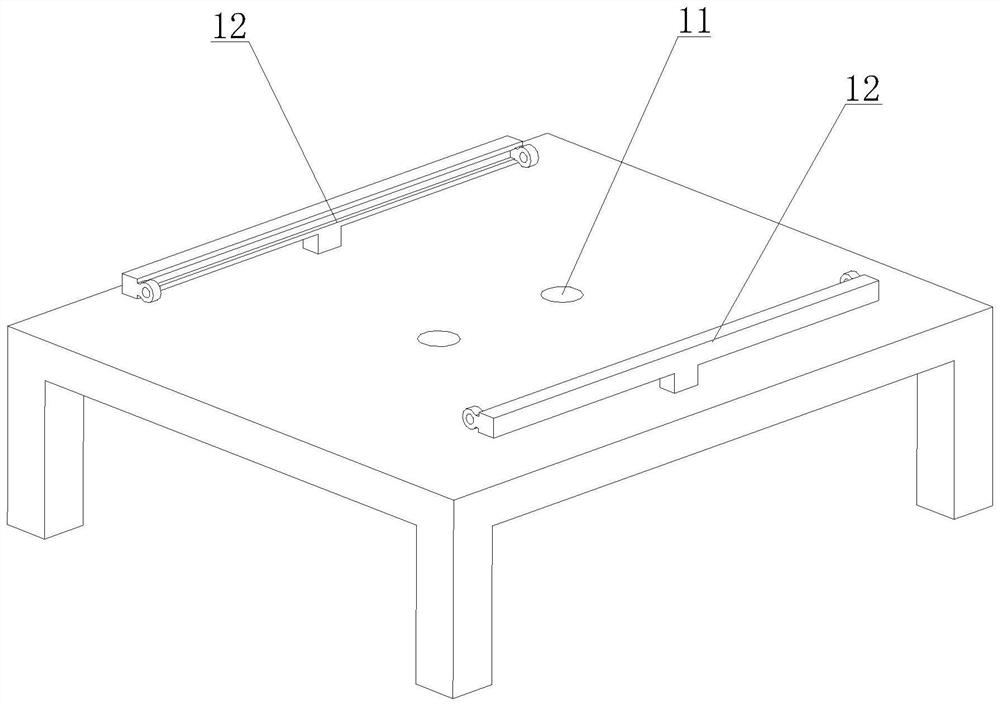

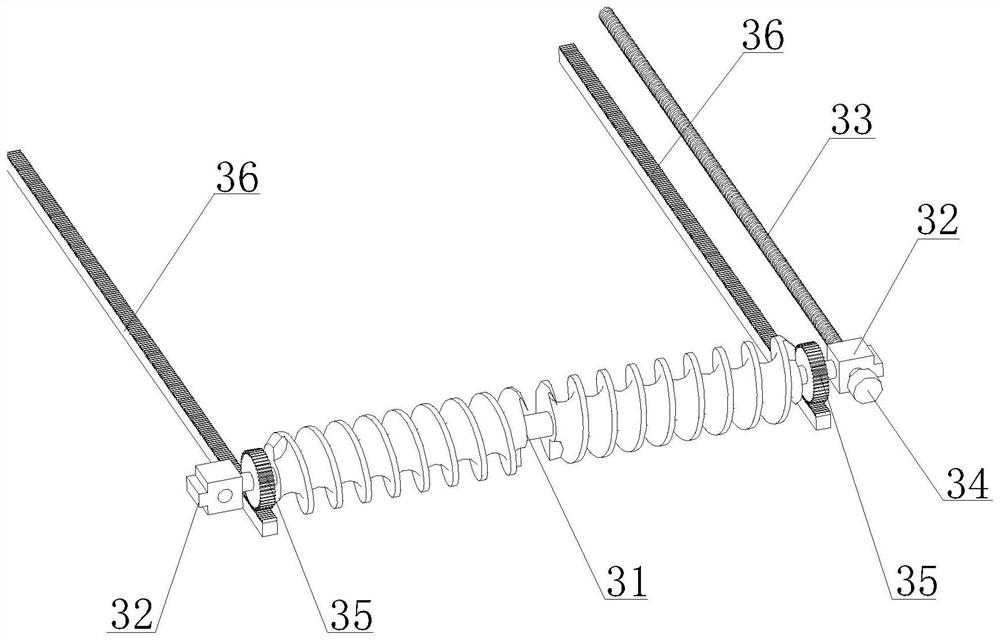

Positioning and leveling device for paper slitting and using method of positioning and leveling device

PendingCN114393631AAvoid interferenceAvoid the influence of slitting accuracyMechanical working/deformationMetal working apparatusAugerEngineering

The invention discloses a positioning and leveling device for paper slitting and a using method of the positioning and leveling device, and belongs to the field of paper slitting. The invention discloses a positioning and leveling device for paper slitting. The positioning and leveling device comprises a workbench, a leveling mechanism, a mounting frame, a pressing mechanism and a clamping mechanism, the leveling mechanism is arranged on the workbench, the leveling roller capable of sliding and rotating at the same time is arranged in the leveling mechanism to level a whole piece of paper, and the first auger and the second auger which are coaxial and opposite in rotation direction are arranged in the leveling roller to level the paper from two directions perpendicular to each other, so that the leveling effect is guaranteed; the pressing mechanism is arranged on the mounting frame to press and fix paper on the workbench so as to guarantee the slitting quality, the clamping mechanism is arranged to control the pressing time of the pressing mechanism, and the situation that a pressing plate is pressed downwards to interfere with a leveling roller, and consequently the structure of the device is damaged is avoided; the using method of the positioning and leveling device for paper slitting comprises the steps of feeding, leveling, pressing, slitting and material taking.

Owner:JI LONG MACHINERY CO LTD

Leveling device for concrete paving

ActiveCN107217852BQuality assuranceImprove work performanceRoads maintainenceBuilding material handlingWork performanceEngineering

Owner:HUBEI CHANGJIANG ROAD & BRIDGE HLDG

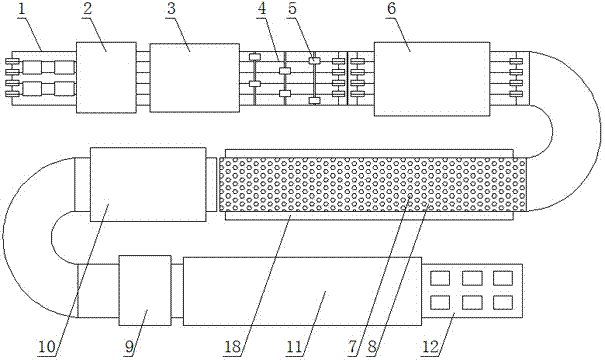

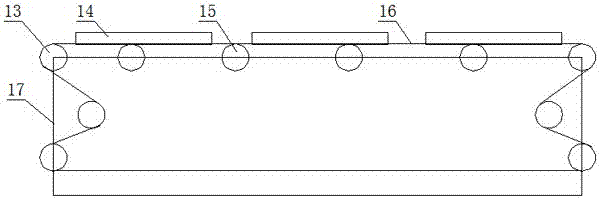

Leveling Natural Stone Paint External Insulation Decorative Panel Spray Painting Production Line

ActiveCN104772265BIncrease productivityReduce labor intensityPretreated surfacesCoatingsProduction lineOscillating flow

The invention relates to a painting production line for leveling natural stone paint external thermal insulation decorative boards, which sequentially includes a substrate conveyor belt, a primer spraying machine, a conveyor belt after primer spraying, a multi-color natural stone paint spraying machine, a stone paint spraying conveyor belt, and a stone paint spraying machine. Quality paint layer drying room, top paint spraying machine, conveyor belt after top paint spraying, primer drying room and cooling fan are installed on the conveyor belt after primer spraying, and the conveyor belt after spraying stone paint is a flexible wide belt with air holes , and a gas vibrator is arranged under the conveyor belt, and a topcoat drying chamber is arranged on the conveyor belt after the topcoat is sprayed. The painting production line has high production efficiency, low cost, and low labor intensity. The primer, natural stone paint, and top paint are sprayed and dried separately, and the paint layer is stable and firm. Flattening and drying cooperate with each other, which not only ensures the flatness, but also realizes the realistic simulation effect. The paint recycling rate is high, and the pollution to the environment is avoided, and the environmental protection is good.

Owner:信阳新天意绿色建材有限公司

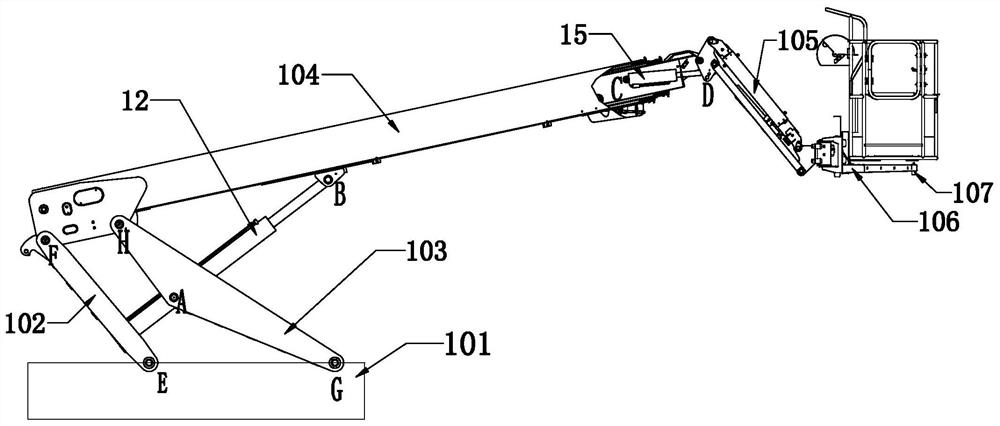

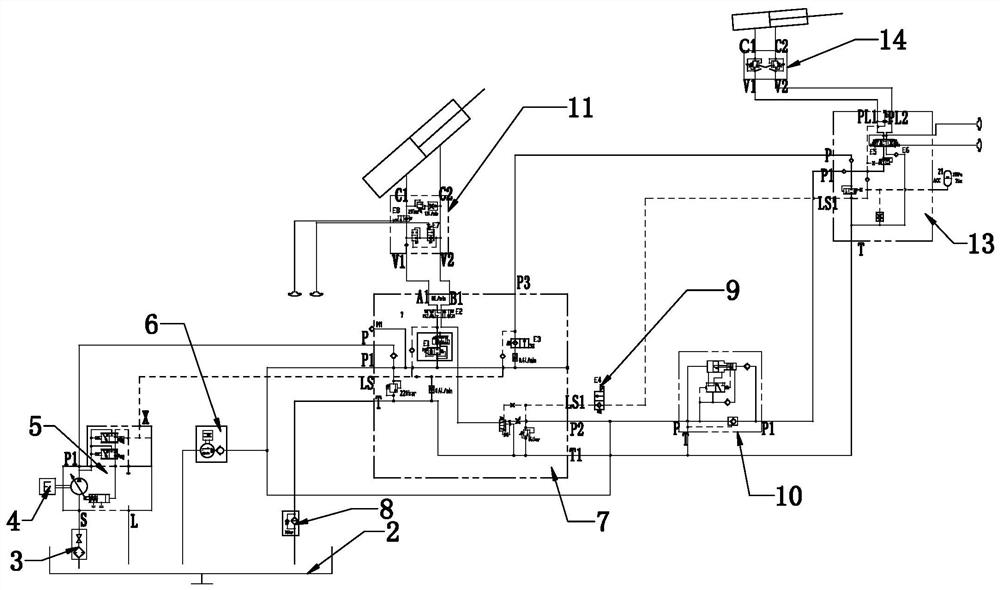

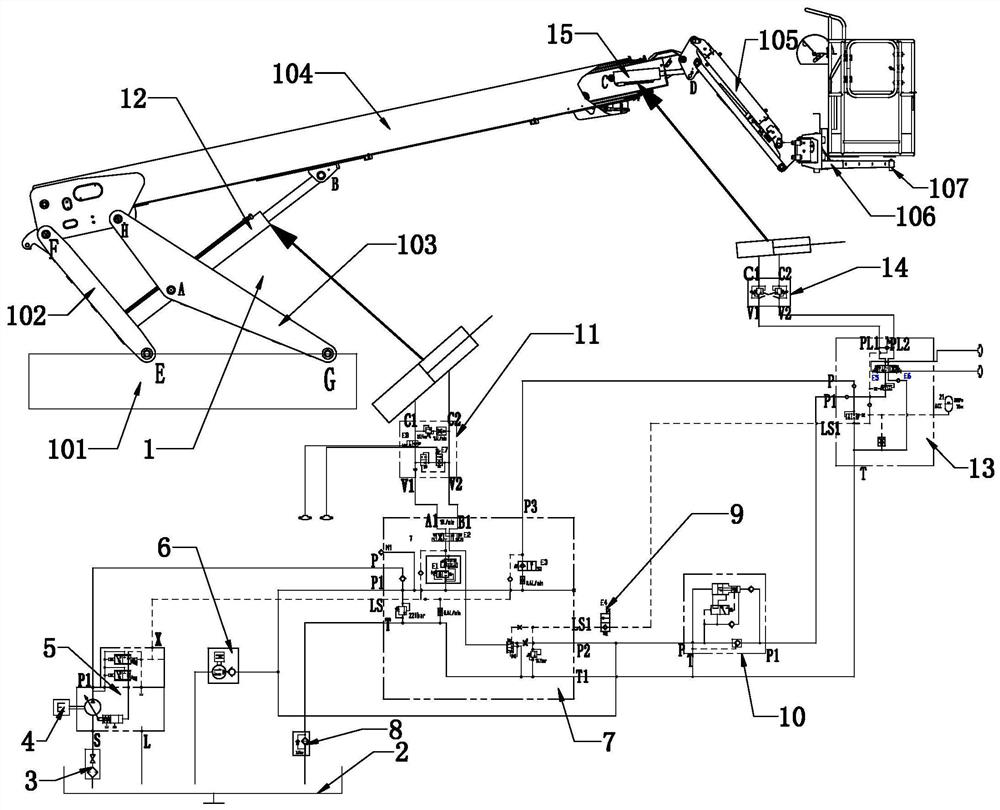

Amplitude-changing leveling hydraulic control system for boom type aerial work platform

PendingCN113582093AQuick levelingLeveling precisionSafety devices for lifting equipmentsServomotor componentsElectric controlControl valves

The invention discloses an amplitude-changing leveling hydraulic control system for a boom type aerial work platform. The system comprises an amplitude-changing oil cylinder and a leveling oil cylinder, and further comprises a hydraulic oil tank as well as a load-sensitive pump, an emergency power unit and a rotary table control valve which are connected with the hydraulic oil tank respectively, a gravity descending valve is arranged on the amplitude-changing oil cylinder, a leveling balance valve is arranged on the leveling oil cylinder, and the leveling balance valve is connected with a platform control valve; and the power end of the load-sensitive pump is connected with a power device. The system has the advantages that when an arm support raises in an amplitude-changing mode, the stability and accuracy of amplitude changing and leveling are ensured; when the arm support falls in an amplitude-changing mode, the stability of variable changing and leveling is guaranteed, meanwhile, the problems that shaking is is prone to occur, the stability is poor and the energy consumption is large in an existing scheme are solved; the system is efficient and capable of saving energy in whole, good in amplitude-changing stability, high in leveling precision, particularly simple in emergency falling control and high in reliability; and when an electric control system and a power system of a complete machine fail, safe arm falling can still be realized on the premise of ensuring the leveling performance of the work platform.

Owner:JIANGSU LIUGONG MACHINERY

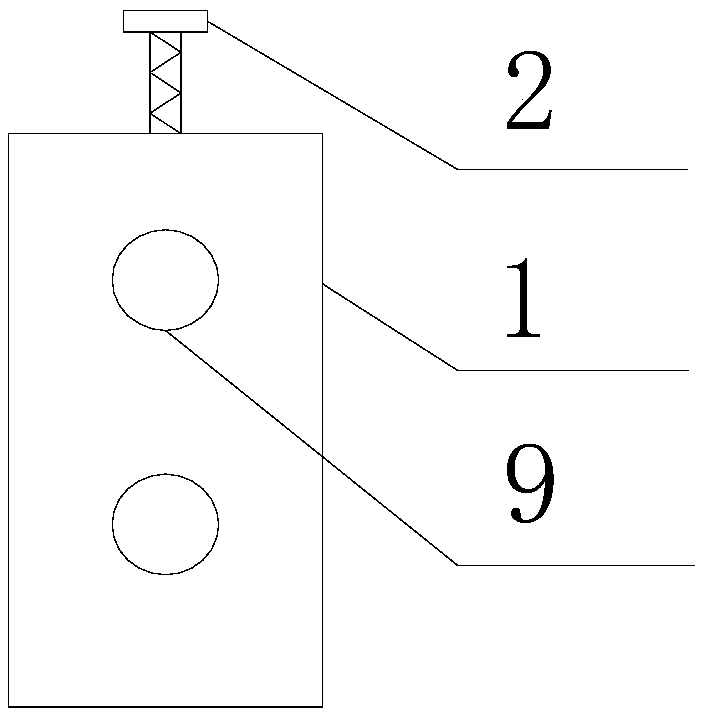

Adjusting device

InactiveCN101962124AGuaranteed craftsmanshipAvoid circulationConveyor partsPulp and paper industryScrew thread

The invention relates to the structure field of grain machinery, in particular to an adjusting device used for adjusting feeding or discharging. The adjusting device comprises a frame, wherein the frame is provided with a bolt and a nut; the bolt is connected with the nut through a screw thread; the nut is fixedly connected with the frame; the bolt penetrates the frame; the free end of the bolt is connected with an adjusting plate; and the adjusting plate is arranged in the frame. The adjusting device of the invention is arranged at the discharge port of an intensive dampener; the bolt is adjusted to drive the adjusting plate to move up and down; and the material flow can be adjusted at any time according to technological requirements to ensure the best use effect of the device. Or the adjusting device of the invention can be arranged at the feed port of a circulating air separator, and the bolt is rotated to adjust the size of the adjusting plate opening, ensure the blending effect, prevent the internal circulating air from circulating with the outside and ensuring the technical effect of the circulating air separator.

Owner:扬州市仙龙粮食机械有限公司

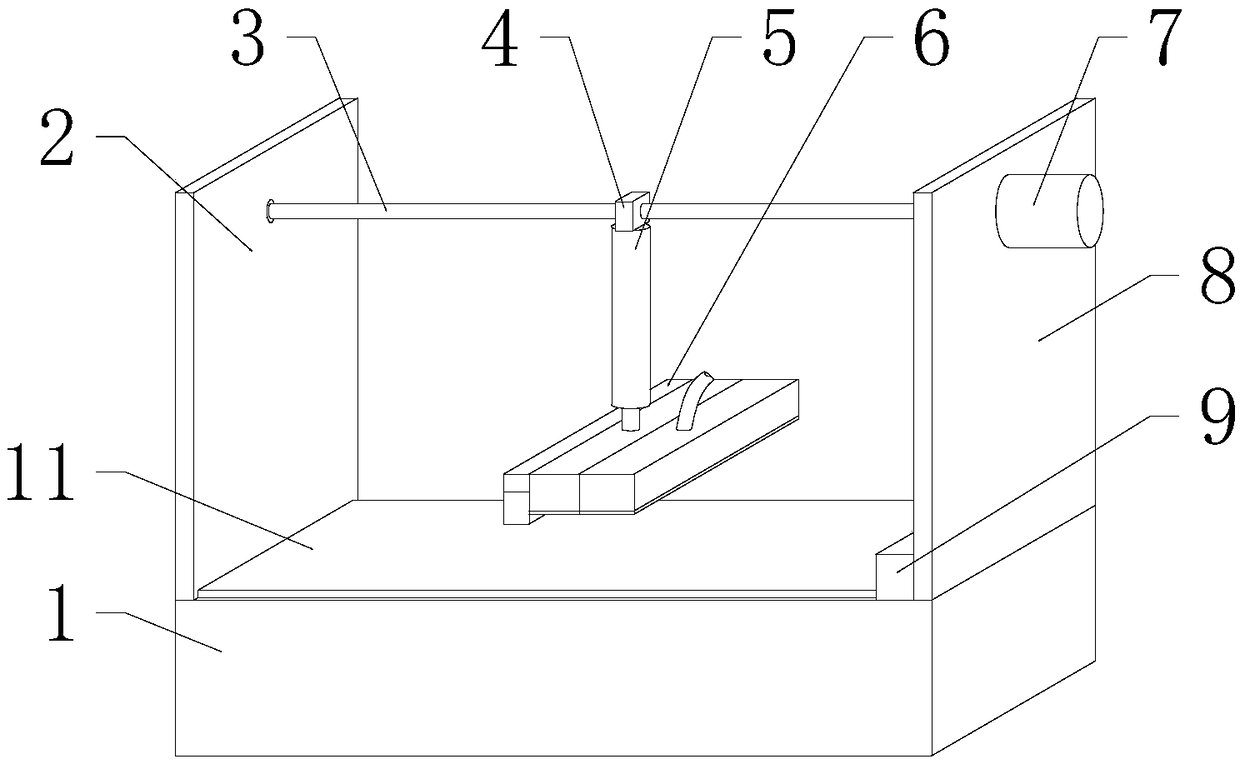

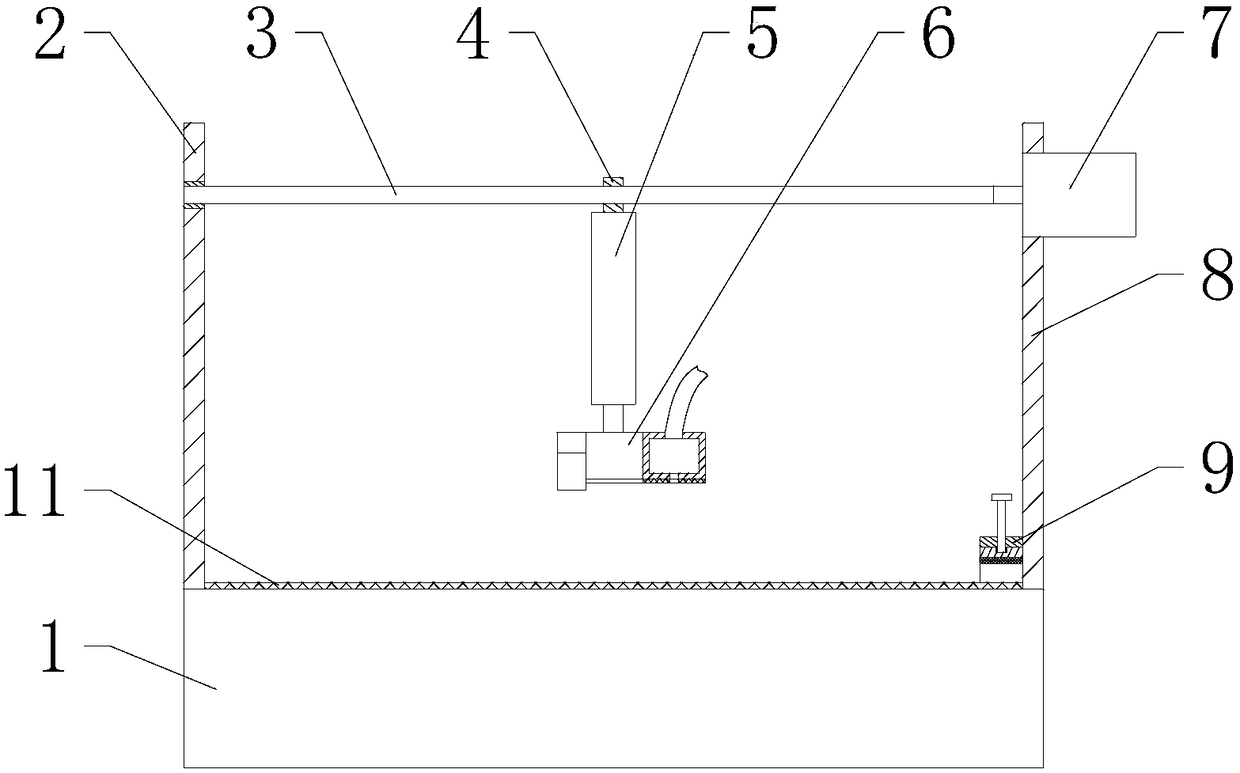

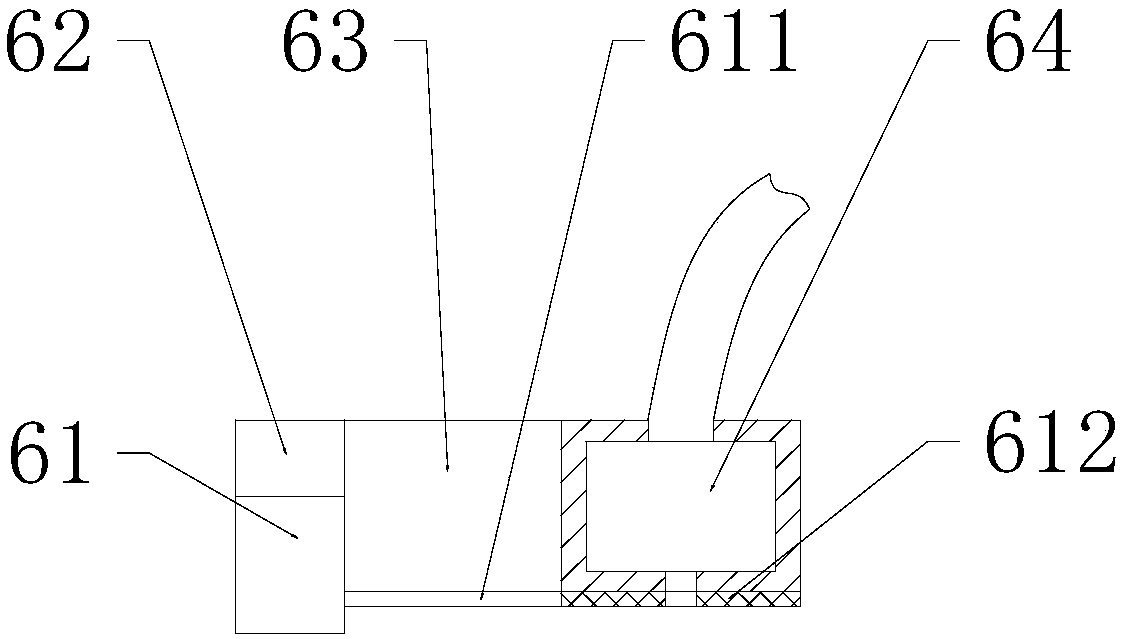

Leveling device for road and bridge construction

InactiveCN113789702AGuaranteed stabilityGuaranteed leveling effectRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to the technical field of road surface leveling, and discloses a leveling device for road and bridge construction, which comprises a working box and moving wheels, the moving wheels are arranged at the bottom of the working box, the leveling device for road and bridge construction further comprises a rolling roller and a lifting device, and the lifting device is used for driving the rolling roller to move; wherein a through hole is formed in the bottom of the working box, the rolling roller extends out of the working box through the through hole to grind the ground or retract into the working box, through first-round grinding of the rolling roller, the leveling property of the middle part can be guaranteed, and traces left when the moving wheels pass by cannot be treated by the rolling roller, so that an auxiliary device is arranged, two auxiliary rollers are arranged behind the moving wheels, so that traces left by the moving wheels are eliminated, the effect of assisting in rolling the rollers is achieved, and a push shovel device is arranged, so that shielding objects possibly existing on the road surface are eliminated, and the road is effectively cleaned for the rollers.

Owner:李立博

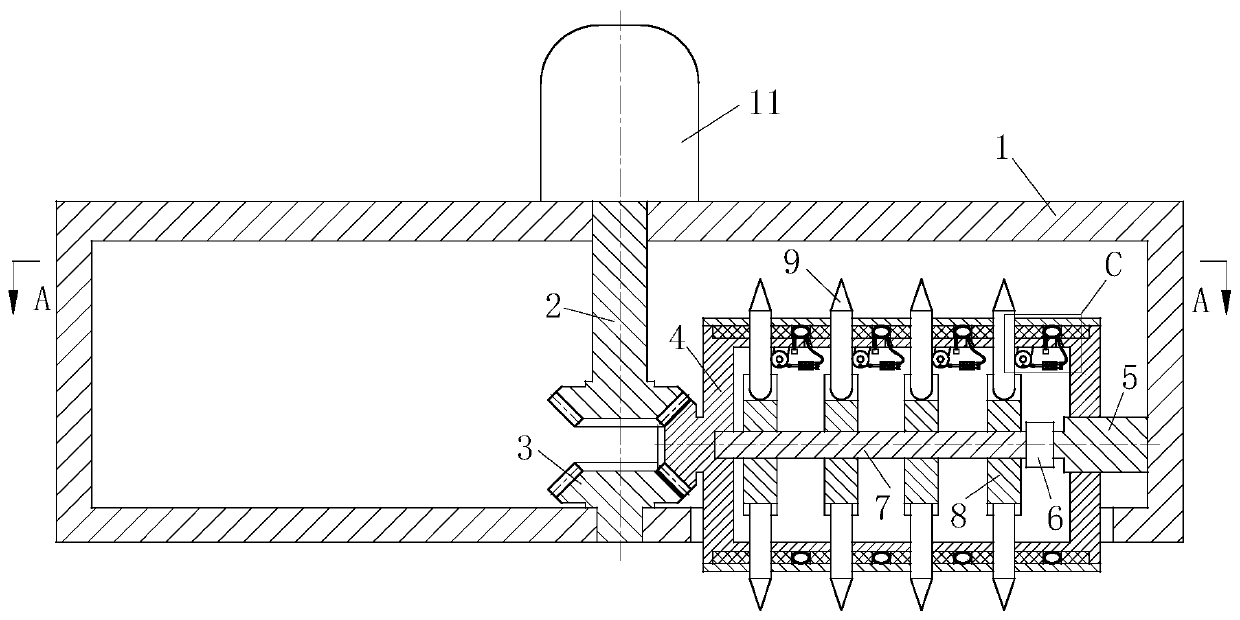

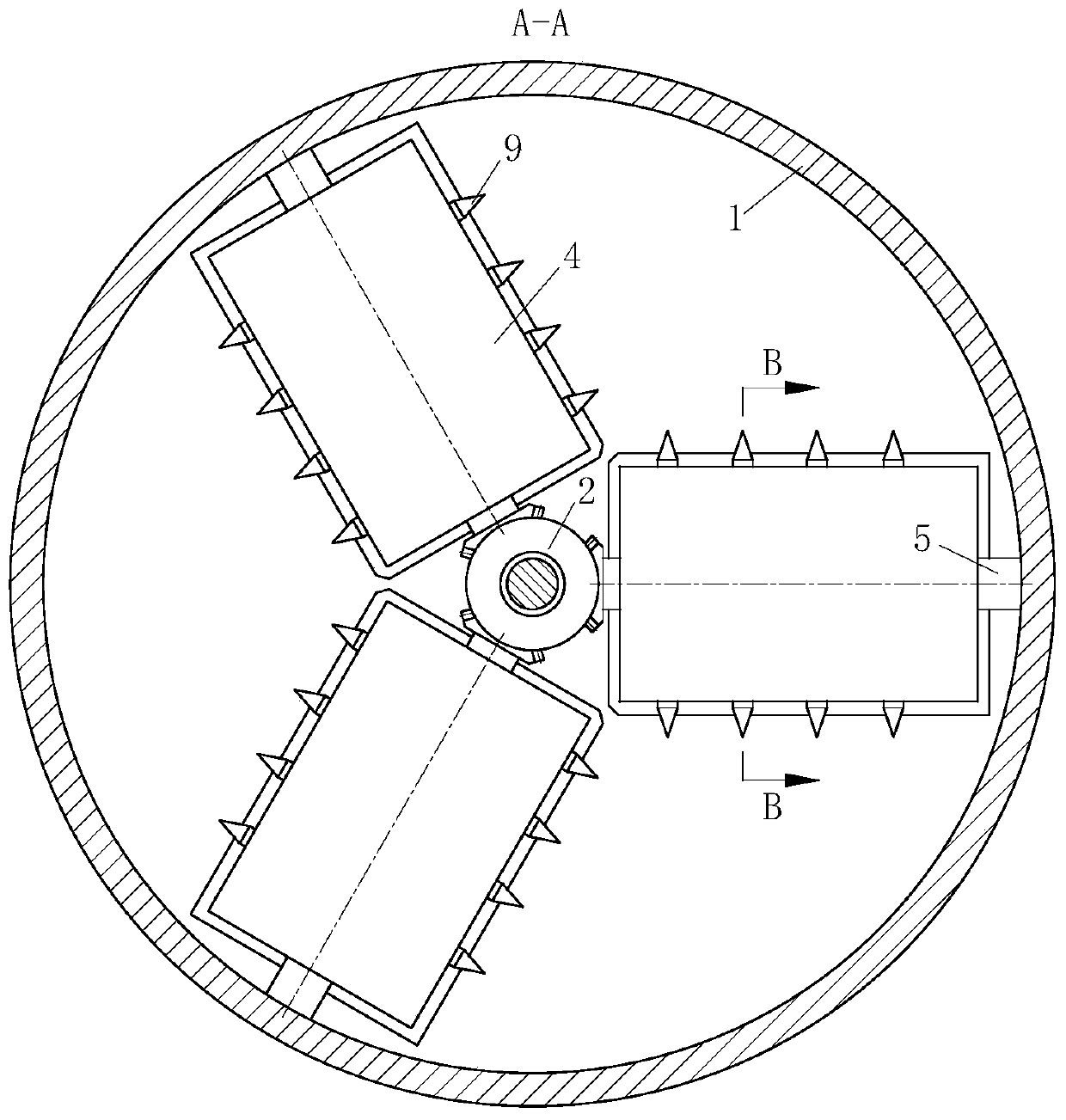

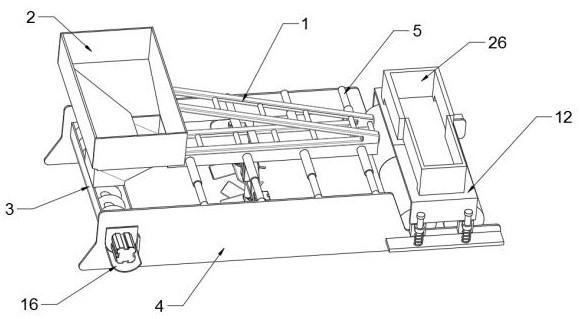

Expressway pavement repair device

The invention belongs to the technical field of pavement repair devices, Specifically, the invention relates to an expressway pavement repair device, include a housing, Motor, gear shaft, driven gear,rolling drum, a fixed shaft, a clutch, a transmission shaft, a pattern cam and a perforated steel needle, wherein one end of the rolling drum is rotatably installed on the side wall of the housing through the fixed shaft, a bevel gear is arranged on the other end face of the rolling drum, the upper part of the bevel gear at the end of the rolling drum is meshed with the bevel gear at the lower end of the gear shaft, and the lower part of the bevel gear at the end of the rolling drum is meshed with the driven gear; As that clutch is arrange at one end of the transmission shaft, and uniformly arranging a group of pattern cams on the transmission shaft, The perforated steel heated on the rolling drum is used to punch holes on the damaged pavement, and the pavement is heated at the same time,and the shrinkage can be realized; furthermore, the softened pavement is rolled by the rolling drum, the pavement is leveled, the pavement is repaired quickly, and the smoothness of the expressway isensured.

Owner:广州华南路桥实业有限公司

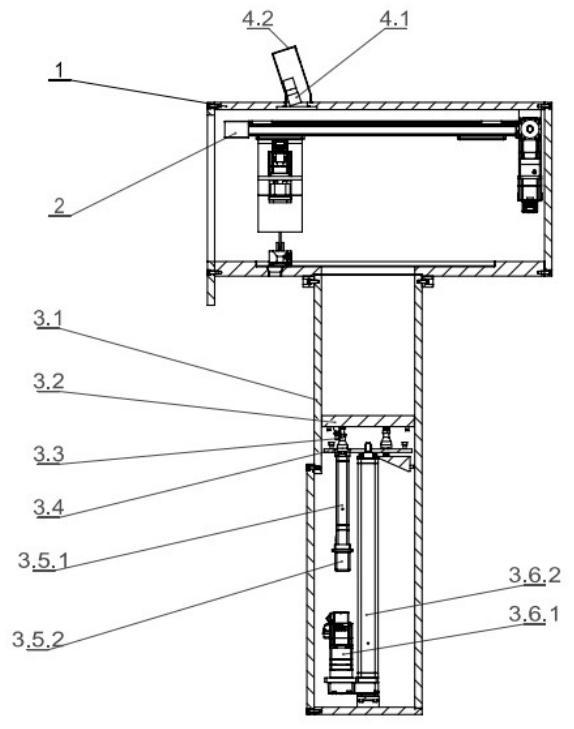

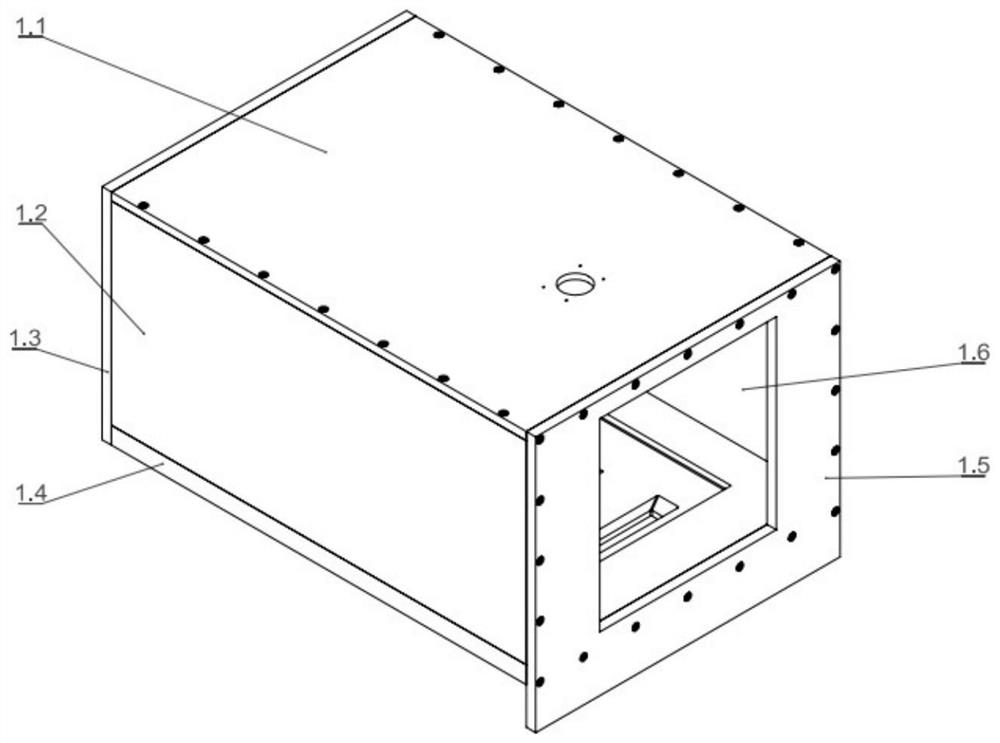

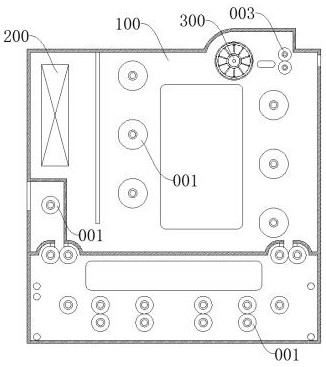

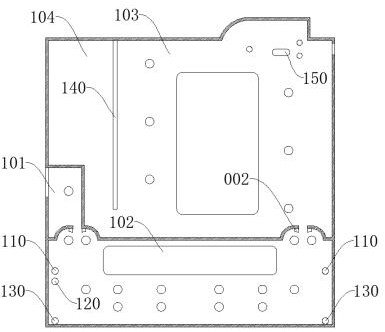

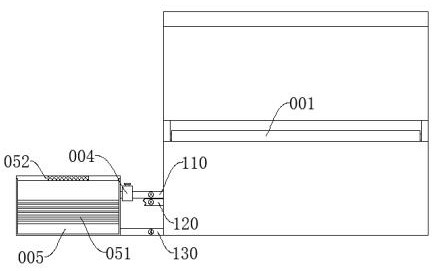

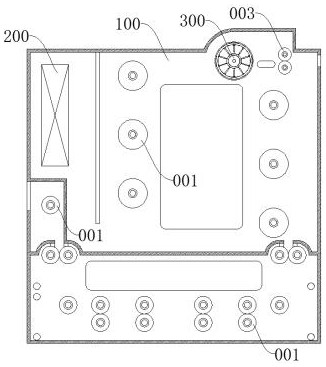

A 3D printing equipment leveling system and automatic leveling method thereof

ActiveCN112846237BHigh leveling accuracyHigh measurement accuracyAdditive manufacturing apparatus3D object support structuresReduction driveElectric machinery

The invention discloses a 3D printing equipment leveling system and an automatic leveling method thereof, belonging to the field of research and development of powder additive manufacturing equipment. The system includes: working chamber, including working platform, working chamber roof, working chamber left vertical board, working chamber right vertical board, working chamber front vertical board, working chamber rear vertical board; powder spreading device, including knife rest, posture adjustment Unit, drive guide rail, reducer, adapter shaft, drive motor; forming part lifting device, including cylinder block, base plate, universal adjustment bearing, jacking support plate, leveling unit and lifting unit; and image acquisition device and data processing device. The invention can automatically perform leveling, saves a lot of time, ensures leveling accuracy, can eliminate subtle errors caused by scraper jamming, substrate processing, manual loading and unloading of substrates, etc., and is more efficient and smarter.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

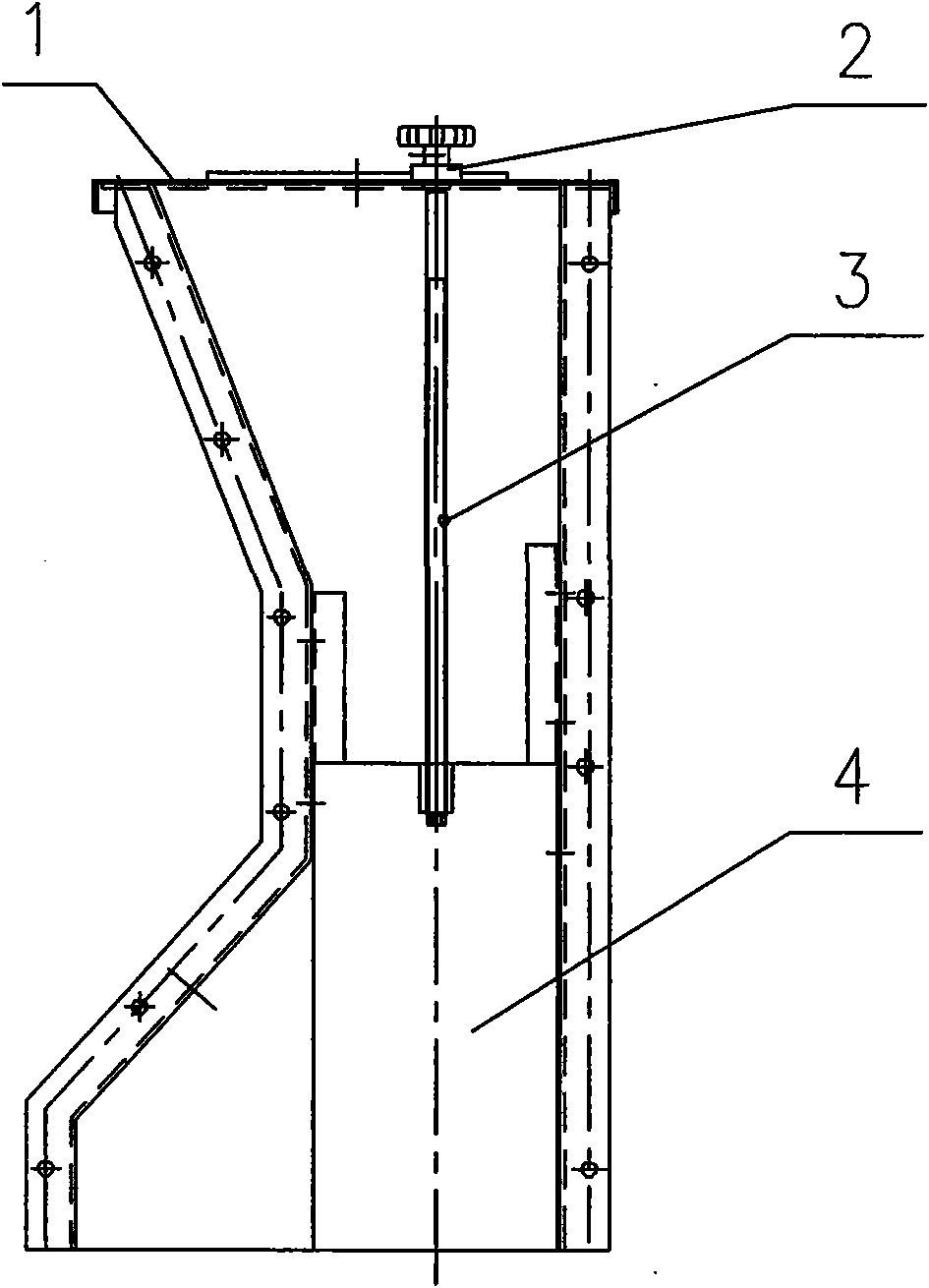

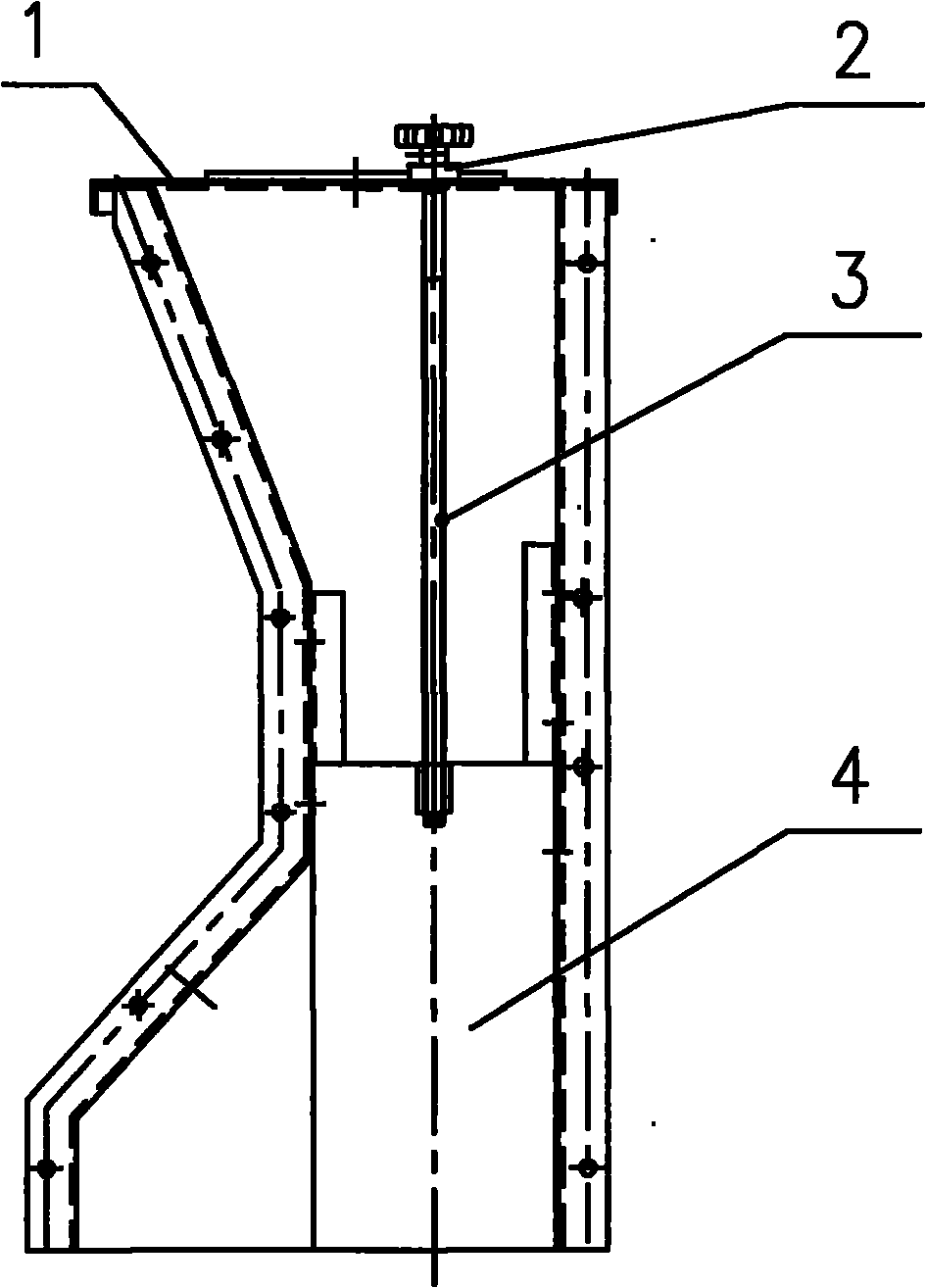

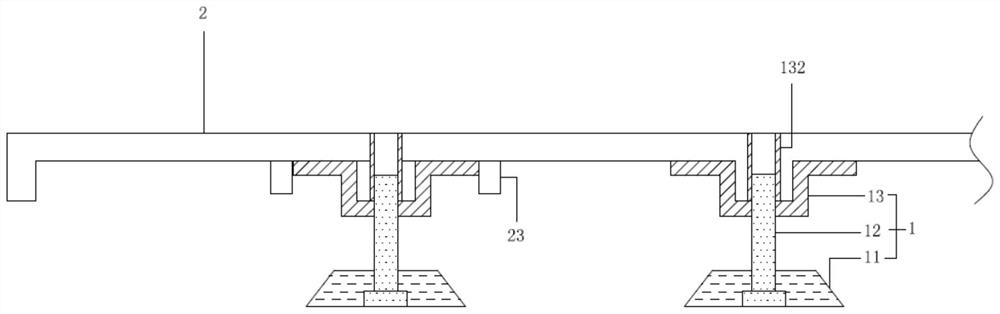

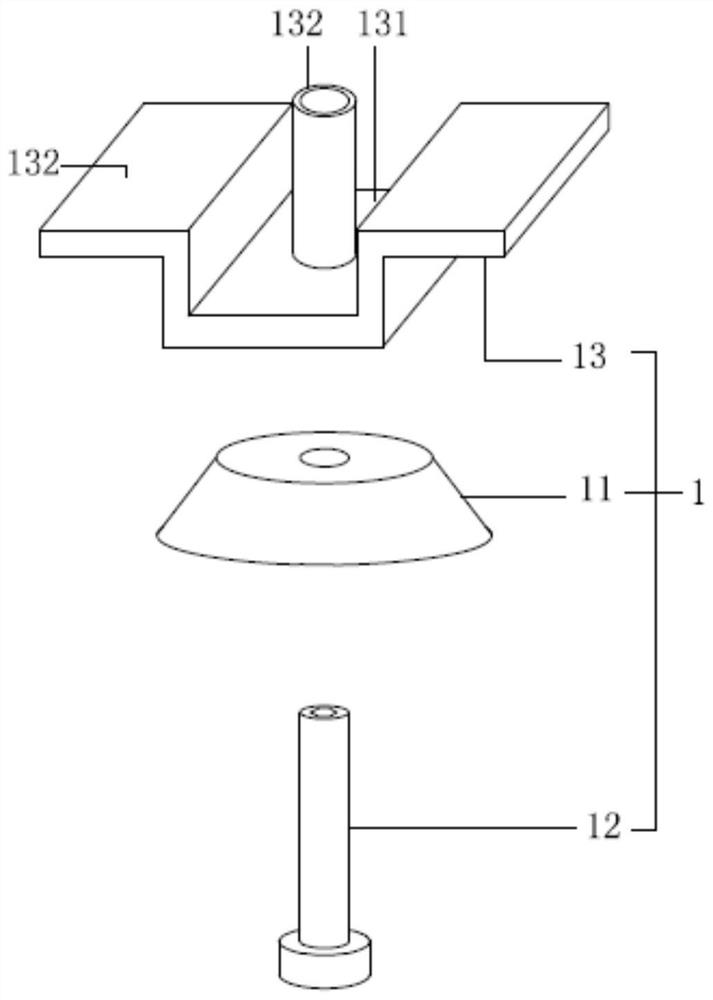

Dual-leveling decorative wall surface assembly type overhead mounting structure

PendingCN114046013AIncrease leveling rangeGuaranteed leveling effectCovering/liningsKeelScrew thread

The invention discloses a double-leveling decorative wall surface assembly type overhead mounting structure. The structure comprises a leveling base, a first leveling piece, a second leveling piece, a light steel keel and a wall panel unit, wherein the leveling base comprises a bottom plate and a connecting part, the connecting part is fixedly installed on the bottom plate, the bottom plate is fixedly installed on a wall base layer through two first fastening bolts, the two first fastening bolts are symmetrically arranged on the two sides of the connecting part, the first leveling part is connected into the connecting part in a sliding mode and fixedly installed on the connecting part through at least one screw, a second leveling part is in threaded connection to the first leveling part through the threaded connecting part, and a mounting protrusion is arranged on a surface of a base plate of the second leveling part; the light steel keel is fixedly installed on the mounting protrusion, and the wall panel unit is fixedly installed on the light steel keel. Compared with the prior art, the leveling range of the keel is widened, and the leveling effect of the wall surface is guaranteed.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

A desizing machine for circulating drying and deodorizing

ActiveCN111926500BReduce rippleGuaranteed leveling effectLiquid/gas/vapor removalTextile treatment machine arrangementsThermodynamicsEngineering

The invention discloses a circulative drying and deodorizing desizing machine which belongs to the technical field of fabric desizing. The circulative drying and deodorizing desizing machine comprisesguide rollers, seal parts and an outer box, wherein the outer box is of a square box body structure, one inner cavity of the outer box is separated into a receiving guide cavity, a deodorizing cavity, a drying cavity and a heating cavity, the rear wall of one inner cavity of the left portion of the deodorizing cavity is provided with liquid injecting pipelines, an overflowing pipeline and liquiddischarging pipelines, a heat insulation plate is arranged between the drying cavity and the heating cavity, and one inner cavity of the upper right portion of the drying cavity is provided with a support plate. According to the circulative drying and deodorizing desizing machine, fabrics enter into the deodorizing cavity to be subjected to soaking-rolling deodorizing and then enter into the drying cavity to be dried, the fabric wave-rising phenomenon can be reduced by a wave flattening device, the flattening effect of squeeze rollers on the fabrics is guaranteed, namely appearance of the situation of the fabrics being pleated is reduced, and increasing of the qualified rate of the fabrics is facilitated.

Owner:FOSHAN NANHAI DEYAO TEXTILE IND CO LTD

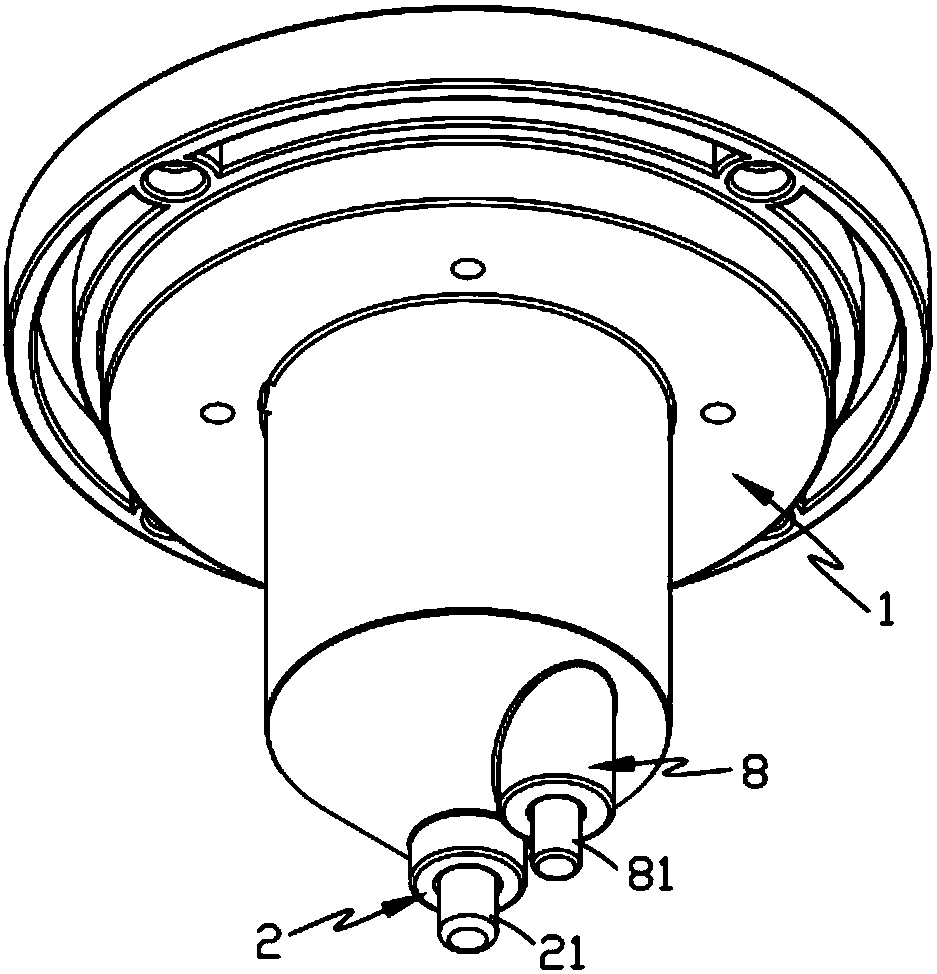

A high-frequency induction welding method for battery terminals

ActiveCN107695503BEffective control of different heating temperaturesSimplify the welding processHigh frequency current welding apparatusEngineeringFusion welding

The invention relates to a high-frequency induction welding method for terminals of storage batteries. The high-frequency induction welding method comprises the following working steps of a, a prepressing and feeding-in procedure is performed, namely, the to-be-welded storage batteries are moved to a position right below a set position of a welding gun in sequence, a gun head is driven by a driving mechanism to move downwards till a welding assembly abuts against one storage battery, the gun head moves downwards continually till a control unit above the welding assembly makes contact with a pressure sensor, and posts on the storage battery are heated by the welding assembly through a high-frequency electromagnetic induction heating method; b, a reshaping procedure is performed, namely, thegun head moves downwards continually, the heated and softened posts on the storage battery are pressed down synchronously by the welding assembly till the posts make contact with wiring pieces of theterminals, and the flattening of the end portions of the posts is completed; c, a welding procedure is performed, namely, after step b is completed, in the process that the gun head is driven by thedriving mechanism to move upwards to the initial position, the welding assembly breaks away from the posts, and the surface fusion welding of the posts is completed. By means of the high-frequency induction welding method for the terminals of the storage batteries, the conventional storage battery welding procedure is simplified, and the automated and continuous production of the storage batteriesis facilitated.

Owner:浙江金麦特自动化系统有限公司

A high-frequency welding induction gun head and a welding gun using the same

ActiveCN107442918BEffective control of different heating temperaturesSimplify the welding processHigh frequency current welding apparatusMetal working apparatusRobotic armEngineering

Owner:浙江金麦特自动化系统有限公司

Toilet paper rewinder leveling device

The invention relates to the technical field of paper processing, in particular to a leveling device for a toilet paper rewinding machine. Compared with the prior art, a cylindrical gas pad is arranged in the scheme, the length of the gas pad is the same with that of a paper picking-up rod, gas is inflated into the gas pad, the gas pad is arranged on the paper picking-up rod in a sleeving manner and is fixedly connected with the paper picking-up rod, a magnet part in sliding connection with a guide rod and an electromagnet fixedly connected with the guide rod are arranged on the guide rod, the magnet part is fixedly connected with one end of the paper picking-up rod, the paper picking-up rod is arranged in the horizontal direction, a gas pressure inductor is further arranged in the gas pad, and is electrically connected with a current controller outside the gas pad, and the current controller is electrically connected with an electric appliance. The problems that in the prior art, in the rewinding and slitting process, due to sudden tightening of paper, paper is prone to breakage, and the production cost of an enterprise is increased are solved.

Owner:重庆一锄科技有限公司

Circulative drying and deodorizing desizing machine

ActiveCN111926500AReduce rippleGuaranteed leveling effectLiquid/gas/vapor removalTextile treatment machine arrangementsThermodynamicsMechanical engineering

The invention discloses a circulative drying and deodorizing desizing machine which belongs to the technical field of fabric desizing. The circulative drying and deodorizing desizing machine comprisesguide rollers, seal parts and an outer box, wherein the outer box is of a square box body structure, one inner cavity of the outer box is separated into a receiving guide cavity, a deodorizing cavity, a drying cavity and a heating cavity, the rear wall of one inner cavity of the left portion of the deodorizing cavity is provided with liquid injecting pipelines, an overflowing pipeline and liquiddischarging pipelines, a heat insulation plate is arranged between the drying cavity and the heating cavity, and one inner cavity of the upper right portion of the drying cavity is provided with a support plate. According to the circulative drying and deodorizing desizing machine, fabrics enter into the deodorizing cavity to be subjected to soaking-rolling deodorizing and then enter into the drying cavity to be dried, the fabric wave-rising phenomenon can be reduced by a wave flattening device, the flattening effect of squeeze rollers on the fabrics is guaranteed, namely appearance of the situation of the fabrics being pleated is reduced, and increasing of the qualified rate of the fabrics is facilitated.

Owner:FOSHAN NANHAI DEYAO TEXTILE IND CO LTD

A kind of plastic film preparation and leveling machine

ActiveCN114538172BImprove the leveling effectStrong process controllabilityWebs handlingEngineeringStructural engineering

The invention provides a plastic film preparation and leveling machine, which belongs to the technical field of plastic film leveling. Connected to the front and rear ends of the bottom plate, and any side of the regular polygon side plate is completely connected to the bottom plate, and the symmetrical regular polygon side plates are connected with a first leveling component and a second leveling component. The summation is equal to the number of sides of the regular polygon side plates, and they are respectively connected to the corners of the regular polygon side plates correspondingly in rotation, and a central inflatable piece is connected between the symmetrical regular polygon side plates. The plastic film preparation and leveling machine can effectively tension and level the wrinkles in the longitudinal direction and the transverse direction of the plastic film at the same time, which fully improves the leveling effect of the plastic film. The flat combination improves the controllability of the plastic film leveling process.

Owner:徐州金太阳包装材料有限公司

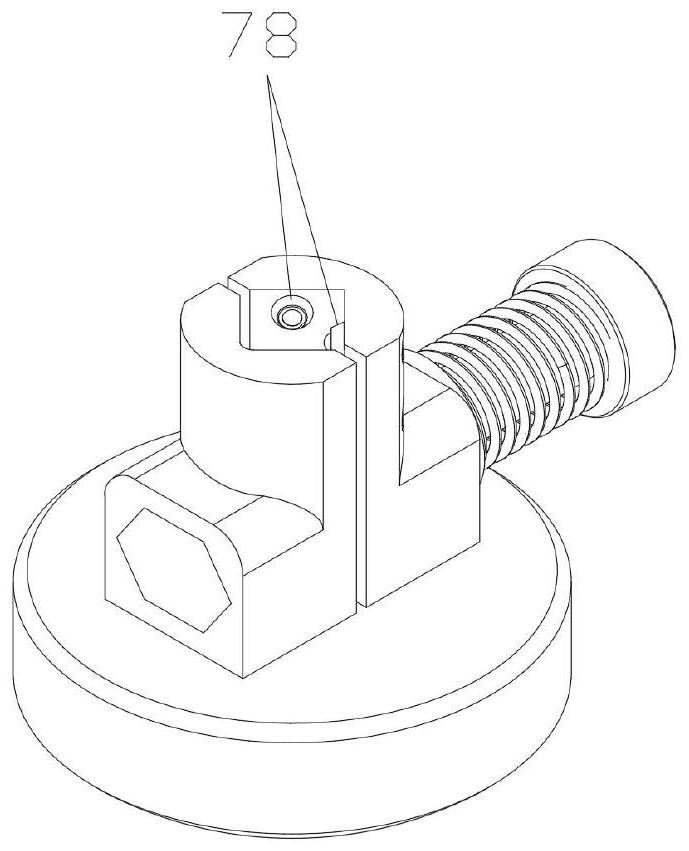

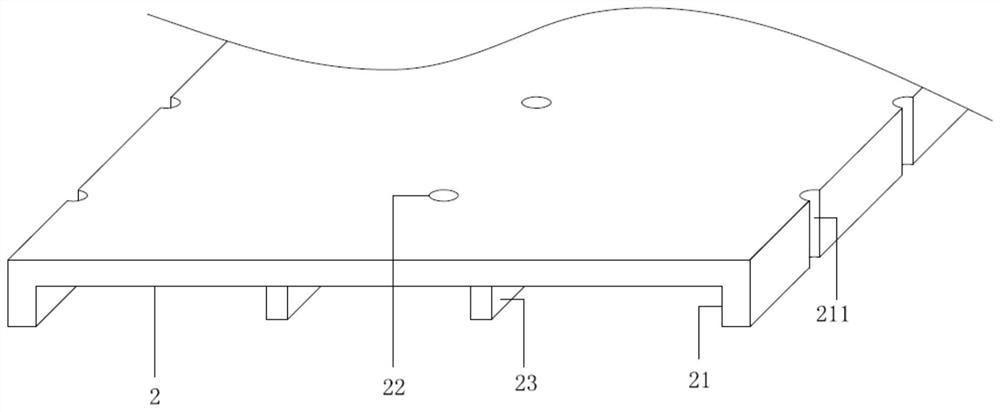

Leveling structure of assemble type ground

The invention provides a leveling structure of an assemble type ground. The leveling structure comprises a leveling member and base plates; and the leveling member comprises bases, headless screws andbearing seats, the bases are fixedly arranged on the ground, the bottoms of the headless screws are provided with mounting blocks, the mounting blocks are rotatably arranged in grooves in the bases,the headless screws penetrate through the bases and are in threaded connection with the bearing seats, the cross section of each bearing seat is U-shaped, the side walls of two adjacent base plates are clamped in the mounting grooves in the surface of the bearing seats, each bearing seat is provided with a column sleeve, the headless screws penetrate through the column sleeves, and the side wallsof the base plates are provided with avoidance grooves matched with the column sleeves. According to the leveling structure of the assembly type ground provided by the invention, the leveling member is simple in leveling mode and good in leveling effect.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

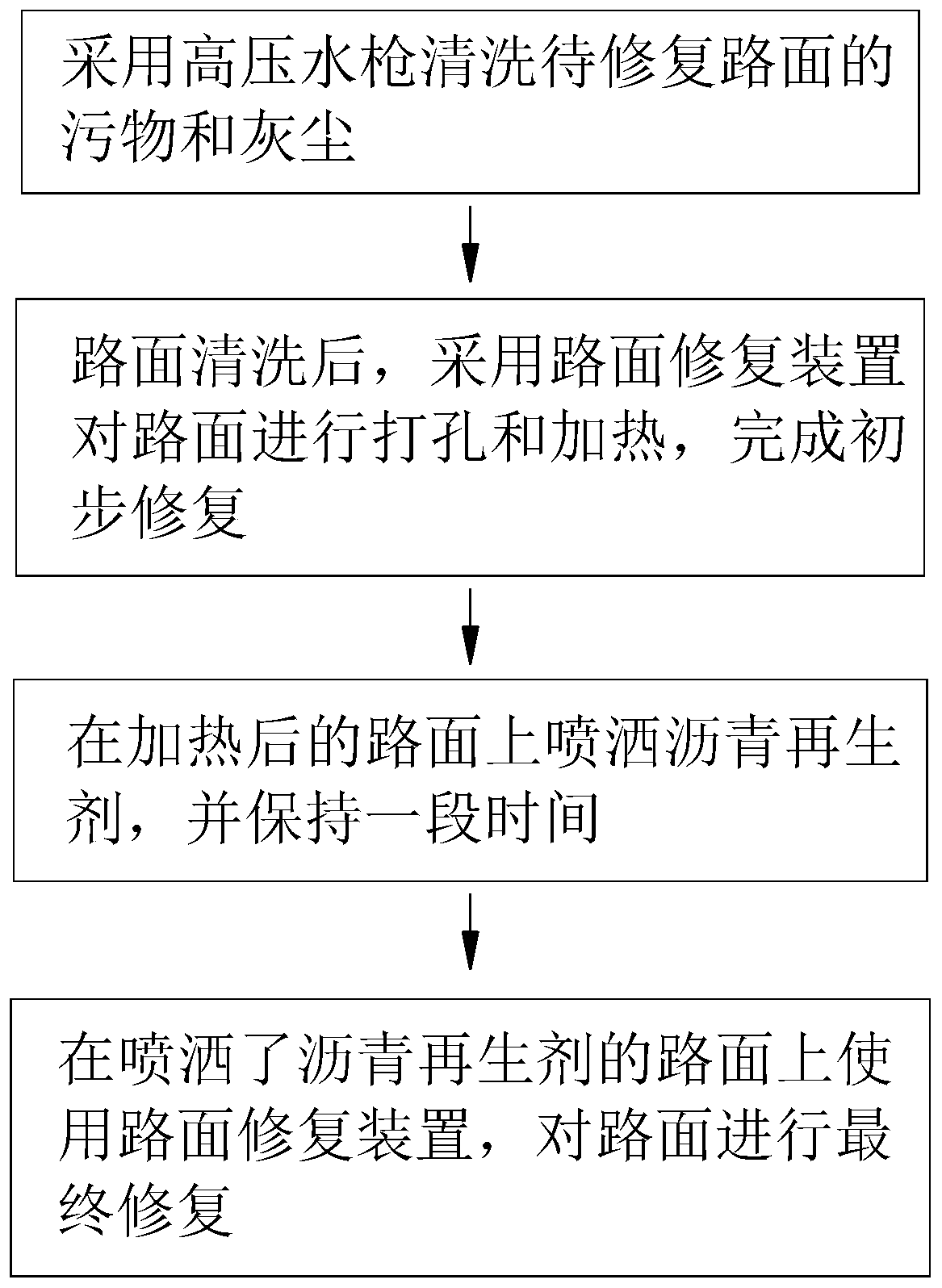

A kind of expressway pavement finishing method

The invention belongs to the technical field of road maintenance, Specifically, the invention relates to an expressway pavement repairing method, the pavement restoration device in the method comprises a housing, an electric motor, a gear shaft, a driven gear, a rolling drum, a fixed shaft, a clutch, a transmission shaft, a pattern cam, and a perforated steel needle, wherein one end of the rollingdrum is rotatably installed on a side wall of the housing through the fixed shaft, a bevel gear is arranged on the other end face of the rolling drum, and the upper part of the bevel gear at the endof the rolling drum is meshed with the bevel gear at the lower end of the gear shaft to realize transmission; because the clutch is arranged at one end of the transmission shaft, and a group of pattern cams is uniformly arranged on the transmission shaft, The perforated steel heated on the rolling drum is used to punch holes on the damaged pavement, and the pavement is heated at the same time, andthe shrinkage can be realized; furthermore, the softened pavement is rolled by the rolling drum, the pavement is leveled, the pavement is repaired quickly, and the smoothness of the expressway is ensured.

Owner:广东衍发建设工程管理有限公司

Asphalt laying equipment for construction engineering

ActiveCN111535127BImprove compactionAvoid flashRoads maintainenceArchitectural engineeringStructural engineering

The invention discloses asphalt laying equipment for construction engineering, which comprises a mounting frame body, a feeding hopper is fixedly arranged on the mounting frame body, a material spreading groove is horizontally arranged on the lower side of the material conveying hopper, a paving scraper is fixedly arranged on one side of the material spreading groove, and a material spreading groove There are two-way material conveying components inside, and several discharge openings are evenly arranged on the lower surface of the laying trough, and two baffles are vertically and symmetrically arranged on the lower side of the installation frame body, and there are random baffles between the two baffles and the laying trough. The closed assembly for the movement of the baffle; the strip frame is connected with the installation frame body and two baffles through the rotating assembly; a number of flattening cylinders are provided on the side of the strip frame away from the material laying trough, and the upper side of the several flattening cylinders is equipped with a Telescopic weight rack. The invention can be used for laying asphalt, which is divided into three steps of laying, scraping and compacting. During the overall laying process, the baffle plate is used to ensure that the asphalt is laid in a constant range, and there is no need for manual follow-up shoveling. At the same time, the range of laying can be changed freely , so as to adapt to different road widths, and it is more convenient to lay.

Owner:盐城市恒兴建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com