Unloading type spiral rotor

A screw and rotor technology, applied in the field of core components, can solve problems such as increased running resistance, affecting flexibility, flow meter sticking, etc., and achieves the effects of reducing resistance, enhancing flexibility, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

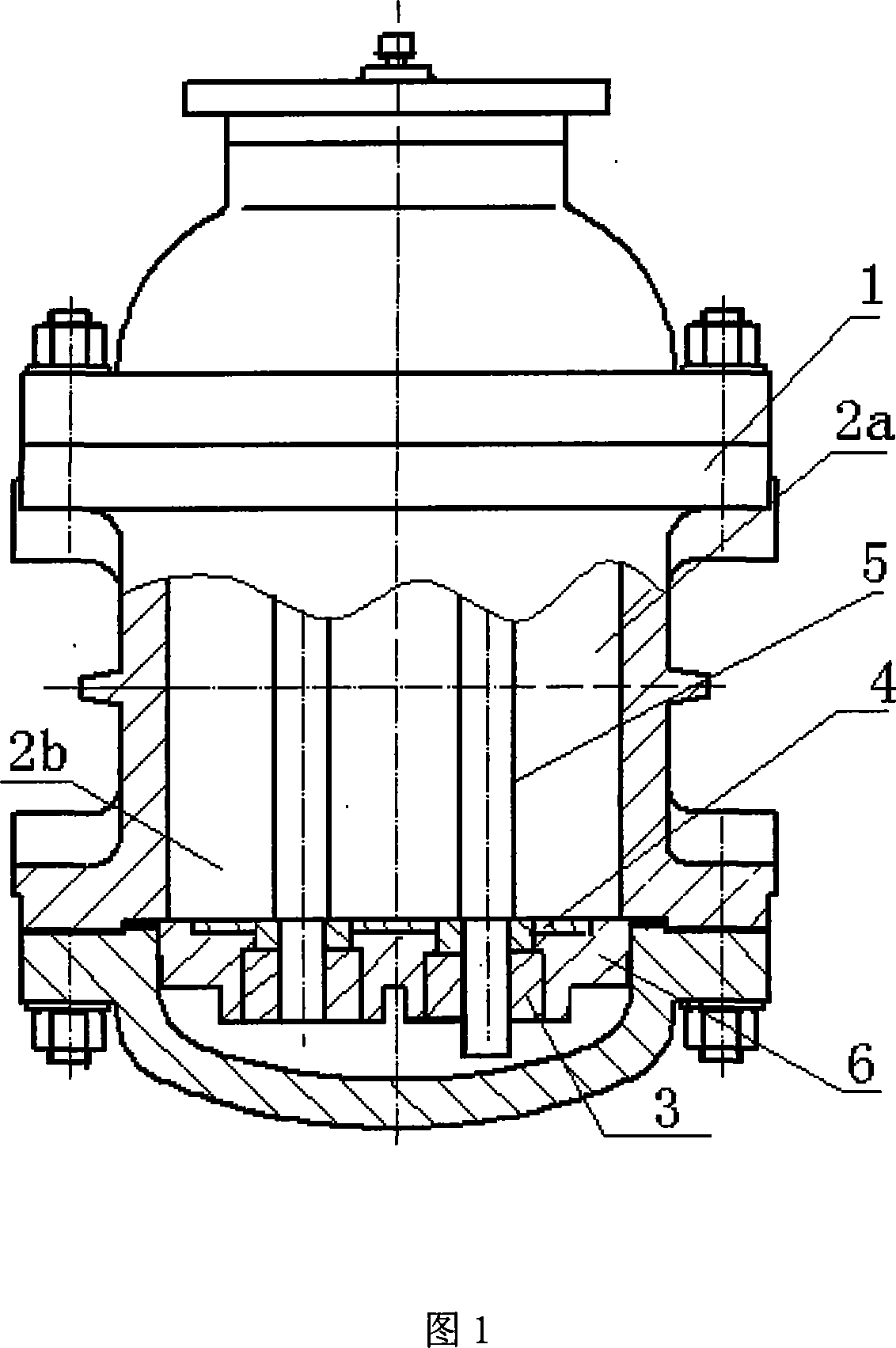

[0021] Referring to Fig. 1 and Fig. 2, this embodiment is aimed at the structural form of the helical rotor flowmeter, and a housing 1 is provided, and there are two upper and lower metering box cover plates 6 and a pair of intermeshing helical rotors in the housing 1, that is, the left Helical rotor 2a and right helical rotor 2b.

[0022] As shown in Figure 1, in this embodiment, the rotor shaft 5 of the left helical rotor 2a is supported in the shaft holes on the upper and lower metering box cover plates 6 in the casing 1 through the sliding bearing 3, and a plane bearing is arranged on the end surface of the rotor 4. Both the sliding bearing 3 and the planar bearing 4 are made of flexible graphite with self-lubricating properties. This assembly structure can more effectively reduce wear between parts and improve the stability of moving parts.

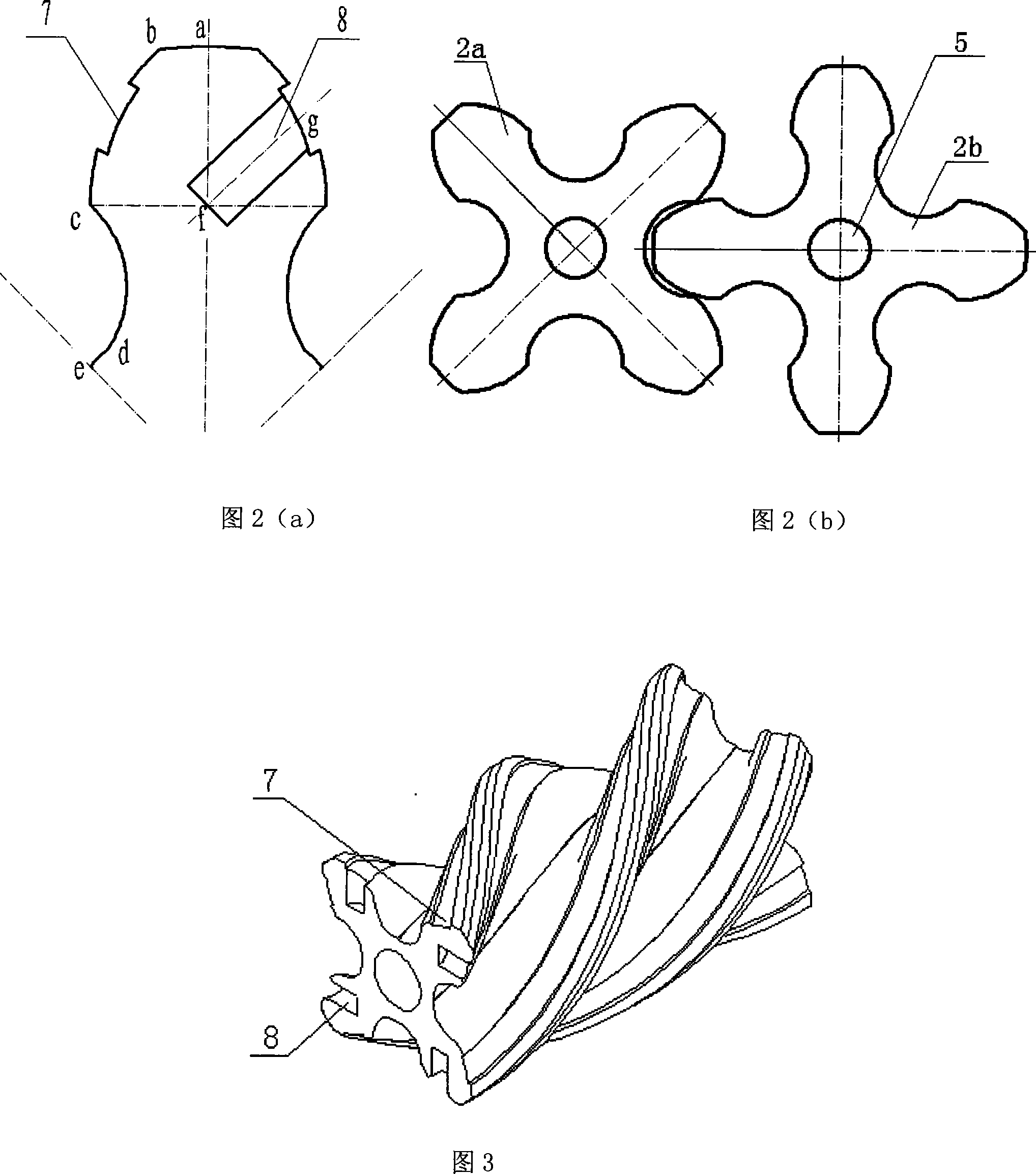

[0023] In this embodiment, the tooth profile curve of the left helical rotor 2a is processed as shown in Fig. 2(a) and Fig. 3, spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com