Orthogonal Magnetic Path Directional Magnetic Suspension Bearing Based on Symmetrical Self-lubricating Flexible Auxiliary Bearing Structure

A magnetic suspension bearing and auxiliary bearing technology, which is applied in the directions of magnetic bearings, bearings, shafts and bearings, can solve the problems of stuck auxiliary bearings, reduce the rigid mode of the rotor, asymmetry between the magnetic gap and the auxiliary gap, and improve the rigidity mode. state, avoid high heat phenomenon, reduce the effect of rotor length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

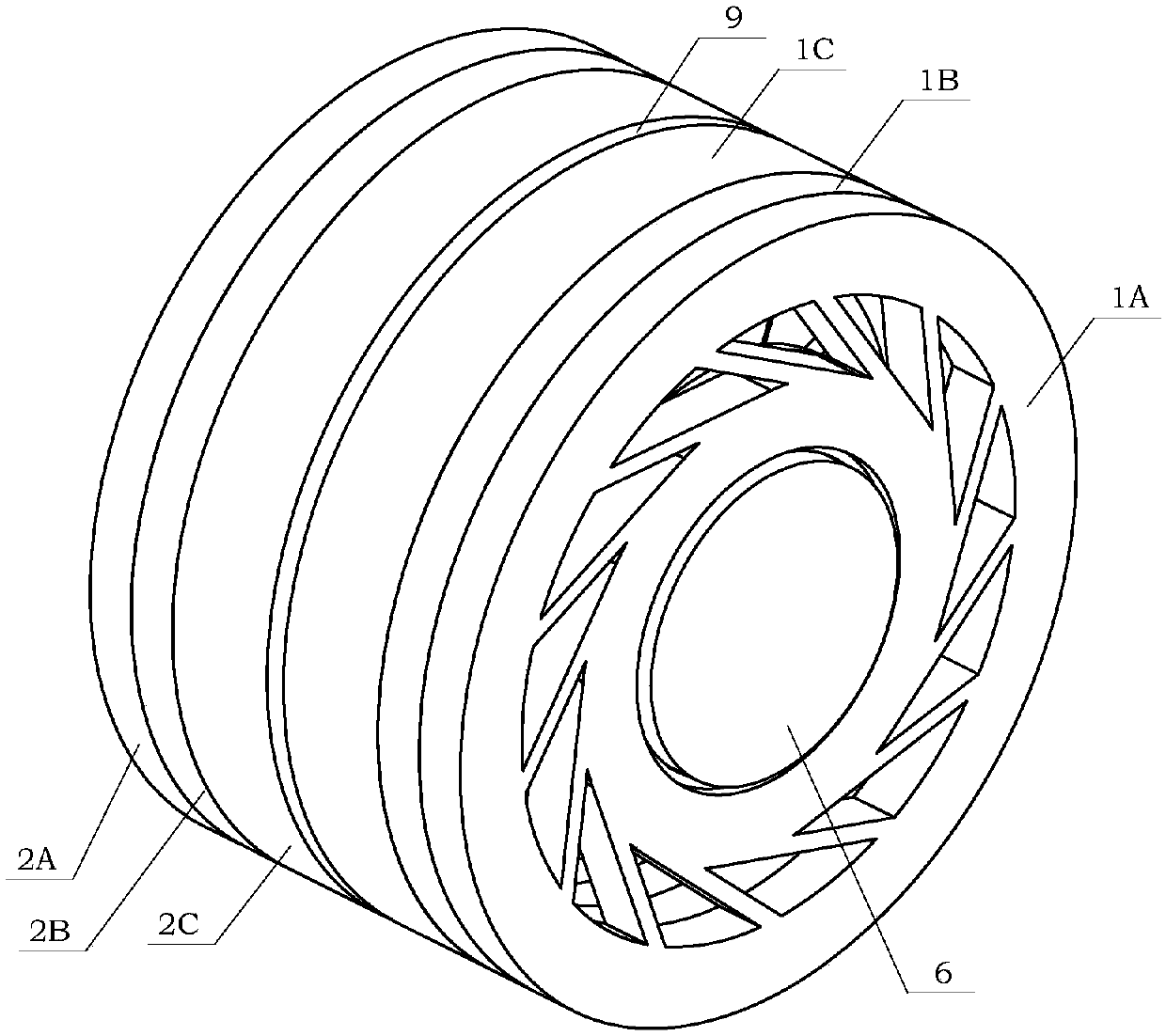

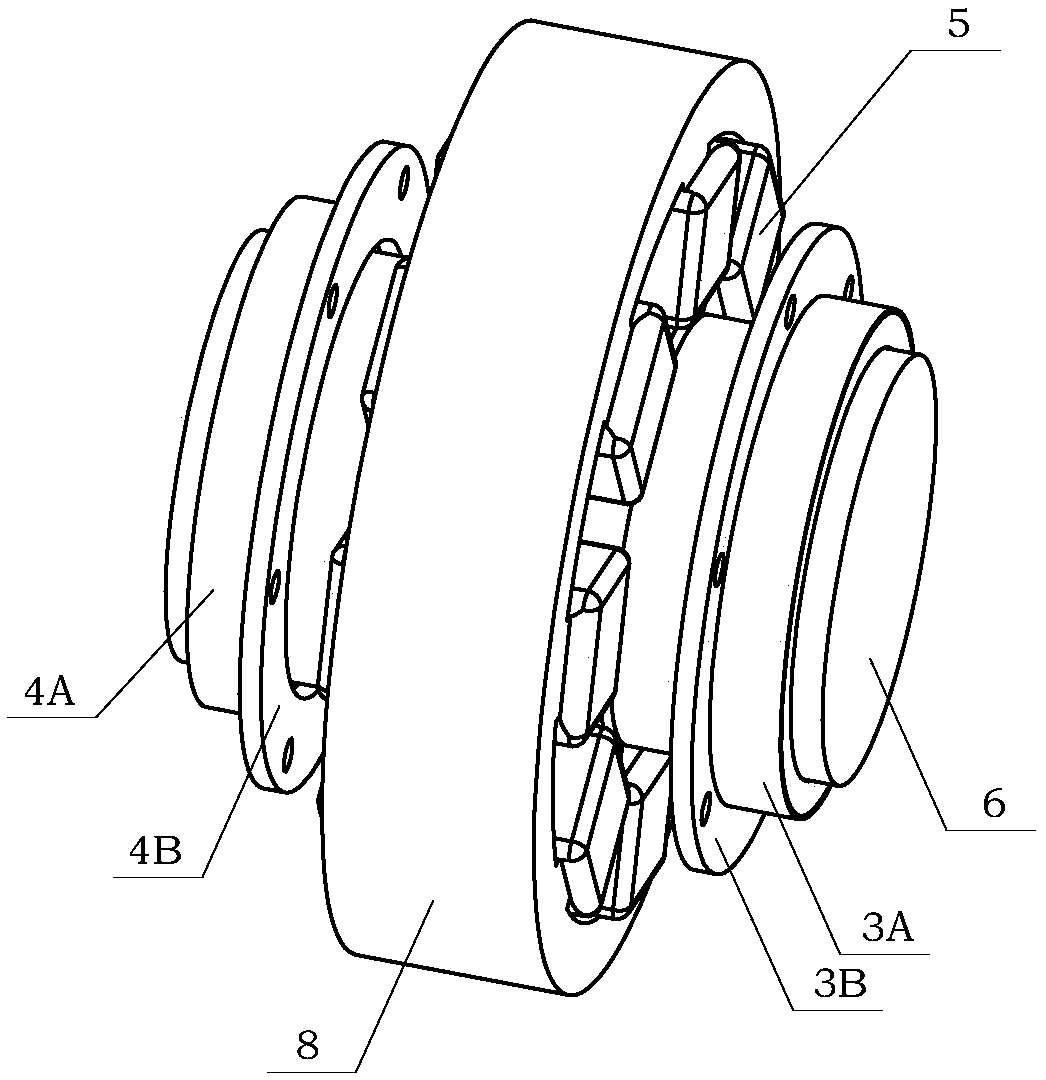

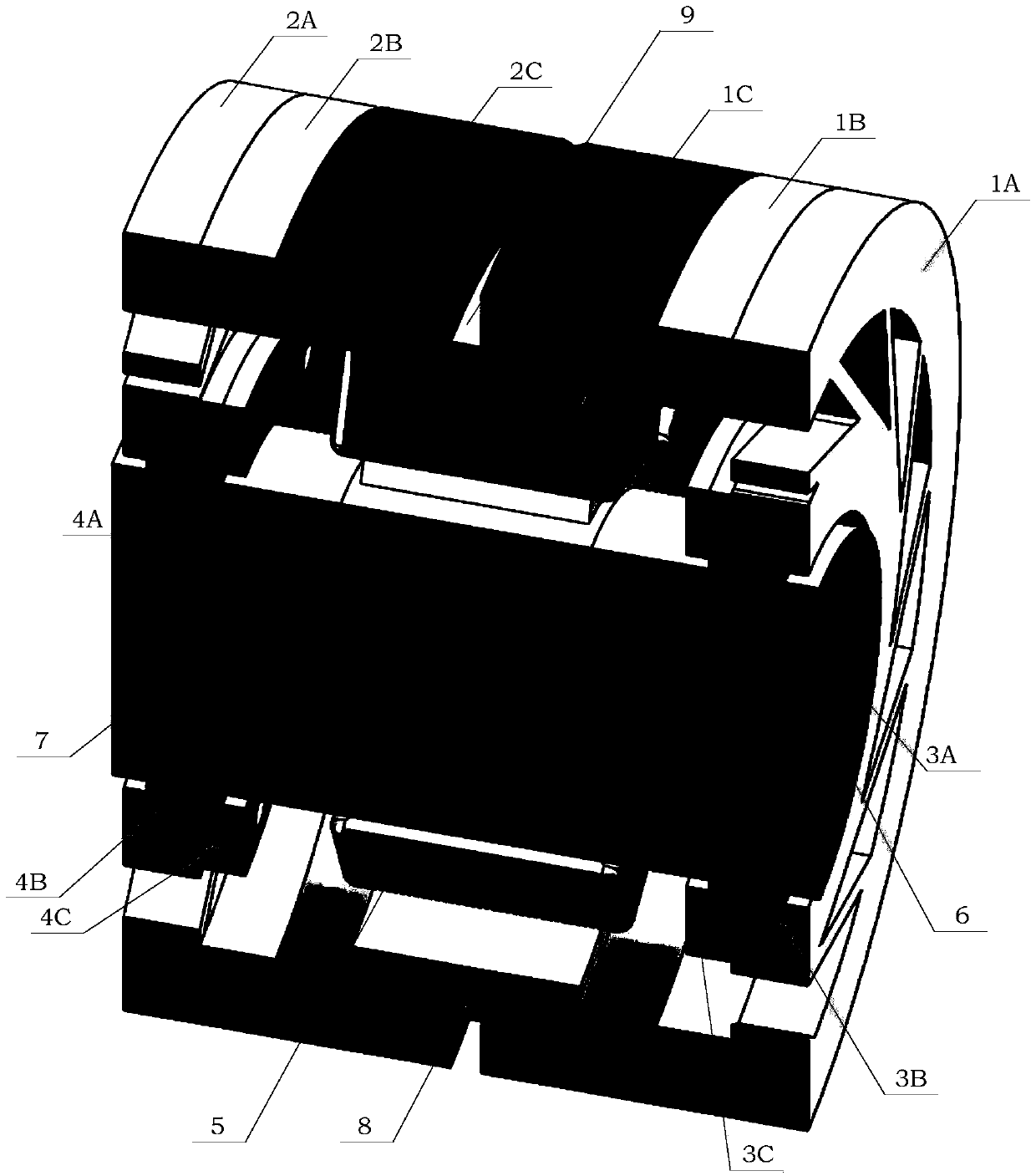

[0124] see Figure 7 As shown, the orthogonal magnetic path based on the symmetrical self-lubricating flexible auxiliary bearing structure designed by the present invention is applied to the high-speed magnetic levitation motor for performance description.

[0125] Apply the orthogonal magnetic path direction magnetic suspension bearing based on the symmetrical self-lubricating flexible auxiliary bearing structure designed by the present invention to the high-speed magnetic suspension motor, that is, replace the rotor shaft 6 with the output shaft of the motor, through the rotor core 7 and the magnetic bearing stator core The axial position corresponding relationship of 8, the assembled orthogonal magnetic path of the present invention is installed on the motor output shaft to the magnetic suspension bearing, and a radial bearing stop ring 4C on the left end is installed between the magnetic bearing stator core 8 The displacement sensor 20 is equipped with the stator 30 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com