Dynamic steering simulation device for dynamic directional rotary steering drilling tool

A technology of dynamic pointing and drilling tools, which is applied in the field of oil drilling engineering, can solve the problems of lack of experiments, inability to break through key technologies, and impossibility of experimental research, etc., and achieve the effect of uniform loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

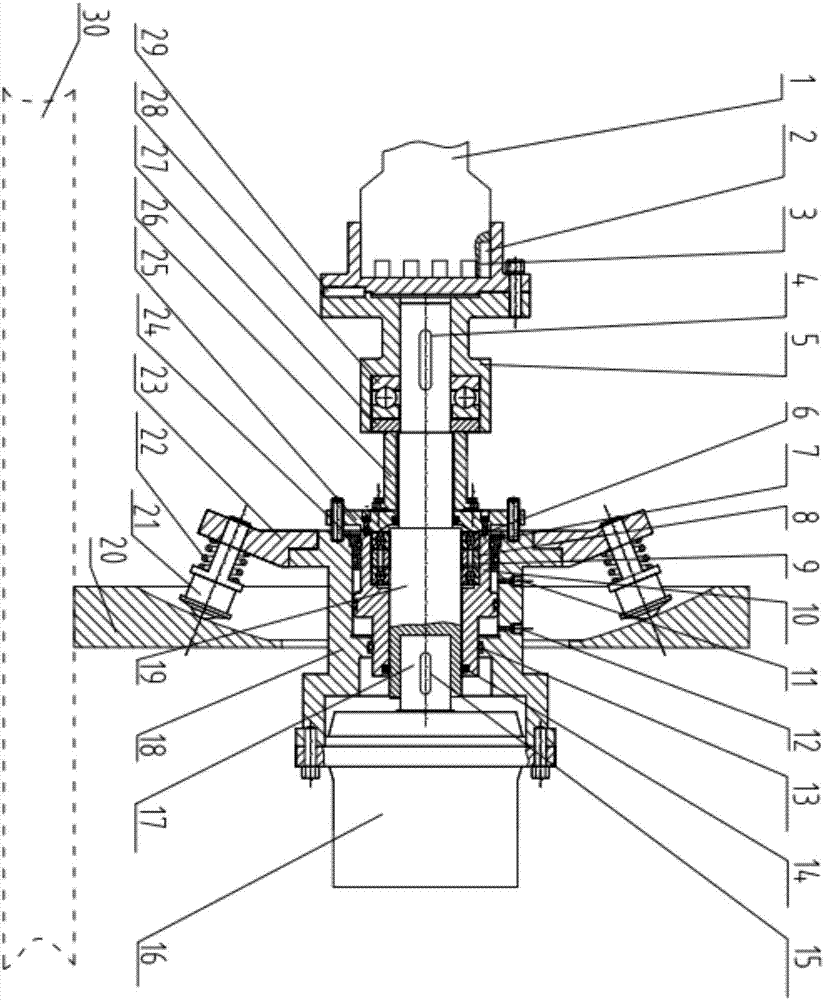

[0036]If it is necessary to load the drilling pressure to the tool, the oil pump will pressurize the oil chamber on the right side through oil hole two 12. The oil pressure pushes the cylinder hollow shaft 10 to transmit the axial force to the drill bit 1 through the transparent cover 25, the pressure sensor 26, the retaining ring one 27, the thrust ball bearing 28, the flange one 5, and the flange two 2. If unloading is required, oil hole two 12 releases pressure first, and then the oil pump pressurizes the left oil chamber through oil hole one 11 to achieve unloading effect.

Embodiment 2

[0038] If loading torque is needed, the hydraulic motor is delivered to the drill bit 1 by output shaft 17, flat key one 15, load shaft 19, flat key two 4, flange one 5, flange two 2, clip 3.

Embodiment 3

[0040] If the drill bit 1 needs to swing when loading, the drill bit 1 drives the parts except the baffle plate to swing in any direction. The baffle counteracts the axial reaction force generated by the axial force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com