Antiseize fuel gas control valve for waste mine gas use unit

A control valve and anti-jamming technology, which is applied to sliding valves, valve details, valve devices, etc., can solve problems such as increasing equipment operating costs, hidden dangers of equipment safety, burning of control modules or motors, and failure of electric control systems. The effect of prolonging the use of orders, facilitating maintenance and reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

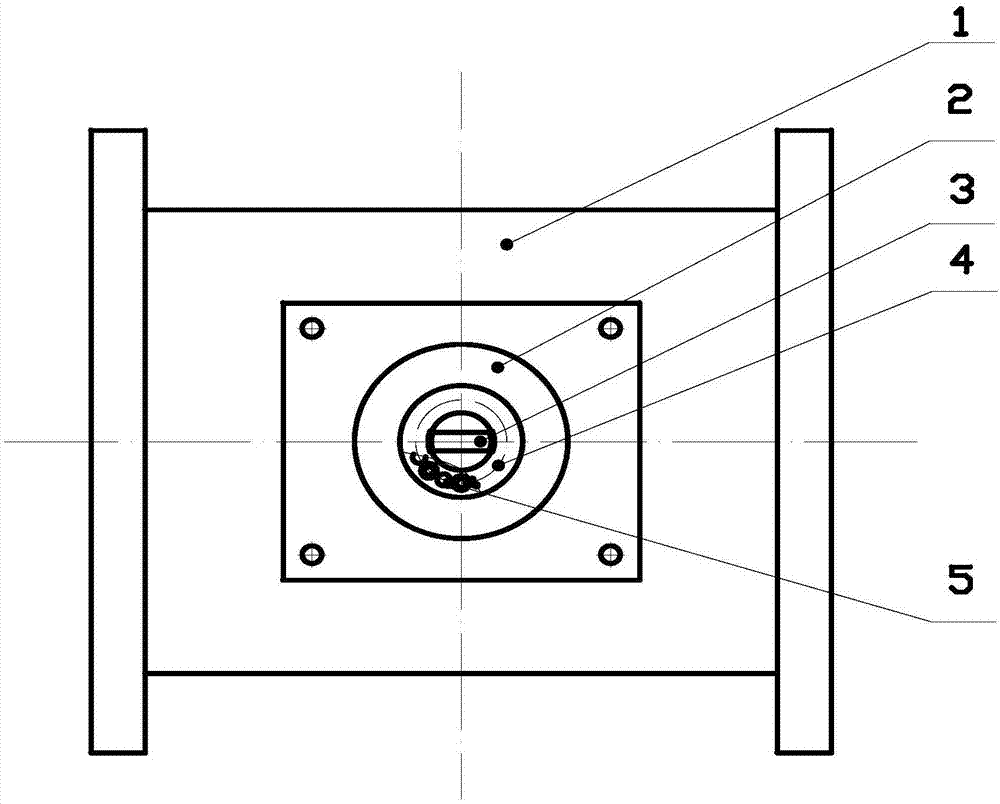

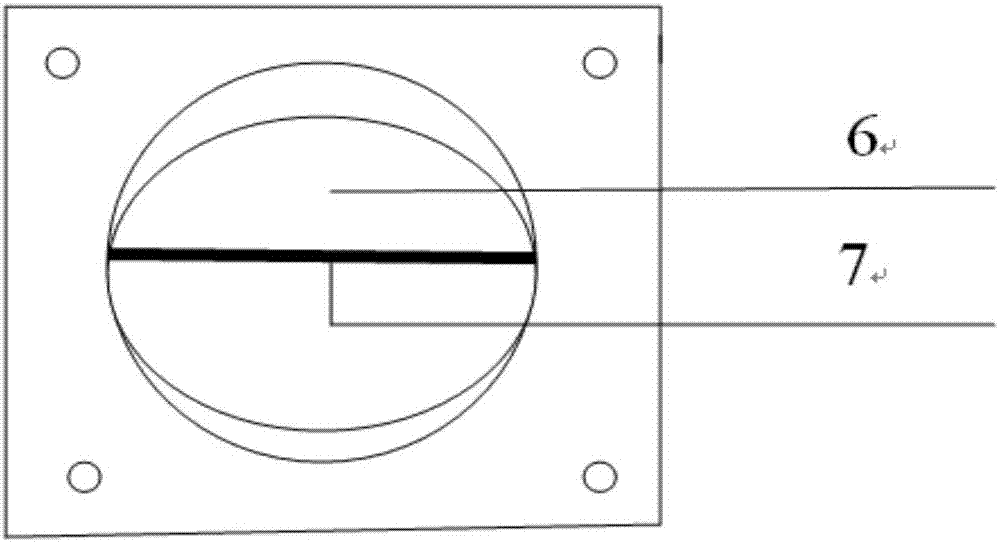

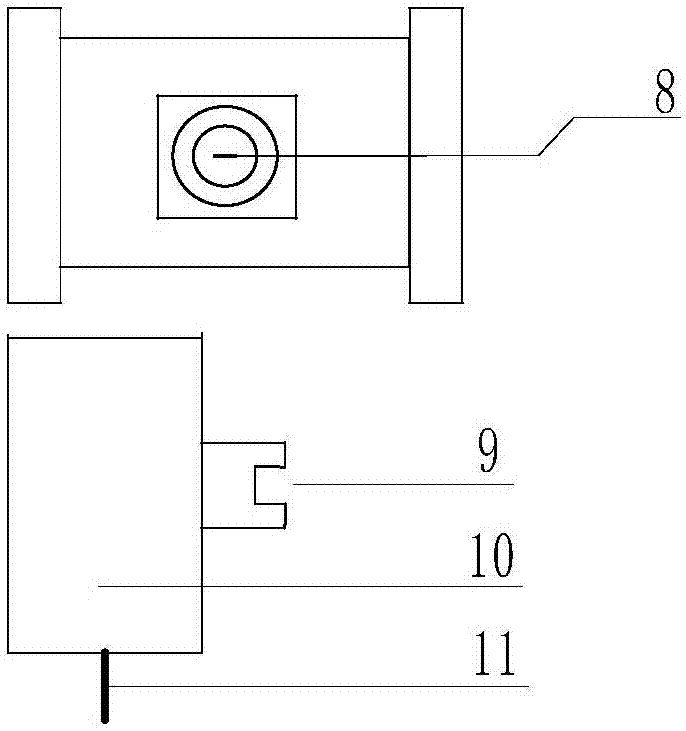

[0011] Such as figure 1 , figure 2 , image 3 As shown, an anti-jamming gas control valve of an abandoned mine gas utilization unit. The control valve includes a gas control valve body 1, a bearing seat hole 2, a valve stem 3, a bearing cover 4, and a bearing 5. The valve body 1 is provided with a bearing seat hole 4, and the bearing 5 is installed in the bearing seat hole 4. The valve stem 3 is nested in the bearing hole and located on both sides of the valve body. Its function is mainly to fix the position of the gas valve, 6 and connect the outer contact of the valve stem with the slot of the electric contact of the 24V DC motor. Through the control system module Realize the valve plate 0-90 0 opening and closing. The main function of the valve body is the bridge connecting the gas secondary air intake valve and the gas unit. The installation of rolling bearings or sliding bearings in the valve body is to prevent the valve stem and valve plate of the gas control valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com