Adjustment and optimization method and system for combustion of power plant boiler

A boiler combustion and optimization method technology, applied in the field of thermal power plants, can solve problems such as emissions, large nitrogen oxides, and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

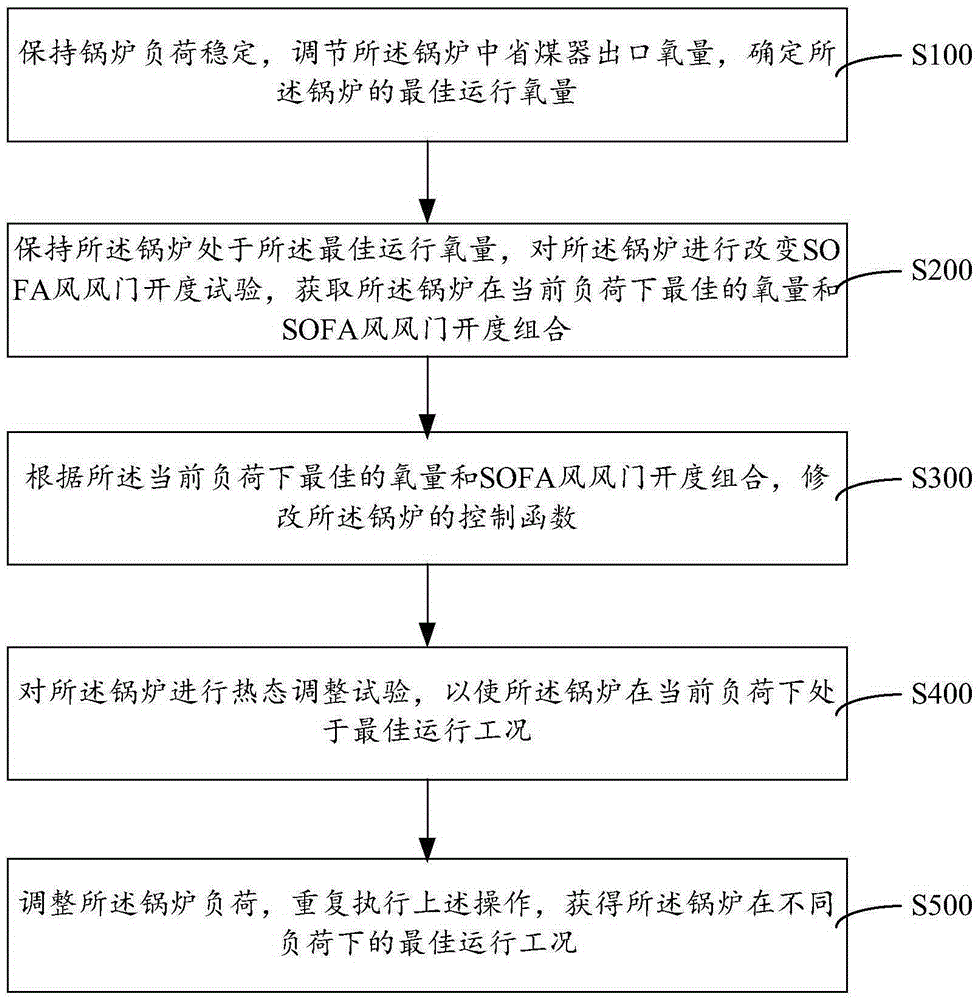

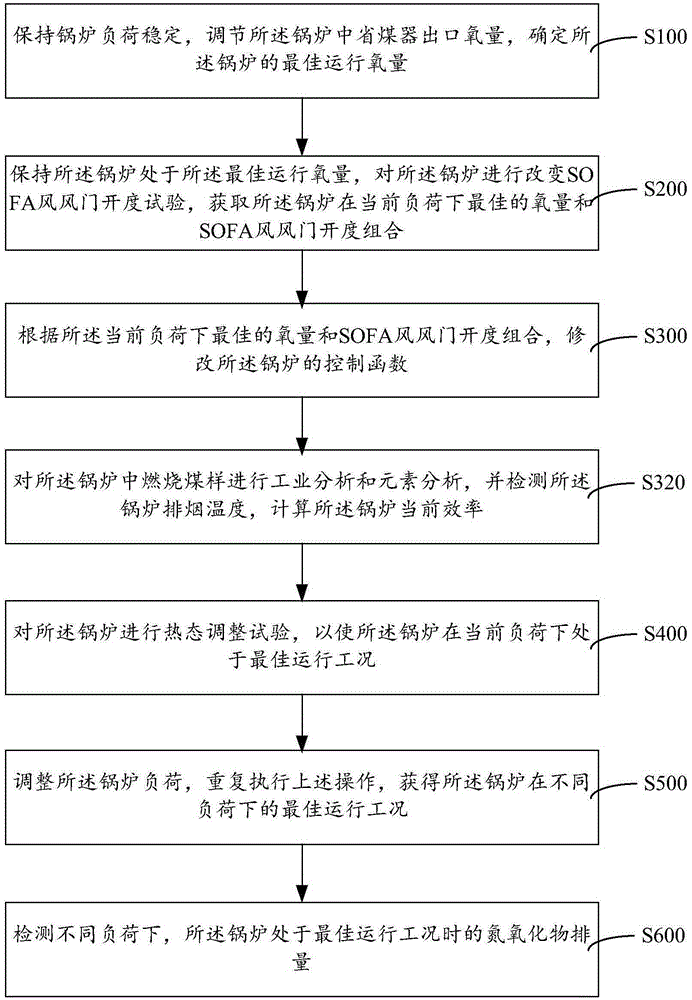

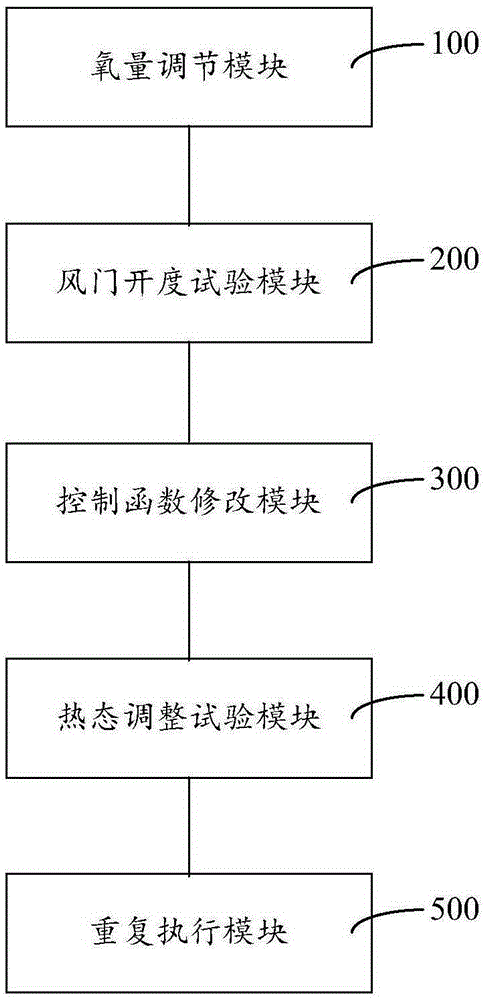

[0023] Such as figure 1 As shown, a thermal power plant boiler combustion adjustment optimization method, including steps:

[0024] S100: Keep the boiler load stable, adjust the oxygen quantity at the outlet of the economizer in the boiler, and determine the optimal operating oxygen quantity of the boiler.

[0025] The economizer refers to the heating surface in the tail flue of the boiler that heats the boiler feed water into saturated water under the drum pressure. Since the operating environment and operating conditions of boilers under different load conditions will be quite different, in order to achieve accurate adjustment and optimization of boiler combustion in thermal power plants, it is necessary to conduct separate studies for different loads. Specifically, firstly, adjust the oxygen quantity at the outlet of the economizer, take the oxygen quantity at the outlet of the economizer as the control parameter, and realize the change of the total air volume by changing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com