Powder scraper

A technology of powder dispenser and cover plate, applied in the directions of drug delivery, capsule delivery, pharmaceutical formulation, etc., can solve the problems of machine running, stuck, blocked, etc., to eliminate sticking and blockage, improve startup rate, and meet production desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

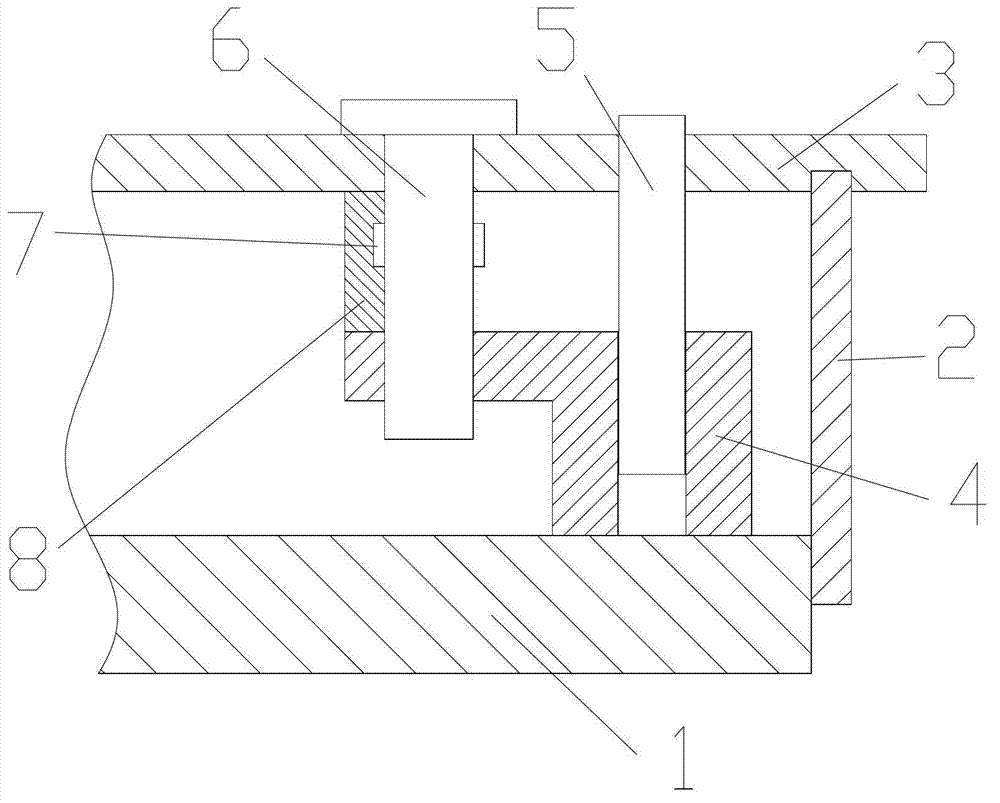

[0012] The present invention is described below in conjunction with accompanying drawing.

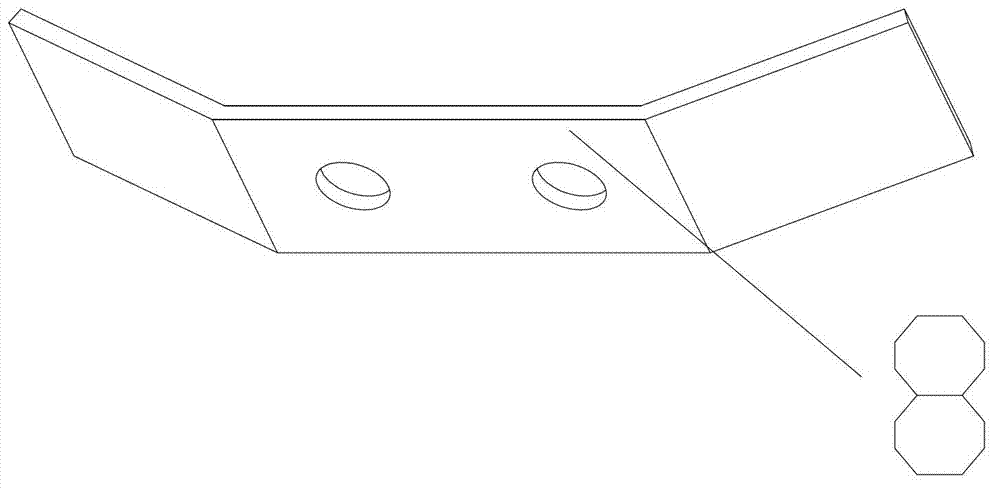

[0013] as attached figure 1 , 2 The powder scraper of the present invention includes a dosage plate 1, a material holding ring 2 and a cover plate 3, and the dosage plate 1 is fixedly arranged on the inner side wall of the bottom of the material holding ring 2 and covered with the cover plate 3; The dosage disc 1 is provided with a spacer 4, and a certain gap is left between the spacer 4 and the cover plate 3; The upper end surface of the upper end is set on the upper side of the cover plate 3; the other side of the spacer 4 is provided with a filling rod 6, and the part of the filling bar 6 between the spacer 4 and the cover plate 3 is connected with a stopper 7; the material blocking block 7 is fixedly connected with a material blocking plate 8 through screws (not shown in the figure), and the upper end surface of the material blocking plate 8 is tangent to the lower surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com