A compound transition structure and processing method of oblique line and r of cylindrical rolling element

A transitional structure and processing method technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as unreasonable chamfering structure of rolling elements, stress concentration, etc., achieve technical quality problems to prolong, eliminate stress concentration, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

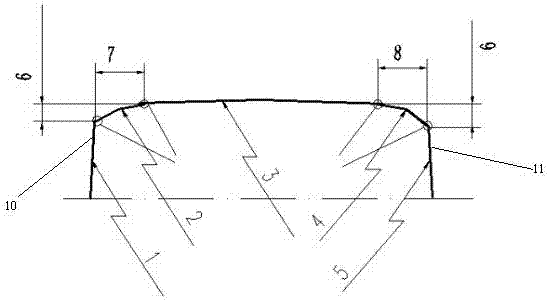

[0013] In order to gain an in-depth understanding of a cylindrical rolling element oblique line and R compound transition structure, combined with figure 1 The description is as follows: It includes one end surface convex arc R1, one end surface chamfer R2, rolling body diameter convex arc R3, two end surface chamfers R4, two end surface convex arcs R5, one end surface angle tangent line L1, one end surface diameter angle The tangent line L2, the diameter angle tangent line L3 of the two end faces, the angle tangent line L4 of the two end faces; the cylindrical surface of the rolling element forms a convex arc R1 of one end face and a tangent line L1 of an end face angle, and the convex arc R5 of the two end faces is tangent to the angle tangent line L4 of the two end faces. Tangent; one end face chamfer R2 is tangent to one end face angle tangent L1 and one end face diameter angle tangent L2, and two end face chamfers R4 is tangent to two end face angle tangents L4 and two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com