Variable nozzle ring component for effectively preventing blade from clamping stagnation

A nozzle ring and blade technology, applied in engine components, stators, machines/engines, etc., can solve problems such as failure to automatically eliminate stagnation, reduce turbine power efficiency, increase air leakage, etc., to eliminate high temperature stagnation and eliminate stagnation. Lag problem, the effect of improving low-speed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will now be described in more detail with reference to the accompanying drawings, in which some, but not all embodiments of the invention are shown. Indeed, the invention may be embodied in many different forms and should not be construed as limited to only the embodiments described below; rather, these embodiments are provided so that this disclosure will satisfy applicable legal requirements.

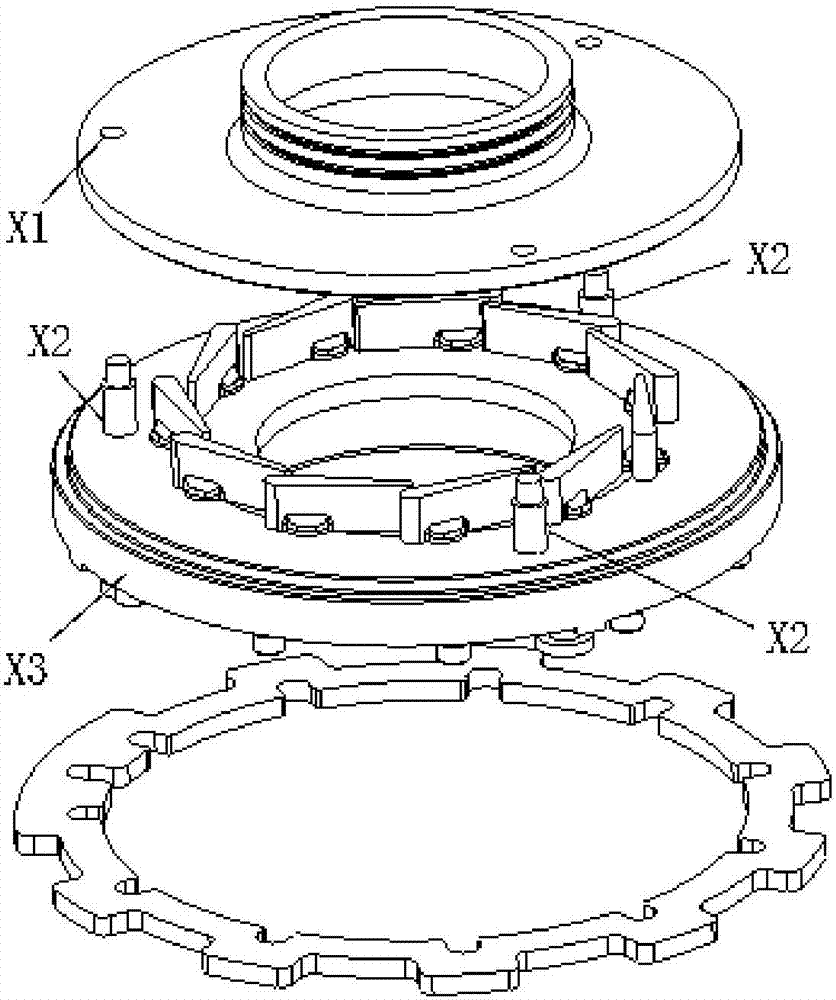

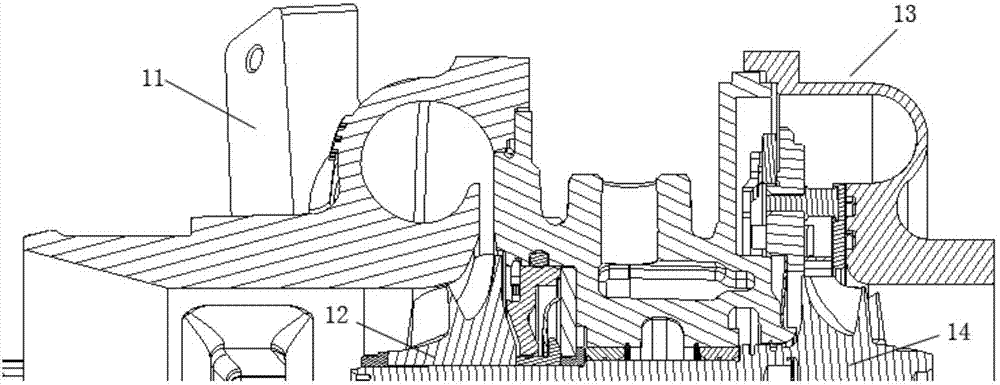

[0032] Such as image 3 As shown, the scroll end of the turbocharger with variable nozzle ring assembly includes a volute 13 and a turbine 14, the turbine 14 is arranged in the volute 13, the annular flow path of the volute 13 receives exhaust gas from the engine, and the ring can be The variable nozzle ring assembly is arranged between the annular flow channel of the volute 13 of the turbocharger and the turbine 14, guides the exhaust gas in the annular flow channel of the volute 13 to blow to the turbine 14; and can adjust the angle of the airflow blowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com