Patents

Literature

33results about How to "Eliminate stuck phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

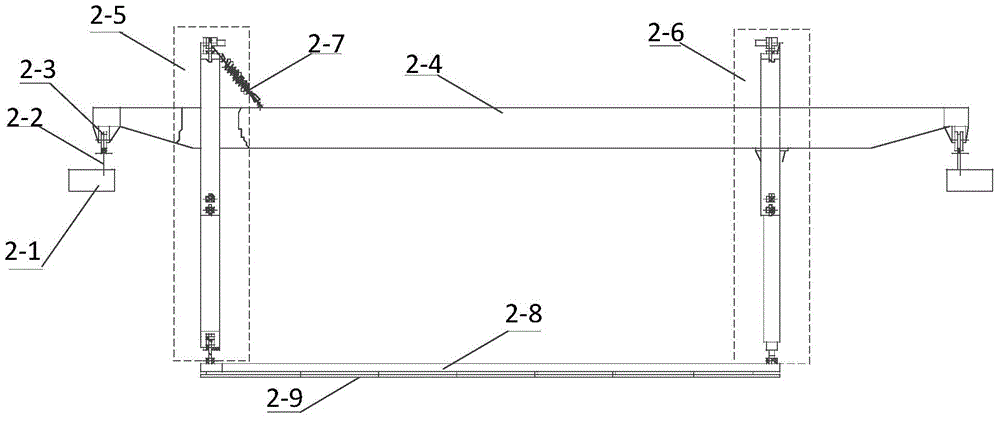

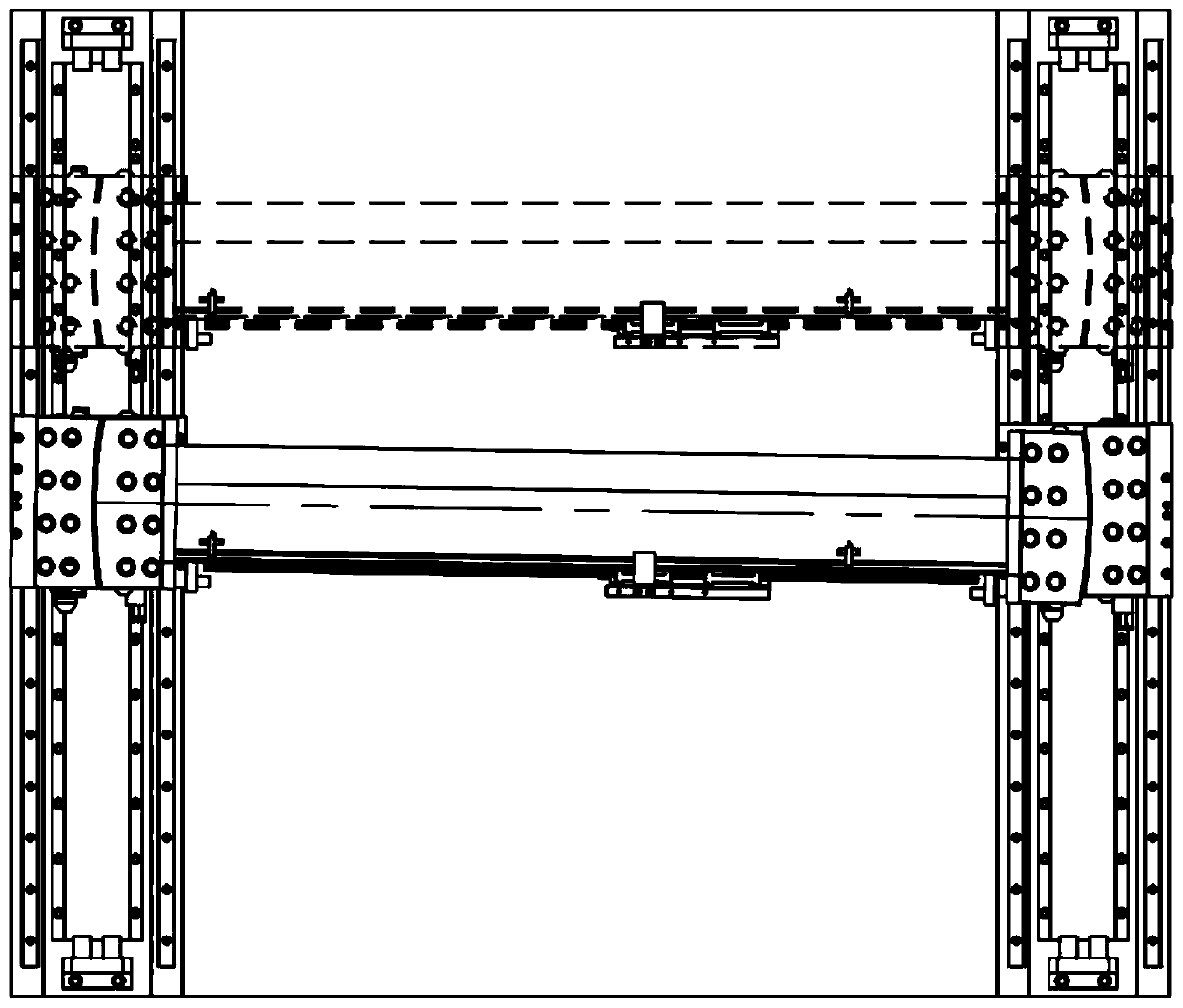

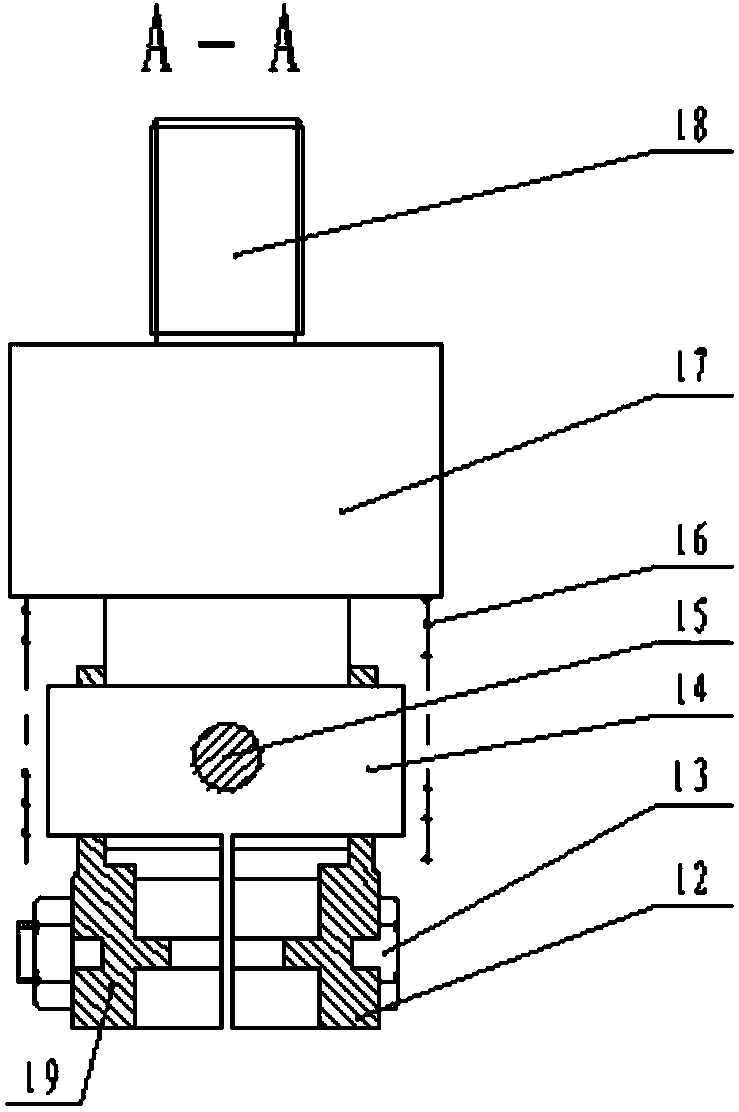

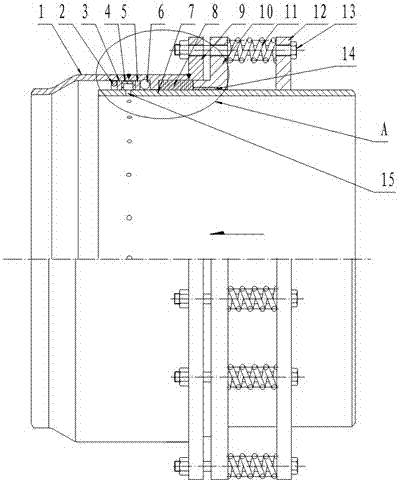

General satellite sun wing expanding frame automatically adjusting levelness

InactiveCN104943877AEliminate wobbleAccurate automatic adjustmentCosmonautic condition simulationsControl systemSatellite

The invention discloses a general satellite sun wing expanding frame automatically adjusting levelness. The general satellite sun wing expanding frame automatically adjusting levelness is composed of a mechanical system and a control system. The mechanical system mainly comprises two upper guide rails, two driving mechanisms, a main beam, a hinged telescopic mechanism and a rigid connection telescopic mechanism. The mechanical system of the sun wing expanding frame is fixed to opposite brackets arranged on the two sides of an infrastructure, and the two upper guide rails are welded to the brackets. The upper guide rails are connected with the main beam. The main beam is driven by the driving mechanisms to move on the upper guide rails, and then the whole system can move in the appointed area. According to the general satellite sun wing expanding frame automatically adjusting levelness, a contact gap and unnecessary constraint are eliminated, a lifting mechanism ascends and descends freely, the clamping phenomenon in the lifting process is eliminated, swinging of a platform is eliminated, the leveling effect and stability of the system are guaranteed, the position of the expanding frame is changed freely, and the expanding frame ascends and descends freely in the height direction, and the accurate and automatic adjustment of 0.04 mm / m of the levelness of the guide rails is achieved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

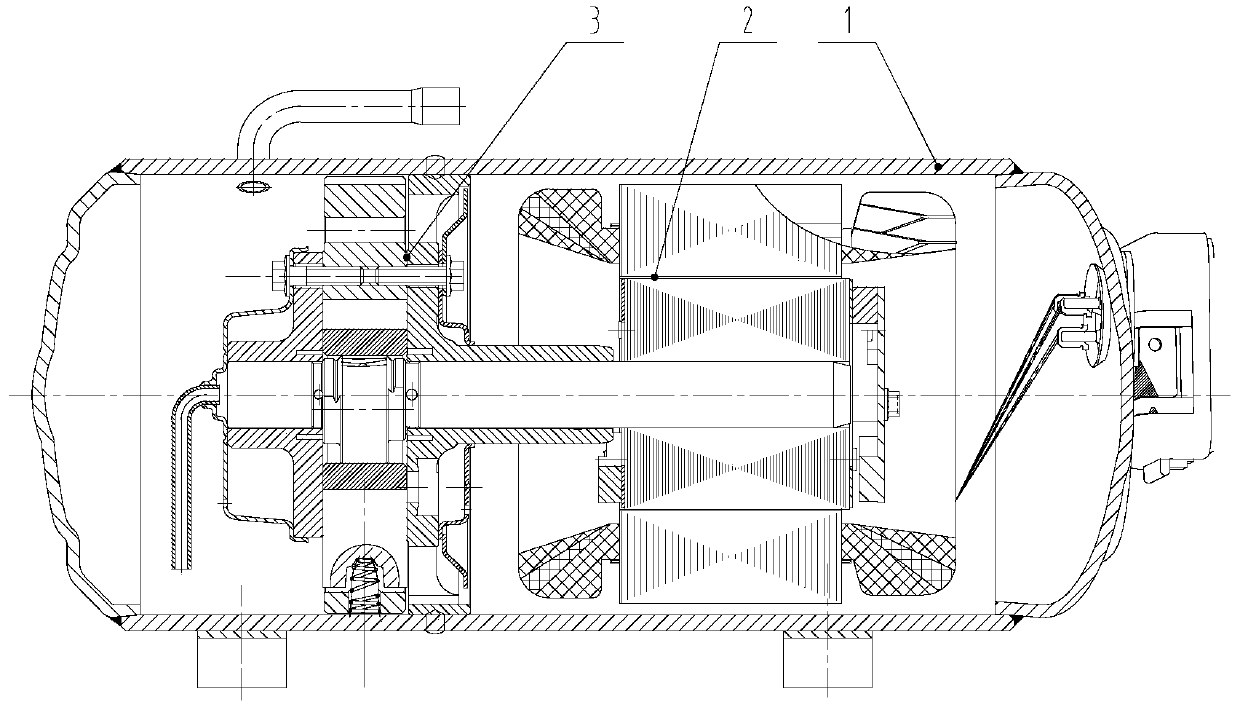

Inner-outer-pressure balanced waterproof car electric horn

InactiveCN103745716AEliminate stuckEliminate electrical short circuit burntSound producing devicesBreathingEngineering

The invention relates to an inner-outer-pressure balanced waterproof car electric horn. The electric horn comprises a horn rear cover assembly, a coil assembly, a connector assembly and a contact plate assembly, wherein the horn rear cover assembly comprises a rear cover shell, an iron core, a pressure balance hole and a plugging hole, the pressure balance hole and the plugging hole are arranged on a soleplate of the rear cover shell, the coil assembly is sleeved on the iron core in the middle of the horn rear cover assembly, the connector assembly is installed on the soleplate of the horn rear cover assembly, the contact plate assembly is arranged above the coil assembly and fixed on the rear cover shell of the horn rear cover assembly, the inner side surface of the pressure balance hole is provided with a waterproof breathing film, so that not only can the balance of the pressure inside and outside the horn be solved, but also the waterproof problem of the horn can be solved, the damage of water on the internal circuit can be avoided, the service life of the entire horn is longer, and the reliability is higher.

Owner:JIANGSU KAILING AUTO ELECTRIC

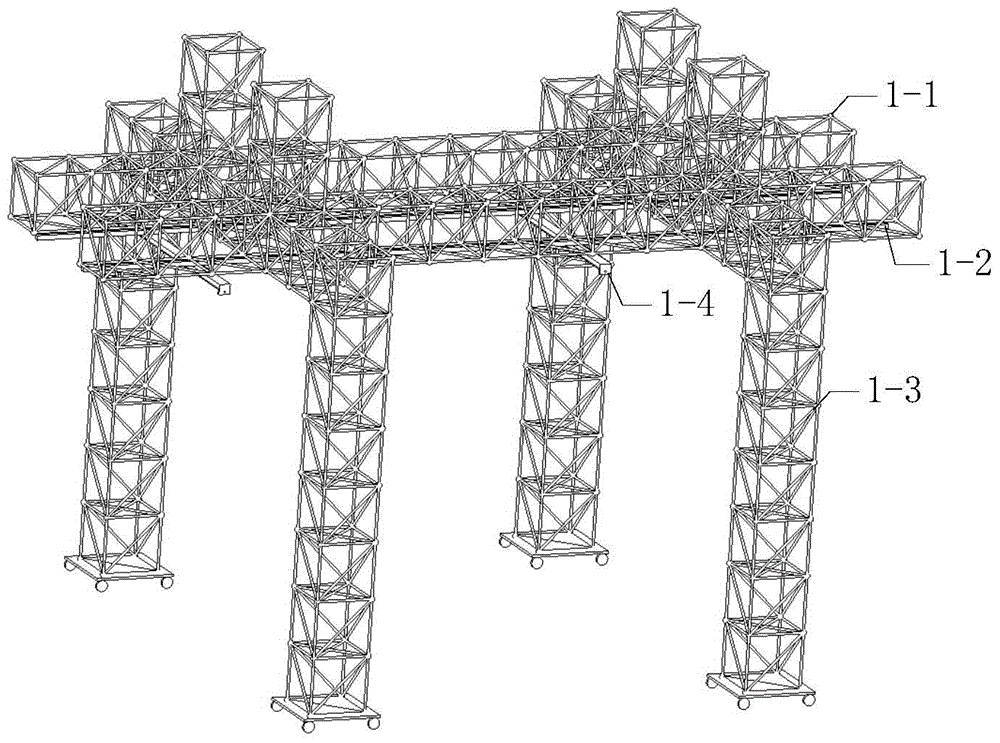

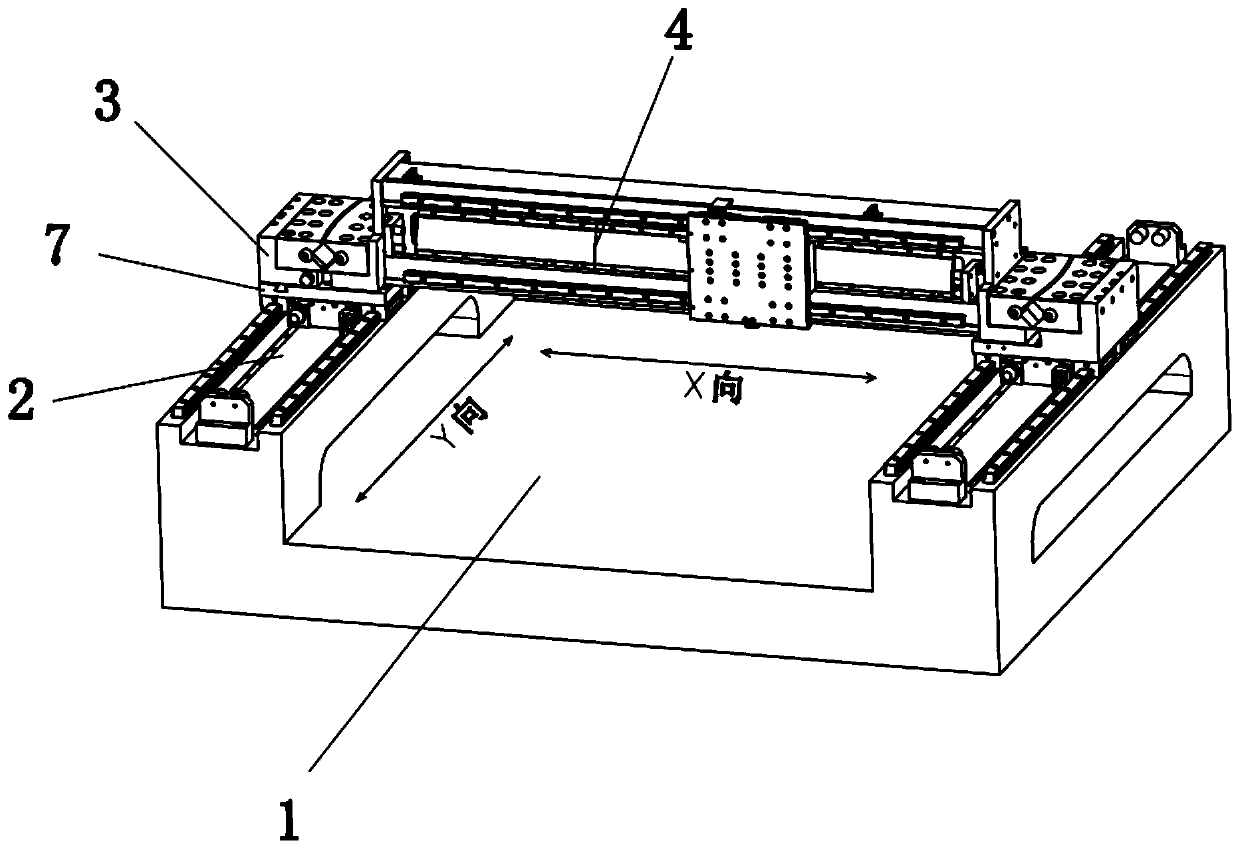

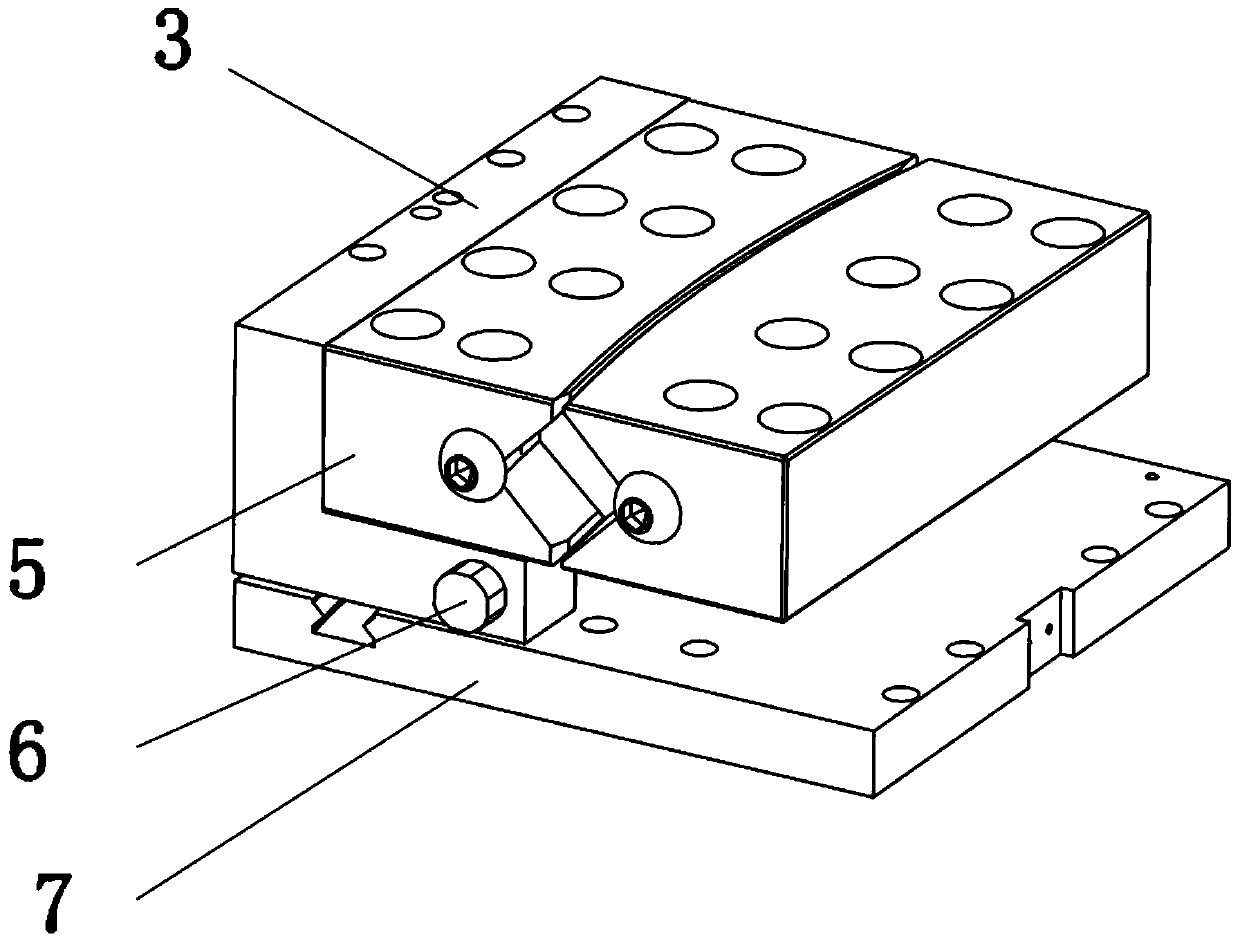

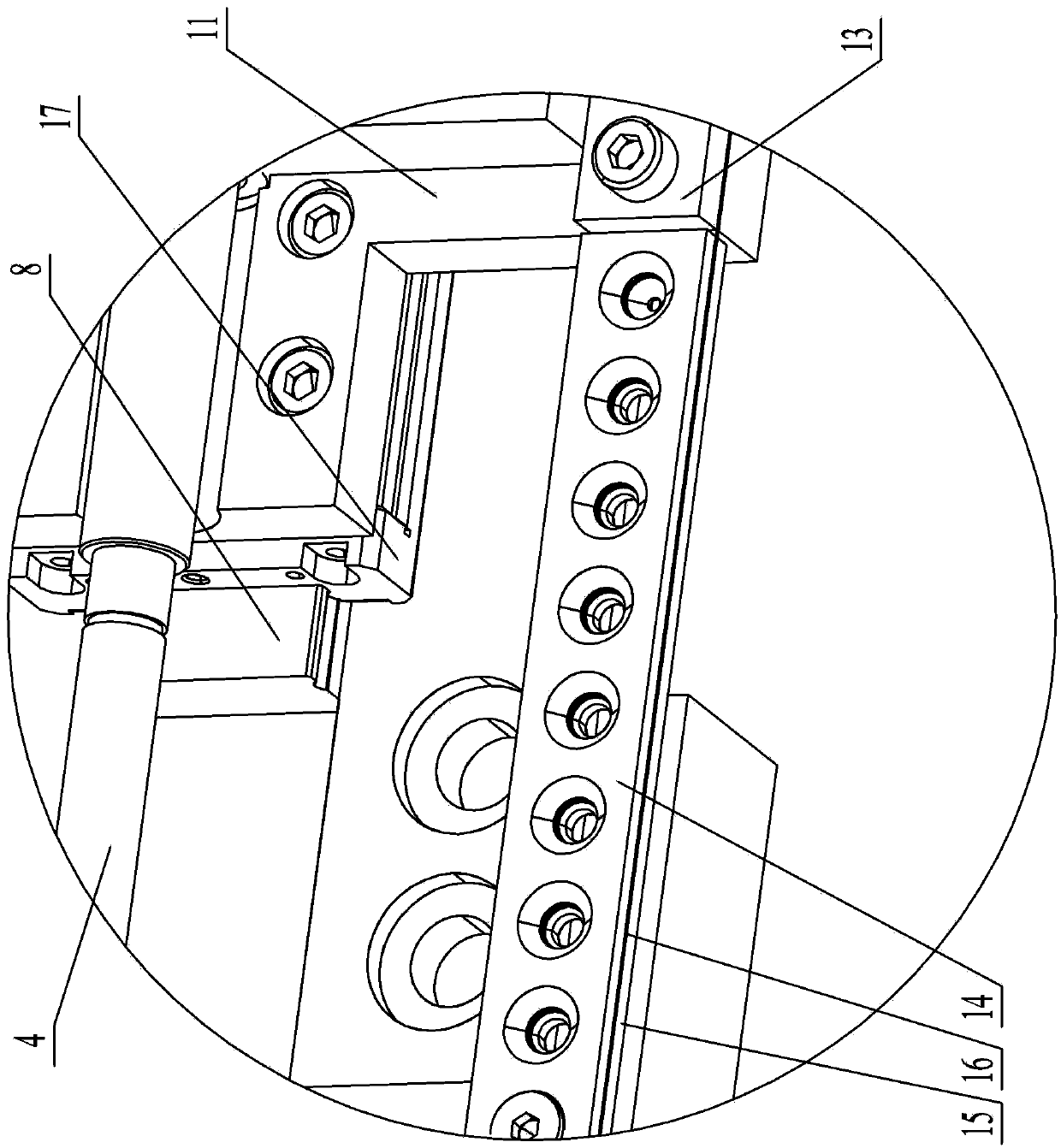

Flexible linear motor double-drive gantry platform

PendingCN109968047AEliminates squareness errorsEliminate internal stressFeeding apparatusLarge fixed membersEngineeringLinear motor

The invention discloses a flexible linear motor double-drive gantry platform. The flexible linear motor double-drive gantry platform comprises a base, longitudinal linear motors are fixedly connectedto the left side and the right side of the top end of the base correspondingly, connecting plates are fixedly connected to the top ends of the two longitudinal linear motors, sliding grooves are formed in the top ends of the left sides of the connecting plates, supports are arranged on the top ends of the connecting plates, pulleys are arranged on the bottoms of the front ends of the supports, thepulleys are movably connected with the supports, the pulleys are clamped with sliding grooves in a sliding manner, straight cylinders are fixedly connected to the front end and the rear end of the inner portion of the right side of each support, and straight rods are inserted in the straight cylinders. According to the flexible linear motor double-drive gantry platform, the phenomenon that due tomachining and mounting, the large parallelism error between the longitudinal linear motors on the two sides is caused, and structure interior inner stress is caused is effectively removed, through changing of rotation of a transverse cross beam relative to the transverse direction, the platform can well adapt to desynchrony of the longitudinal linear motors, and the aim of removing clamping caused by desynchrony of driving of the longitudinal motors on the two sides can be achieved.

Owner:横川机器人(深圳)有限公司

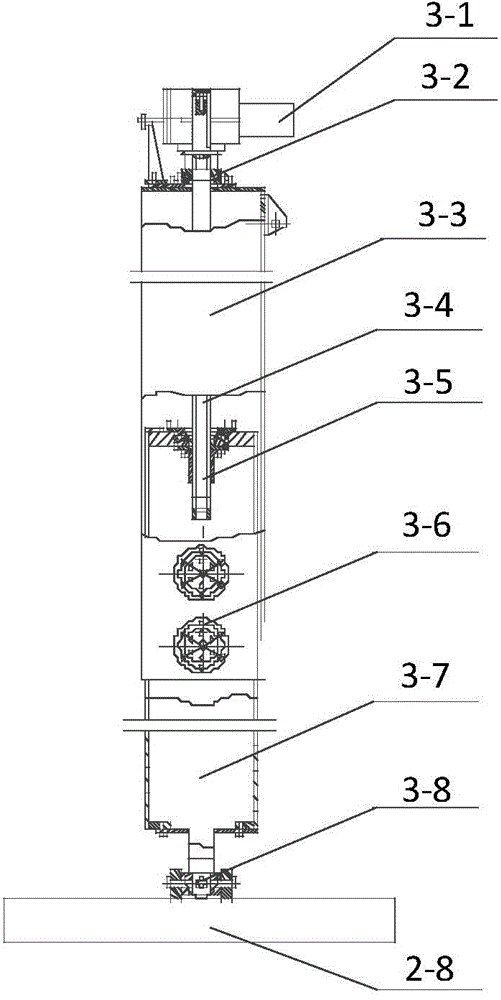

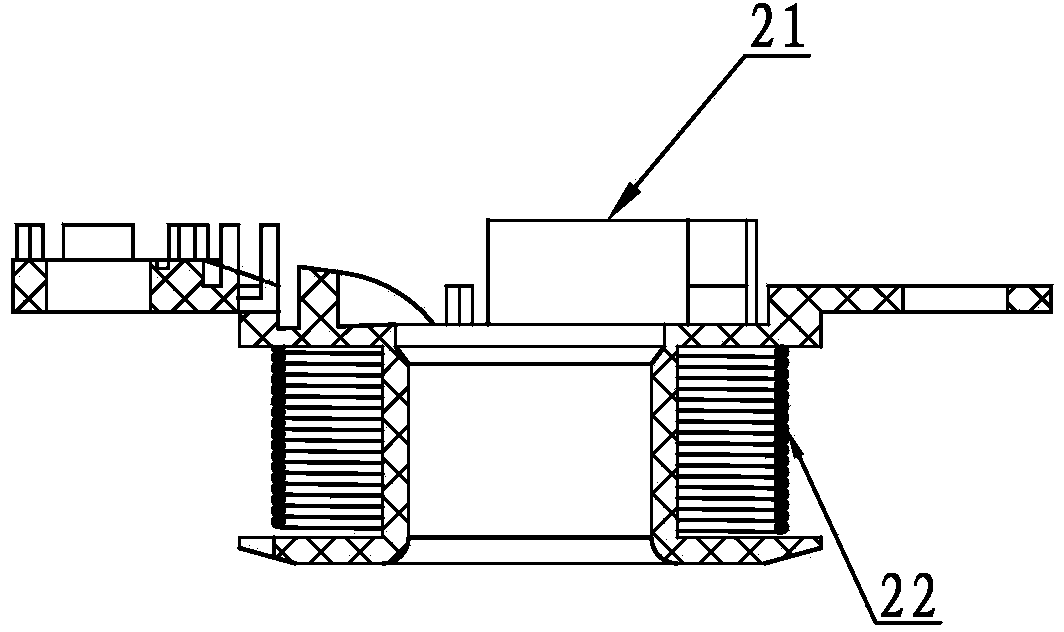

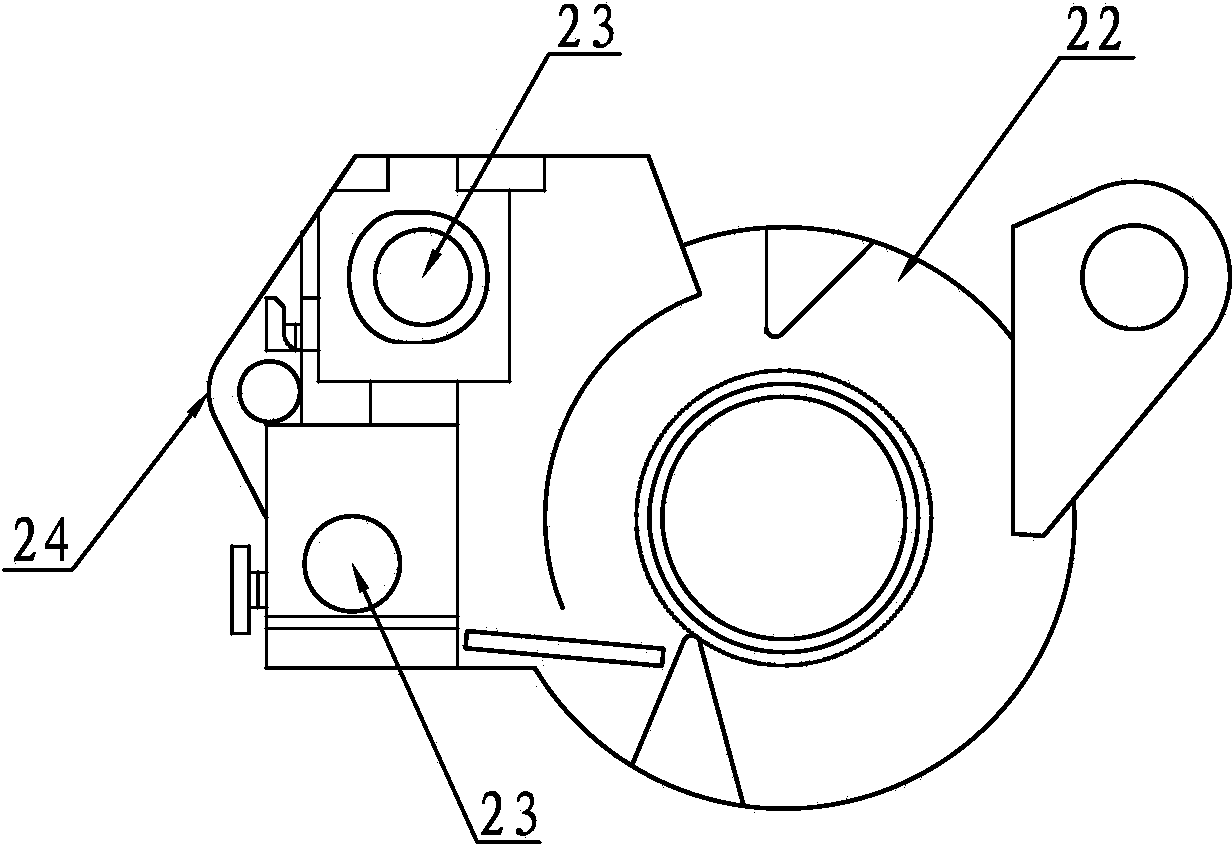

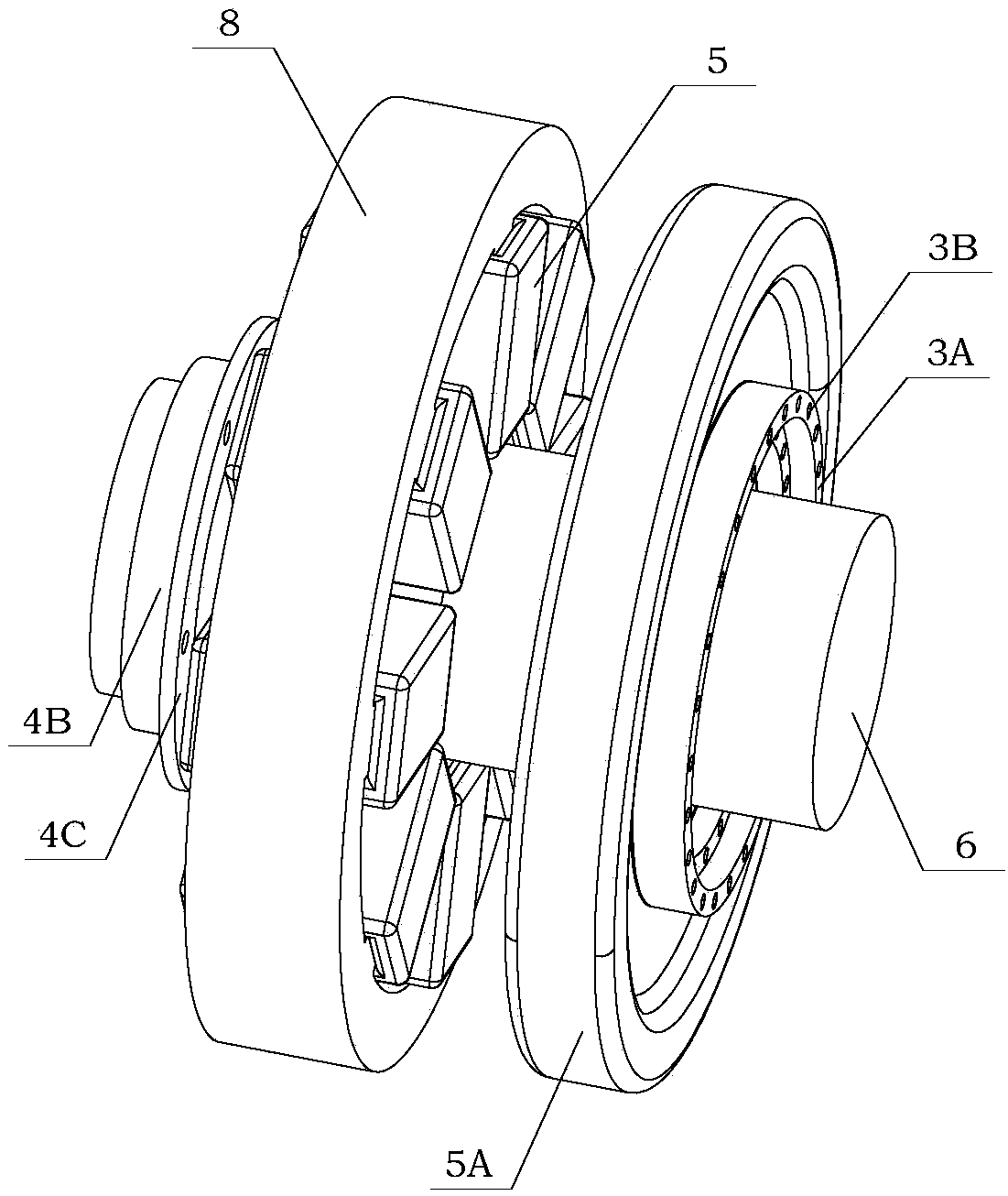

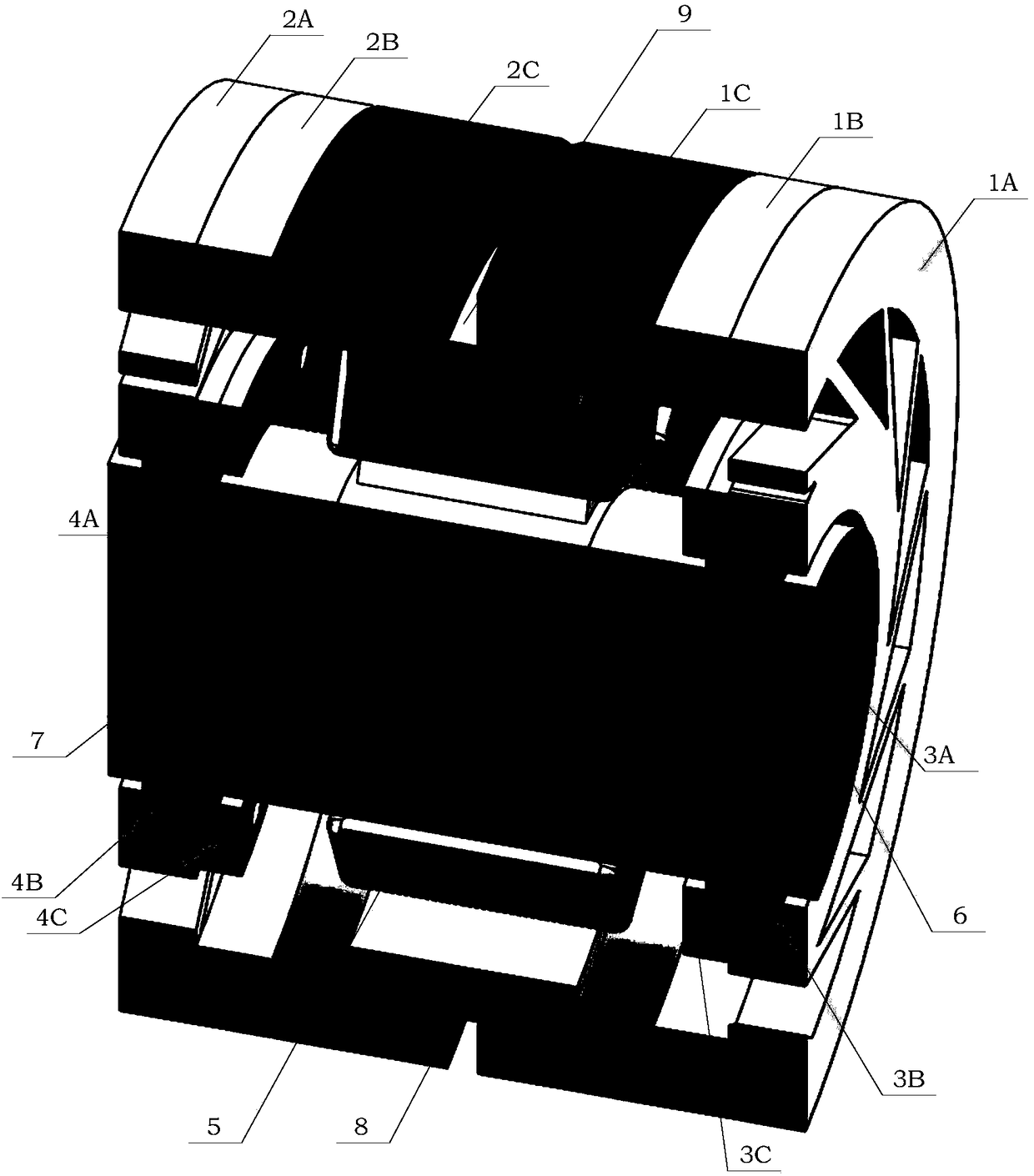

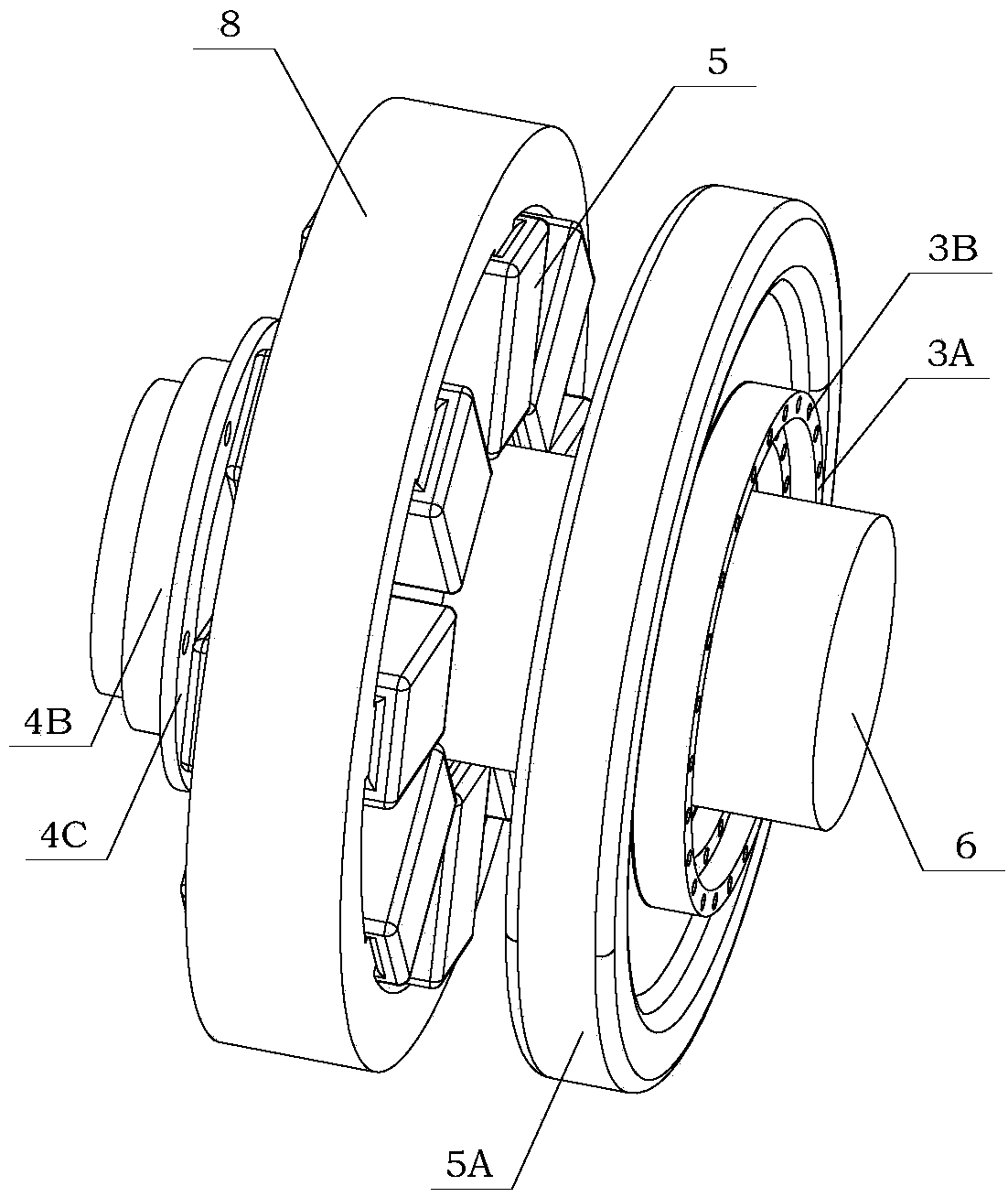

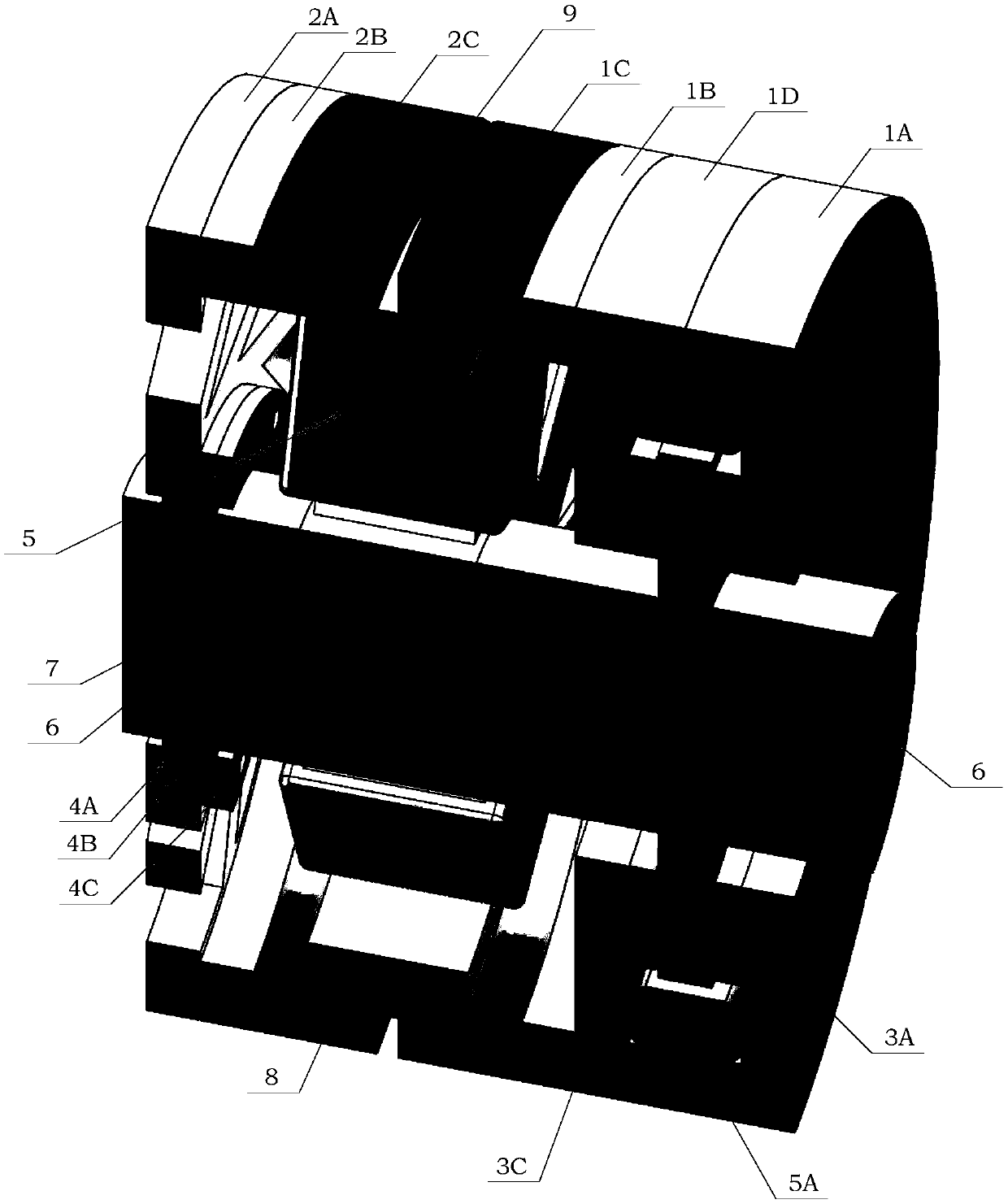

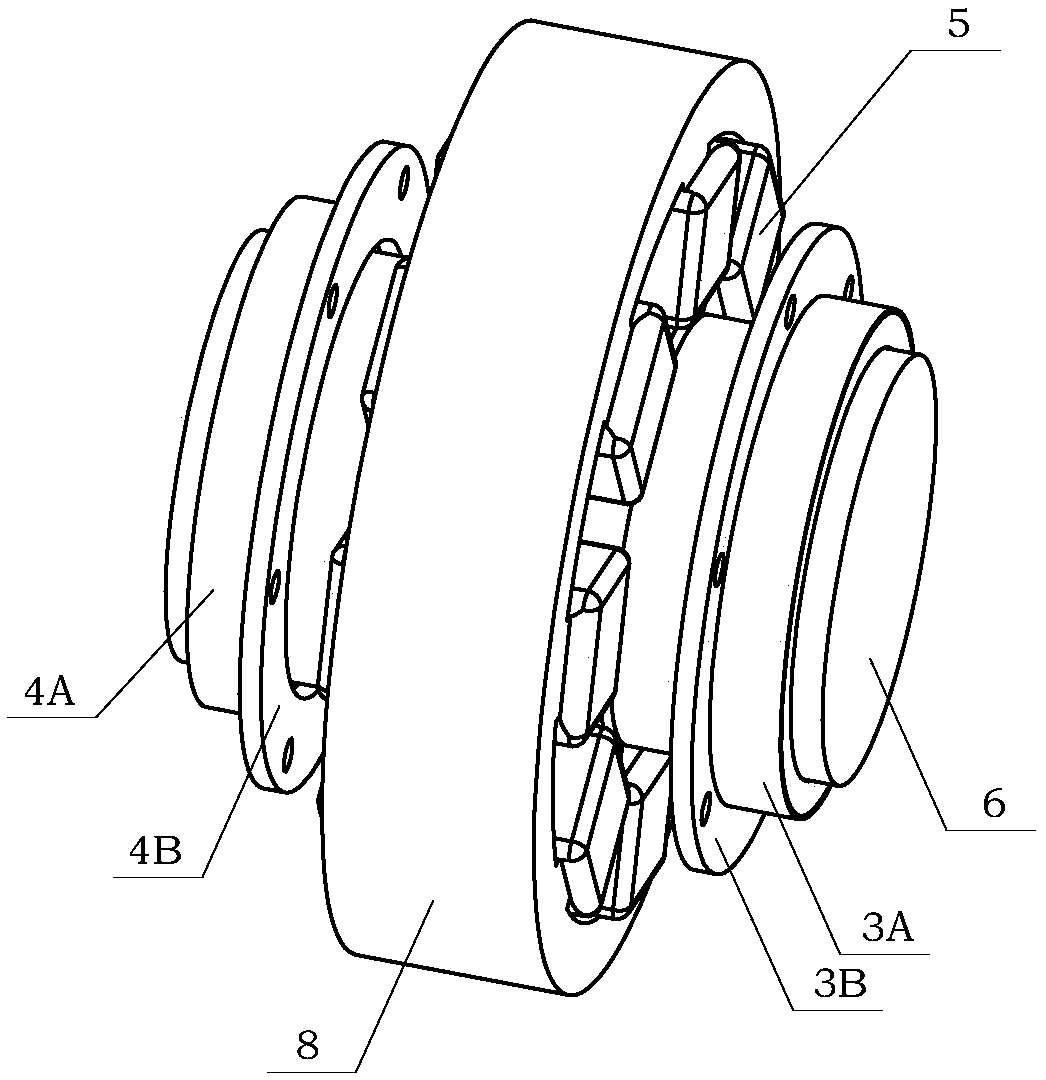

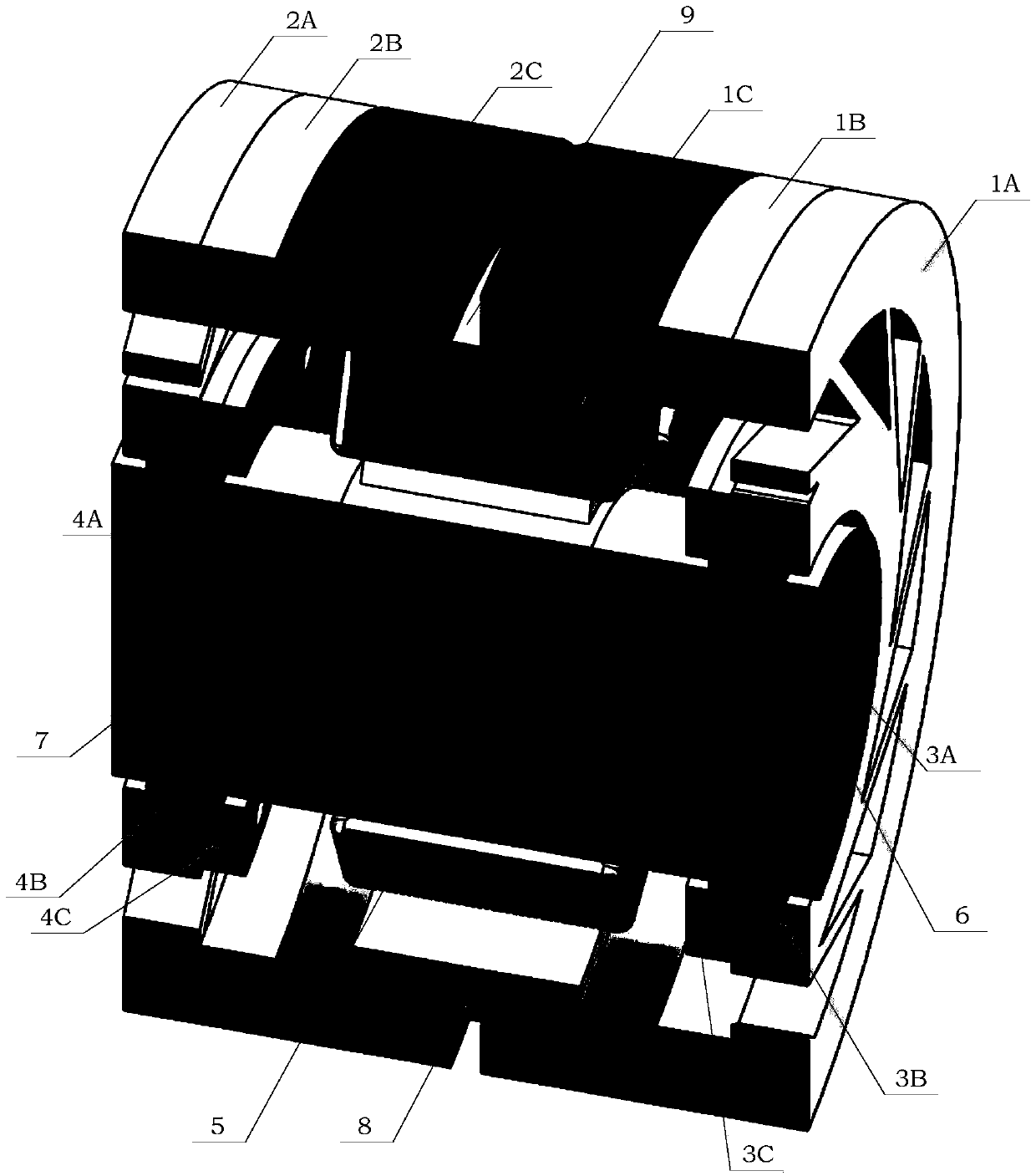

Orthogonal magnetic circuit radial-axial-integrated magnetic bearing based on symmetrical self-lubricating flexible backup bearing structure

ActiveCN108361279AAvoid hyperthermiaAvoid scrapping the whole machineShaftsMagnetic bearingsStatorEngineering

The invention discloses an orthogonal magnetic circuit radial-axial-integrated magnetic bearing based on a symmetrical self-lubricating flexible backup bearing structure. A radial magnetic bearing coil of the orthogonal magnetic circuit radial-axial-integrated magnetic bearing is mounted on a stator tooth set of a stator iron core; two radial rigid magnetic-conductive rings are mounted at an outerdisc of the stator iron core so as to prevent the short circuit problem of permanent magnetic circuits, wherein a certain gap exists between the two radial rigid magnetic-conductive rings; an axial magnetic bearing coil is located at a thrust disc of a rotor shaft and mounted in a cavity formed by the two magnetic-conductive rings; graphite rings and backup bearing skeletons which achieve the axial self-lubricating effect are arranged on the two sides of the thrust disc correspondingly; and a radial backup bearing skeleton and a graphite internal convex ring are arranged in an inner ring cavity of a radial flexible magnetic conductive ring for achieving the radial self-lubricating effect. By adopting the technical means that axial and radial electromagnetic circuits are combined into a whole, and a radial magnetic bearing and a backup bearing are combined into a whole, the technical problem that traditional magnetic bearings are low in coaxiality is solved.

Owner:BEIHANG UNIV

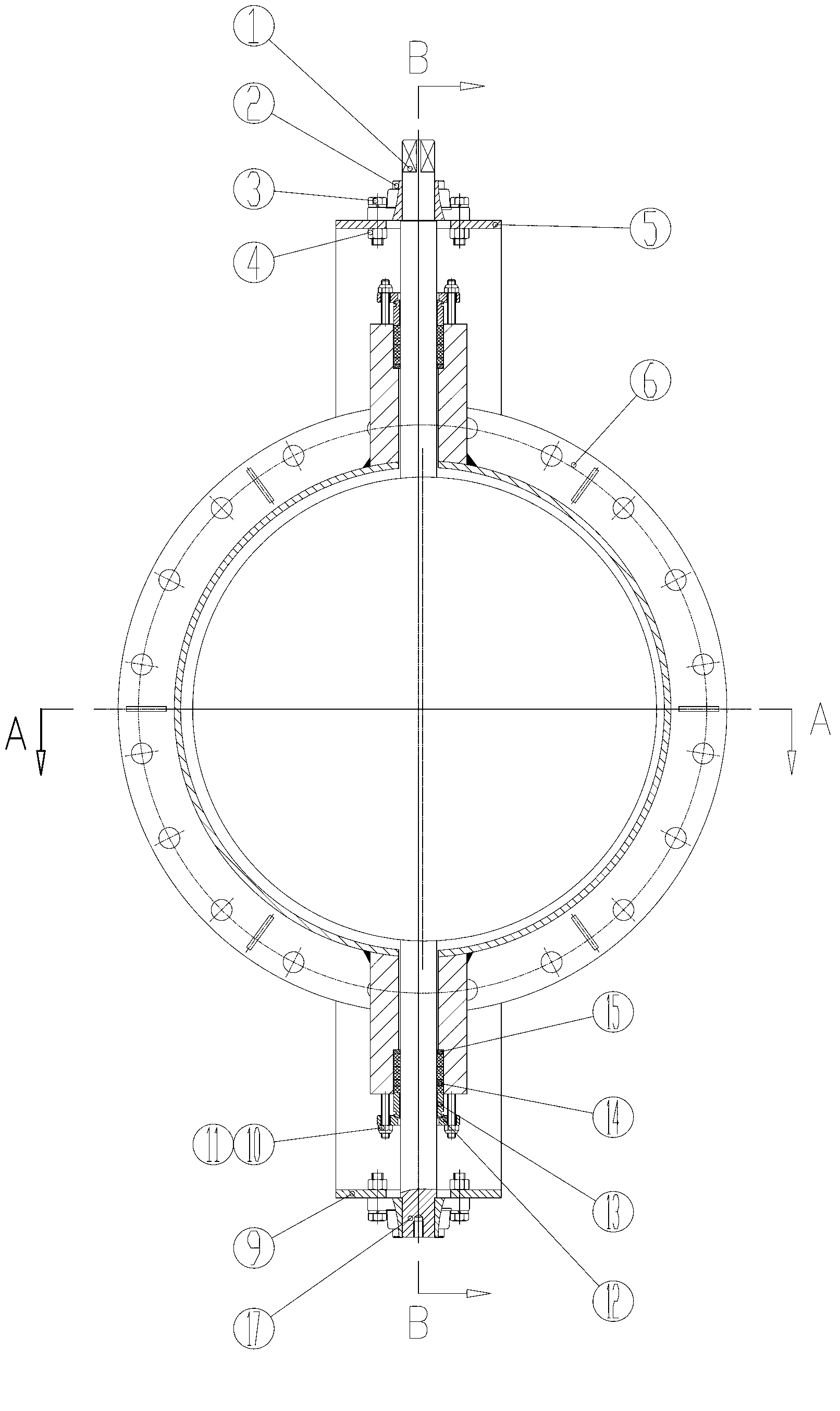

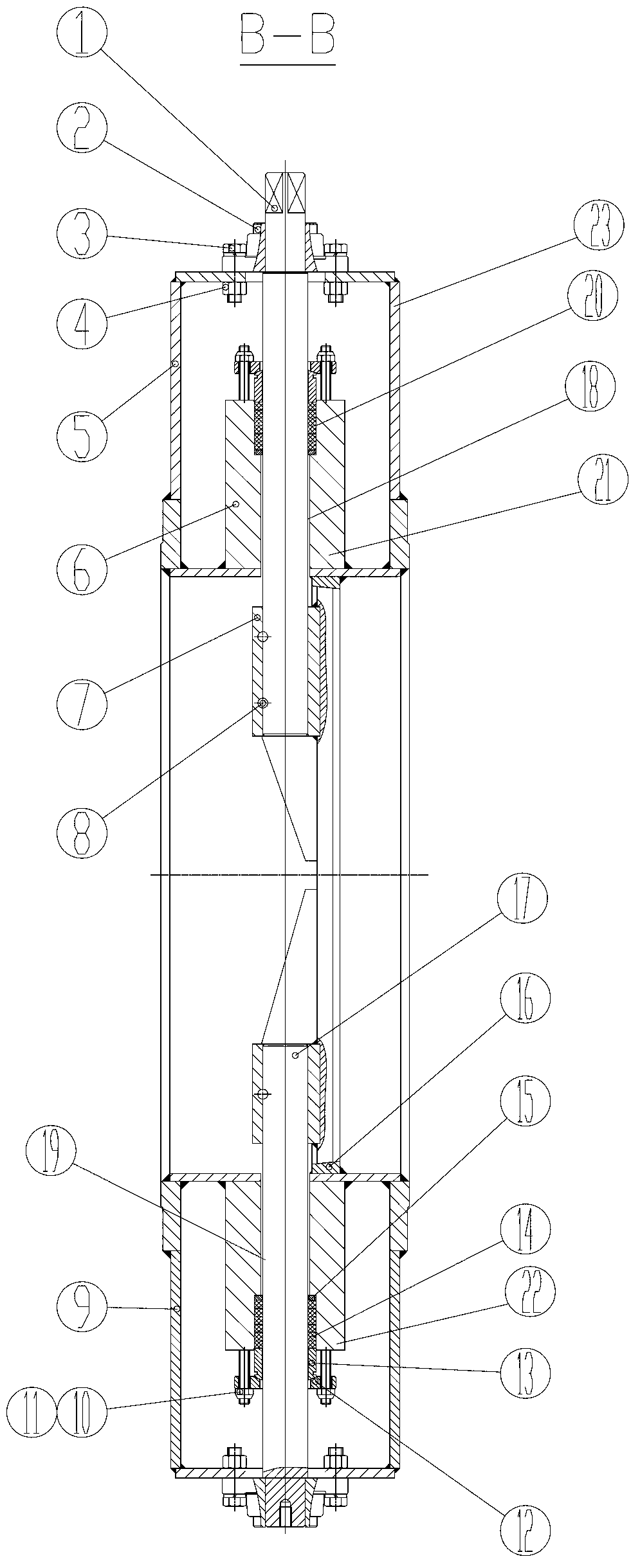

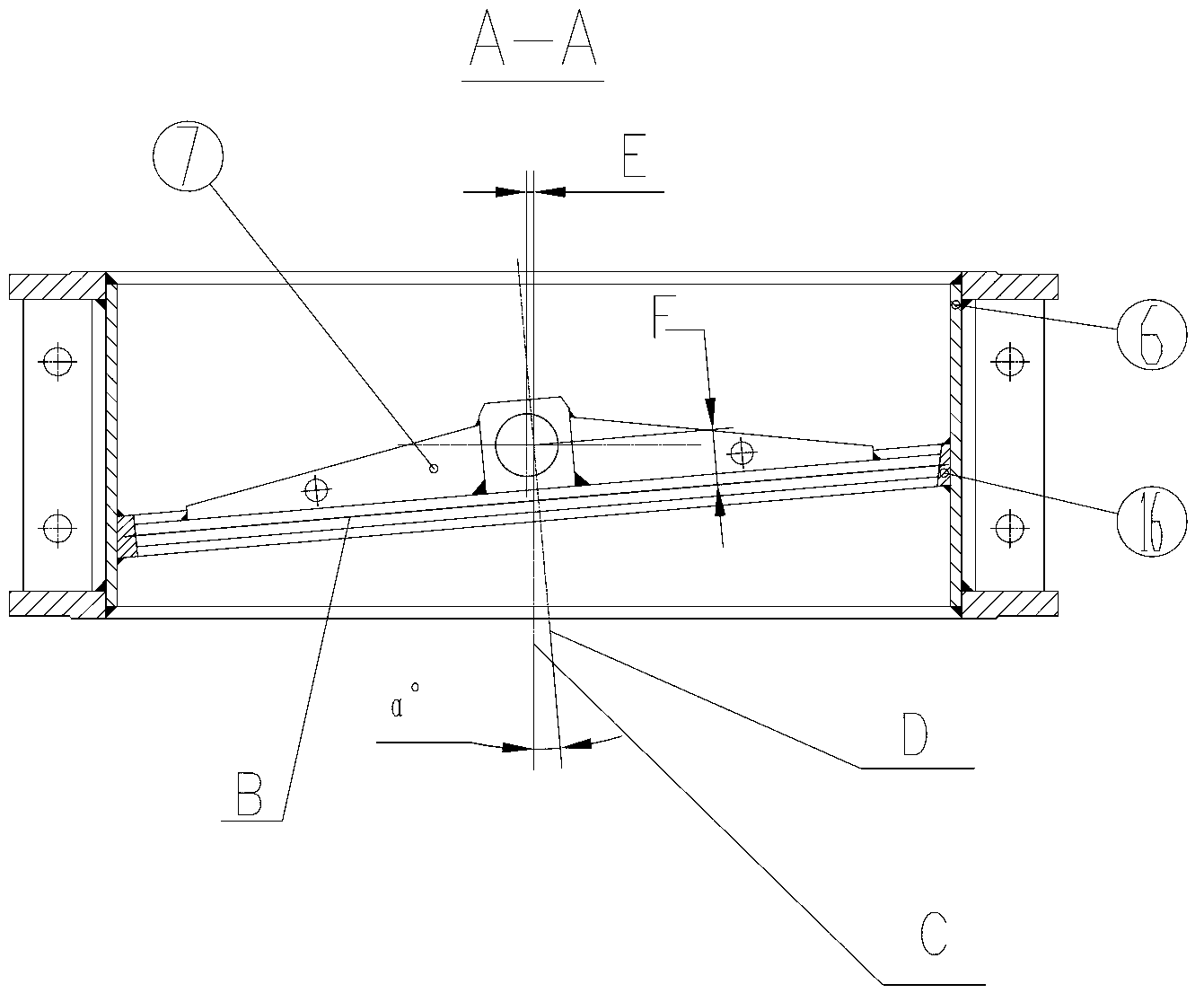

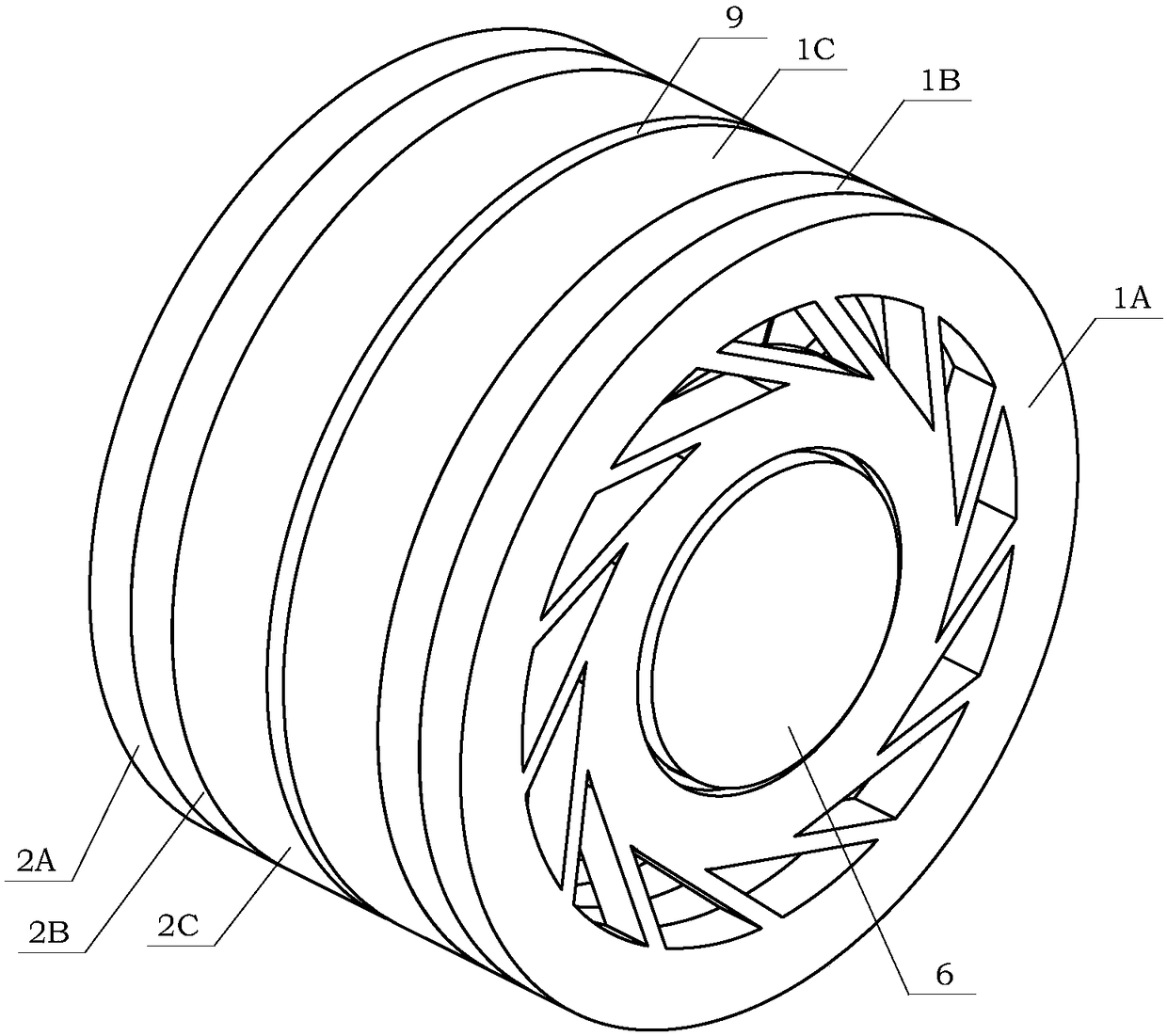

Low-load type cut-off butterfly valve

The invention relates to a low-load type cut-off butterfly valve, in particular to a low-load cut-off butterfly valve which is developed for working conditions that the nominal pressure is low and cutting off is required, and belongs to the field of fluid control valves. A valve plate is mounted in a valve body; the valve body comprises sleeves provided with stuffing boxes, a stuffing component is arranged in each stuffing box, filler pressure plates are arranged on the outer side of the stuffing components, and the filler pressure plates are fixed at the end parts of a first sleeve and a second sleeve through screw rods and lock nuts; a first shaft hole and a second shaft hole are formed on the valve body, wherein the first shaft hole and the second shaft hole penetrate the first sleeve and the second sleeve respectively, a valve rod is arranged in the first shaft hole, and a driven shaft is arranged in the second shaft hole; a valve seat is arranged in the inner chamber of the valve body; the upper end and the lower end of the valve plate are in rotational connection with the valve rod and the driven shaft respectively; the valve seat is embedded in the inner chamber of the valve body to form a certain angle; the valve plate is an integral part with a triple eccentric structure; and when at open and middle positions, the valve seat is not in contact with the valve plate and dose not interfere with the valve plate.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

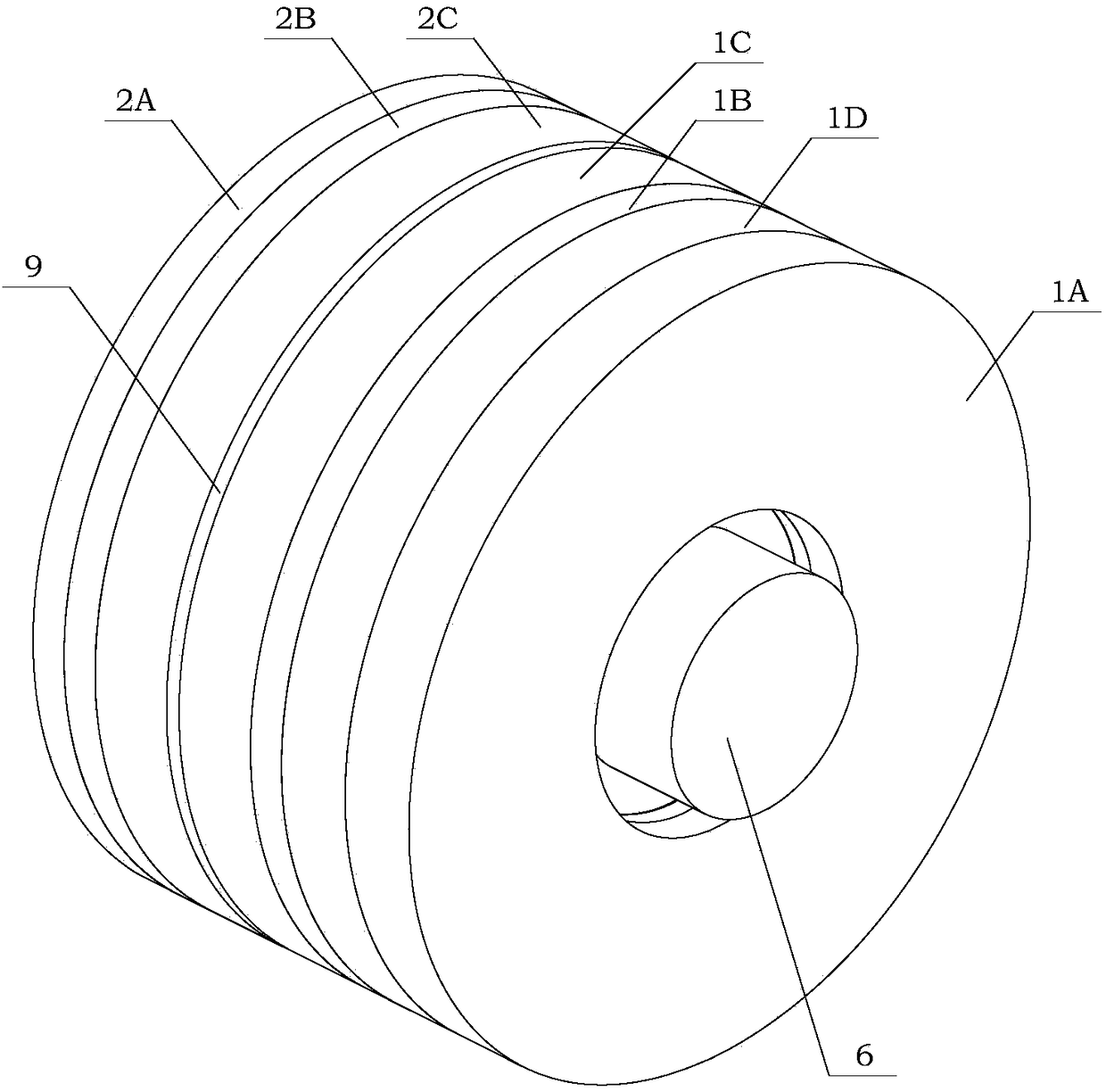

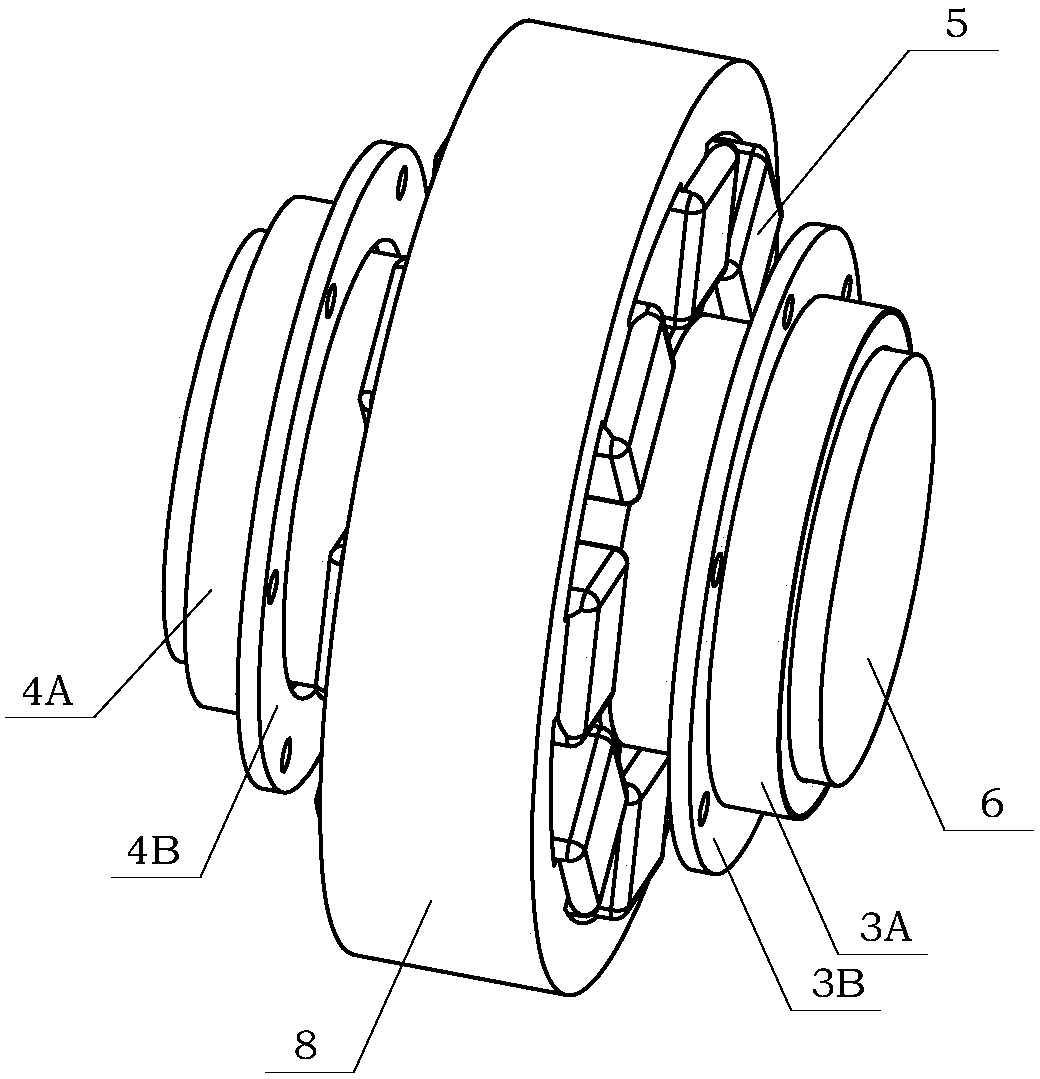

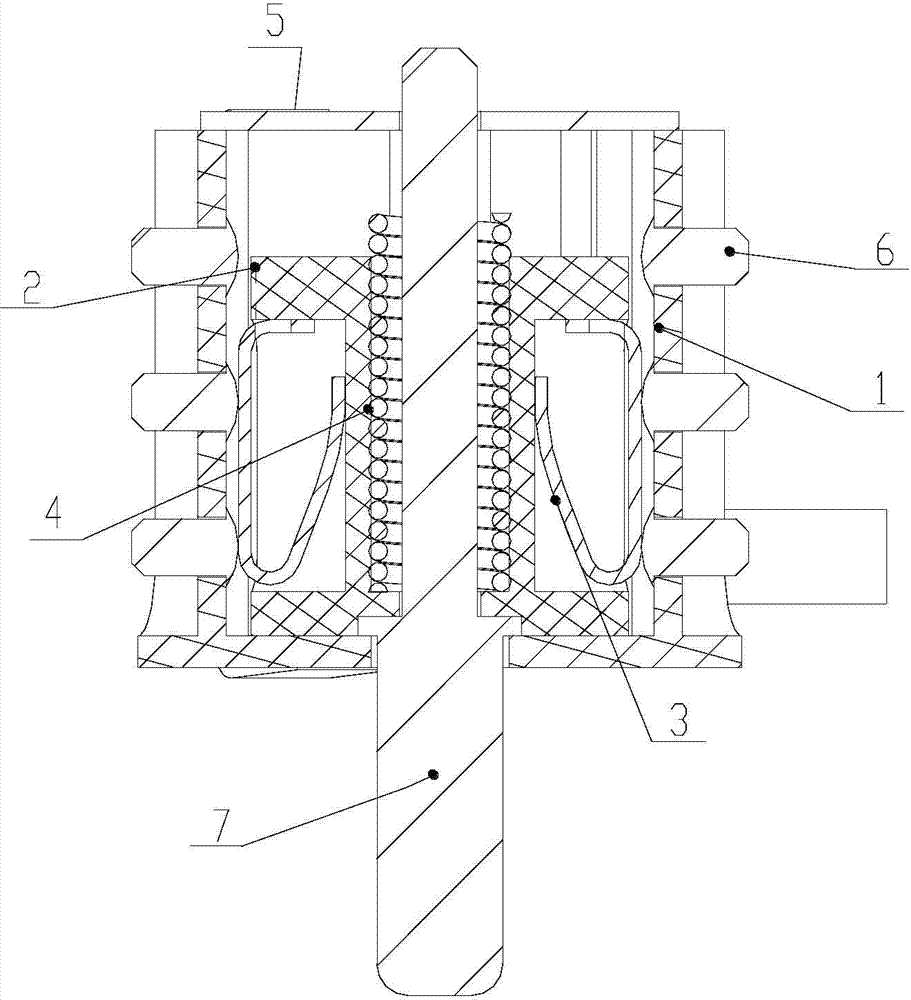

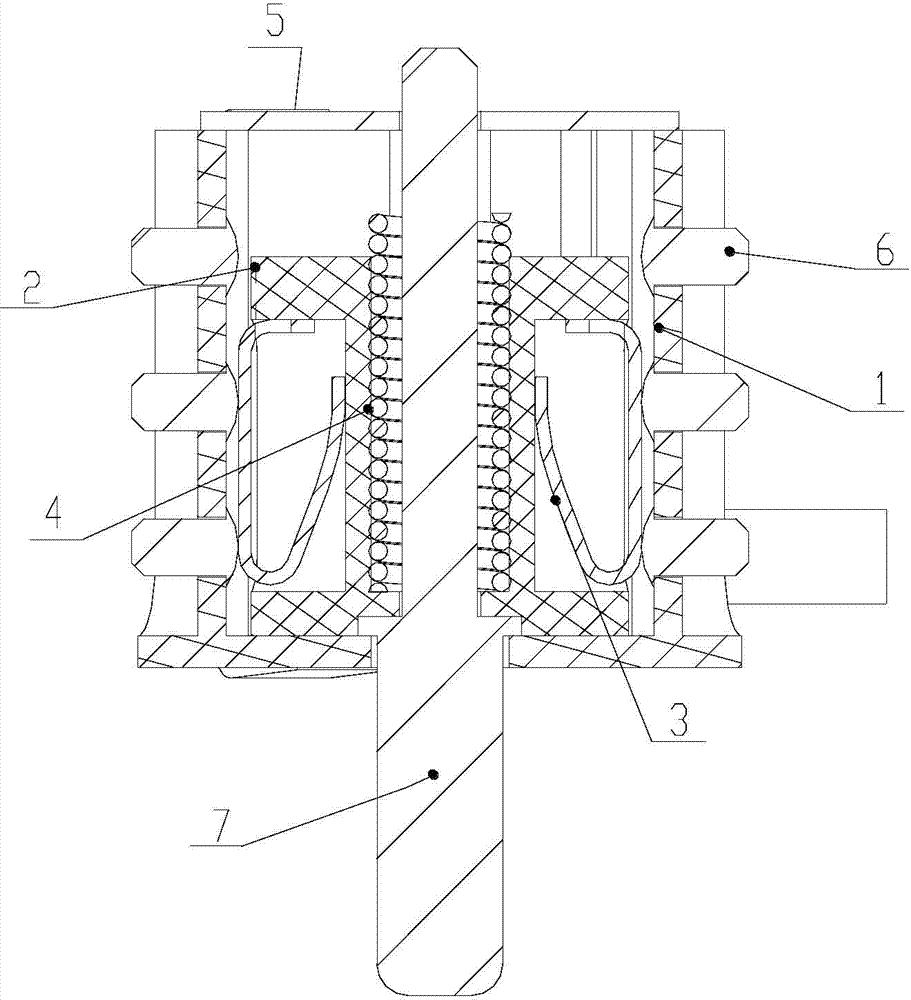

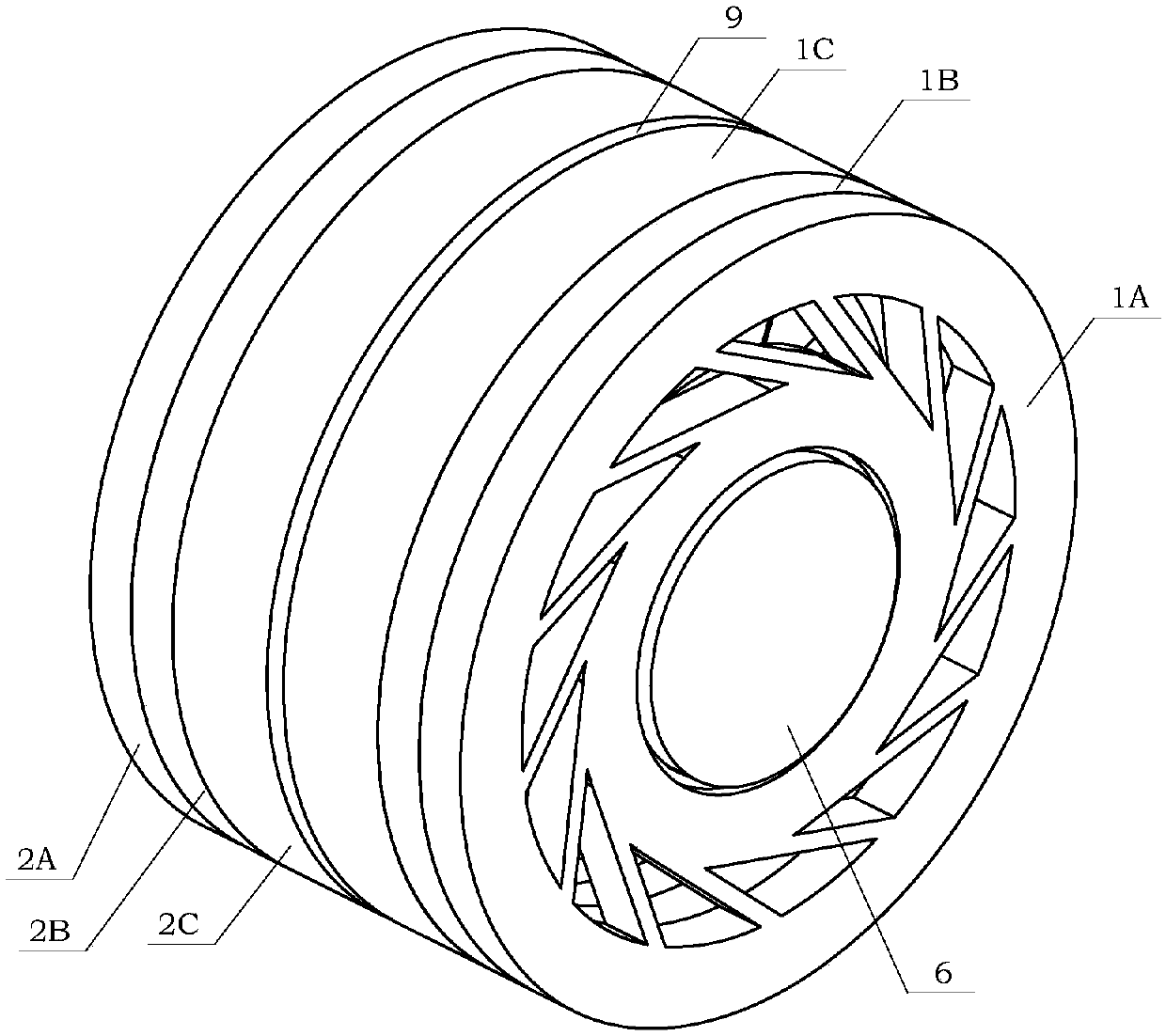

Orthogonal magnetic circuit radial magnetic suspension bearing based on symmetric self-lubricating flexible auxiliary bearing structure

The invention discloses an orthogonal magnetic circuit radial magnetic suspension bearing based on a symmetric self-lubricating flexible auxiliary bearing structure. A rotor shaft (6) of the magneticsuspension bearing is sleeved with a rotor core (7), and the rotor core (7) is located on a stator tooth set (8A) of a stator core (8). A coil is mounted on the stator tooth set (8A) of the stator core (8), and two radial rigid magnetic conducting rings are mounted on an outer disc of the stator core (8). A certain clearance exists between the two radial rigid magnetic conducting rings in the axial direction to prevent the short circuit of a permanent magnetic circuit. A graphite inward protruding ring cooperates with a radial auxiliary bearing framework, is arranged in an inner ring cavity ofa radial flexible magnetic conducting ring and is compressed by a radial bearing check ring, and the graphite inner ring is prevented from axially sliding. A permanent magnet is mounted between the radial rigid magnetic conducting rings and the radial flexible magnetic conducting ring. The magnetic suspension bearing is divided into two parts in bilateral symmetry around the stator core in the axial direction, the design method that a radial magnetic bearing and an auxiliary bearing are combined into a whole is adopted, and the technical problem that the coaxiality of a traditional magnetic bearing and auxiliary bearing is low is solved.

Owner:BEIHANG UNIV

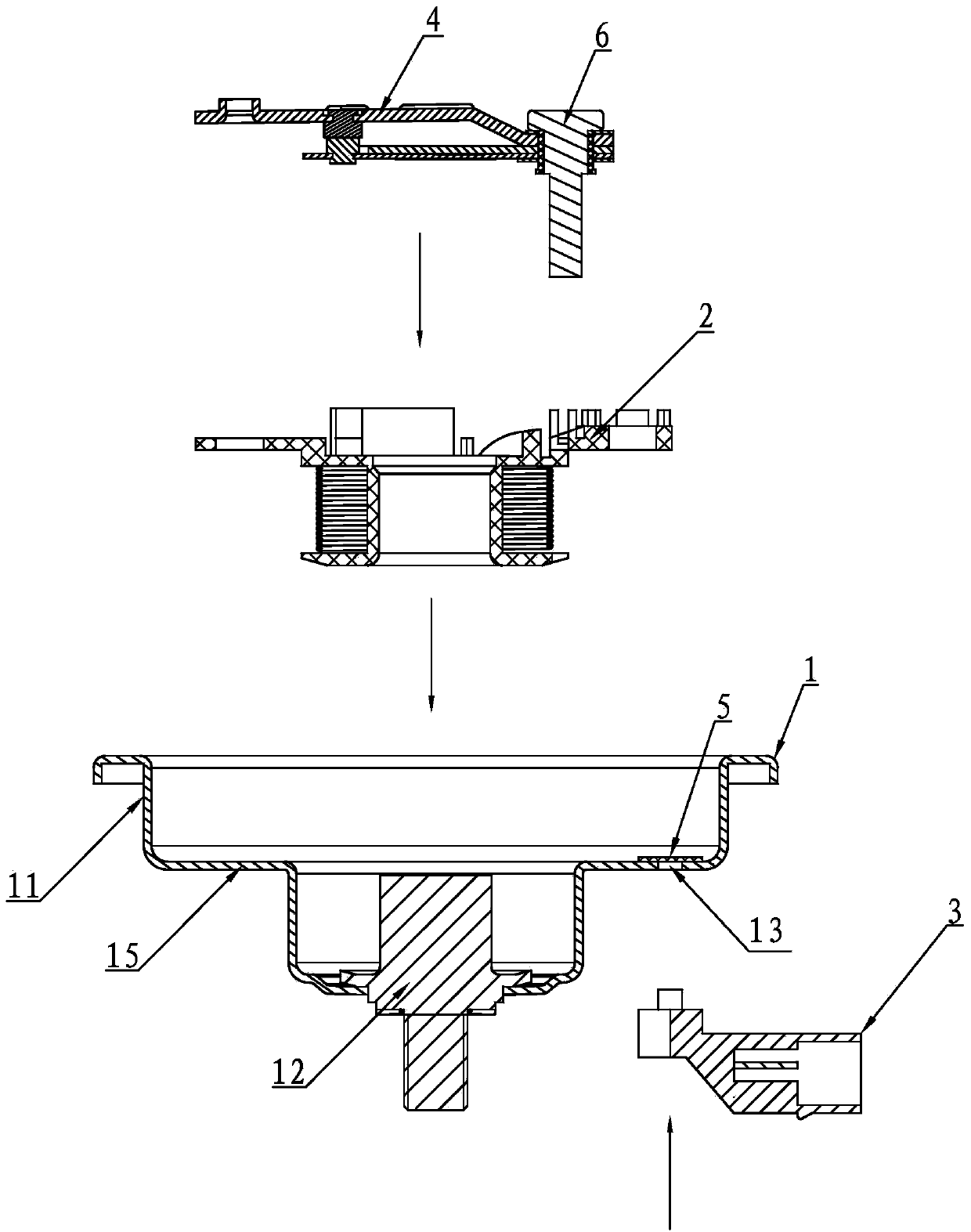

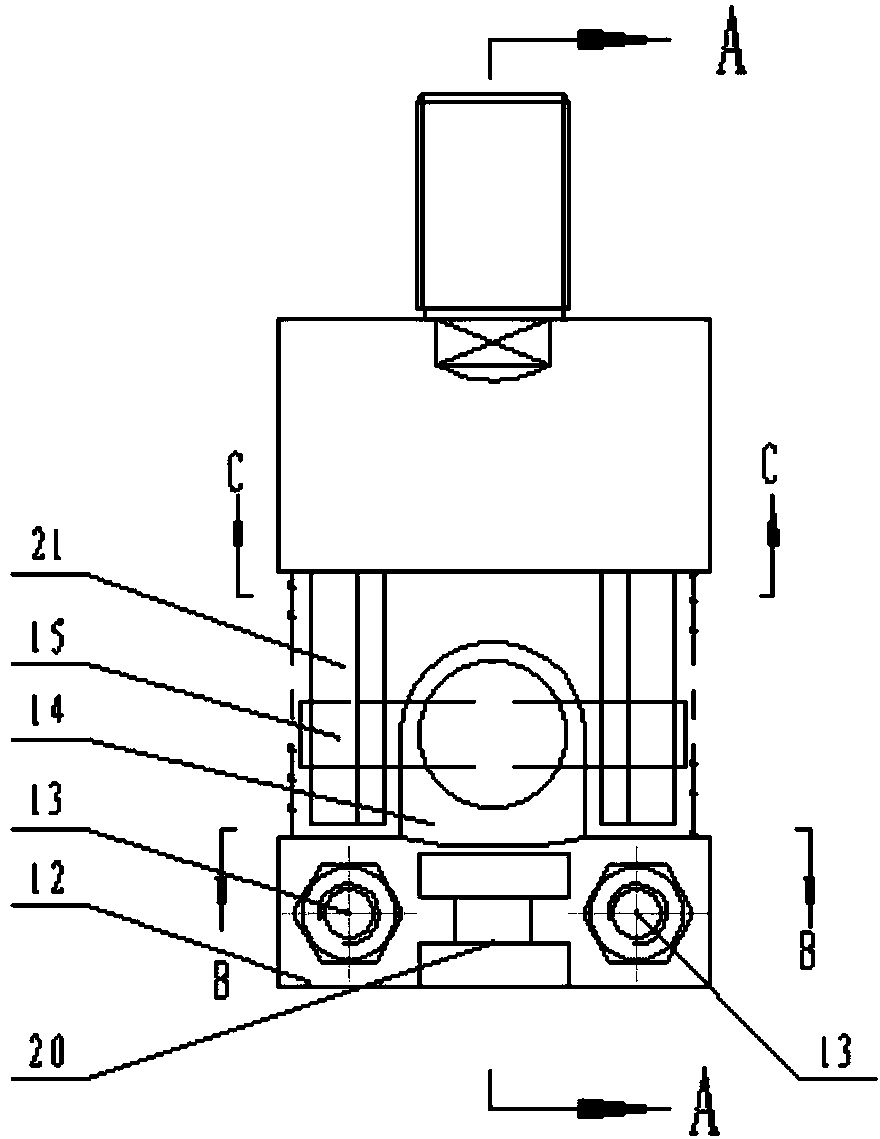

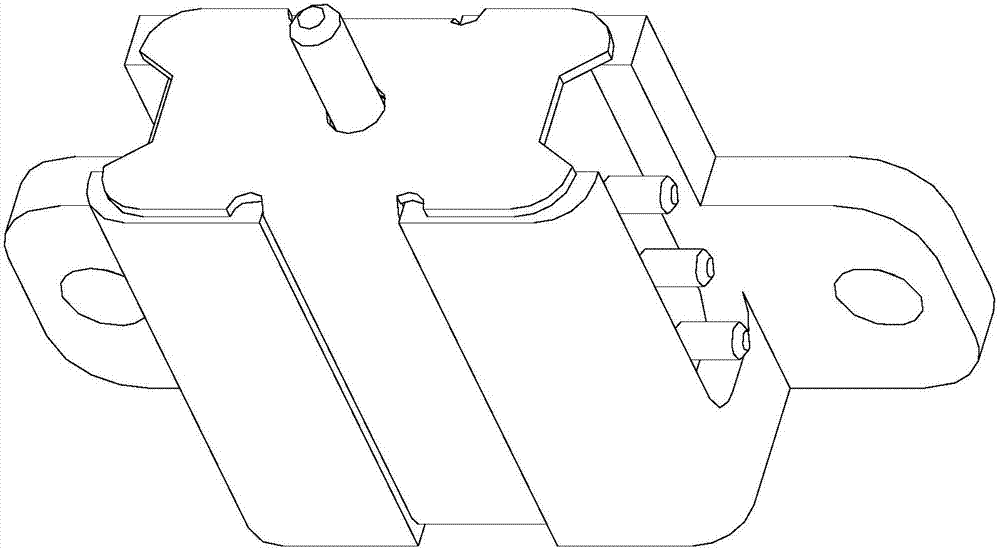

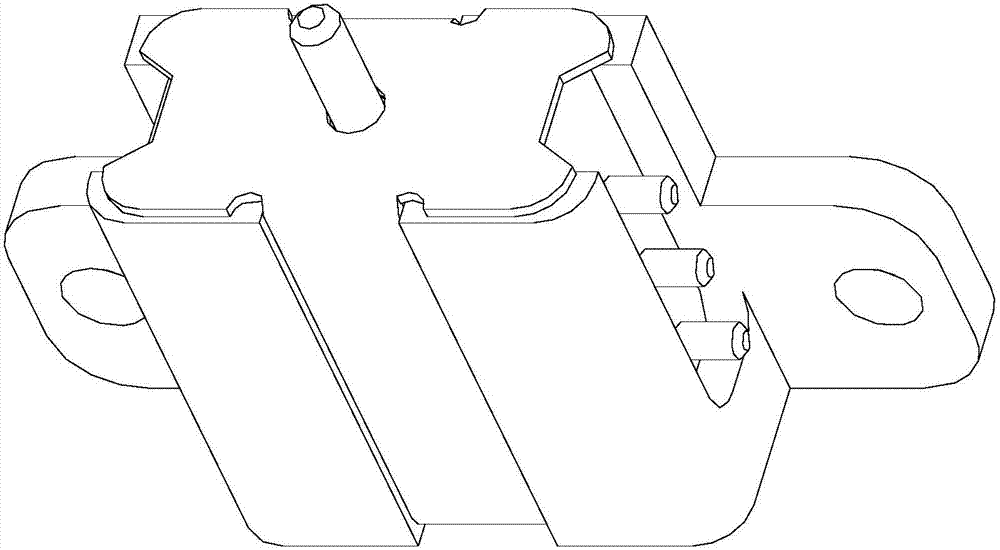

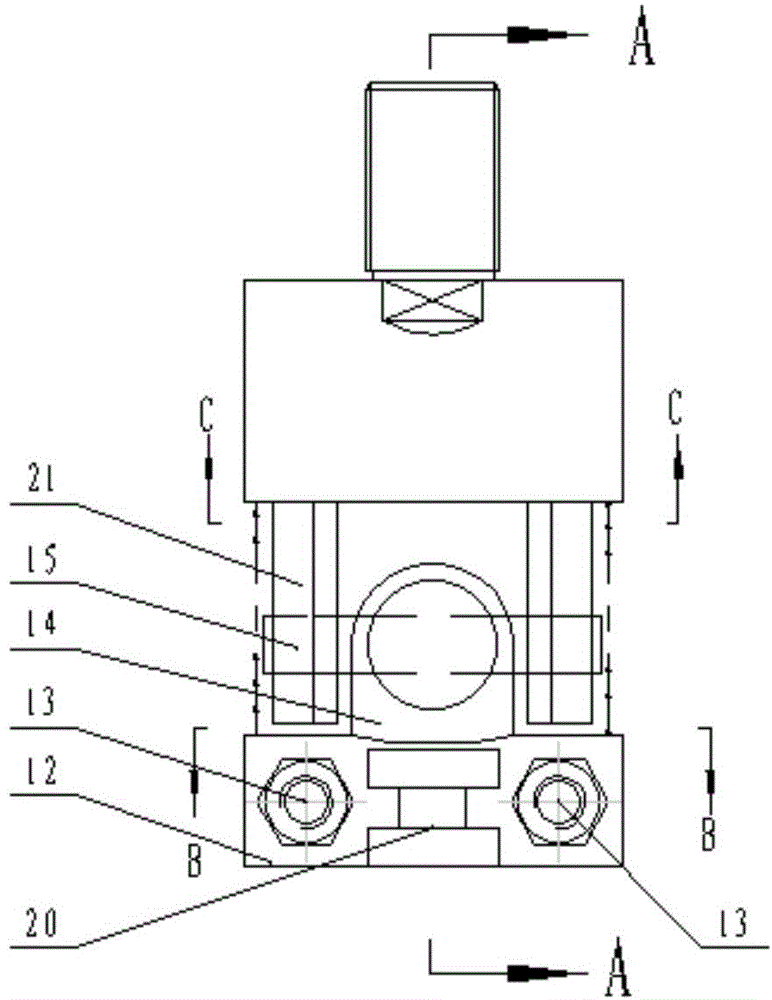

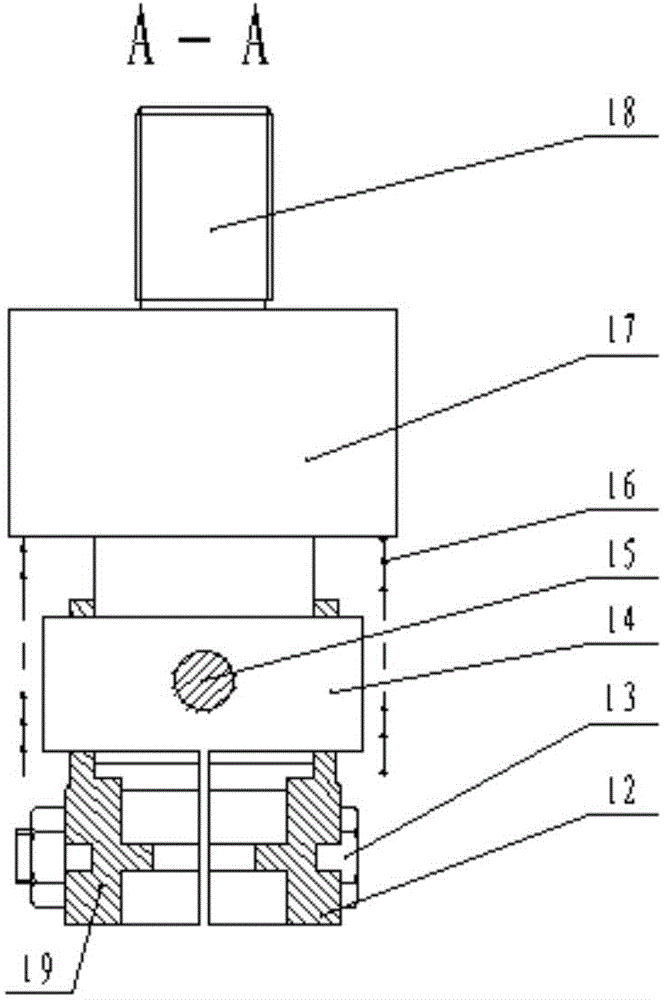

Control valve flexible connection kit

ActiveCN104197081AChange the openingAutomatic correction of position differencesYielding couplingOperating means/releasing devices for valvesEngineeringEvening

The invention discloses a control valve flexible connection kit which comprises a left lug ring and a right lug ring. A groove matched with the top end of a valve rod is formed between the left lug ring and the right lug ring, and the left lug ring and the right lug ring are connected to the two ends of a large round pin in series respectively. The middle of the large round pin is provided with a small hole perpendicularly crossed with the axis of the large round pin and penetrating through the large round pin, and a small round pin connecting the large round pin and an upper seat arc shaft frame penetrates through the small hole. The upper seat arc shaft frame is sleeved with an antiskid force-evening spring capable of exerting pre-tightening force on the upper seat arc shaft frame, and the large round pin and the small round pin are surrounded by the antiskid force-evening spring. The upper end of the antiskid force-evening spring abuts against an upper seat, the lower end of the antiskid force-evening spring abuts against the left lug ring and the right lug ring, and the upper seat is provided with a head thread matched with a piston rod.

Owner:SHANDONG UNIV

Circuit changing switch

ActiveCN103578833AIncrease the use of spaceAchieve contactElectric switchesLarge sizeElectrical and Electronics engineering

Owner:湖北三江航天红林探控有限公司

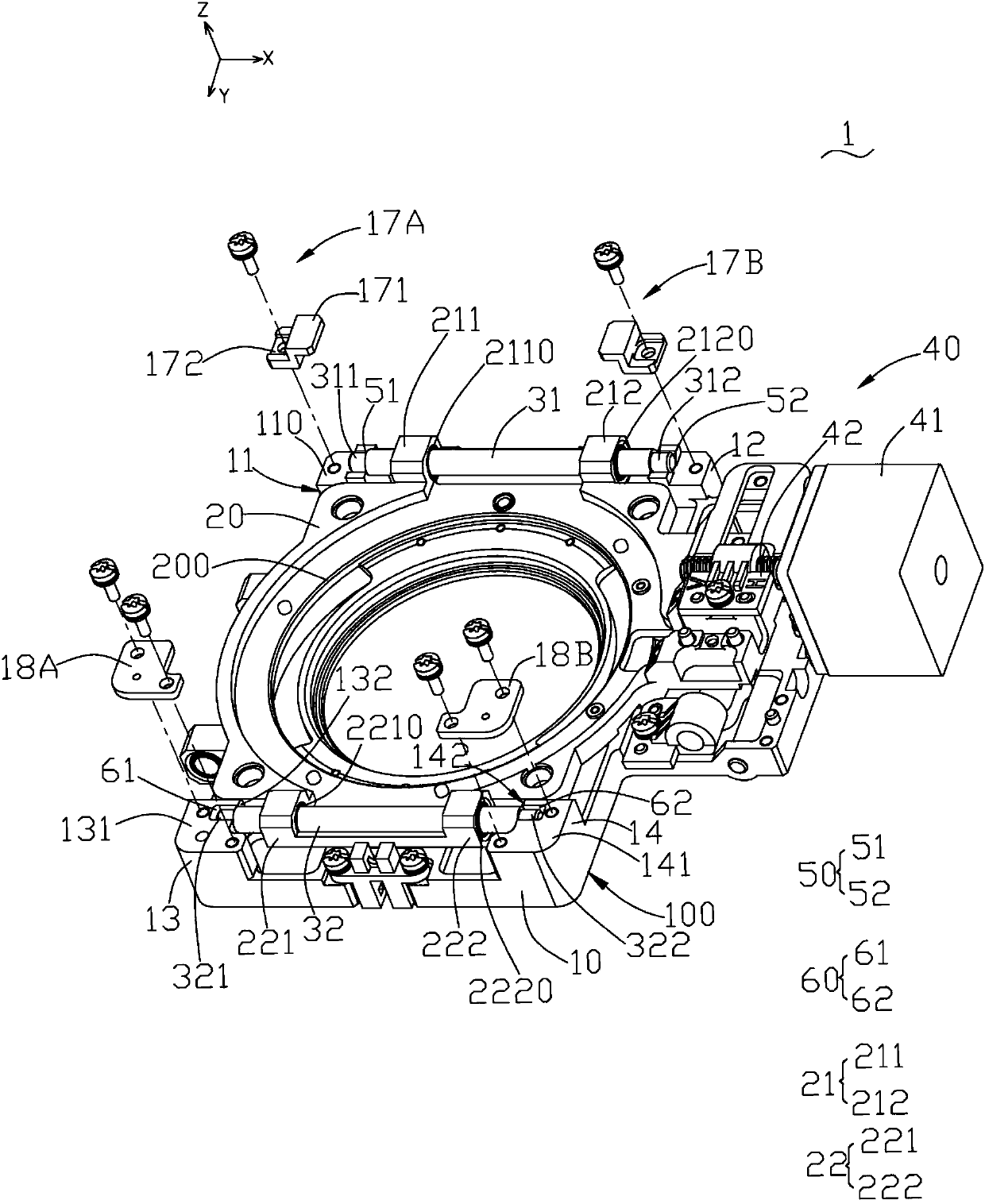

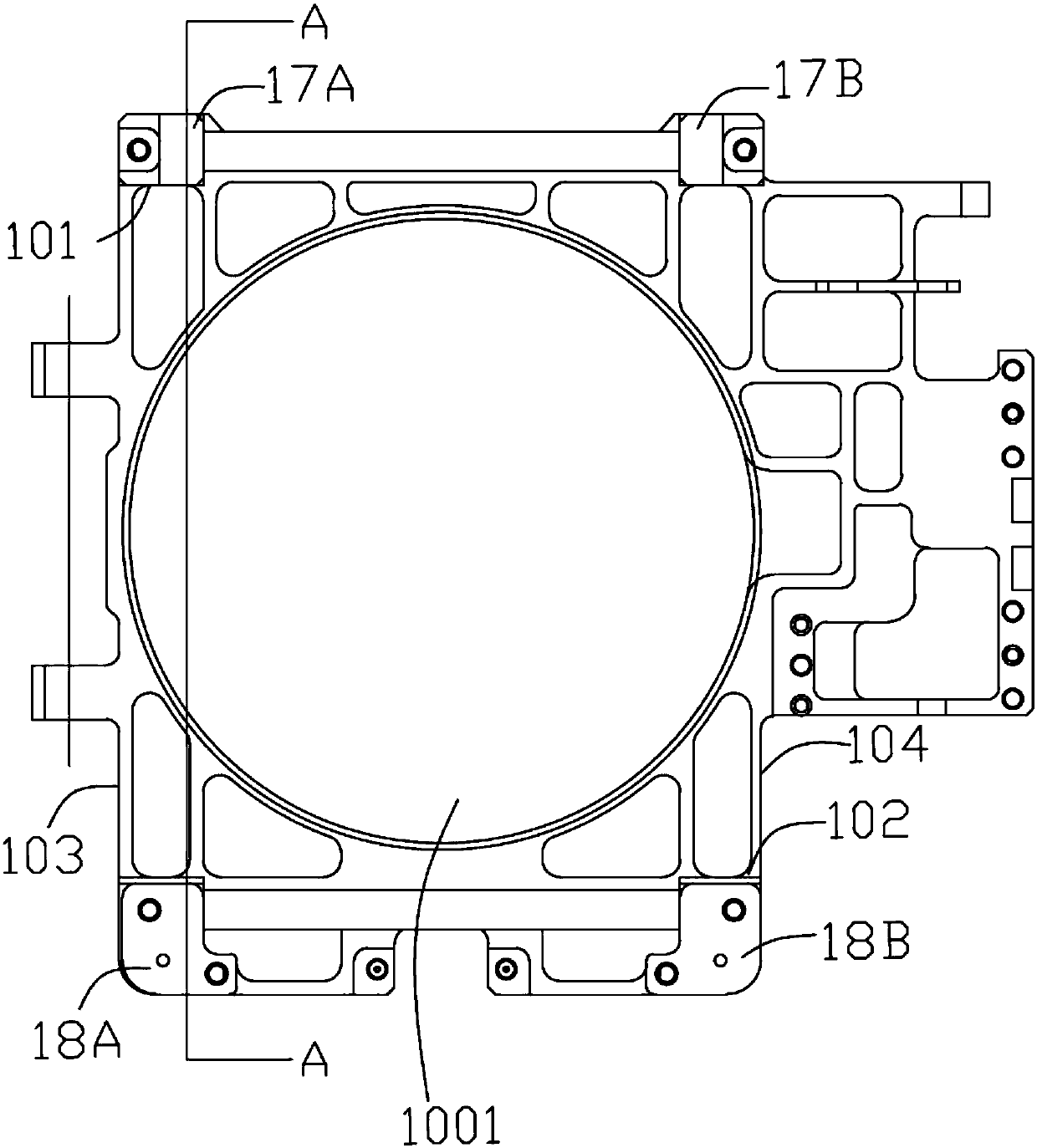

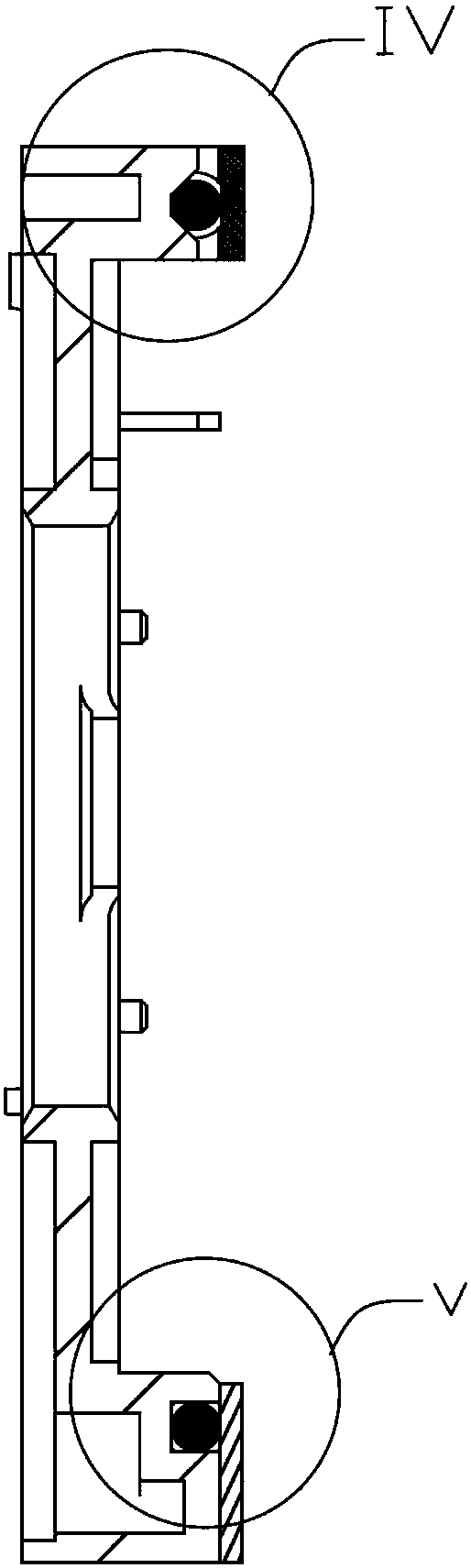

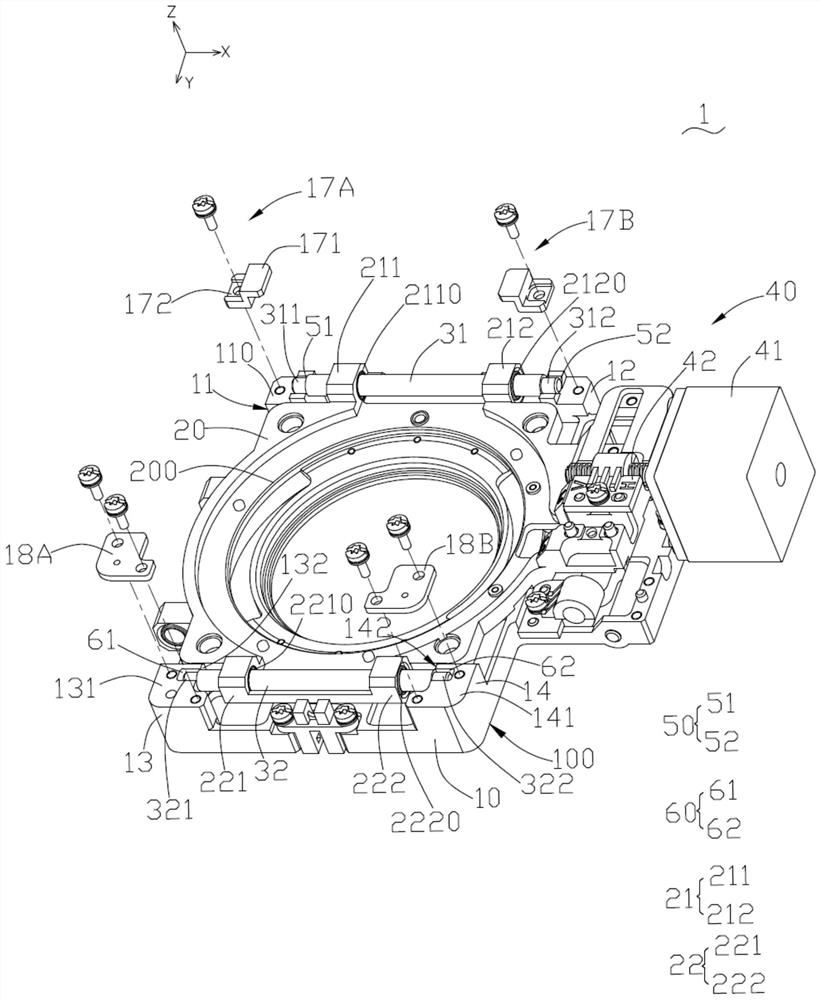

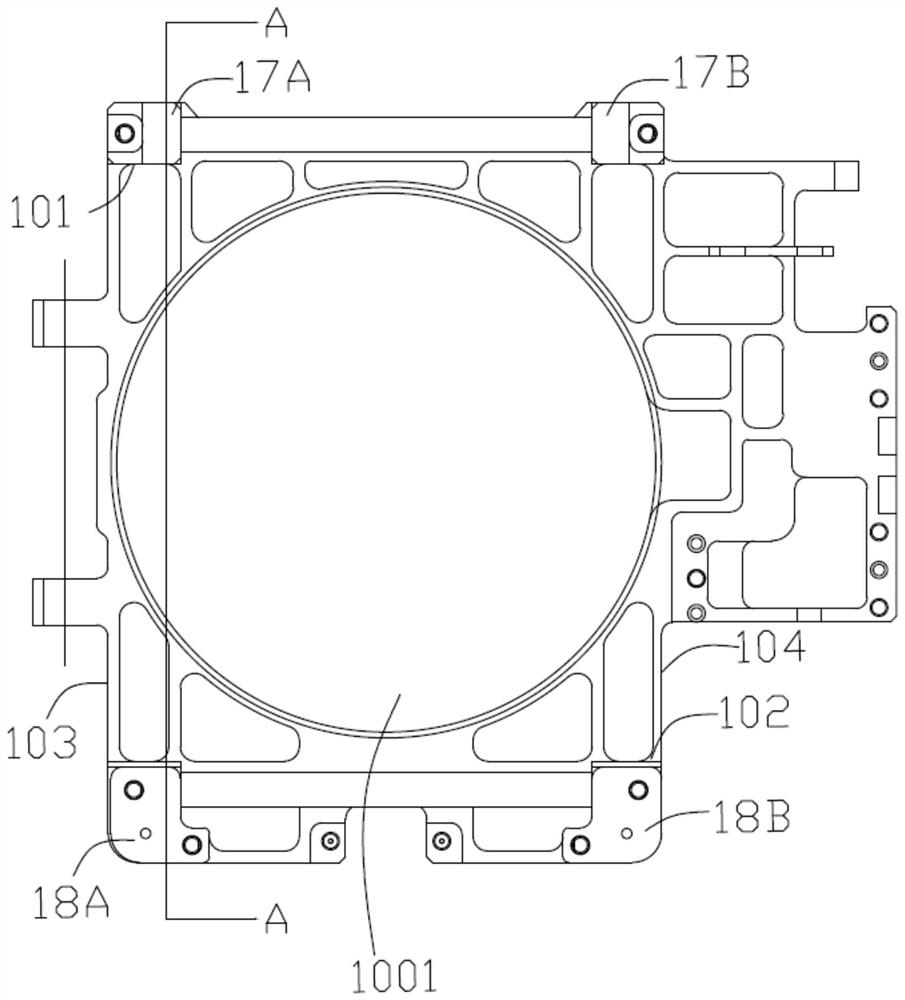

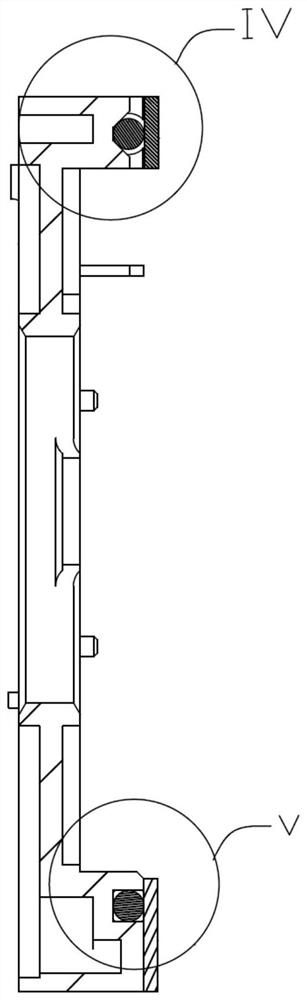

Lens displacement adaptive device and projection device

ActiveCN110095924AEnsure smooth movementImprove yield rateProjectorsMountingsCamera lensControl theory

The invention provides a lens displacement adaptive device, which comprises a sliding shaft fixing base, a sliding bracket, a first sliding shaft, a second sliding shaft and a driving mechanism. The two opposite ends of the sliding shaft fixing base are provided with a first groove and a first groove respectively. Thus, when the sliding bracket slides in the X direction, by means of a gap betweenthe first groove and the first sliding shaft in the Z direction, and a gap between the second groove and the second sliding shaft in the Y direction, a purpose of adjusting the displacement in the three directions of X, Y, and Z is achieved, and the machining deviation and the assembly deviation between components are absorbed so that the sliding bracket slides smoothly on the sliding shaft and agood adjustment effect is achieved. The invention also provides a projection device including the lens displacement adaptive device.

Owner:APPOTRONICS CORP LTD

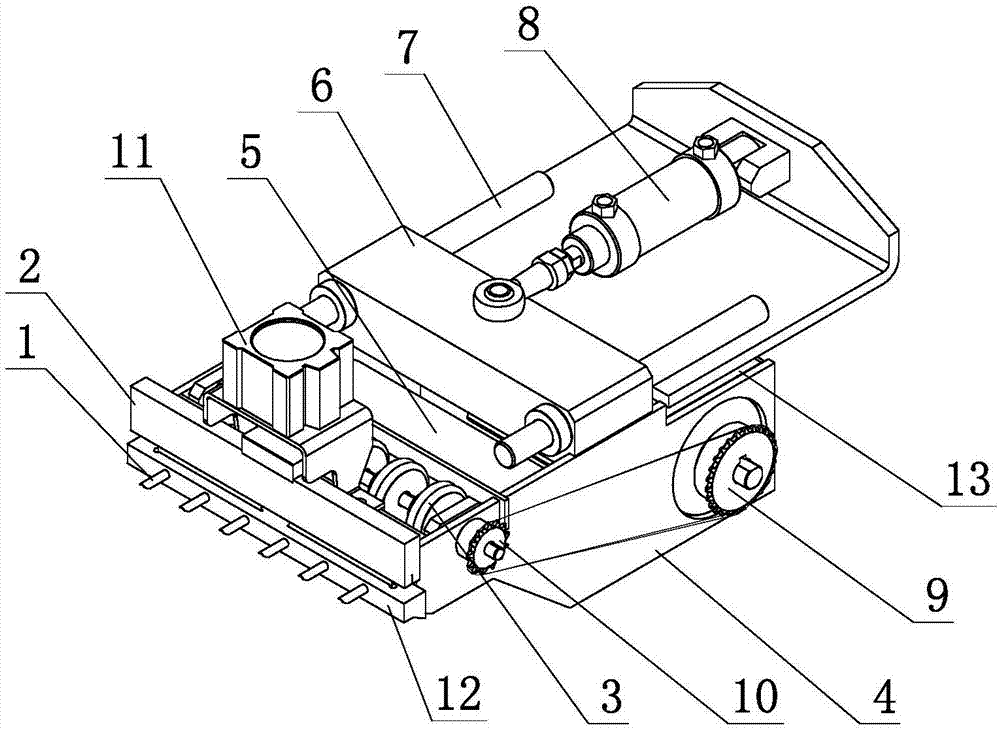

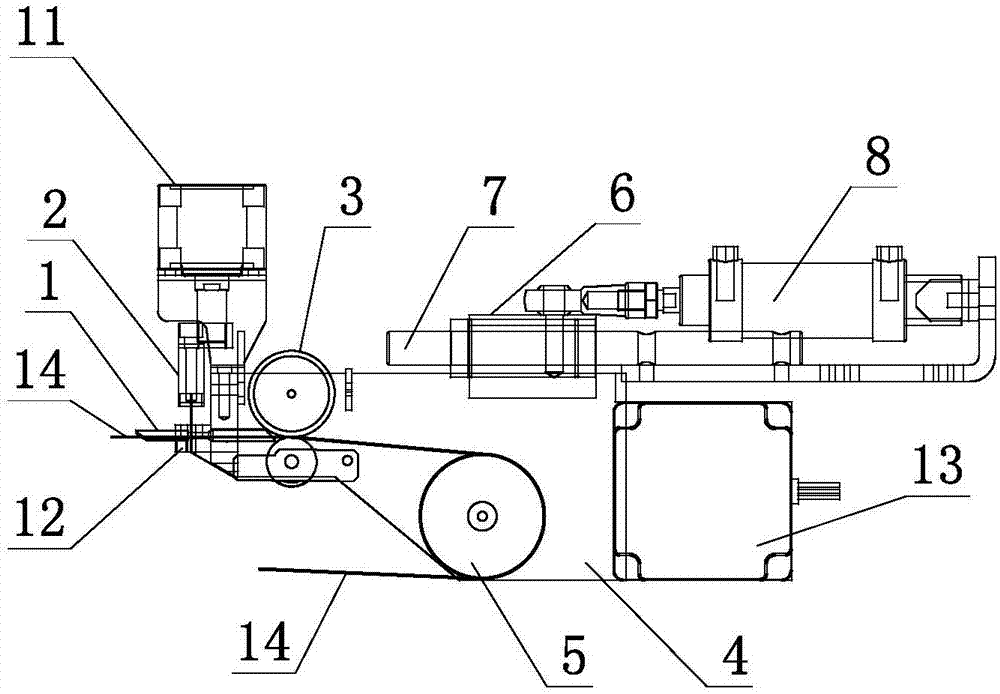

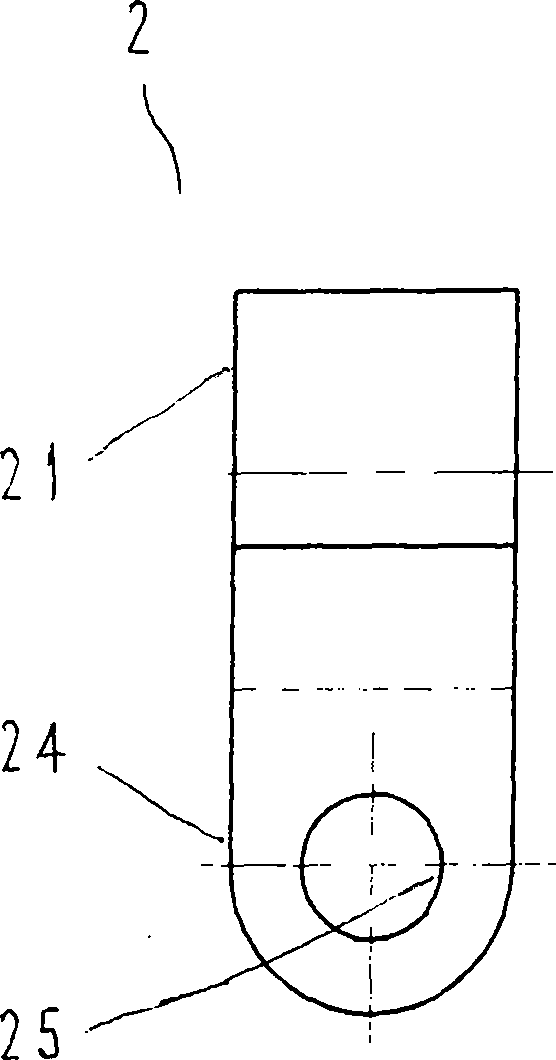

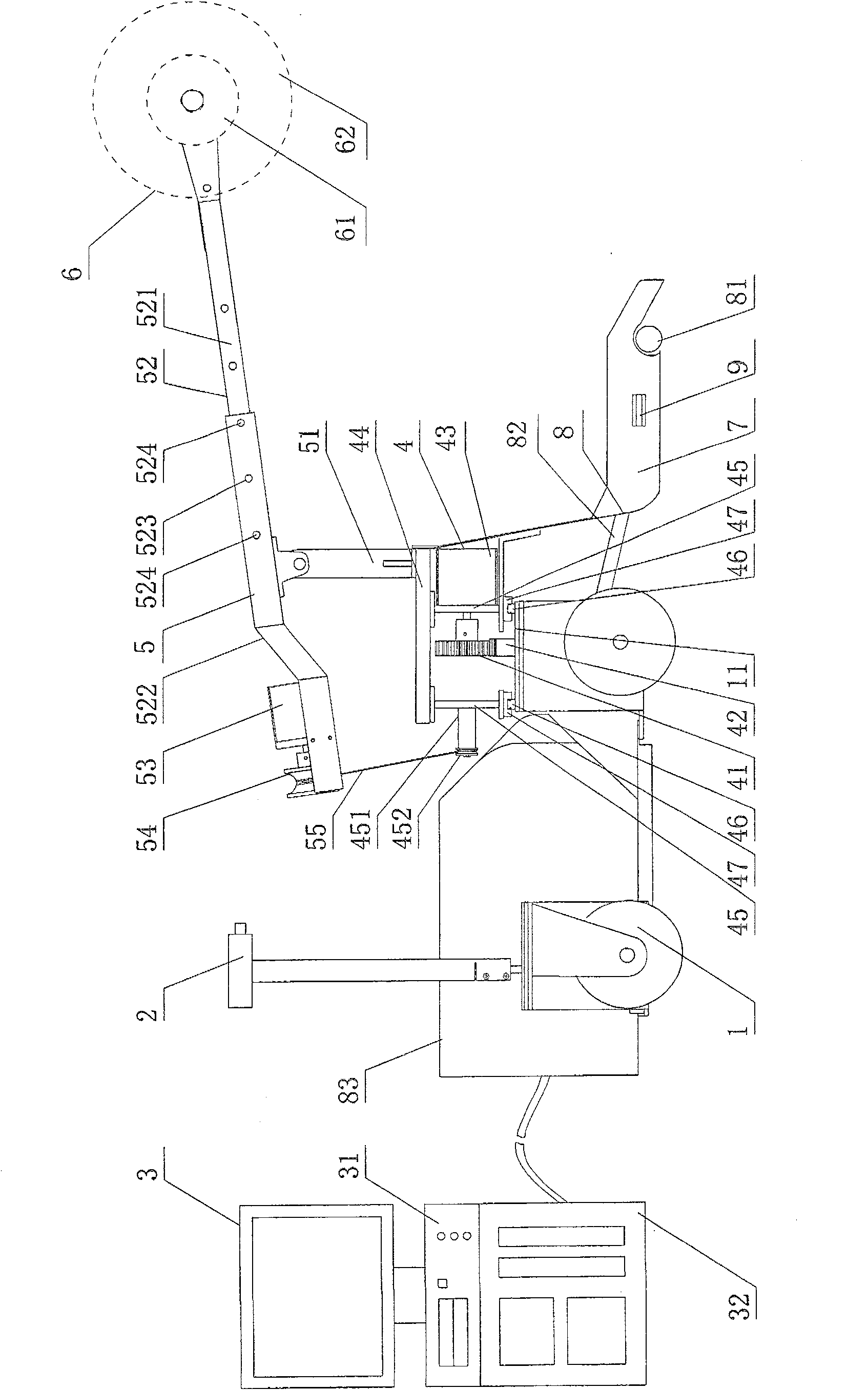

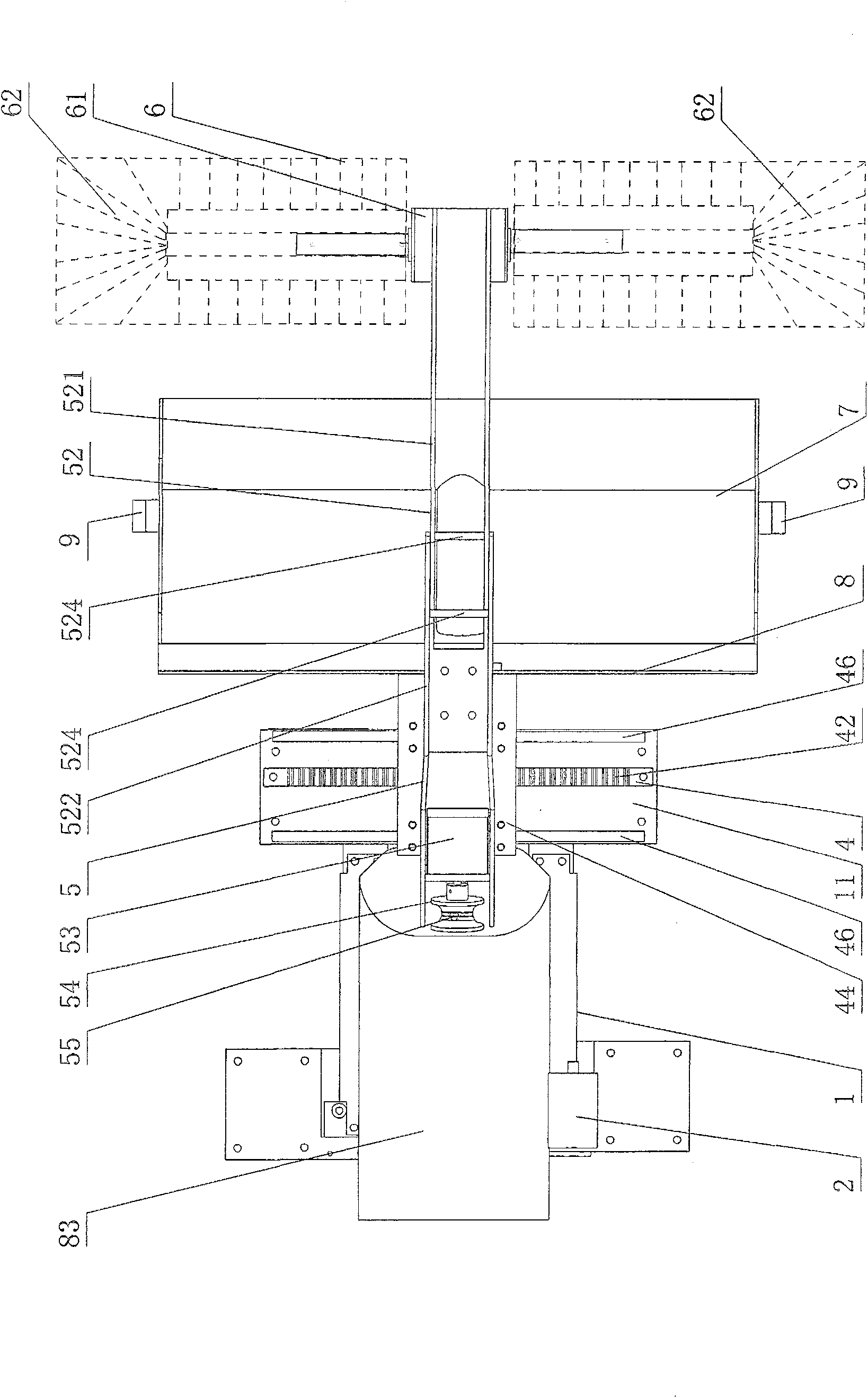

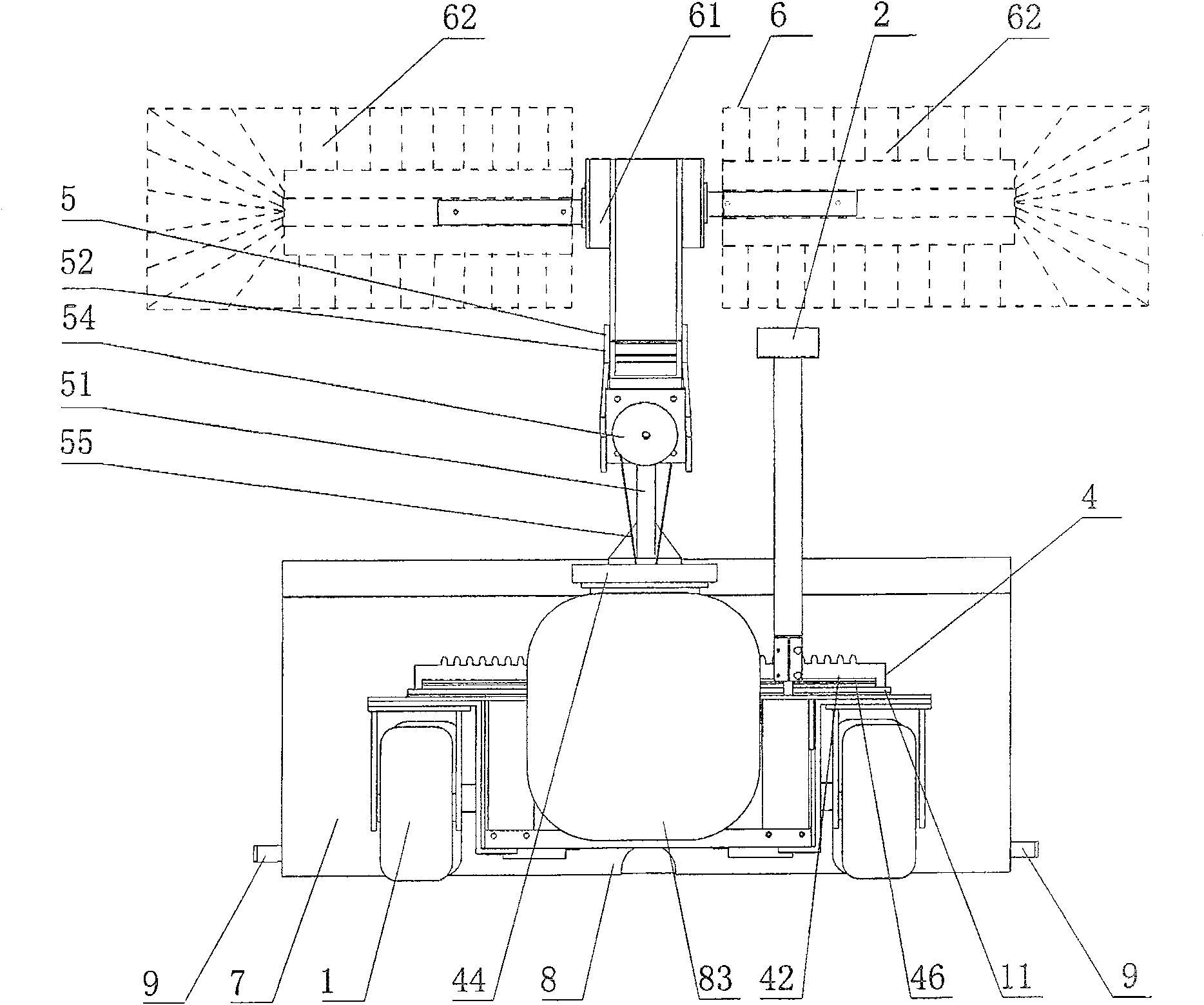

Telescopic lead inserting device for automatic molding machine for double-bang fireworks

PendingCN107401955AAvoid bending deformationEliminate stuck phenomenonFireworksMolding machineFireworks

The invention discloses a telescopic lead inserting device for an automatic molding machine for double-bang fireworks. The telescopic lead inserting device is characterized by comprising a lead inserting base, lead inserting tubes, a lead cutting board, a lead cutting form board, lead feeding wheels, a lead feeding guide wheel, a movable board and lead inserting stroke shafts, wherein the lead cutting board and the lead cutting form board are oppositely arranged at one end of the lead inserting base; the multiple lead inserting tubes are arranged on the lead cutting form board side by side respectively, the multiple lead feeding wheels correspond to the lead inserting tubes respectively and are arranged in the lead inserting base, the lead feeding guide wheel is arranged on one side of each lead feeding wheel, the lead inserting base is connected with the movable board, the movable board is arranged on the lead inserting stroke shafts in a sliding sleeve manner and is connected with a lead inserting stroke driving mechanism for driving, the lead cutting board is connected with a lead cutting driving mechanism for driving, the lead feeding wheels are connected with a lead feeding driving mechanism, the movable board moves the lead inserting base to a lead inserting station, and leads are conveyed to a barrel of the double-bang fireworks through the lead inserting tubes under the matching of the lead feeding guide wheel and the lead feeding wheels. The telescopic lead inserting device has the advantages of being high in lead inserting speed, high in production efficiency and unified in product specification, guaranteeing overall quality of products and the like.

Owner:LIUYANG WUYI TECH MACHINERY CO LTD

Circuit changing switch

Owner:湖北三江航天红林探控有限公司

A Reliably Sealed Self-Closing Sealed Rotary Compensator

ActiveCN105042258BImprovement of the problem of poor sealing performanceGuaranteed smoothnessPipeline expansion-compensationAdjustable jointsSteel ballEngineering

Owner:石家庄巨力科技股份有限公司

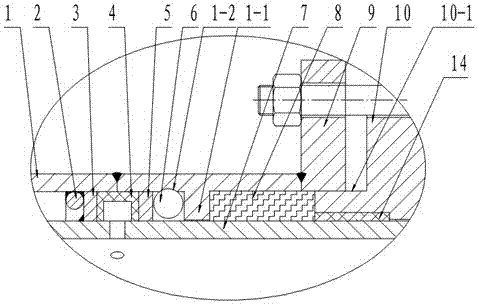

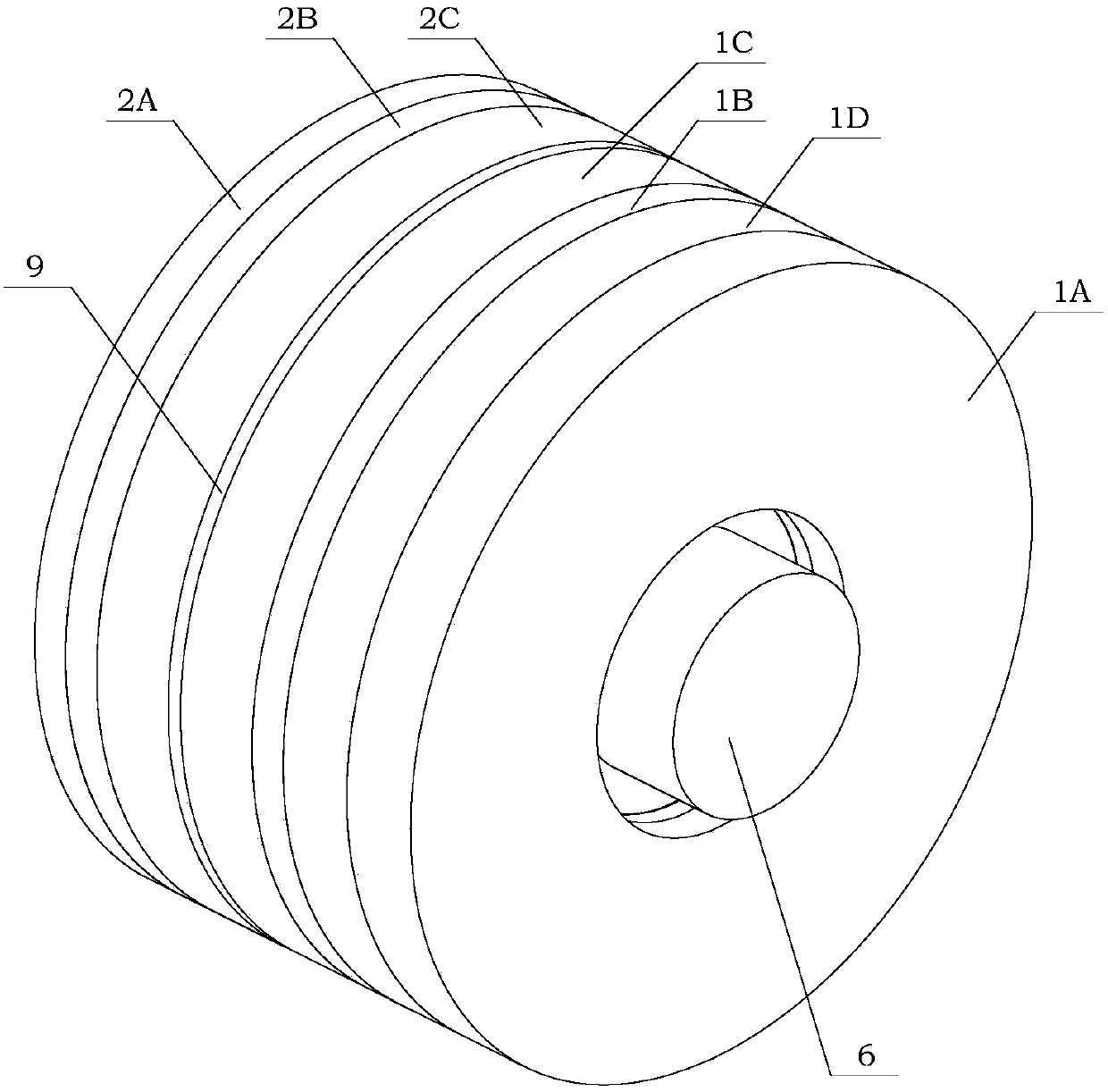

A compound transition structure and processing method of oblique line and r of cylindrical rolling element

ActiveCN104455001BExtended service lifeEliminate early fatigueBearing componentsStress concentrationRolling-element bearing

The invention relates to a cylindrical rolling body slant line and R compound transition structure and processing method, belonging to the field of cylindrical rolling bearing processing; the cylindrical rolling body slant line and R compound transition structure is used to improve the service life of the rolling body, thereby improving the use of the bearing life. Eliminate stress concentration, eliminate the technical quality problems of early fatigue of rolling elements, prolong the service life of bearings, bring benefits to customers, and use forming tools in the state of quenching HRC60 to directly carve the crown and the arc into shape. Very efficient and good quality. Save electricity and save labor hours. The rolling element with this structure has no stress concentration point during work, and it cannot produce uneven contact between the rolling element and the raceway. The end surface is convex and arc-shaped, so it can rotate flexibly and eliminate the phenomenon of jamming.

Owner:WAFANGDIAN GUANGYANG BEARING GRP

A control valve flexible connection kit

ActiveCN104197081BChange the openingAutomatic correction of position differencesYielding couplingOperating means/releasing devices for valvesEngineeringControl valves

The invention discloses a control valve flexible connection kit which comprises a left lug ring and a right lug ring. A groove matched with the top end of a valve rod is formed between the left lug ring and the right lug ring, and the left lug ring and the right lug ring are connected to the two ends of a large round pin in series respectively. The middle of the large round pin is provided with a small hole perpendicularly crossed with the axis of the large round pin and penetrating through the large round pin, and a small round pin connecting the large round pin and an upper seat arc shaft frame penetrates through the small hole. The upper seat arc shaft frame is sleeved with an antiskid force-evening spring capable of exerting pre-tightening force on the upper seat arc shaft frame, and the large round pin and the small round pin are surrounded by the antiskid force-evening spring. The upper end of the antiskid force-evening spring abuts against an upper seat, the lower end of the antiskid force-evening spring abuts against the left lug ring and the right lug ring, and the upper seat is provided with a head thread matched with a piston rod.

Owner:SHANDONG UNIV

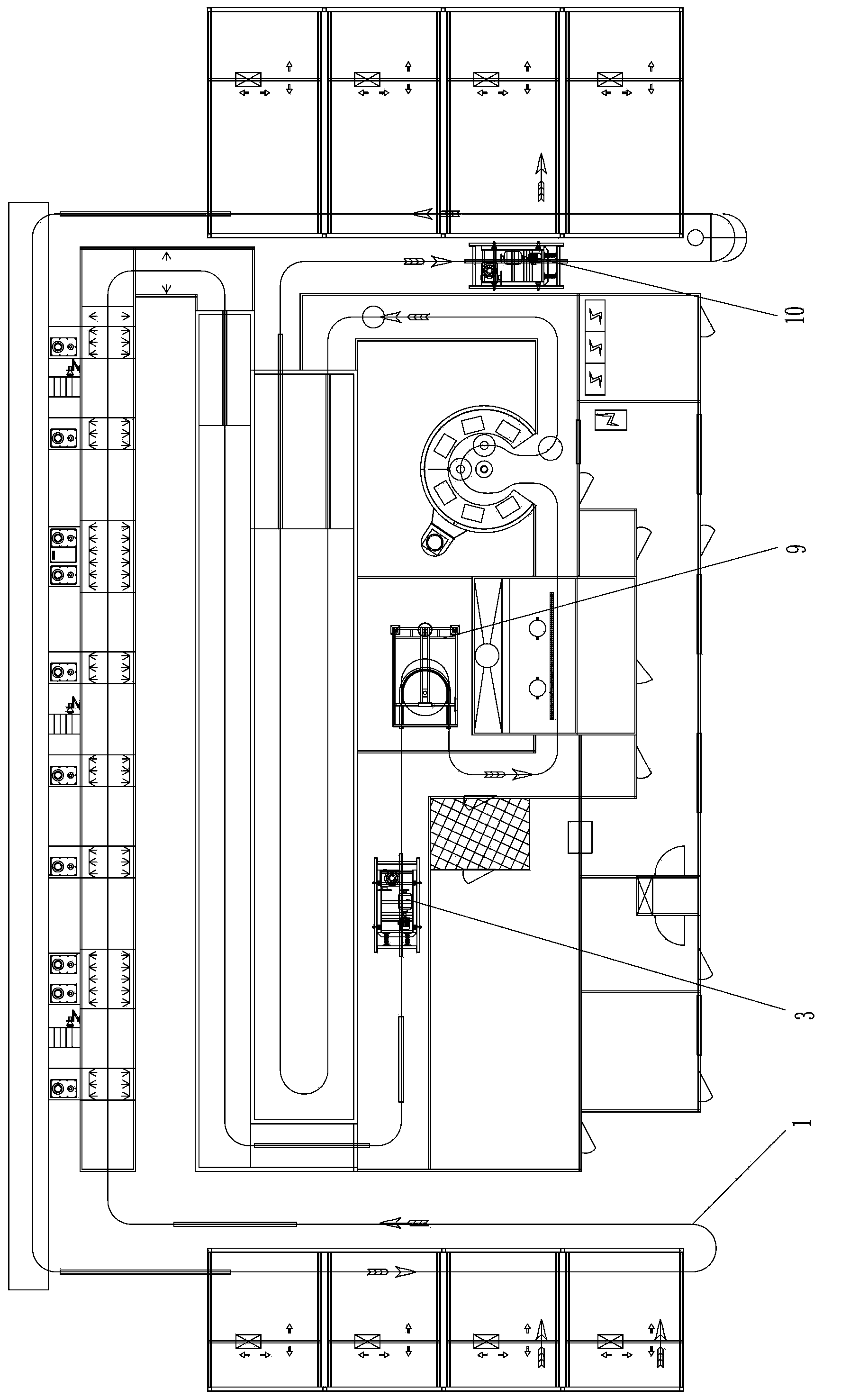

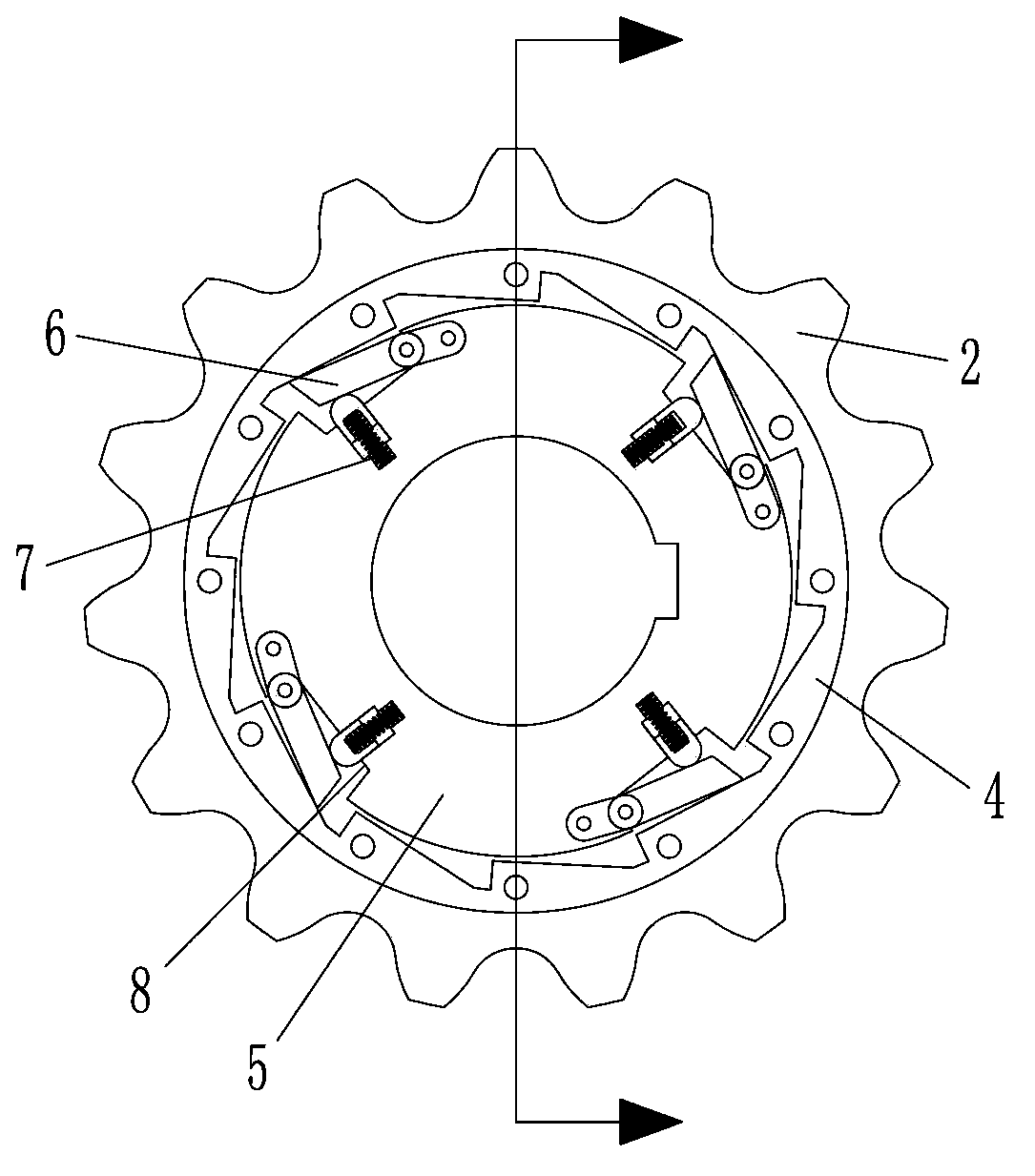

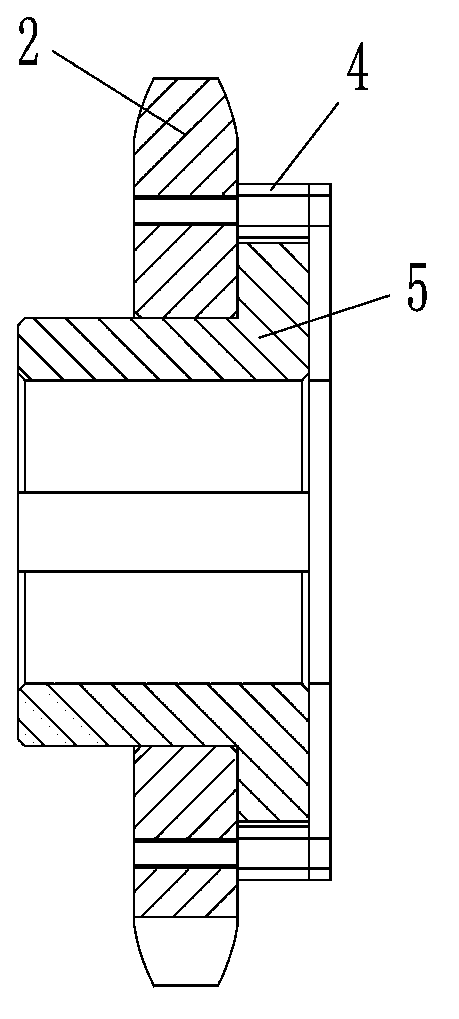

Improved cylinder part on-line transmission system

ActiveCN102745468BGuaranteed uninterrupted operationIncrease transmission speedConveyorsControl devices for conveyorsRatchetControl signal

The invention discloses an improved cylinder part on-line transmission system which comprises a closed transmission chain, a main driving chain wheel meshing with the transmission chain, and a main driving motor, wherein the main driving chain wheel is installed on an output shaft of the main driving motor through a ratchet mechanism which is coaxial with the main driving chain wheel, so that the main driving chain wheel rotates in a single direction of the output shaft of the main driving motor; and the single rotation direction is the same as the rotation direction of the output shaft of the main driving motor. When the transmission chain piles up due to the decline section, the transmission speed of the chain can be greater than the rotational linear speed of the output shaft of the main driving motor, thereby eliminating the phenomenon of binding and effectively ensuring the continuous operation of the production line; since a tension mechanism connected with an auxiliary driving motor through signals is additionally arranged, when sensing tension or loosening of the transmission chain, the tension mechanism transmits a control signal for decelerating or accelerating rotation to the auxiliary driving motor, thereby well protecting the transmission chain and being beneficial to enhancing the production efficiency.

Owner:SUZHOU LIUSH MACHINERY EQUIP

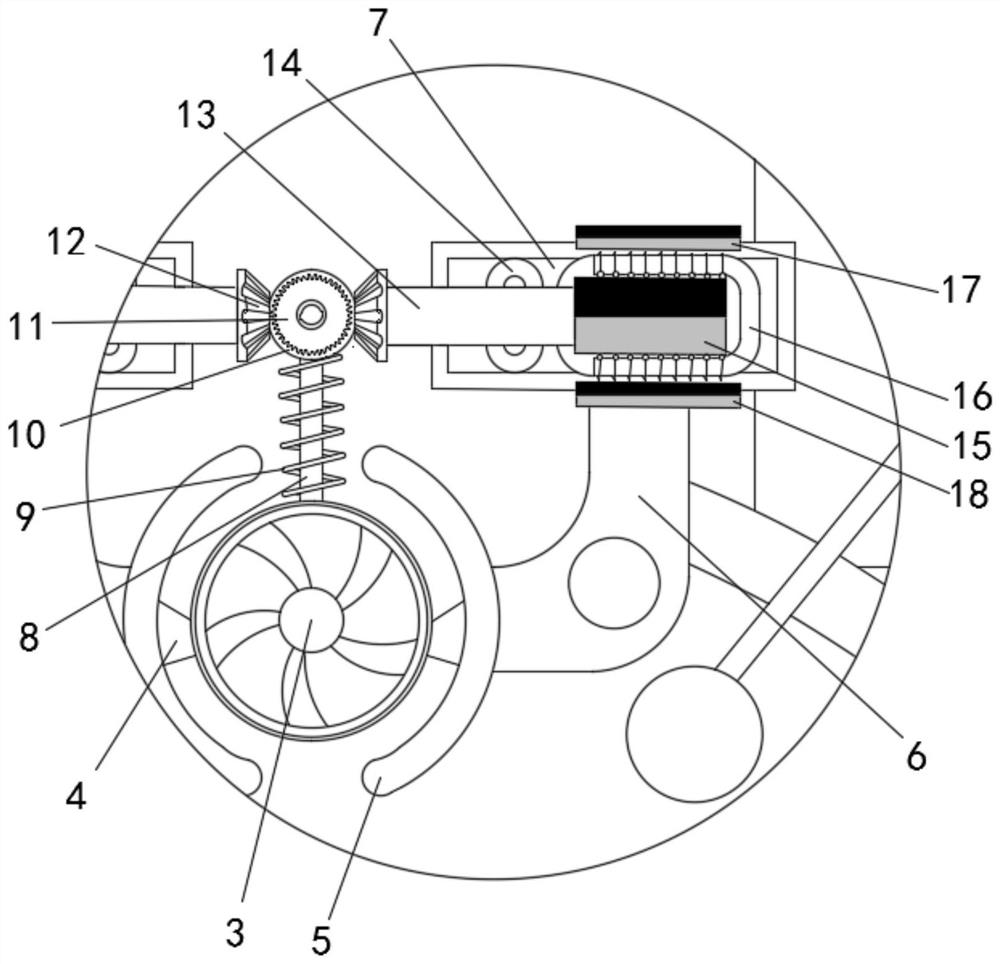

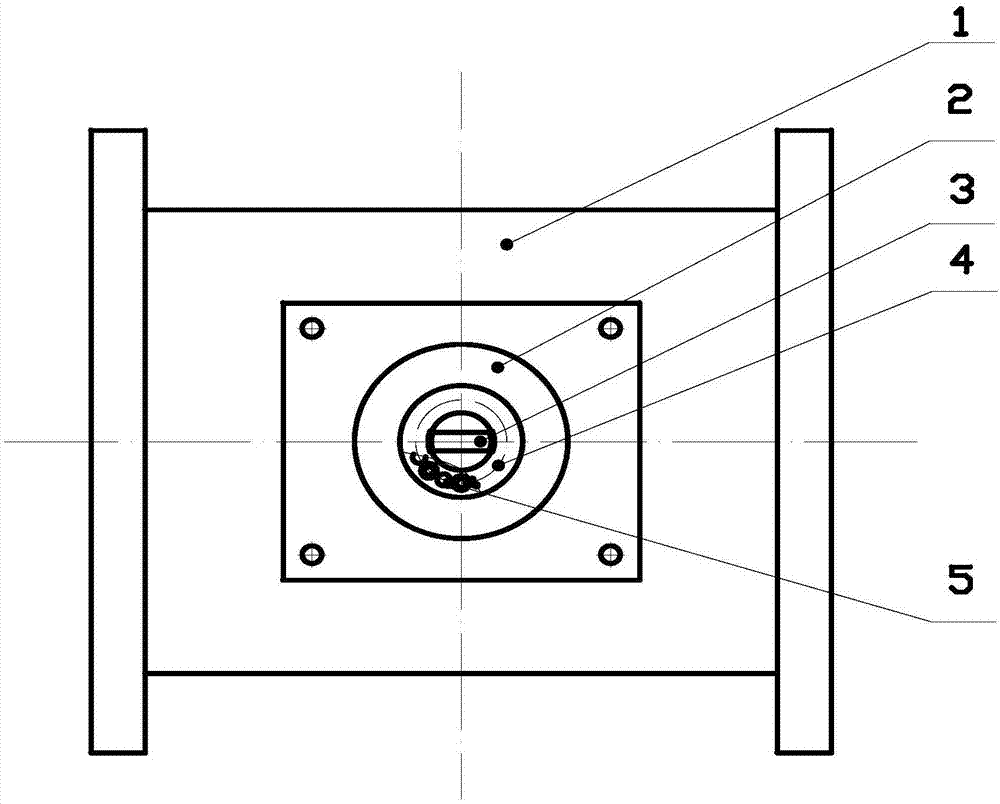

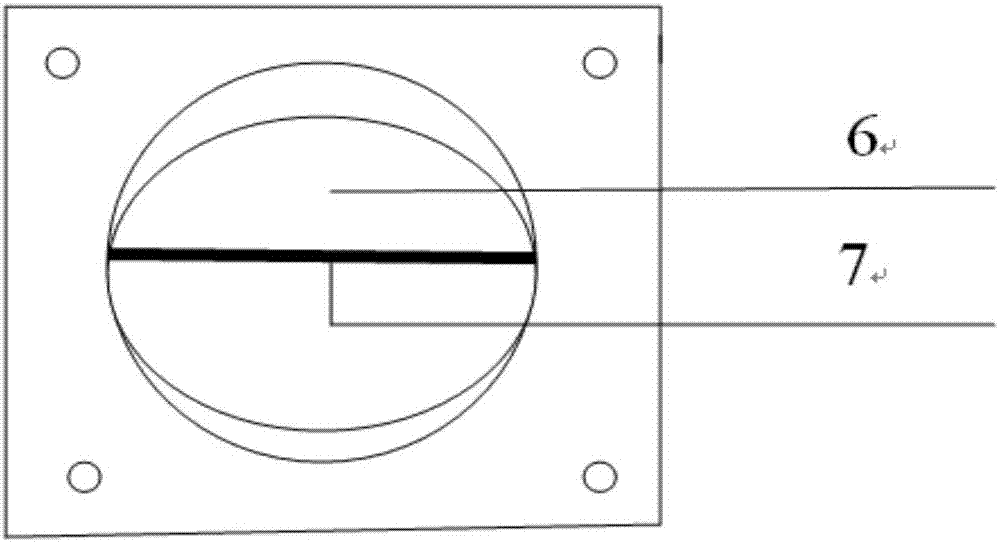

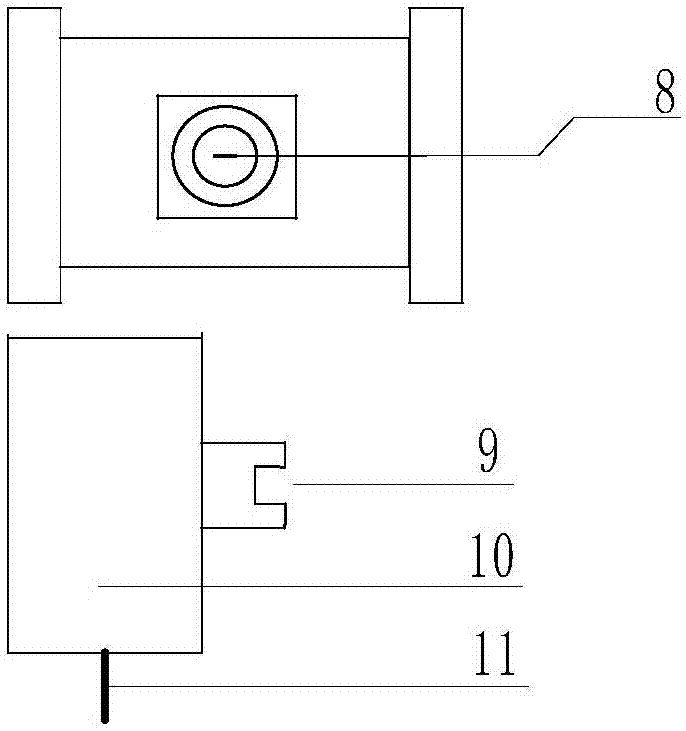

Valve jamming prevention assembly for fault maintenance of steam turbine valve

InactiveCN113323733AJamming phenomenon eliminatedAvoid stuckMachines/enginesEngine componentsPhysicsPiston

The invention relates to the technical field of steam turbine valves, and discloses a valve jamming prevention assembly for fault maintenance of a steam turbine valve. The valve jamming prevention assembly comprises a jamming prevention plate, wherein a valve port is formed in the center of the inner side of the jamming prevention plate; a pneumatic wheel is fixedly connected to the outer side of the valve port; and a connecting block is movably connected to the outer side of the pneumatic wheel. According to the valve jamming prevention assembly for fault maintenance of the steam turbine valve, an elastic column is electrified to move through electric energy converted from kinetic energy of gas, the elastic column drives a movable folding rod to move, the movable folding rod drives a transverse toothed plate to transversely reciprocate at the top of a bevel gear, a negative pressure pushing bin drives descaling liquid in an inner liquid bin to be sucked into the negative pressure pushing bin, an inclined piston pushes the descaling liquid to be discharged into an atomization rod, the atomized descaling liquid is in contact with dirt in the valve through flowing of the gas, and then the dirt in the valve is eliminated, so that the jamming phenomenon of the valve is eliminated.

Owner:潘泓璋

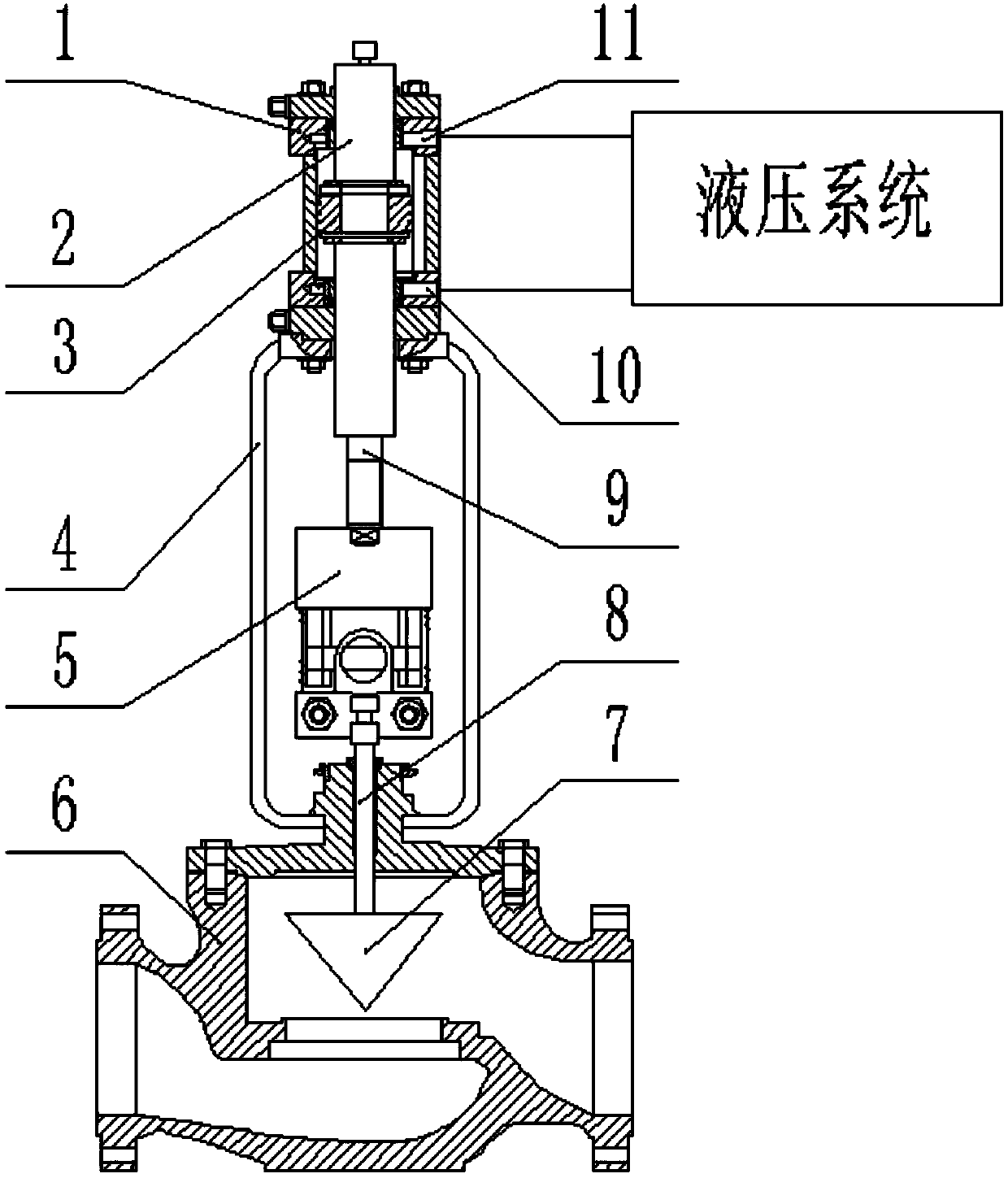

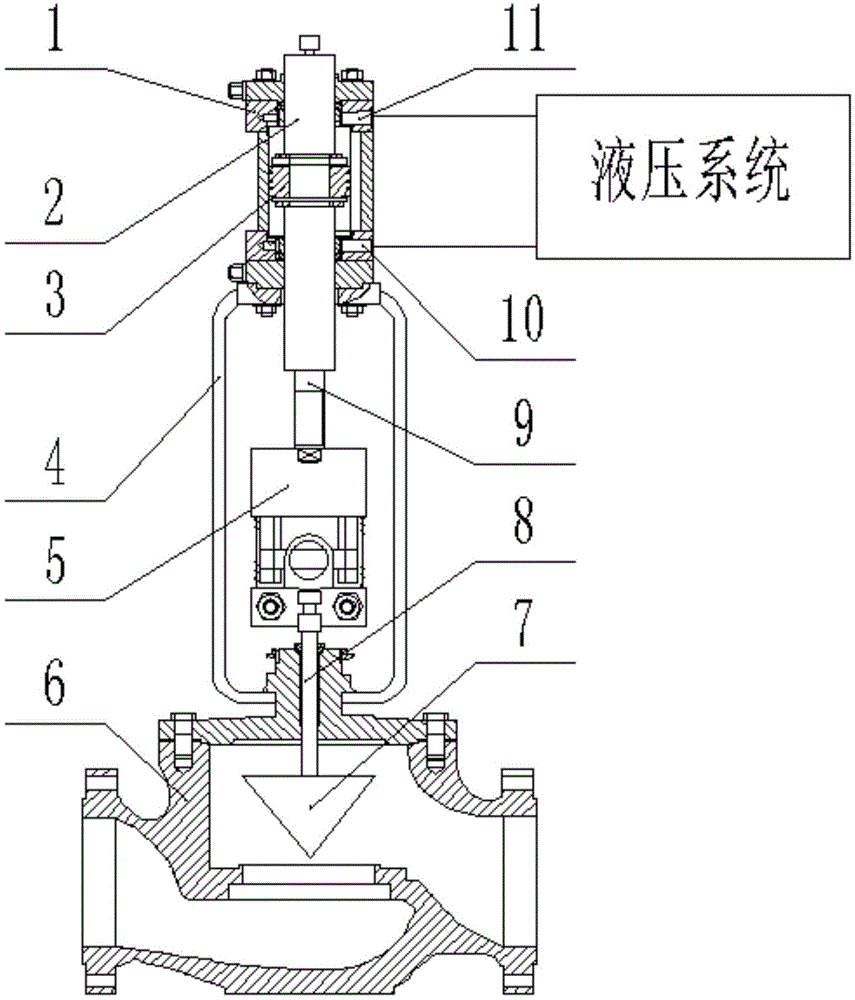

Antiseize fuel gas control valve for waste mine gas use unit

InactiveCN106979350AEliminate stuck phenomenonAvoid corrosionSlide valveValve housingsControl systemElectrical control

An antiseize fuel gas control valve for a waste mine gas use unit comprises a fuel gas control valve body, a bearing block hole, a valve rod and a bearing cap, wherein the bearing valve body is provided with a bearing block hole, and a bearing is mounted in the bearing block hole. The valve rod is nested in the bearing hole and is located on two sides of the valve body. A fuel gas valve plate and a clamping groove of an electrical contact of a contact motor outside the valve rod are fixed to be connected, and the opening and closing of the valve plate for 0-90 degrees is realized by a control system module. The bearing cap is mounted outside the bearing block, lubricating grease can be added, it is ensured that the valve rod rotates flexibly without seizing, corrosion and dust entering are prevented, regular maintenance is convenient, burning loss of an electrical control module and a motor is prevented, the service life is prolonged, and operation and maintenance costs are reduced.

Owner:CECEP NINGXIA NEW ENERGY RESOURCES LTD

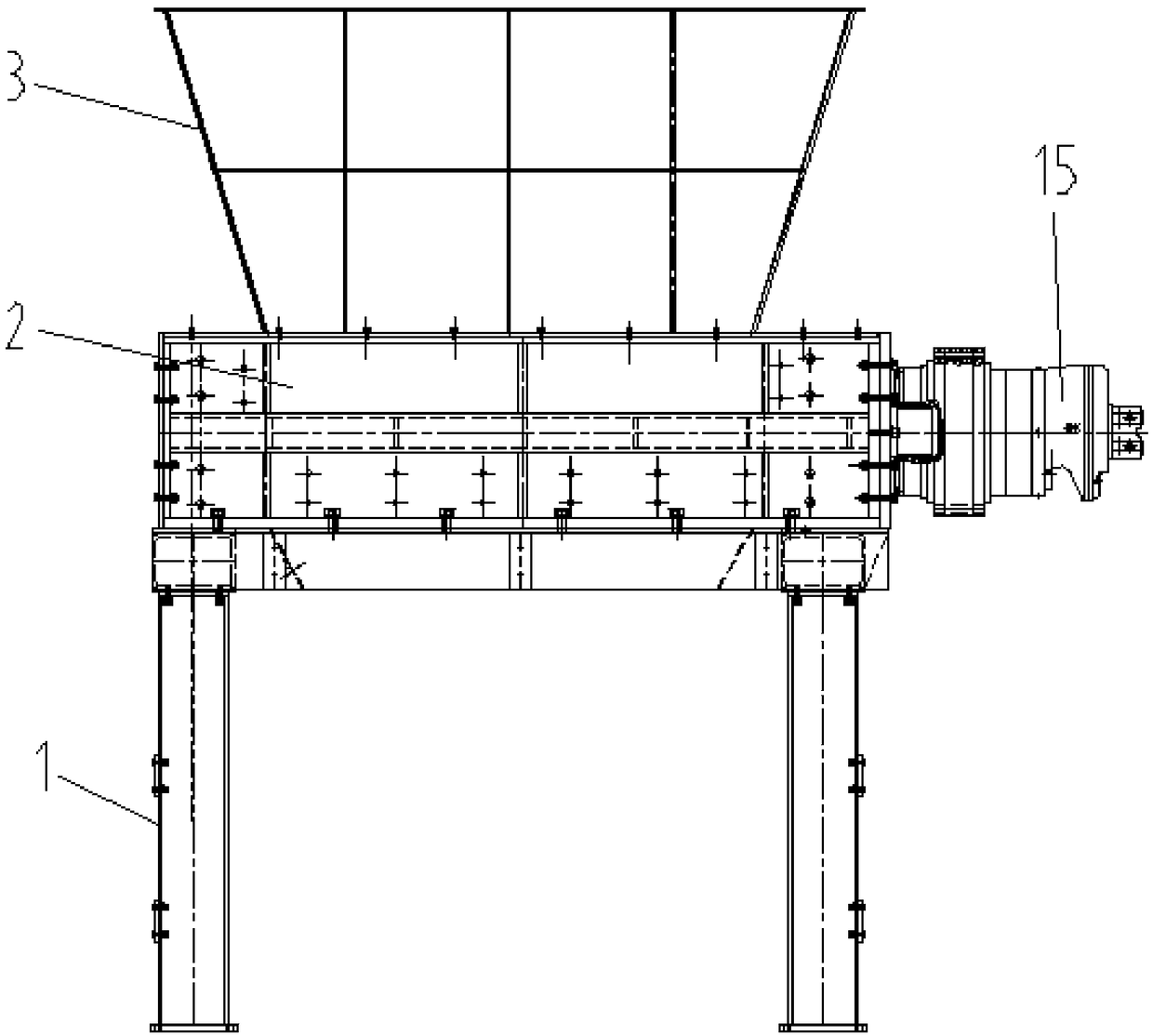

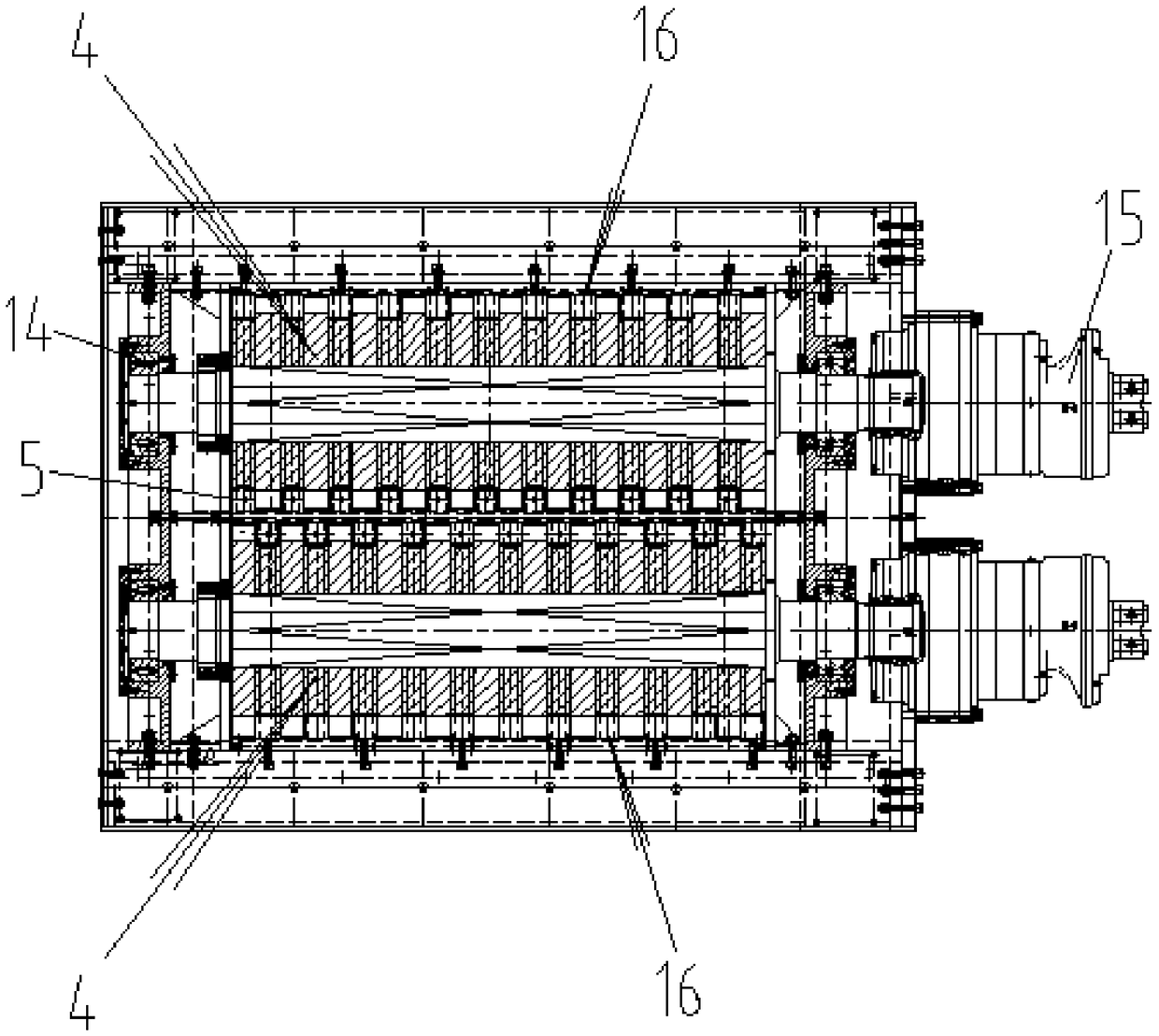

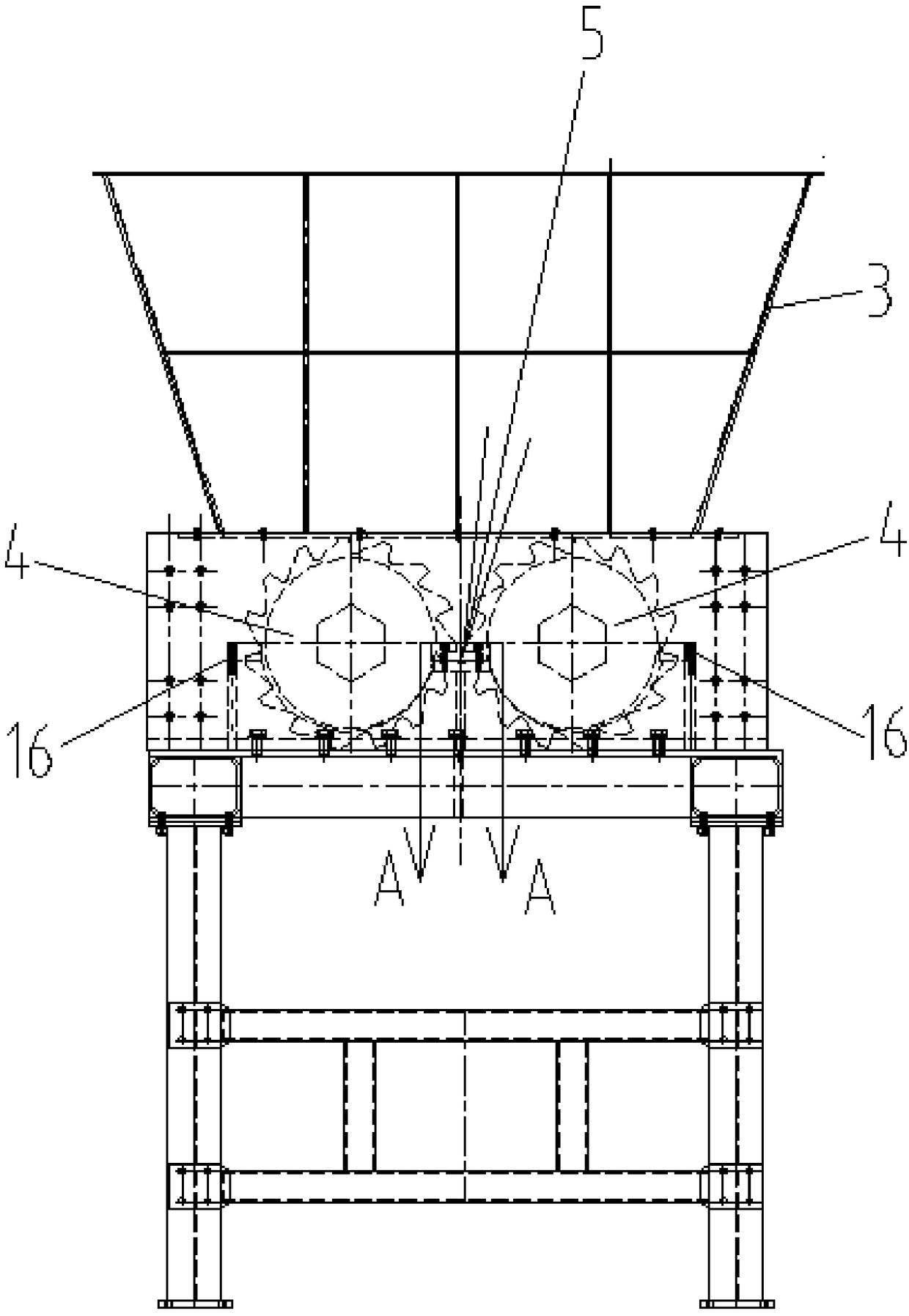

Steel bar crushing method and steel bar crushing equipment adopting same

InactiveCN109201249AFully automatedImprove crushing efficiencyGrain treatmentsArchitectural engineeringSteel bar

The invention relates to the technical field of material crushing and discloses a steel bar crushing method and steel bar crushing equipment adopting the crushing method. The steel bar crushing equipment comprises a pair of rotating cutter shafts and a main shearing cutter seat, wherein the pair of the rotating cutter shafts are correspondingly arranged on two sides of the main shearing cutter seat. Cutter heads are arranged on the rotating cutter shafts, shearing cutter teeth are arranged on the cutter heads, a shearing groove penetrating up and down is formed in the main shearing cutter seat, and the two sides of the tooth width and the tooth top of each shearing cutter tooth are correspondingly matched with the two sides and the groove bottom of the shearing groove. A steel bar is thrown downward from the upper part of the main shearing cutter seat, so that the steel bar falls between the pair of rotating cutter shafts. The rotating cutter shafts rotate, the shearing cutter teeth onthe rotating cutter shafts hook the steel bar, and the steel bar is pressed down to the upper plane of the main shearing cutter seat. The rotating cutter shafts continue to rotate to press and shearthe steel bar located at the groove in the main shearing cutter seat. The steel bar crushing method and the steel bar crushing equipment realize the automation of steel bar crushing and further improve the efficiency and quality of steel bar crushing.

Owner:JIANGYIN GUANGFU MACHINERY

Orthogonal Magnetic Path Shaft Integrated Magnetic Suspension Bearing Based on Symmetrical Self-lubricating Flexible Auxiliary Bearing Structure

ActiveCN108361279BDissipate quicklyPrevent hyperthermiaShaftsMagnetic bearingsMagnetic bearingGraphite

The invention discloses an orthogonal magnetic circuit radial-axial-integrated magnetic bearing based on a symmetrical self-lubricating flexible backup bearing structure. A radial magnetic bearing coil of the orthogonal magnetic circuit radial-axial-integrated magnetic bearing is mounted on a stator tooth set of a stator iron core; two radial rigid magnetic-conductive rings are mounted at an outerdisc of the stator iron core so as to prevent the short circuit problem of permanent magnetic circuits, wherein a certain gap exists between the two radial rigid magnetic-conductive rings; an axial magnetic bearing coil is located at a thrust disc of a rotor shaft and mounted in a cavity formed by the two magnetic-conductive rings; graphite rings and backup bearing skeletons which achieve the axial self-lubricating effect are arranged on the two sides of the thrust disc correspondingly; and a radial backup bearing skeleton and a graphite internal convex ring are arranged in an inner ring cavity of a radial flexible magnetic conductive ring for achieving the radial self-lubricating effect. By adopting the technical means that axial and radial electromagnetic circuits are combined into a whole, and a radial magnetic bearing and a backup bearing are combined into a whole, the technical problem that traditional magnetic bearings are low in coaxiality is solved.

Owner:BEIHANG UNIV

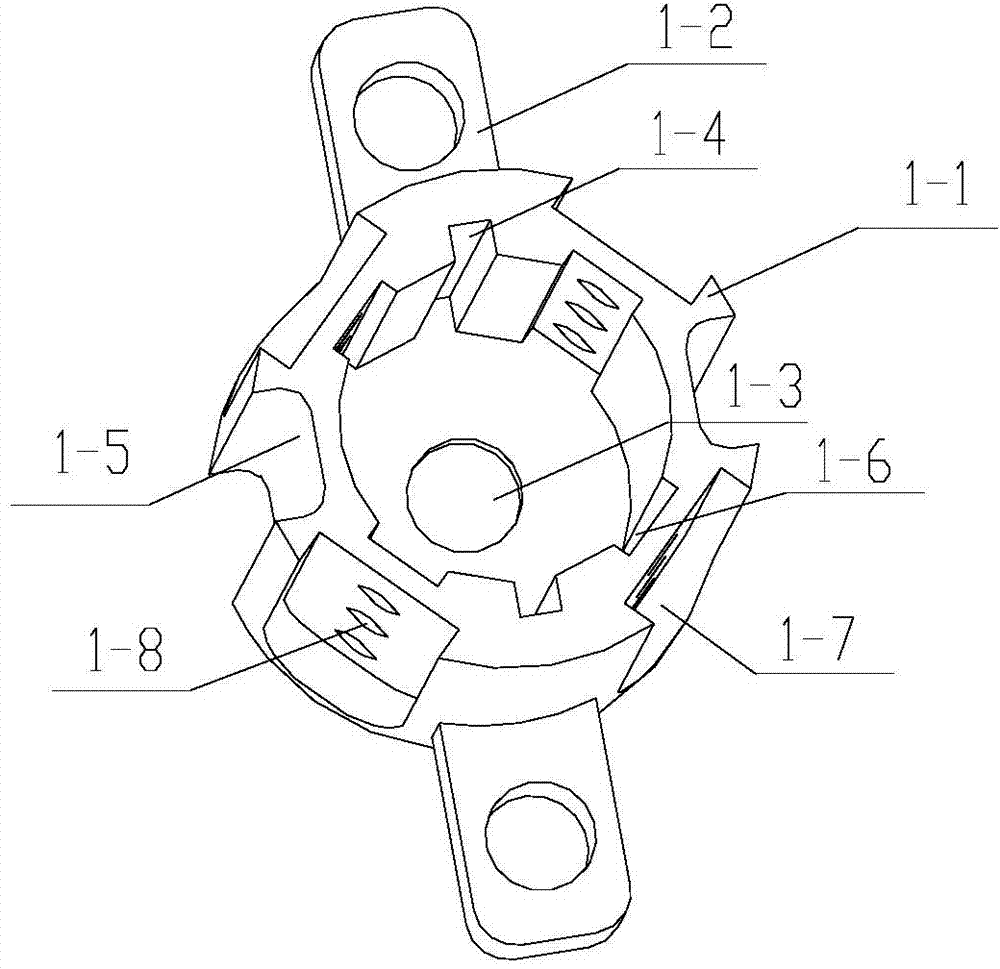

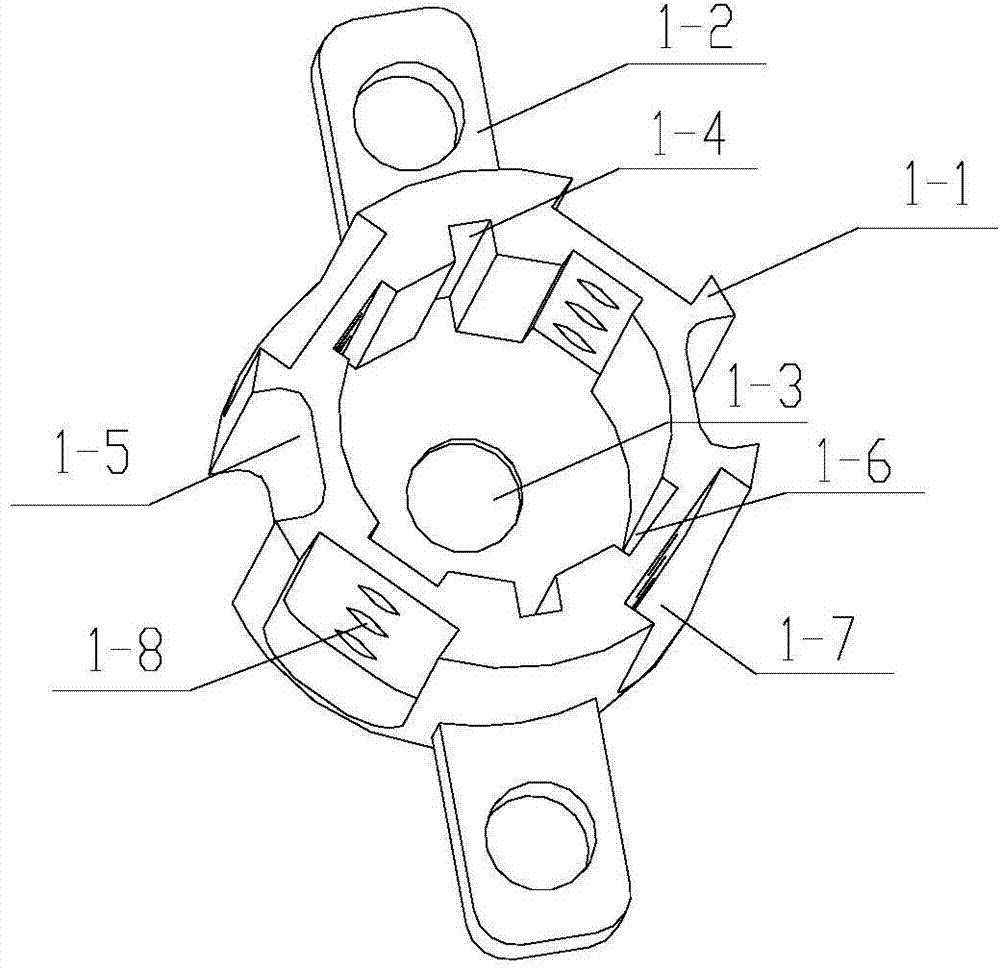

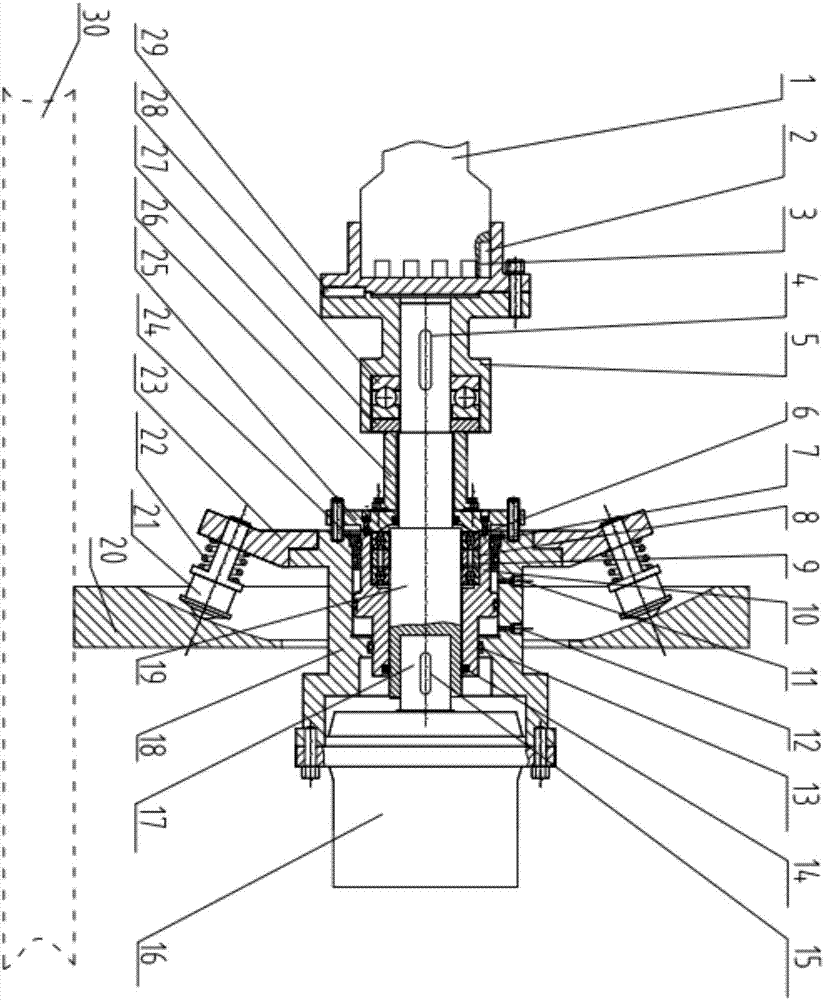

Multisection bearing universal balance compass mechanism

ActiveCN102455194BEasy to wearEliminate "stuck" phenomenonMeasurement apparatus bearings/suspensionsEngineeringMechanical engineering

The invention discloses a multisection bearing universal balance compass mechanism, and is mainly used for solving the technical problem of improving the regulating power of the mechanism freedom and the like. The adopted technical scheme of the compass mechanism is as follows: the mechanism is composed of an upper compass frame, a Y-piece, a rod-shaped piece and a lower compass frame, wherein the upper compass frame is articulated with one end of the Y-piece through a first articulated piece of an articulated assembly, the other end of the Y-piece is articulated with one end of the rod-shaped piece through a second articulated piece of the articulated assembly, and the other end of the rod-shaped piece is articulated with the lower compass frame through a third articulated piece of the articulated assembly; and a shaft line of the first articulated piece and a shaft line of the second articulated piece are vertical. The self-balancing mechanism is suitable for a hanging body and different parts which has requirements on verticality.

Owner:704TH RES INST OF CHINA SHIPBUILDING IND CORP

Program controlled reciprocating dust absorbing, barrier clearing device with automatic guiding function

InactiveCN100569398CSolve the problem of clearingSolve the problem of vacuuming dead angleHollow article cleaningBogieControl manner

The invention relates to a programmable reciprocating dust collecting and barrier cleaning device with automatic guiding function, comprising a carrier bogie, a dust collecting and barrier cleaning part as well as a control part. A camera is arranged on the carrier bogie; a horizontal movement mechanism is arranged horizontally along the carrier bogie. The dust collecting and barrier cleaning part comprises a barrier-cleaning bucket, a sucker, two guiding contact switches, a dust-collecting host machine connected with a hose and fixed on a carrier bogie; the barrier-cleaning bucket is arranged at the front end of the carrier bogie; and the two guiding contact switches are arranged at both sides of the barrier-cleaning bucket. The programmable reciprocating dust collecting and barrier cleaning device can completely collect the dust on the bottom surface of the air duct of a central air conditioner by the horizontal movement travel of the program-controlled dust collecting and barrier cleaning device in accordance with cross-section size of the air duct to be cleaned; the device can be controlled manually to clean the barrier in the air duct of the central air conditioner, and the device can be guided automatically during traveling.

Owner:NAT UNIV OF DEFENSE TECH

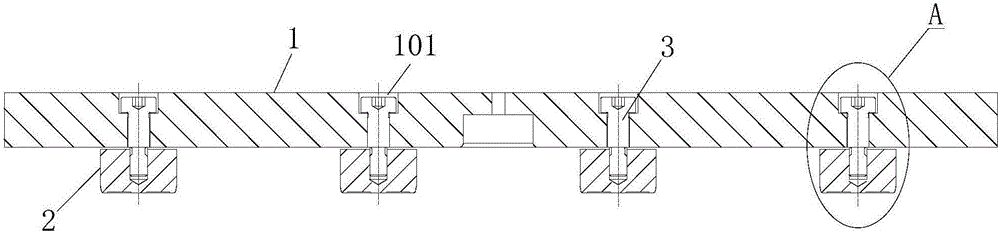

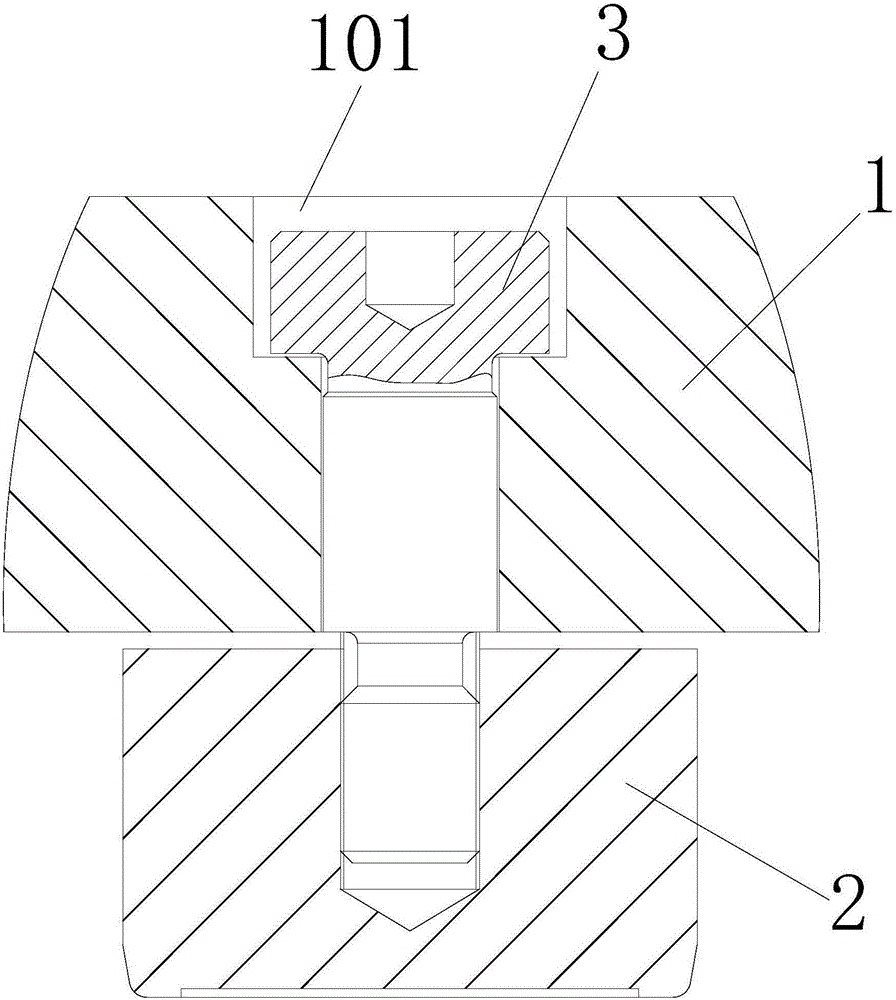

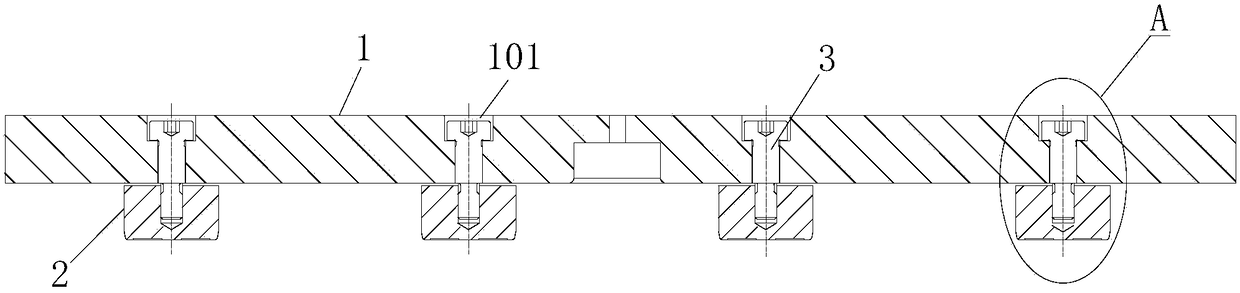

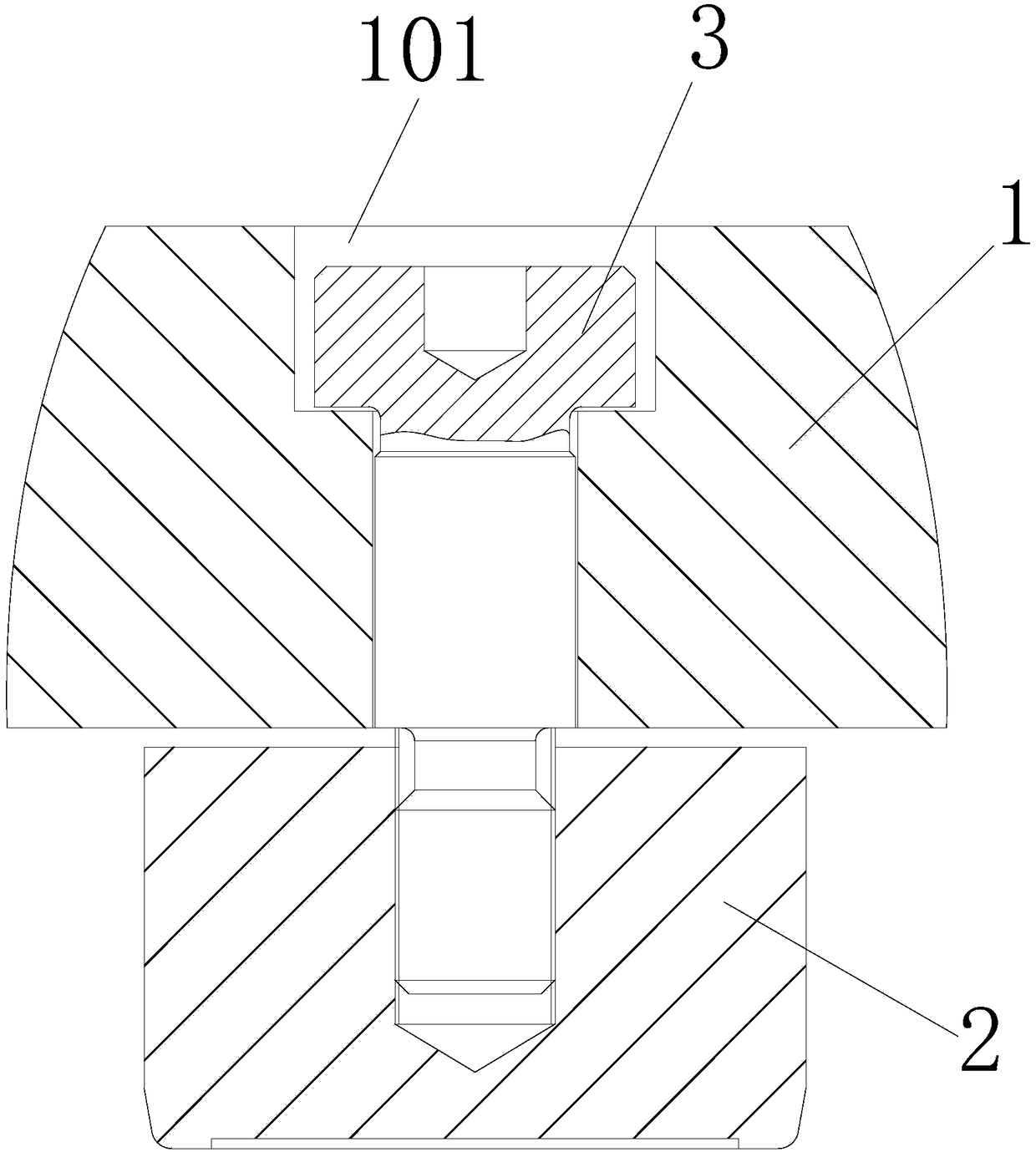

Self-positioning type pour plug

The invention discloses a self-positioning type pour plug. The self-positioning type pour plug comprises a pour plug plate, pour plug bodies and bolts. The pour plug plate is provided with a plurality of first holes, and the first ends of the bolts penetrate through the first holes and are connected with the pour plug bodies. The aperture of the first holes is 0.1-0.5 mm larger than the diameter of rod parts of the bolts. A movable clearance is reserved between each pour plug body and the pour plug plate. The pour plug bodies can be in clearance fit with material cups on molds. The self-positioning type pour plug can effectively prevent the phenomenon that the pour plug bodies get stuck, thereby being beneficial for improving production efficiency.

Owner:安徽宁国中鼎模具制造有限公司

Rotary-motion-oriented reed type linear micro-driving mechanism

The invention relates to a rotary-motion-oriented reed type linear micro-driving mechanism, in particular to a linear micro-driving mechanism. The linear micro-driving mechanism aims to solve the problems that the optimal matching angles of crystals in an electric reflector module and a frequency conversion module are difficult to adjust in a photoelectric control system of an inertial confinement laser nuclear fusion device. A stepper motor is connected with a speed reducer; the speed reducer is provided with a base bending plate and is connected with a rolling screw rod; the base bending plate is provided with a base; the base is provided with a rolling guide rail and a bearing block; a sliding block is arranged on the rolling guide rail; the sliding block is provided with a nut base plate; a rolling nut is arranged on the nut base plate; the rolling screw rod passes through the bearing block and is in threaded connection with the rolling nut; two reeds are horizontally arranged in parallel; each reed is clamped through an upper clamp plate and a lower clamp plate; the left end of each reed is fixedly connected to a connecting block through a reed pressing plate, and the right end of the reed is connected to the nut base plate through a reed pressing plate; and the connecting block is connected with a lens frame. The linear micro-driving mechanism is used for driving optical lenses to do rotary motion such as pitching and deflecting.

Owner:HARBIN INST OF TECH

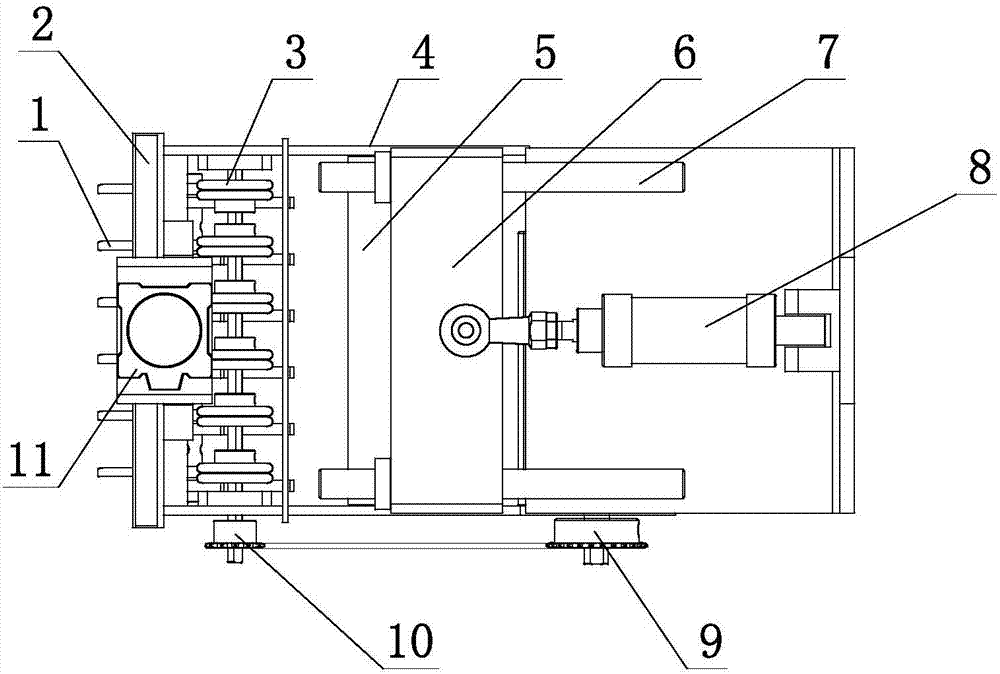

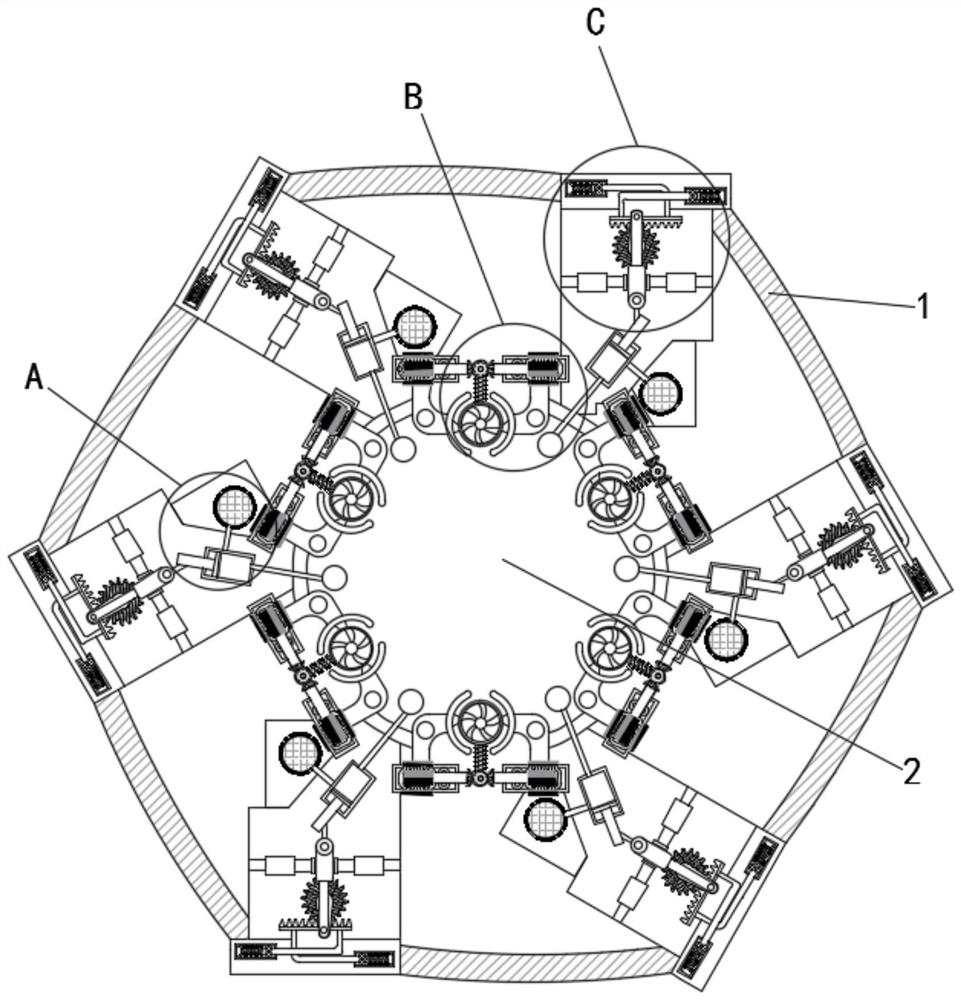

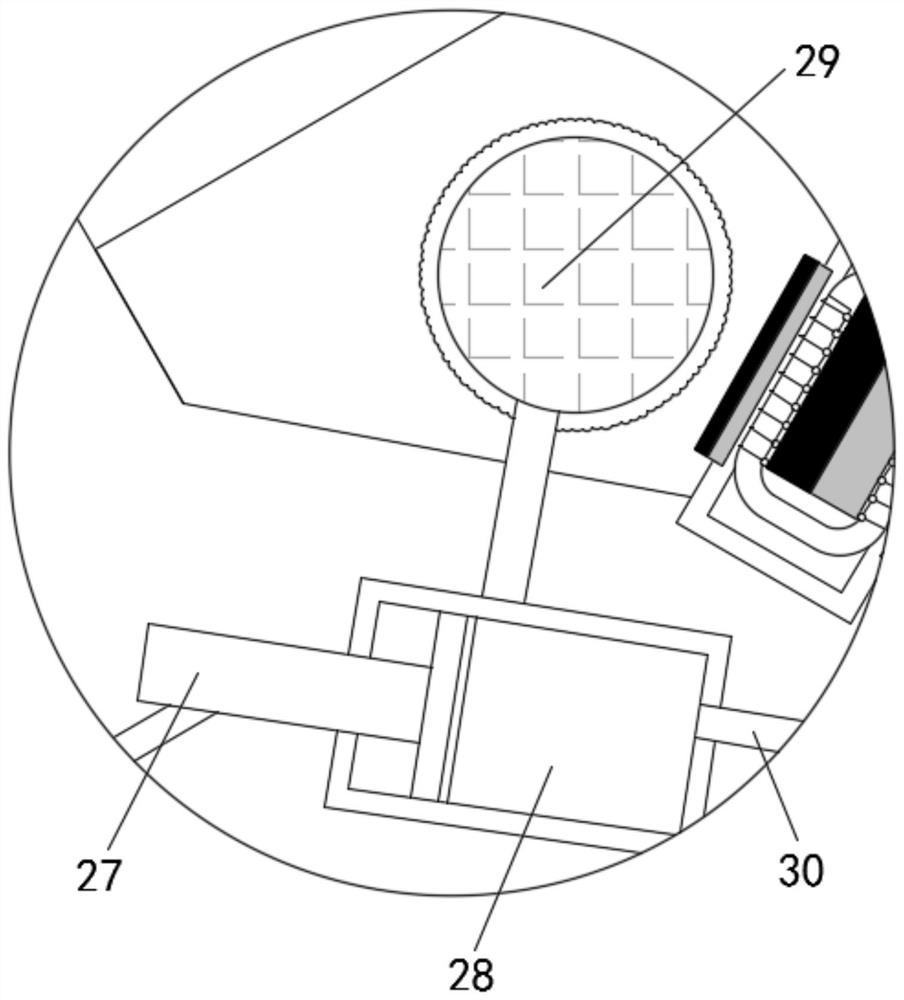

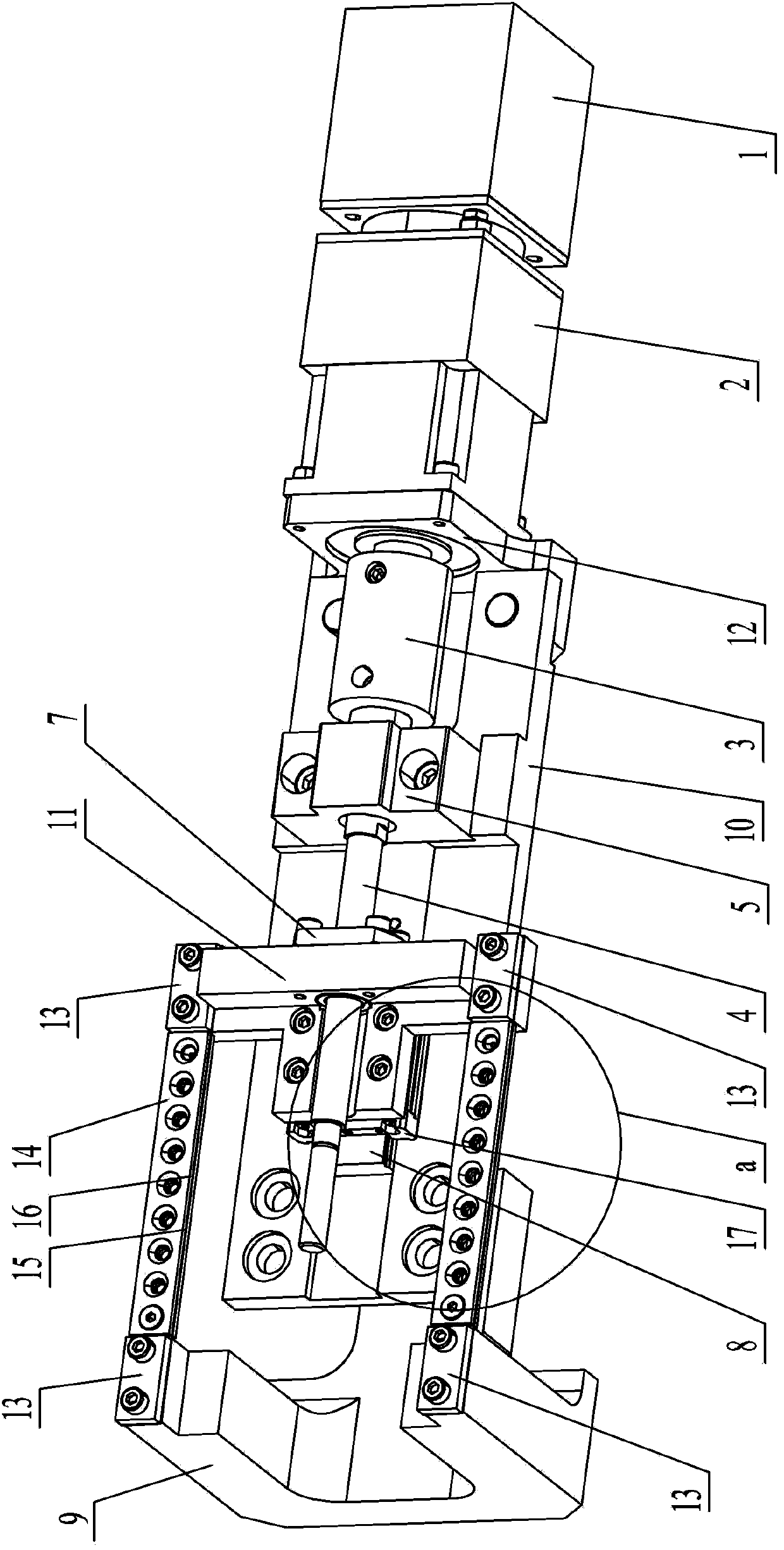

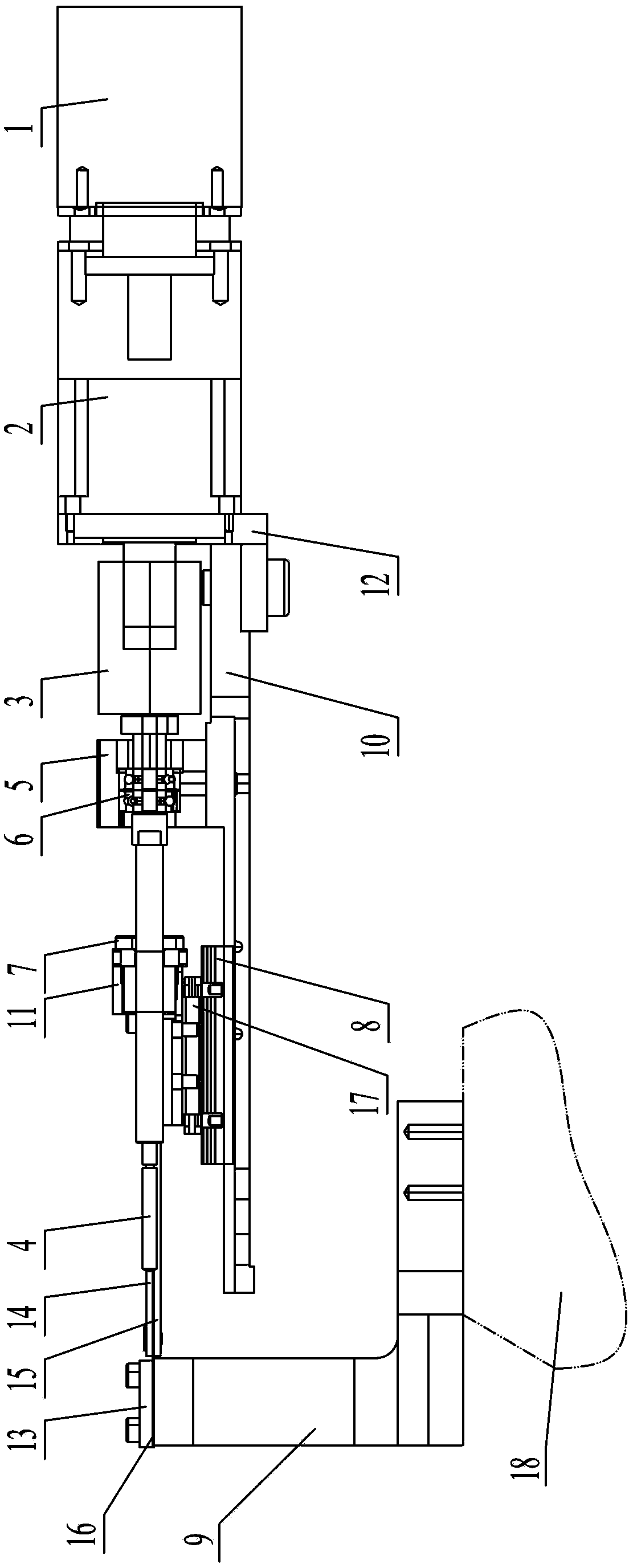

Dynamic steering simulation device for dynamic directional rotary steering drilling tool

ActiveCN107219085AEvenly loadedUniform unloadingStructural/machines measurementExperimental researchHydraulic cylinder

The invention discloses a dynamic steering simulation device for a dynamic directional rotary steering drilling tool, which comprises a rack, a drill bit, a load shaft and a hydraulic motor, and is characterized in that an output shaft of the hydraulic motor is connected with the load shaft and transfers the torque to the load shaft, a cylinder is installed on the load shaft through a radial ball bearing ball ad used for providing an axial force for the load shaft, a plurality of universal balls are uniformly installed on check ring along the circumferential direction, one side of the universal ball is provided with a baffle plate used for counteracting an axial force applied by the hydraulic cylinder to the tool, and a contact surface of the baffle plate and the universal balls is a spherical surface; and experimental research on steering performance and other aspects of the dynamic directional rotary steering drilling tool can be performed through loading the axial force and the torque. The dynamic steering simulation device not only can be used for experimental research, but also can be used for performance testing for the directional rotary steering drilling tool.

Owner:XI'AN PETROLEUM UNIVERSITY

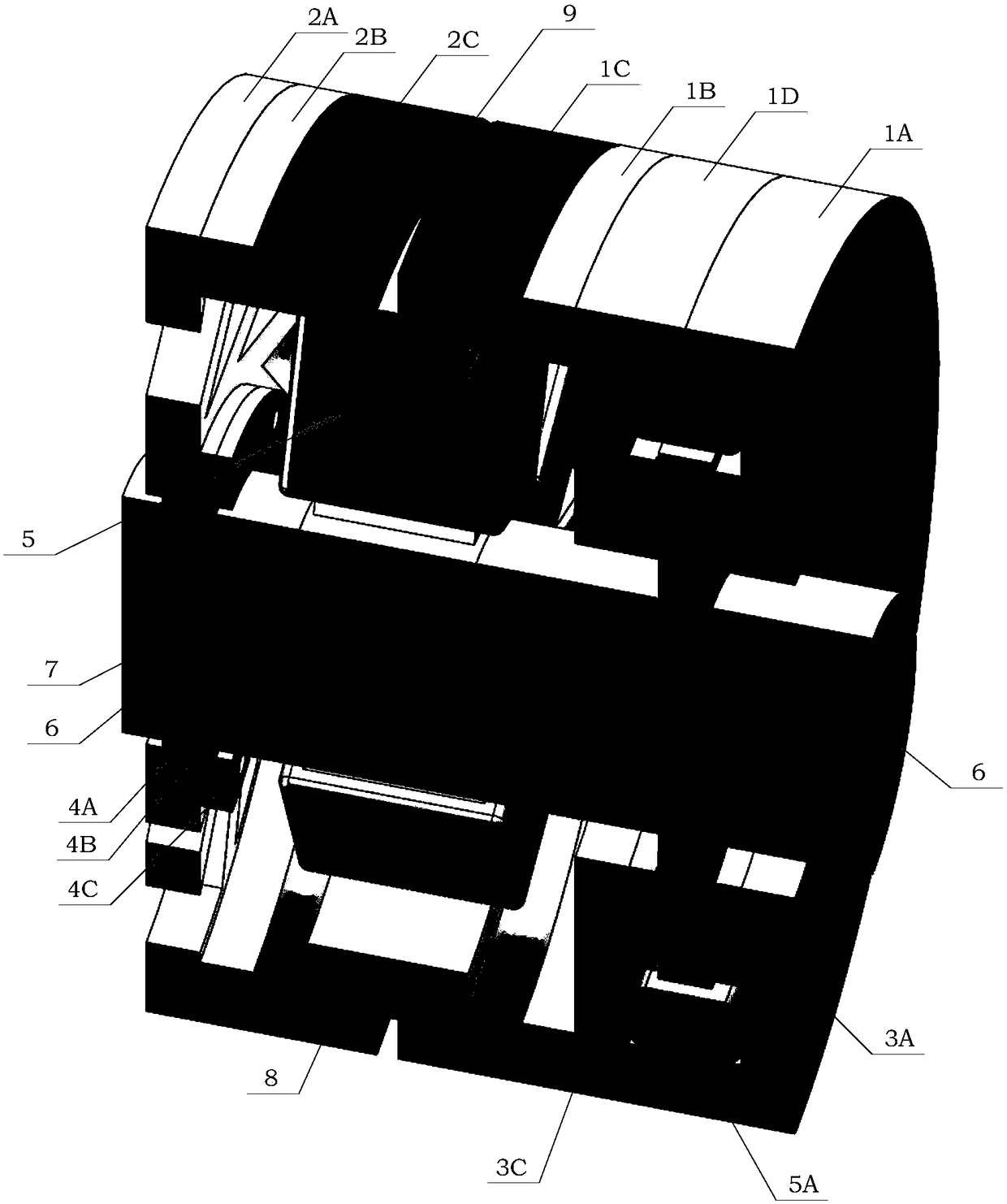

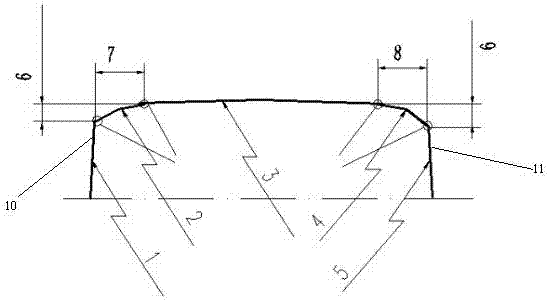

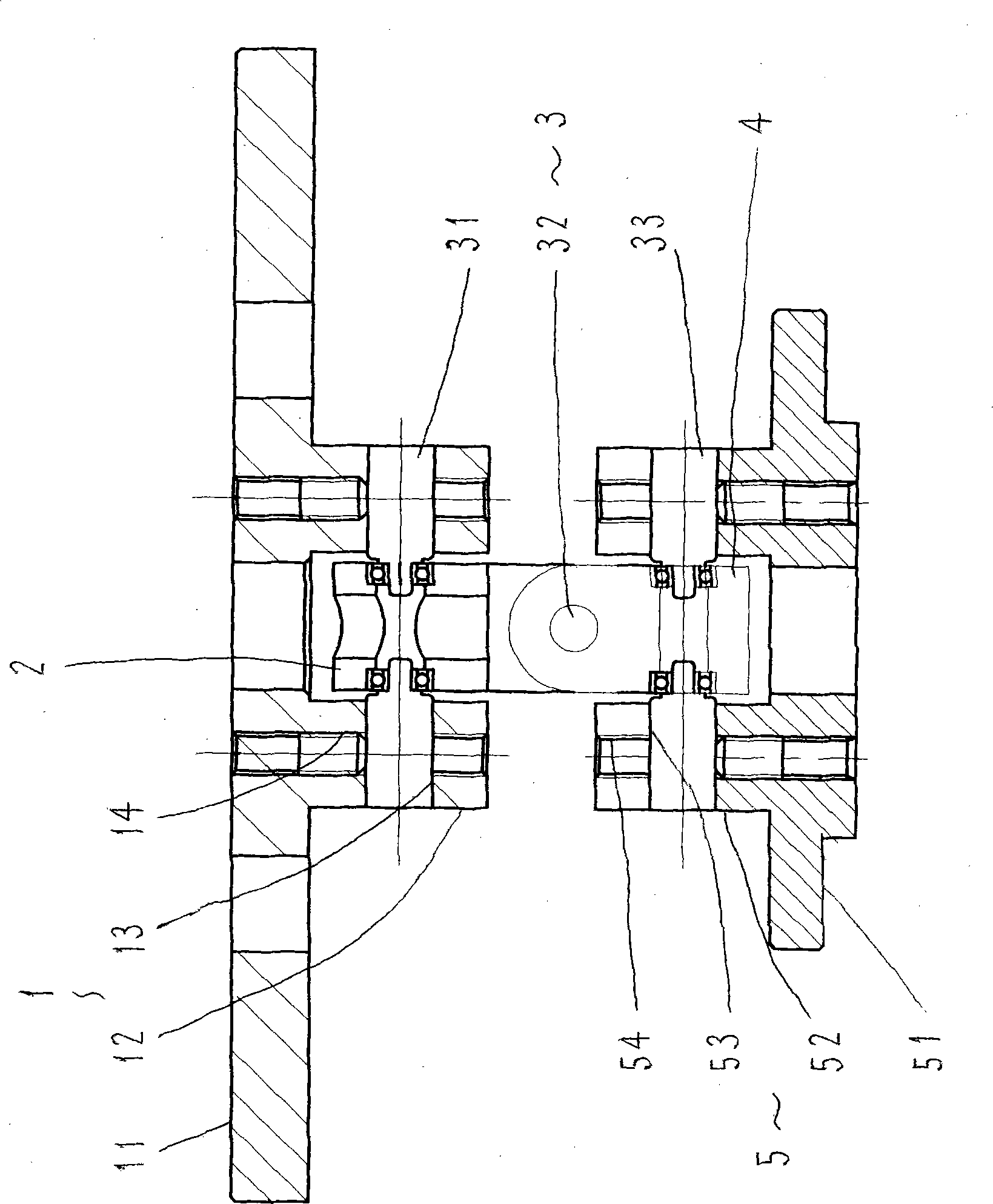

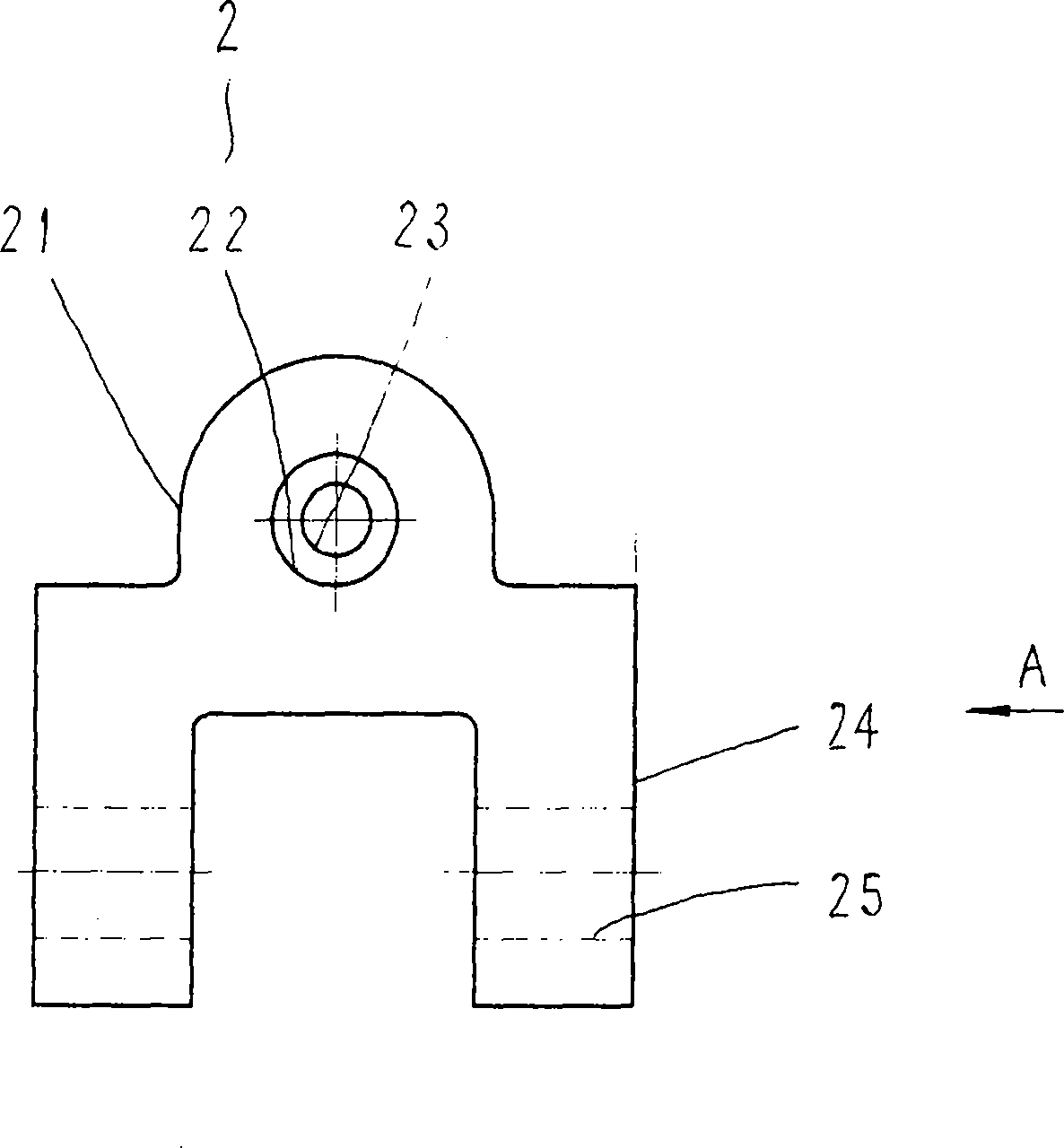

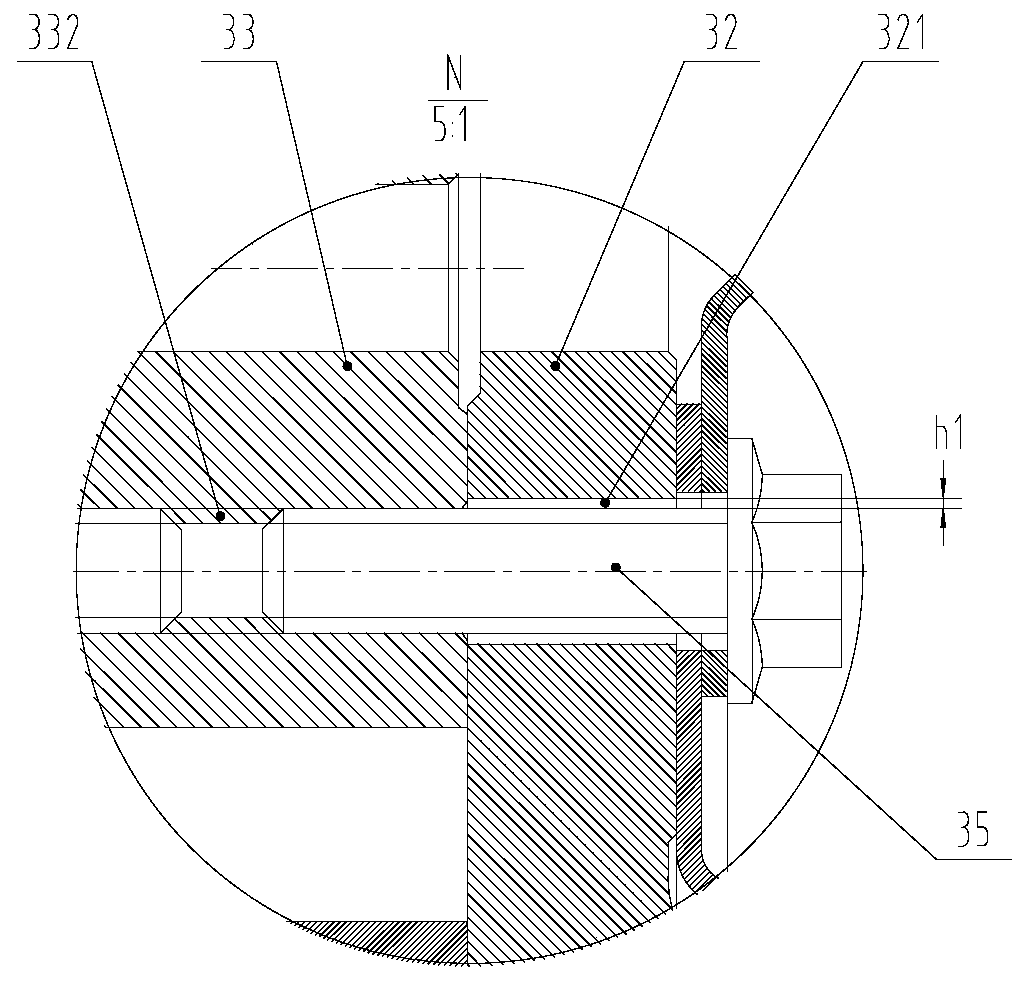

Pump body components, casting molds and rotary compressors

ActiveCN109209876BEliminate stuck phenomenonImprove stuckRotary/oscillating piston combinations for elastic fluidsFoundry mouldsCasting moldEngineering

The invention provides a pump body assembly, a casting die and a rotating compressor. The pump body assembly comprises an air cylinder (3), a first bearing (1) and a second bearing (2), wherein the first bearing (1) and the second bearing (2) are arranged at the two ends of the air cylinder (3). The air cylinder (3) and the first bearing (1) are integrally formed; and / or the air cylinder (3) and the second bearing (2) are integrally formed. According to the pump body assembly, changing of the relative positions of the air cylinder and the bearings can be effectively prevented, and the phenomenon that the compressor is stuck is avoided.

Owner:GREE ELECTRIC APPLIANCES INC +1

Orthogonal Magnetic Path Directional Magnetic Suspension Bearing Based on Symmetrical Self-lubricating Flexible Auxiliary Bearing Structure

ActiveCN108386448BReasonable stiffnessWith self-lubricating functionShaftsMagnetic bearingsMagnetic bearingGraphite

The invention discloses an orthogonal magnetic circuit radial magnetic suspension bearing based on a symmetric self-lubricating flexible auxiliary bearing structure. A rotor shaft (6) of the magneticsuspension bearing is sleeved with a rotor core (7), and the rotor core (7) is located on a stator tooth set (8A) of a stator core (8). A coil is mounted on the stator tooth set (8A) of the stator core (8), and two radial rigid magnetic conducting rings are mounted on an outer disc of the stator core (8). A certain clearance exists between the two radial rigid magnetic conducting rings in the axial direction to prevent the short circuit of a permanent magnetic circuit. A graphite inward protruding ring cooperates with a radial auxiliary bearing framework, is arranged in an inner ring cavity ofa radial flexible magnetic conducting ring and is compressed by a radial bearing check ring, and the graphite inner ring is prevented from axially sliding. A permanent magnet is mounted between the radial rigid magnetic conducting rings and the radial flexible magnetic conducting ring. The magnetic suspension bearing is divided into two parts in bilateral symmetry around the stator core in the axial direction, the design method that a radial magnetic bearing and an auxiliary bearing are combined into a whole is adopted, and the technical problem that the coaxiality of a traditional magnetic bearing and auxiliary bearing is low is solved.

Owner:BEIHANG UNIV

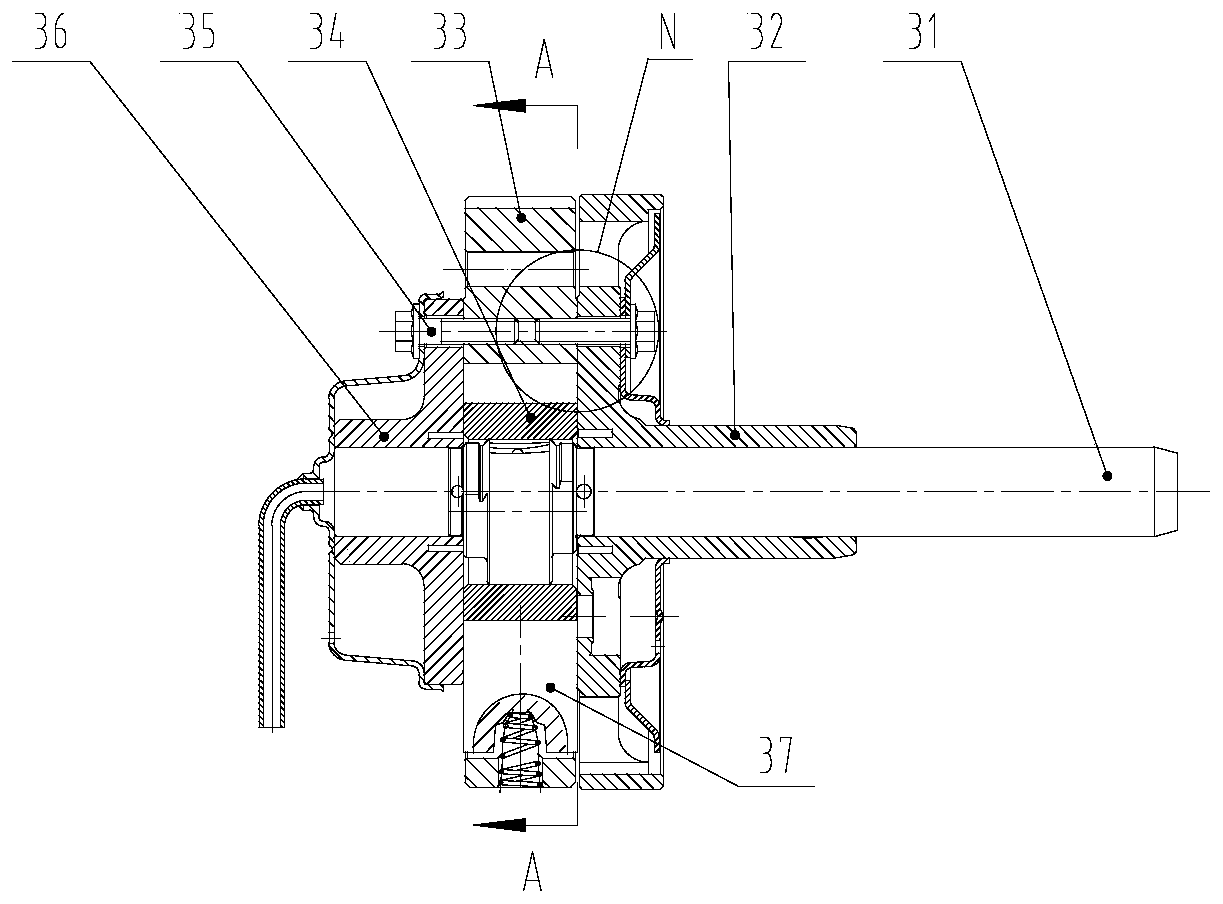

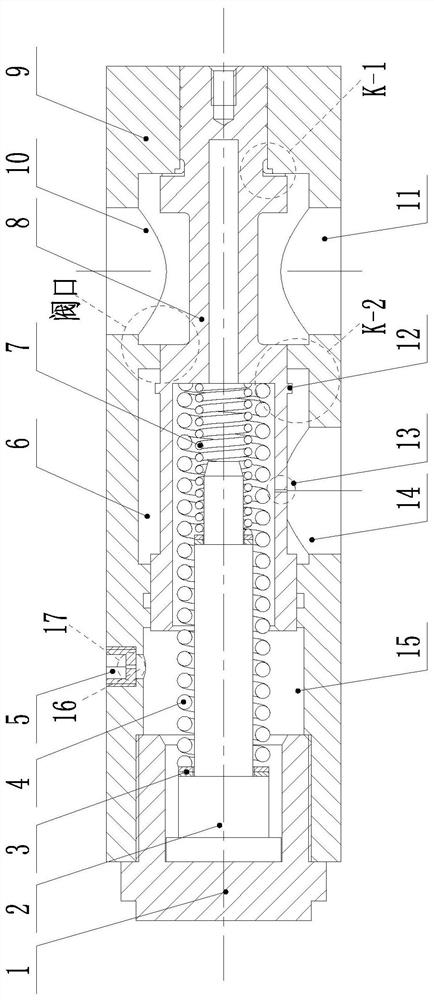

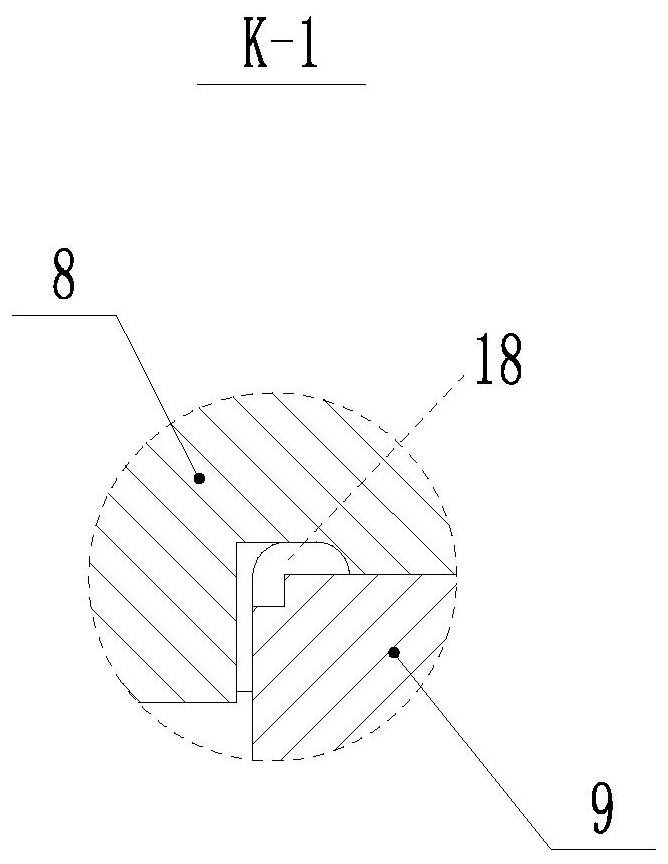

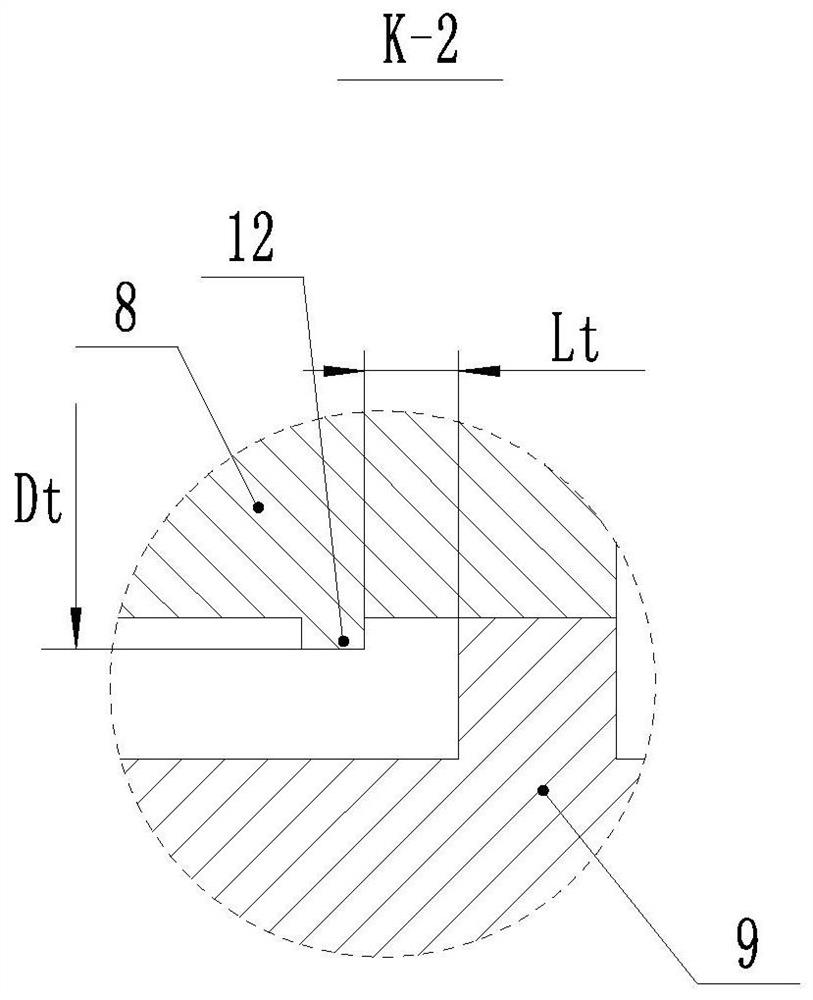

A relief valve suitable for compensating hydraulic power in back pressure condition

The utility model relates to an overflow valve suitable for compensating hydraulic power in working conditions with back pressure, which belongs to the technical field of aerospace servo systems. The valve body is provided with an inlet A, an outlet B, an overflow port C and an oil discharge port D, and a chamber e, an oil chamber f and a spring chamber g are formed between the valve body and the valve core, and the overflow port C and The oil chamber f is connected, the valve core and the valve body are provided with a valve port at the inlet end of the oil chamber f, and a flange structure is provided at the valve core near the valve port. The stepped design, hollow design and parallel double spring design adopted by the valve core of the present invention make the valve compact in structure and have a large thrust-to-weight ratio. By setting a damping hole on the spool, the oil is replenished in time during the retraction process of the spool, which effectively eliminates the "stuck" phenomenon of the spool. By reasonably matching the throttling area of the damping hole of the spool and the damping hole of the oil return port, the adverse effect of the back pressure of the overflow port on the balance of the spool is effectively eliminated.

Owner:HARBIN INST OF TECH

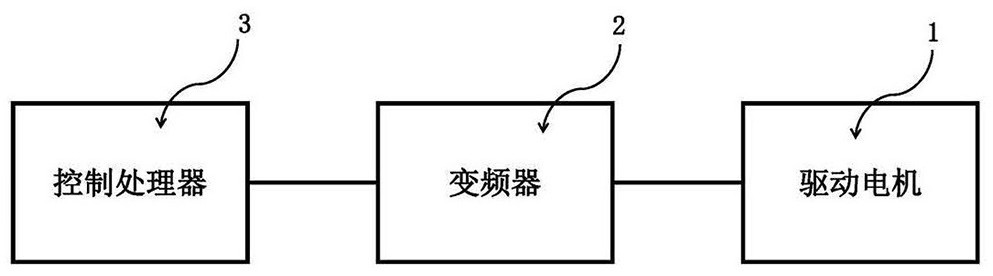

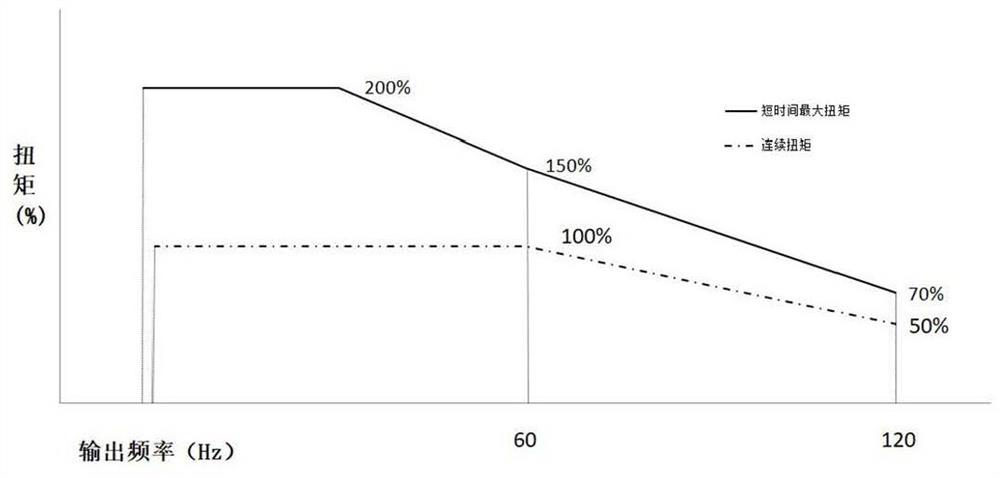

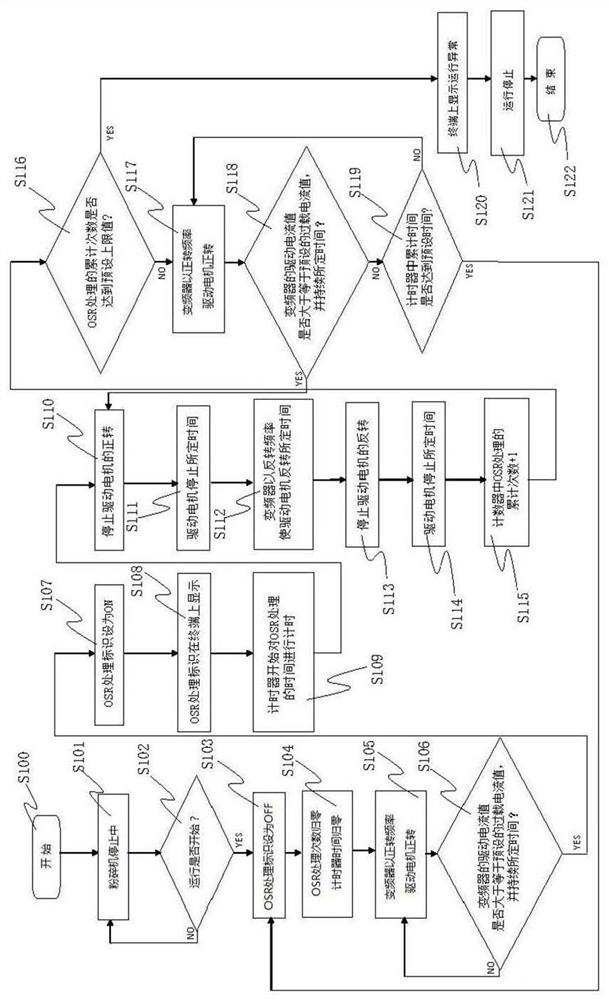

Pulverizer

PendingCN113097974AExtend your lifeReduce consumptionElectronic commutation motor controlElectric motor controlDrive motorPulverizer

The present invention provides a pulverizer for pulverizing an object with a pulverizing blade, the pulverizer comprising: a drive motor for driving the forward and reverse rotation of the pulverizing blade; an inverter for controlling the rotational speed and rotational direction of the drive motor by changing frequency; and a control processor which is used for controlling the frequency converter. The control processor repeats the following overload relieving processing: in the process of enabling the driving motor to rotate forwards at the forward rotation frequency through the frequency converter, the control processor detects that the driving current value of the frequency converter is greater than a preset overload current value and continues for a preset time, and then the overload relieving processing is performed, the frequency converter stops the driving motor, after the driving motor stops for a preset time, the frequency converter enables the driving motor to rotate reversely for a certain time at a reverse rotation frequency and then stops the driving motor, and after the driving motor stops for a preset time, the frequency converter enables the driving motor to rotate forwards at a forward rotation frequency. By adopting the pulverizer, the pulverizing efficiency can be prevented from being influenced by repeated occurrence of a phenomenon that the object to be pulverized is clamped, and the service life of the driving motor can be prolonged.

Owner:SHANGHAI MATSUI MACHINERY

A self-positioning injection plug

The invention discloses a self-positioning type pour plug. The self-positioning type pour plug comprises a pour plug plate, pour plug bodies and bolts. The pour plug plate is provided with a plurality of first holes, and the first ends of the bolts penetrate through the first holes and are connected with the pour plug bodies. The aperture of the first holes is 0.1-0.5 mm larger than the diameter of rod parts of the bolts. A movable clearance is reserved between each pour plug body and the pour plug plate. The pour plug bodies can be in clearance fit with material cups on molds. The self-positioning type pour plug can effectively prevent the phenomenon that the pour plug bodies get stuck, thereby being beneficial for improving production efficiency.

Owner:安徽宁国中鼎模具制造有限公司

Lens shift adaptive device and projection device

ActiveCN110095924BEasy to moveImprove yield rateProjectorsMountingsControl theoryMechanical engineering

The invention provides an adaptive lens displacement device, which comprises a sliding shaft fixing base, a sliding bracket, a first sliding shaft, a second sliding shaft and a driving mechanism. The opposite ends of the sliding shaft fixing base are respectively provided with a first groove and a second groove. Two grooves, so that when the sliding bracket slides in the X direction, with the help of the gap between the first groove and the first sliding shaft in the Z direction, and the gap between the second groove and the second sliding shaft in the Y direction, simultaneously The purpose of adjusting the displacement in the three directions of X, Y, and Z is to effectively absorb the processing deviation and assembly deviation between the components, so that the sliding bracket slides smoothly on the sliding shaft, and the adjustment effect is good. The present invention also provides a projection device including the lens displacement adaptive device.

Owner:APPOTRONICS CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com