Telescopic lead inserting device for automatic molding machine for double-bang fireworks

An automatic forming machine and fireworks technology, which is applied in pyrotechnics, weapon types, offensive equipment, etc., can solve the problems of slow insertion speed, unsmooth lead wire delivery, and many manual requirements, so as to prevent bending deformation and jamming, and ensure the overall The effect of uniform quality and product specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, the present invention will be described in more detail with reference to the drawings and specific embodiments.

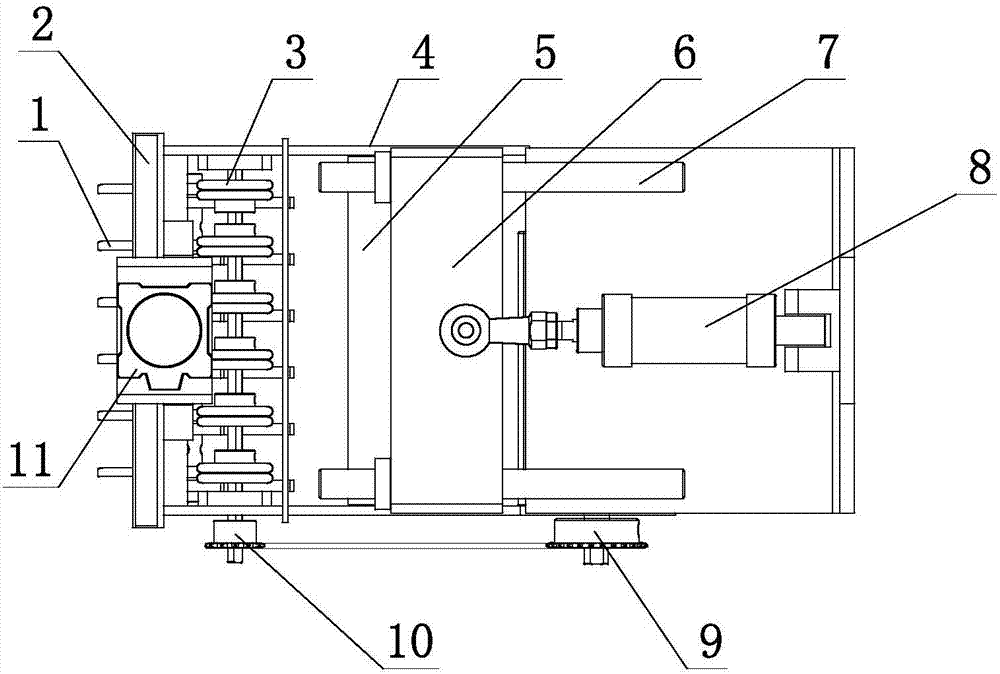

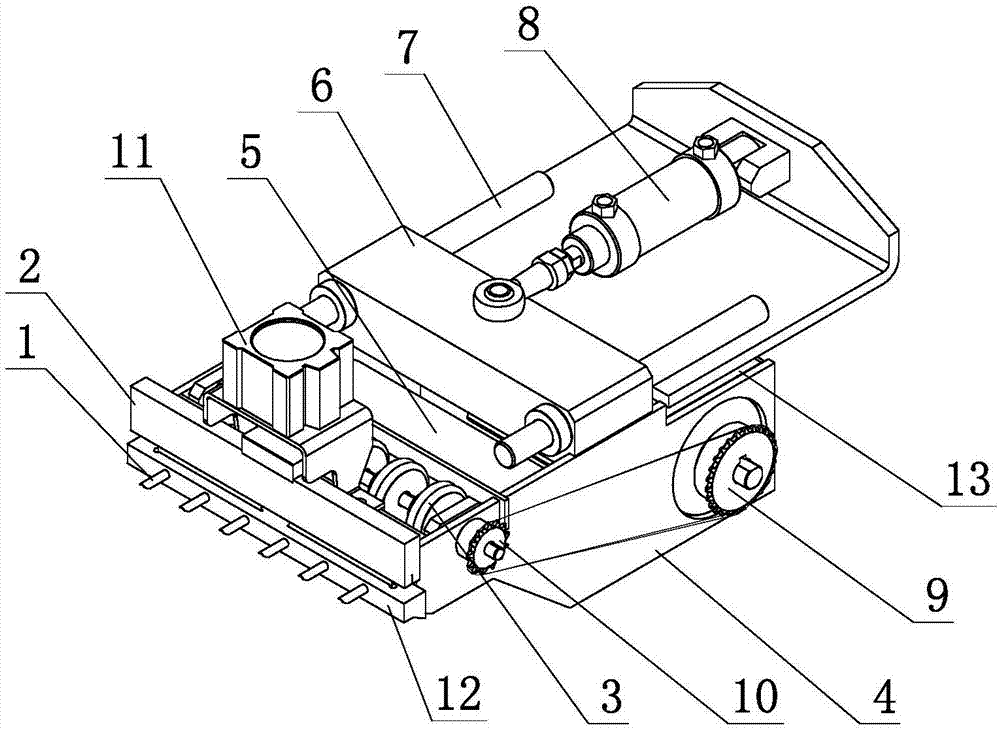

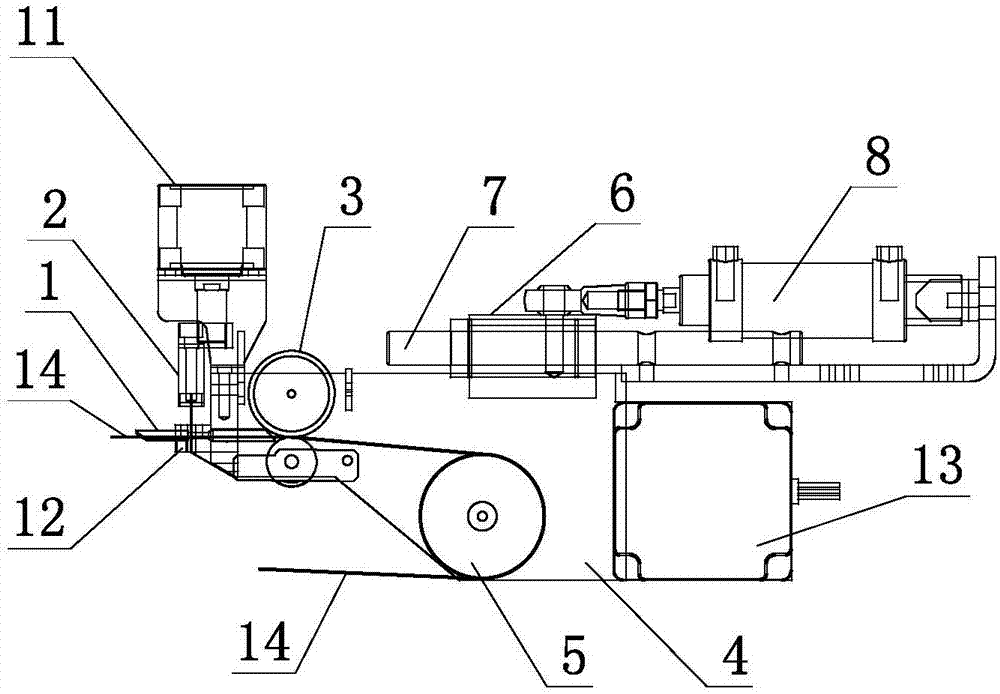

[0014] Such as figure 1 , figure 2 , image 3 As shown, its composition consists of an insertion guide tube 1, a cutting guide plate 2, a guide wheel 3, an insertion base 4, a guide wheel 5, a movable plate 6, an insertion stroke axis 7, and an insertion stroke driving mechanism 8 , driving sprocket 9, auxiliary driving sprocket 10, cutting and guiding drive mechanism 11, cutting and guiding shape plate 12, sending and guiding driving mechanism 13, fasteners and connecting members etc. are assembled.

[0015] The structural features of specific embodiments are:

[0016] Such as figure 1 , figure 2 , image 3 as shown,

[0017] A telescopic insertion and introduction device for a double-sound fireworks automatic forming machine, which is characterized in that it includes an insertion base 4, an insertion and introduction pipe 1, a cutting and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com