Combination sealing and fixing type ball valve

A combined sealing and fixed technology, which is applied to valve details, valve devices, and valve housing structures, can solve the problems of soft-sealed fixed ball valves such as easy wear, unsatisfactory sealing performance, and easy damage to sealing devices, and achieve long service life. , Eliminate the effect that the switch is not in place and the valve is stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

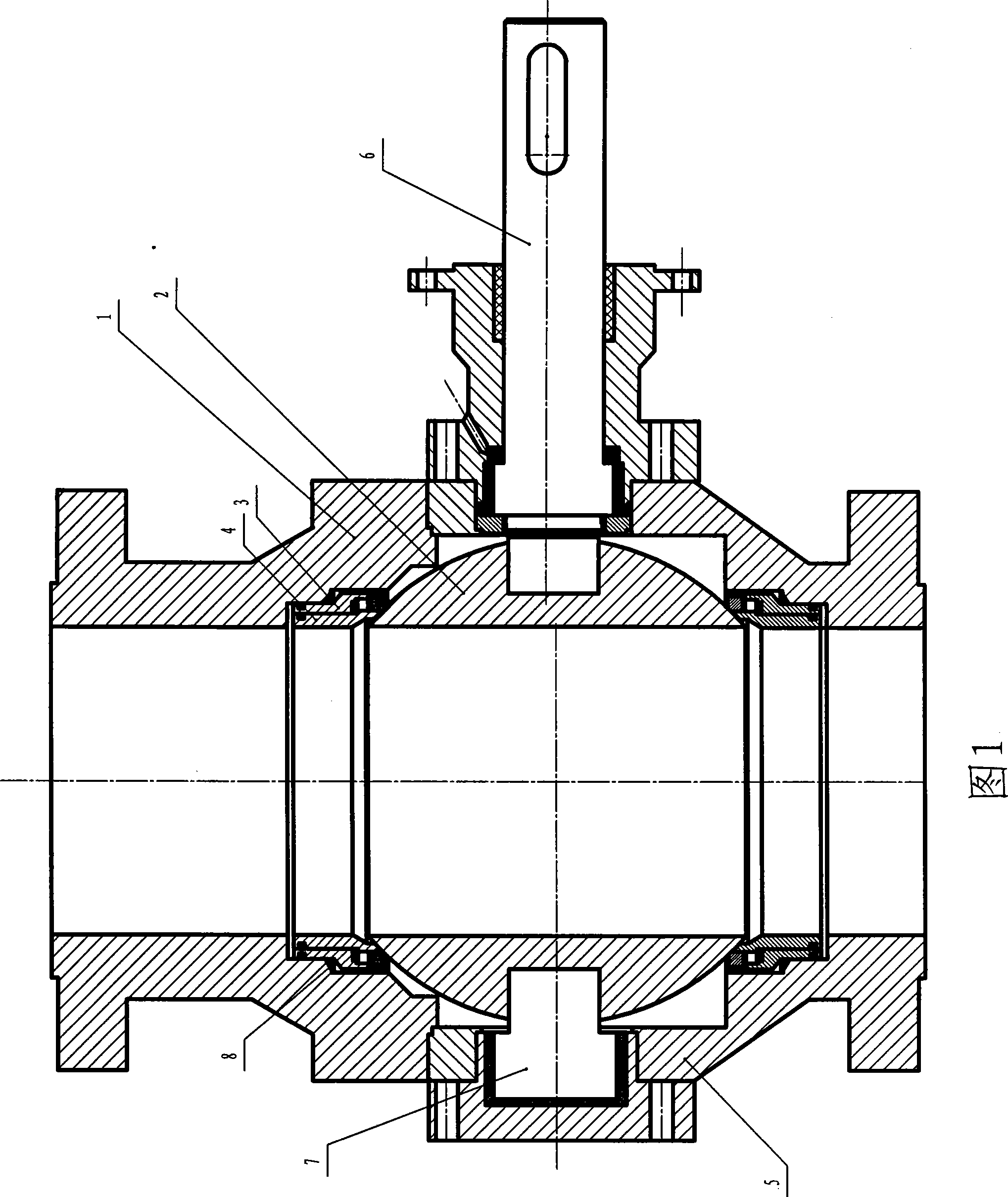

[0012] As can be seen from Figures 1 and 2, the present invention consists of a valve body, a valve core, an opening and closing shaft and a sealing valve seat;

[0013] The valve body is set as an upper valve body 1 and a lower valve body 5, the cavity between the upper and lower valve bodies is provided with a spherical valve core 2 and a sealing valve seat, and the opening and closing shafts are arranged on both sides of the valve body;

[0014] The valve core 2 is a single-channel fixed structure, and the opening and closing shaft passes through the valve body and is arranged on both sides of the valve core 2;

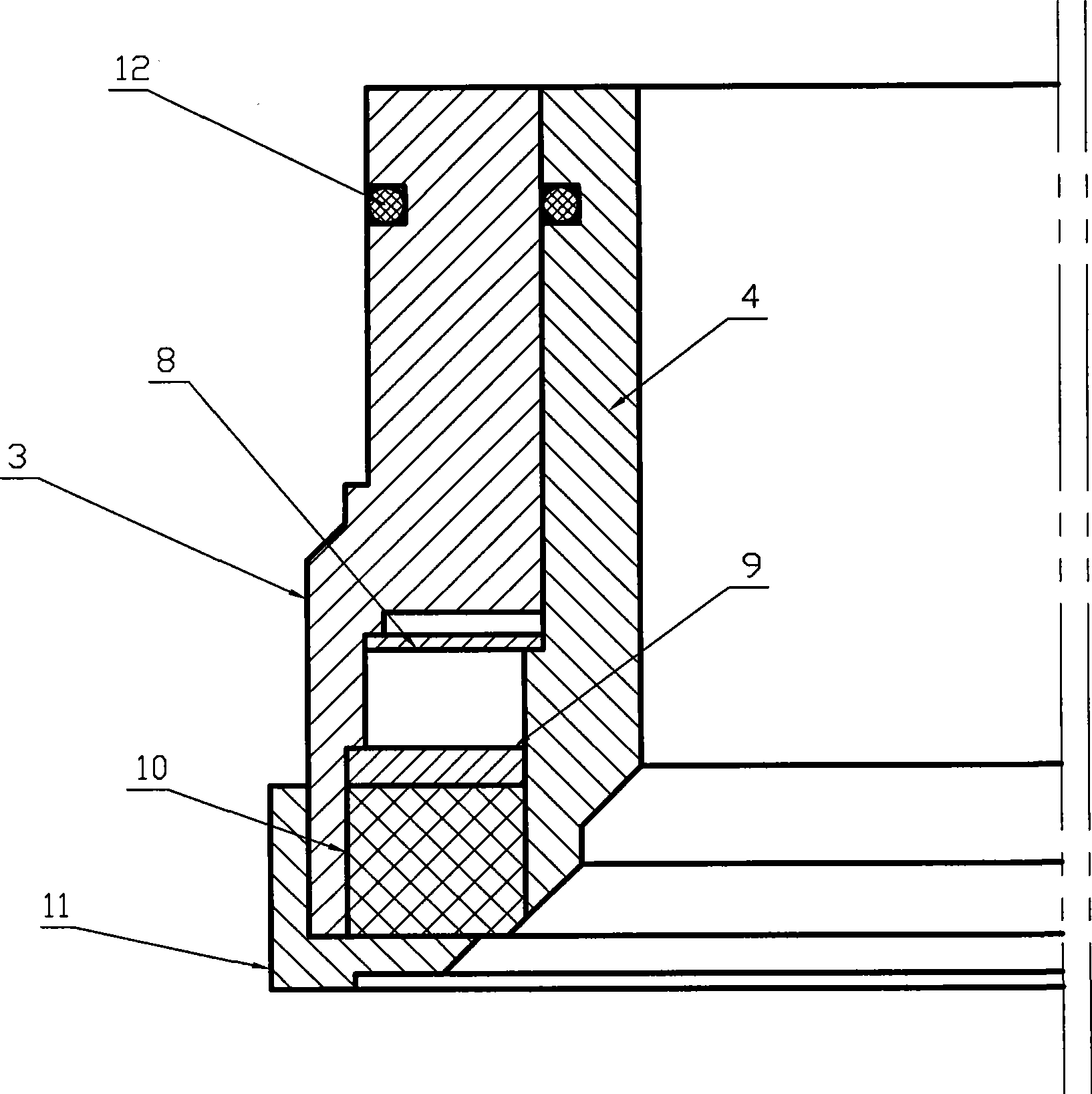

[0015] The sealing valve seat is composed of a hard seal and a soft seal, wherein the hard seal is the first seal, which is used to block and remove granular media and protect the second soft seal.

[0016] The sealing valve seat of the present invention includes a hard sealing valve seat body 4, a soft sealing valve seat body 3, a flat spring 8, a support ring 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com