Pulverizer

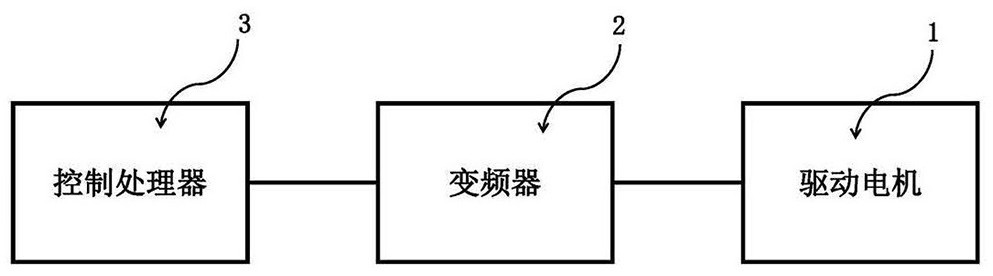

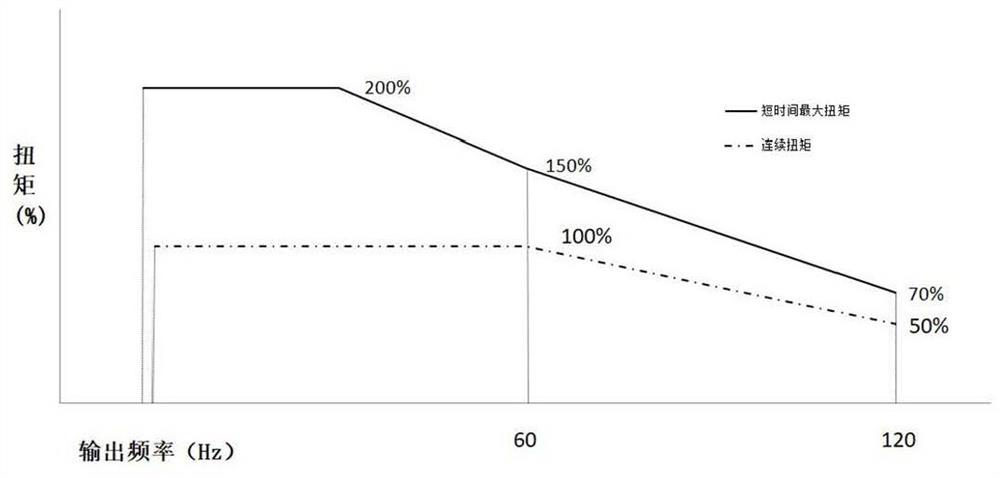

A pulverizer and drive motor technology, which is applied in the control of generators, motor control, motor generator control, etc., can solve the problems of reduced crushing efficiency, small initial torque, and reduced service life of drive motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

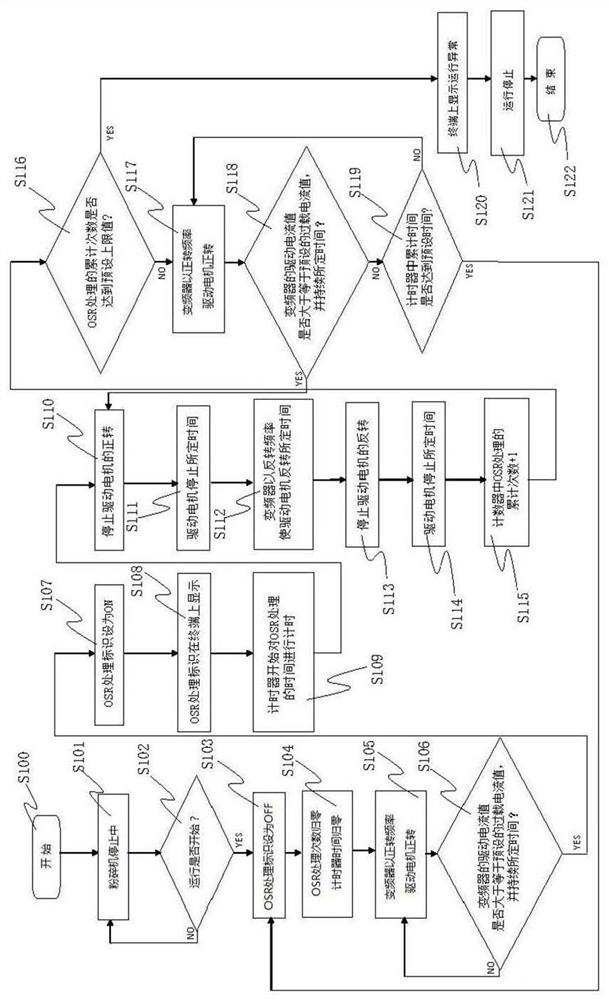

[0030] Hereinafter, the pulverizer and its operation control method according to the present invention will be described in detail with reference to the drawings.

[0031] The pulverizer of this embodiment, as a pulverizer for pulverizing scraps of injection molding products, is similar in overall structure to the pulverizer in the prior art (such as the pulverizer in Patent Document 1), with a hopper, located in the hopper The crushing box below, and the pedestal (not shown) on which the crushing box is fixed. Among them, the hopper is used to put in materials, and the main function of the crushing box is to form a crushing working chamber to crush the input materials (that is, objects). The main function of the base is support, which is used to support the entire crushing box, hopper and other components. There is a crushing blade driven by the drive motor in the crushing box. After the object is sent into the crushing box through the hopper, it is cut and crushed by the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com