A Reliably Sealed Self-Closing Sealed Rotary Compensator

A rotary compensator and sealing technology, which is applied in expansion compensation devices for pipelines, adjustable connections, pipes/pipe joints/fittings, etc., can solve the problems of easy wear of packing, hidden danger of leakage, jamming, etc., and eliminate Stuck phenomenon, improved stability, smoothness guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

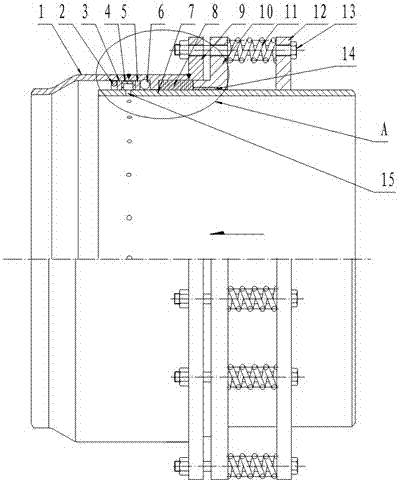

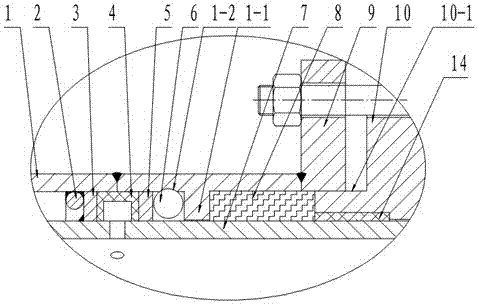

[0015] see figure 1 , the present invention includes a reducer 1 and a core tube 7, the diameter of the left end of the reducer is smaller than the diameter of the right end, the right end of the reducer is provided with a sealing seat 9, one side of the core tube 7 is set in the reducer, and the medium flows from the right to the left, such as figure 1 indicated by the arrow in the middle.

[0016] see figure 1 , figure 2 , the present invention adopts two sealing structures between the reducer tube 1 and the core tube 7, wherein the first sealing structure is the main sealing structure. The first sealing structure includes an annular flexible sealing body 4 , a retaining ring 2 , a first positioning ring 3 , and a second positioning ring 5 . The flexible sealing body 4 is made of rubber, and its cross-sectional shape is U-shaped. The flexible sealing body is set outside the core tube. The open end of the section is in contact with the outer wall of the core tube. Seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com