Self-positioning type pour plug

A self-positioning and bolting technology, applied in the field of rubber vulcanization, can solve the problems of inconsistent expansion and contraction speed, uneven heating of the mold, and jamming of the injection plug. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

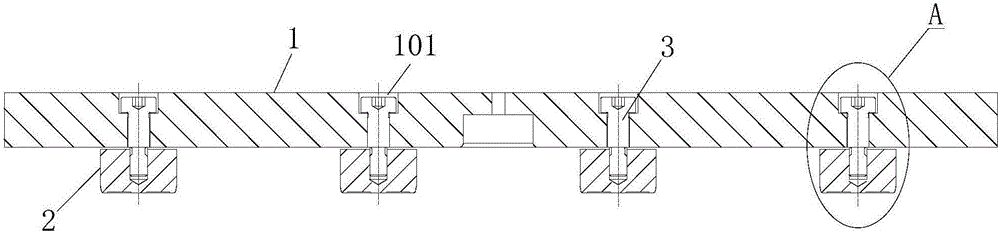

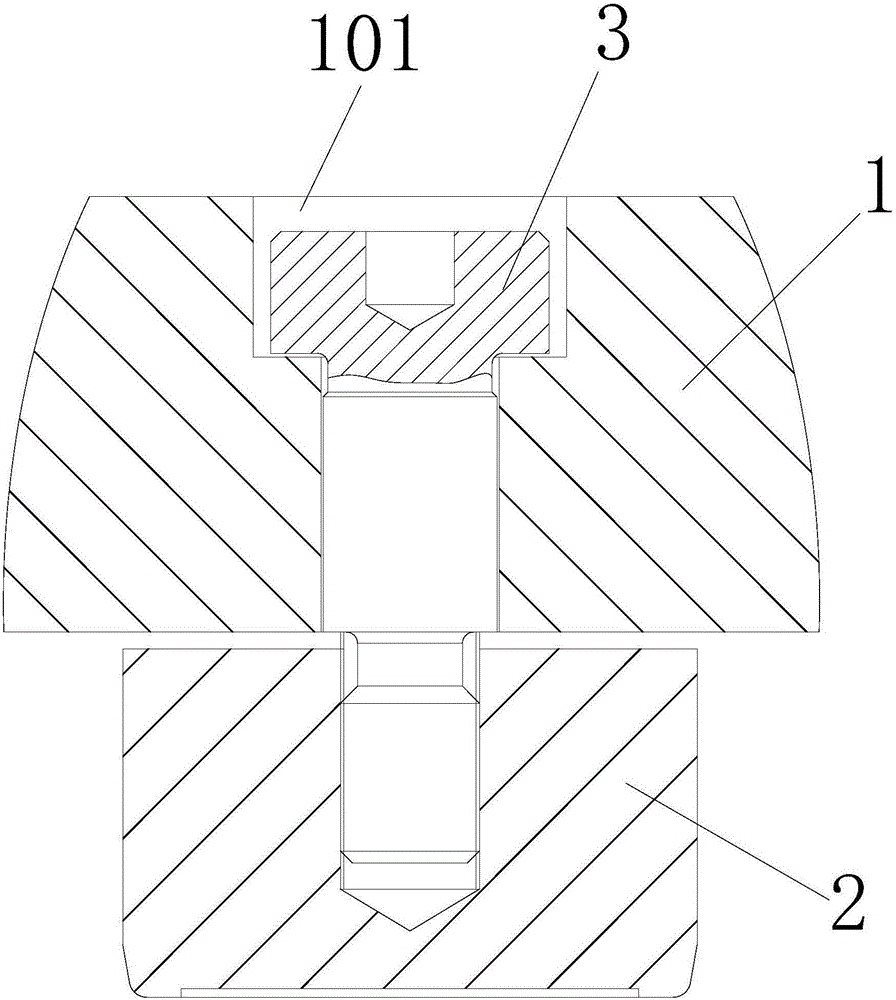

[0020] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Partial enlarged view of A in , including plug plate 1, plug 2 and bolt 3.

[0021] The plug plate 1 is provided with a plurality of first holes 101, and in practice, the first holes 101 are stepped holes. The first end of the bolt 3 passes through the first hole 101 and is connected with the injection plug 2 . During specific implementation, the bolts are shoulder bolts. Since the middle part of the shoulder bolt has no thread, the contact surface with the inner wall of the first hole 101 is relatively smooth, so that the resistance of the injection plug 2 during the automatic adjustment process is relatively small....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com