Inner-outer-pressure balanced waterproof car electric horn

A technology that balances waterproof and internal and external pressures. It is applied in the direction of sounding equipment and instruments. It can solve the problems of speaker circuit board burning, affecting the waterproof performance of the speaker, and short-circuit burning of the speaker circuit board. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

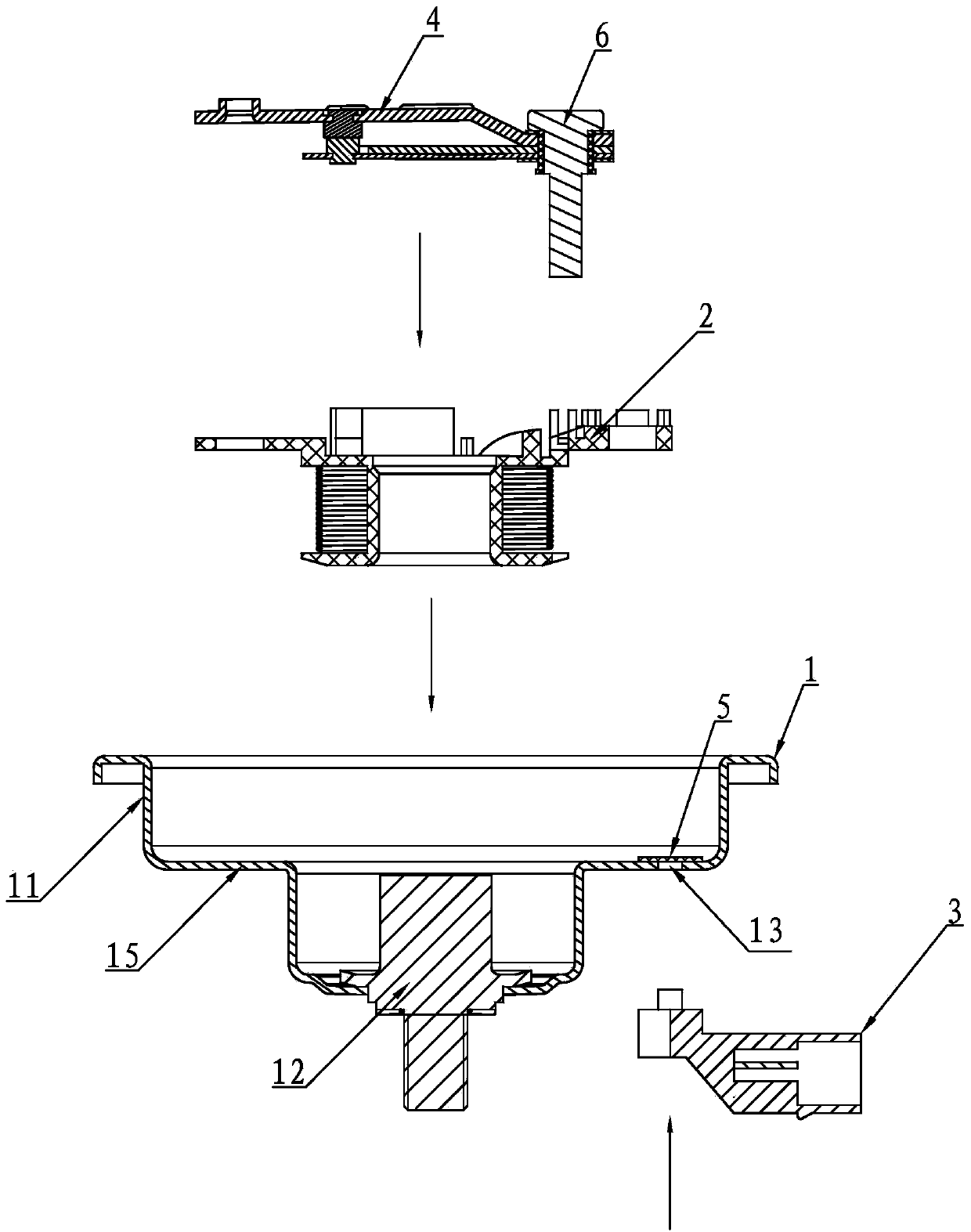

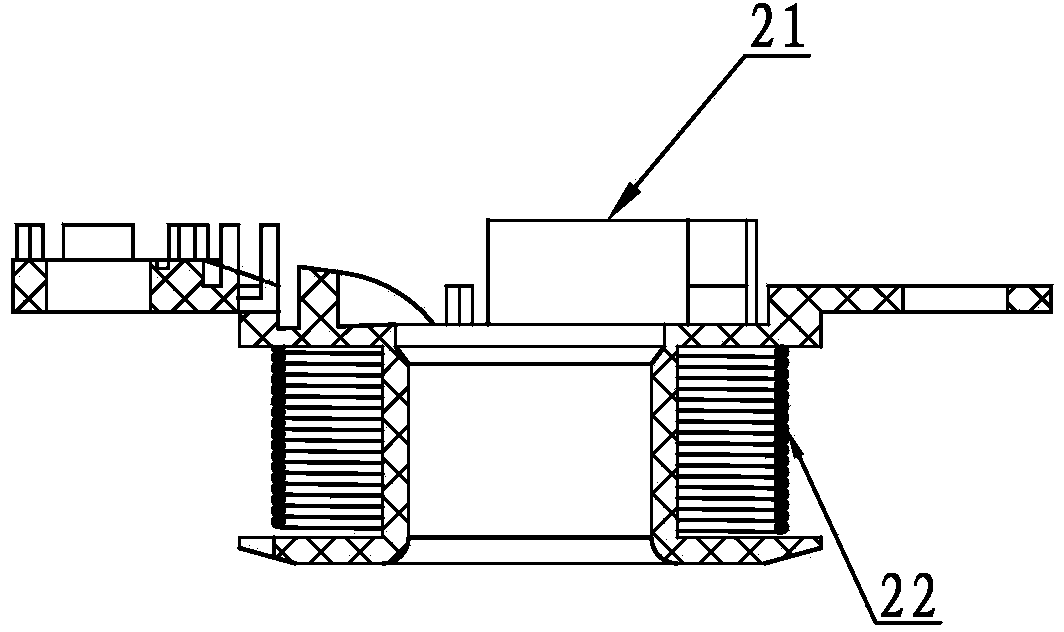

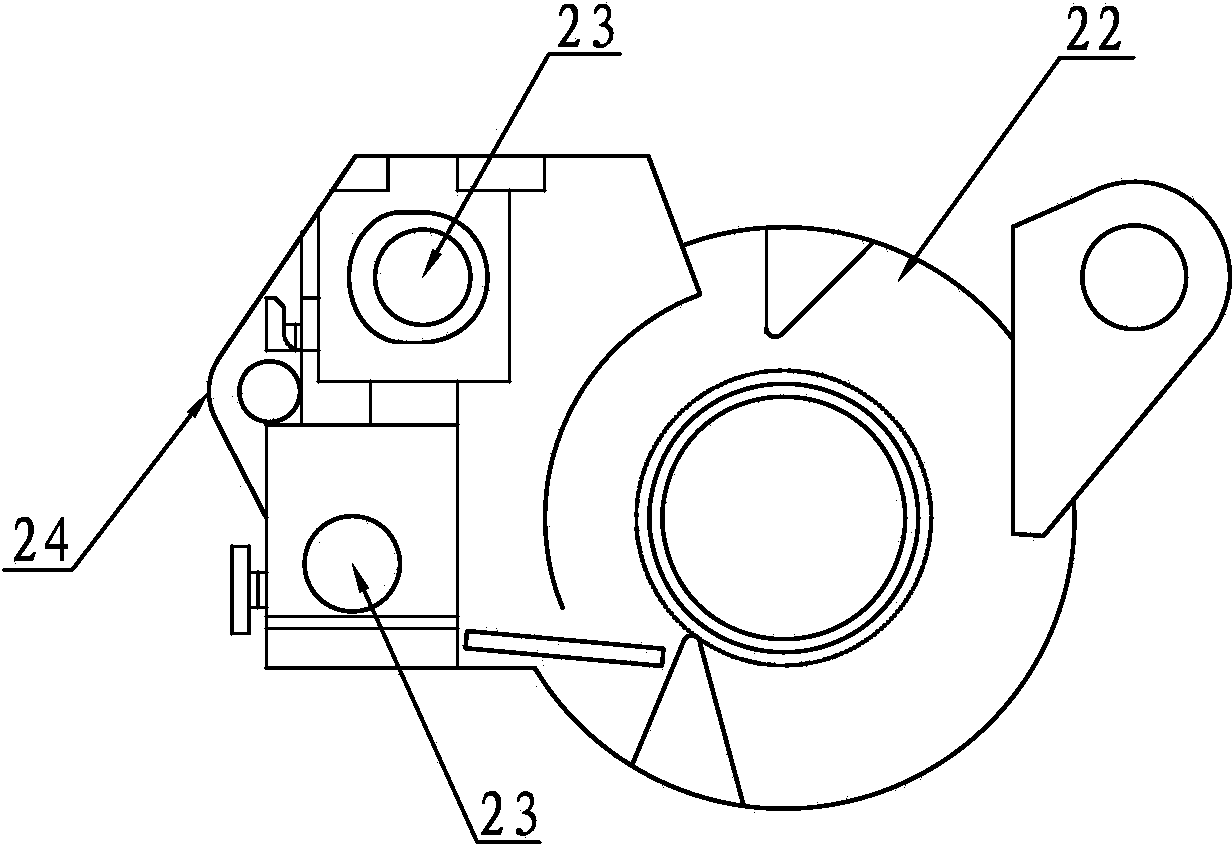

[0019] A kind of internal and external pressure balance waterproof type car electric horn, such as Figure 1~6 Shown: including horn back cover assembly 1, coil assembly 2, plug seat assembly 3, contact piece assembly 4, waterproof breathable membrane 5 and rivet 6, said horn back cover assembly 1 includes back cover shell 11, iron core 12, Pressure balance hole 13, socket connection hole 14, the pressure balance hole 13 and socket connection hole 14 are set on the bottom plate 15 of the rear cover shell 11, the coil assembly 2 is set on the iron core 12 in the middle of the speaker rear cover assembly 1, and the plug The seat assembly 3 is installed on the outer surface of the bottom plate 15 of the rear cover shell 11, the contact piece assembly 4 is located above the coil assembly 2, and is fixed on the inner surface of the rear cover shell 11, and the inner surface of the pressure balance hole 13 is covered with Waterproof and breathable membrane 5, the coil assembly 2 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com