A 100t electric wheel sprinkler water tank for mining

A water sprinkler and electric wheel technology, which is applied in the direction of spraying vehicles, mining equipment, safety devices, etc., can solve the problems of large size and cannot meet the requirements of mine sprinkling and dust reduction, so as to ensure the welding quality, realize lightweight optimization design, and stability reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

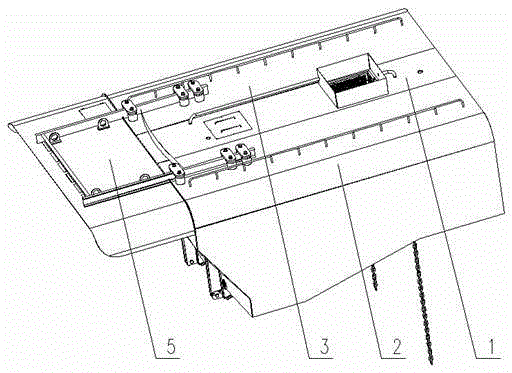

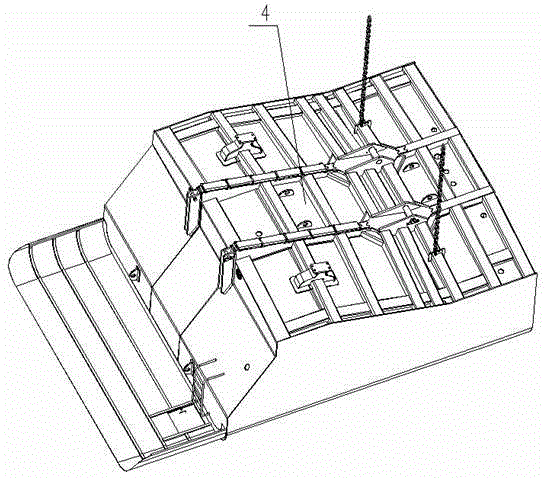

[0045] refer to figure 1 , figure 2 , this embodiment includes a central water tank assembly 1, a mid-sole assembly 4, a left water tank assembly 2 and a right water tank assembly 3;

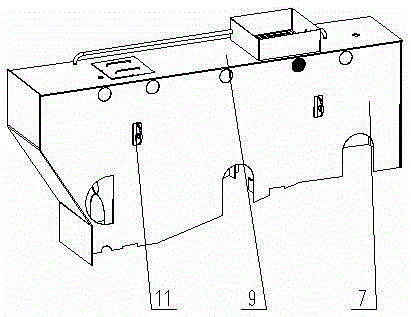

[0046] refer to image 3 , Figure 4, the middle water tank assembly 1 is welded by cover plate I9, front plate I12, longitudinal reinforcement partition I7 (two pieces), transverse reinforcement partition I10 (four pieces), tail plate 6, filter device 8 and lifting lug I11 The longitudinal reinforced partition I7 and the transverse reinforced partition I10 are respectively provided with misplaced half-waist holes and round holes, and the half-waist holes are all opened at the lower part of the reinforced partition, the function is to prevent surge impact and the inside of the water tank. passing channel function;

[0047] refer to Figure 5 , Figure 6 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com