A high-frequency induction welding method for battery terminals

A technology of high-frequency induction welding and terminal blocks, which is applied in the direction of high-frequency current welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high product failure rate, prolong working time, and potential safety hazards, and improve the welding efficiency. quality, improve positioning efficiency, and facilitate the effect of automatic reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

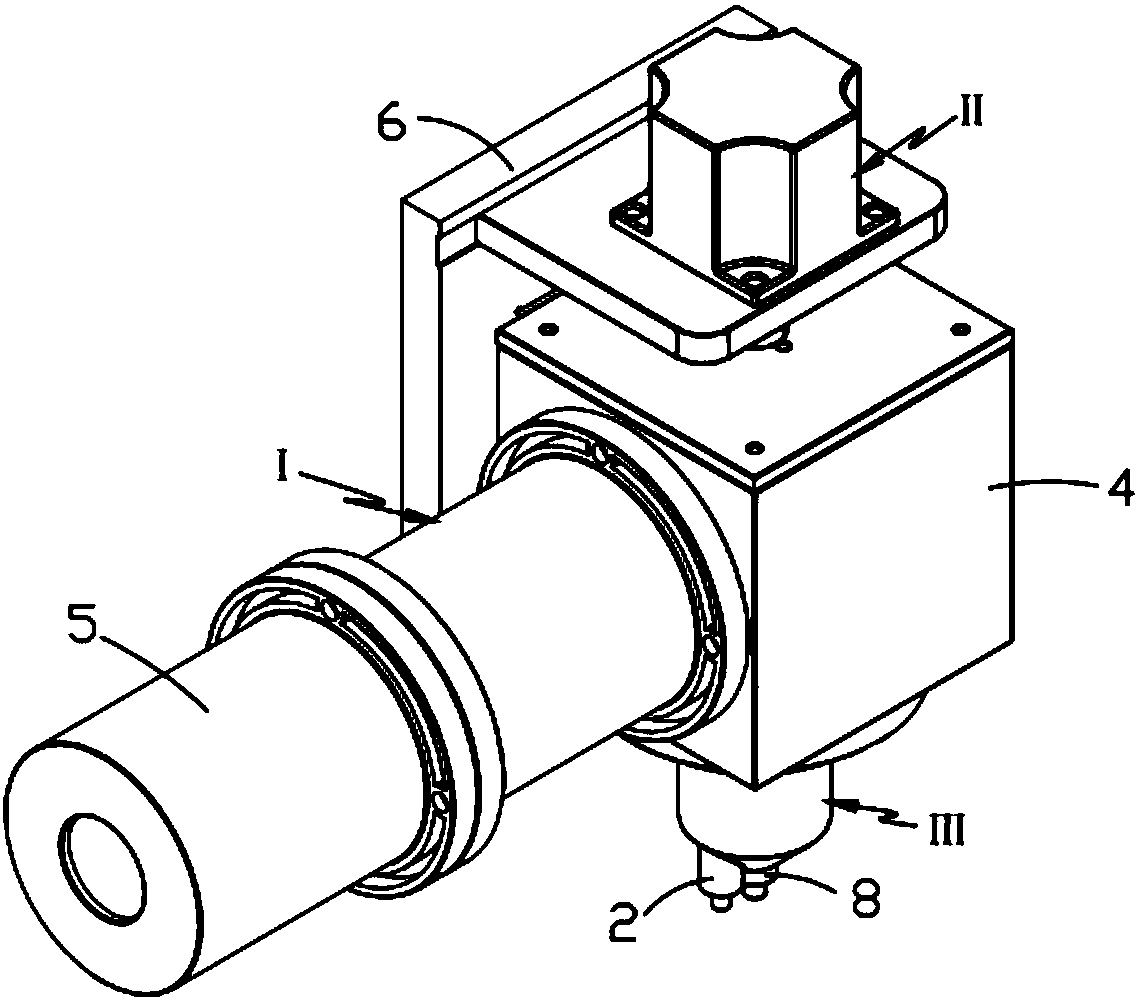

[0041] Refer to the attached Figure 1 to Figure 6 A high-frequency welding induction welding gun according to Embodiment 1 of the present invention is described.

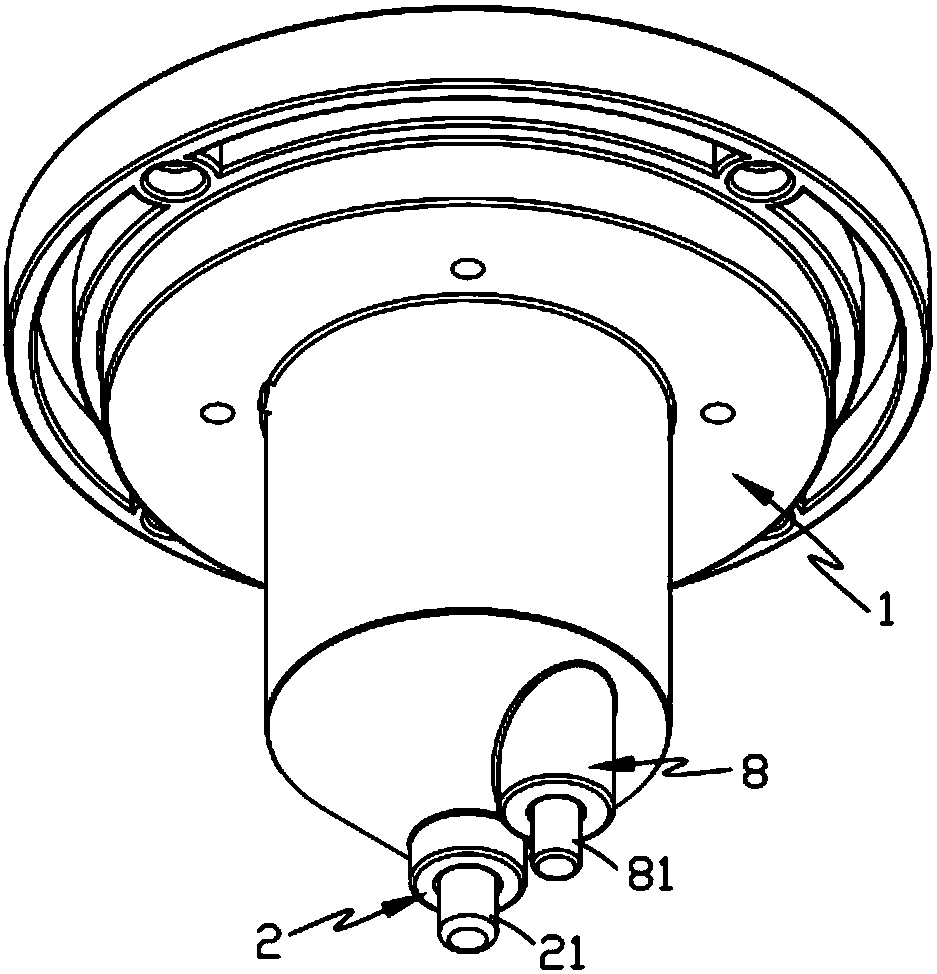

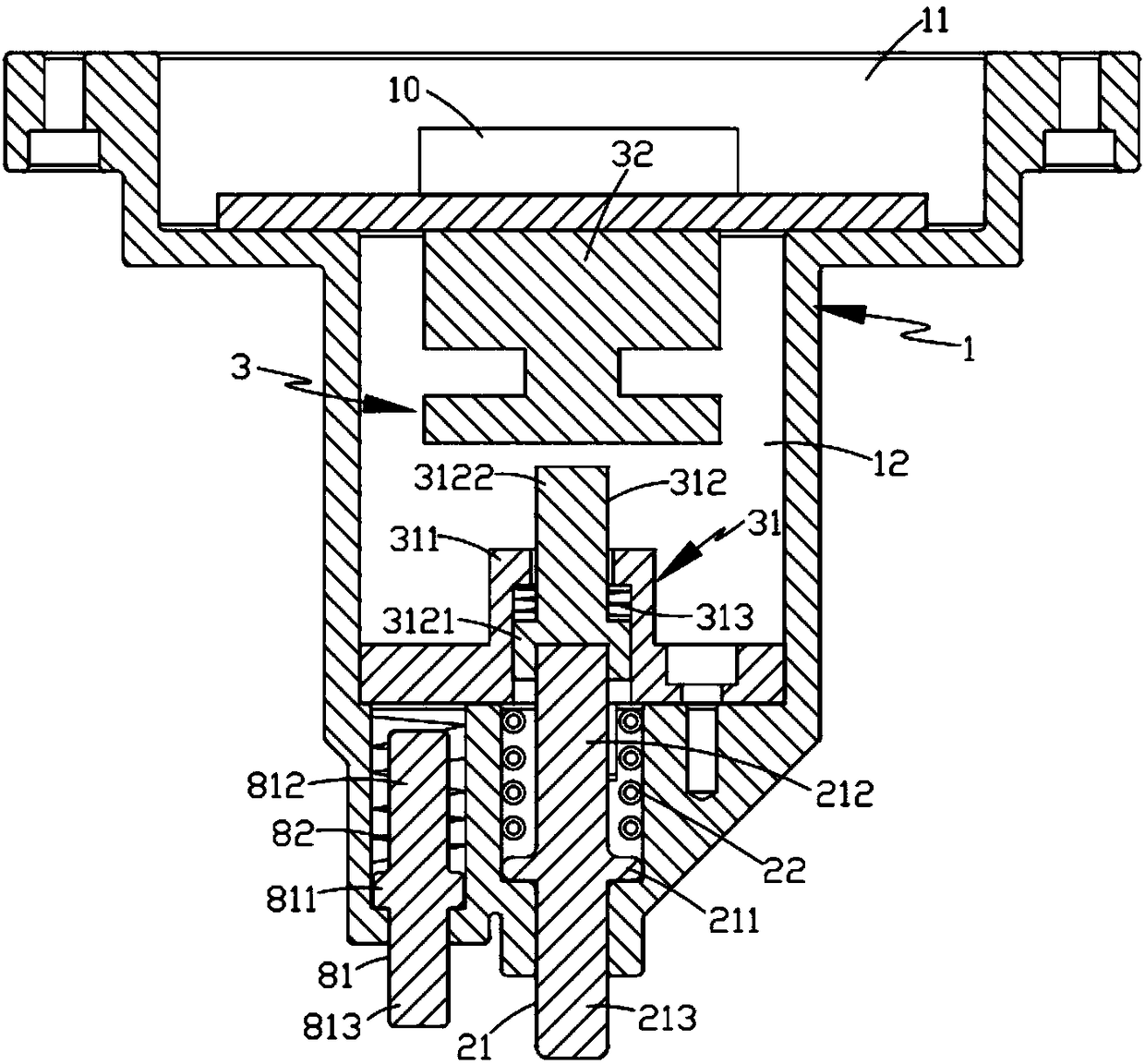

[0042] Such as figure 1 As shown, a high-frequency welding induction welding torch disclosed by the present invention includes a torch body I, a driving mechanism II that drives the torch body I to move up and down, and a torch head III, such as figure 2 with image 3 As shown, the pipette tip III includes:

[0043] Gun tip seat 1, the inside of the gun tip seat 1 is hollow;

[0044] Welding assembly 2, described welding assembly 2 is installed on the front end of described gun head seat 1, and it comprises the magnetic conduction rod 21 that the front end protrudes from described gun head seat 1 and is arranged on the outside of this magnetic conduction rod 21 and an electromagnetic induction coil 22 electrically connected to the control element 10; and

[0045] The control assembly 3, the control assembly 3...

Embodiment 2

[0061] Refer to the attached Figure 7 with Figure 8 A high-frequency induction welding method for battery terminals according to Embodiment 2 of the present invention is described.

[0062] Such as Figure 7 with Figure 8 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The second embodiment is different from that shown in Figure 1. The difference of the first embodiment is that a high-frequency induction welding method for battery terminals of the present invention includes the following working steps:

[0063] a. Pre-pressing and feeding process, the battery 7 to be welded is moved to directly below the set position of the welding torch in sequence, and the driving mechanism II drives the torch head III to move down to the front end of the magnetic rod 21 of the welding assem...

Embodiment 3

[0076] Such as Figure 1 to Figure 10 As shown, the parts that are the same as or corresponding to those in the second embodiment adopt the reference numerals corresponding to the second embodiment. For the sake of simplicity, only the differences between the second embodiment and the third embodiment are described below. figure 1 The difference of the second embodiment shown is that this embodiment also includes a preset positioning process. In the step a, the driving mechanism II drives the gun head III to move down to the position where the positioning assembly 8 and the welding assembly 2 are aligned. Lean on the battery 7; when the welding assembly 2 performs pre-press feeding, shaping and welding on the pole, the positioning assembly 8 is all against the terminal of the terminal through the elastic action of the second elastic member 82 On the one hand, the positioning efficiency is improved, and at the same time, the positioning component 8 can always press and hold the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com