Multisection bearing universal balance compass mechanism

A compass and balance technology, applied in the field of automatic adjustment of verticality, can solve the problems of large support span, poor anti-vibration performance, and high cost of use, and achieve improved anti-vibration ability and stability, good adjustment freedom, and extended use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

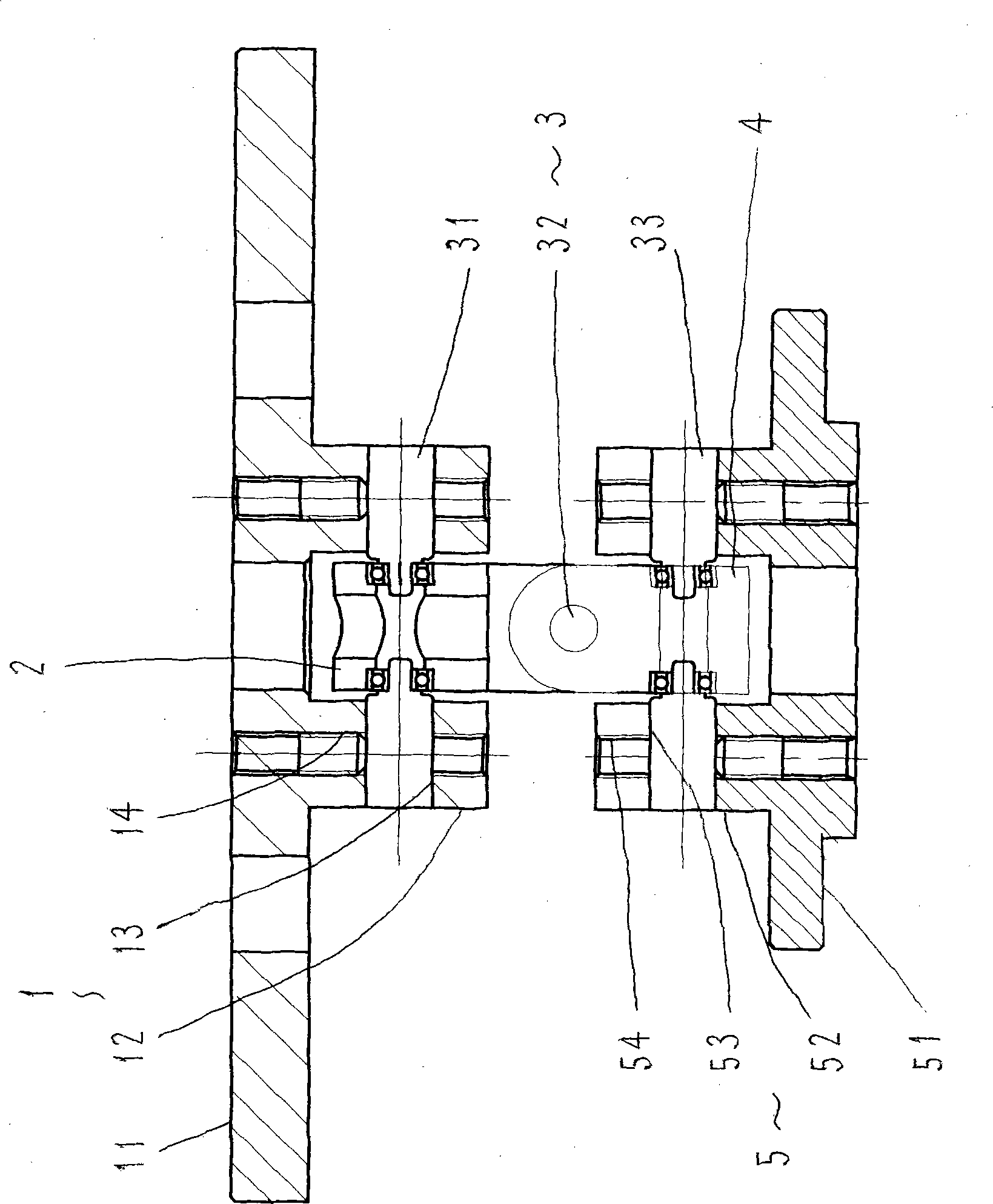

[0020] refer to figure 1 , The multi-section bearing universal balance compass mechanism includes an upper compass frame 1, a fork 2, a hinge assembly 3, a rod-shaped part 4 and a lower compass frame 5, and the figure shows a compass mechanism with a 3-section adjustment structure.

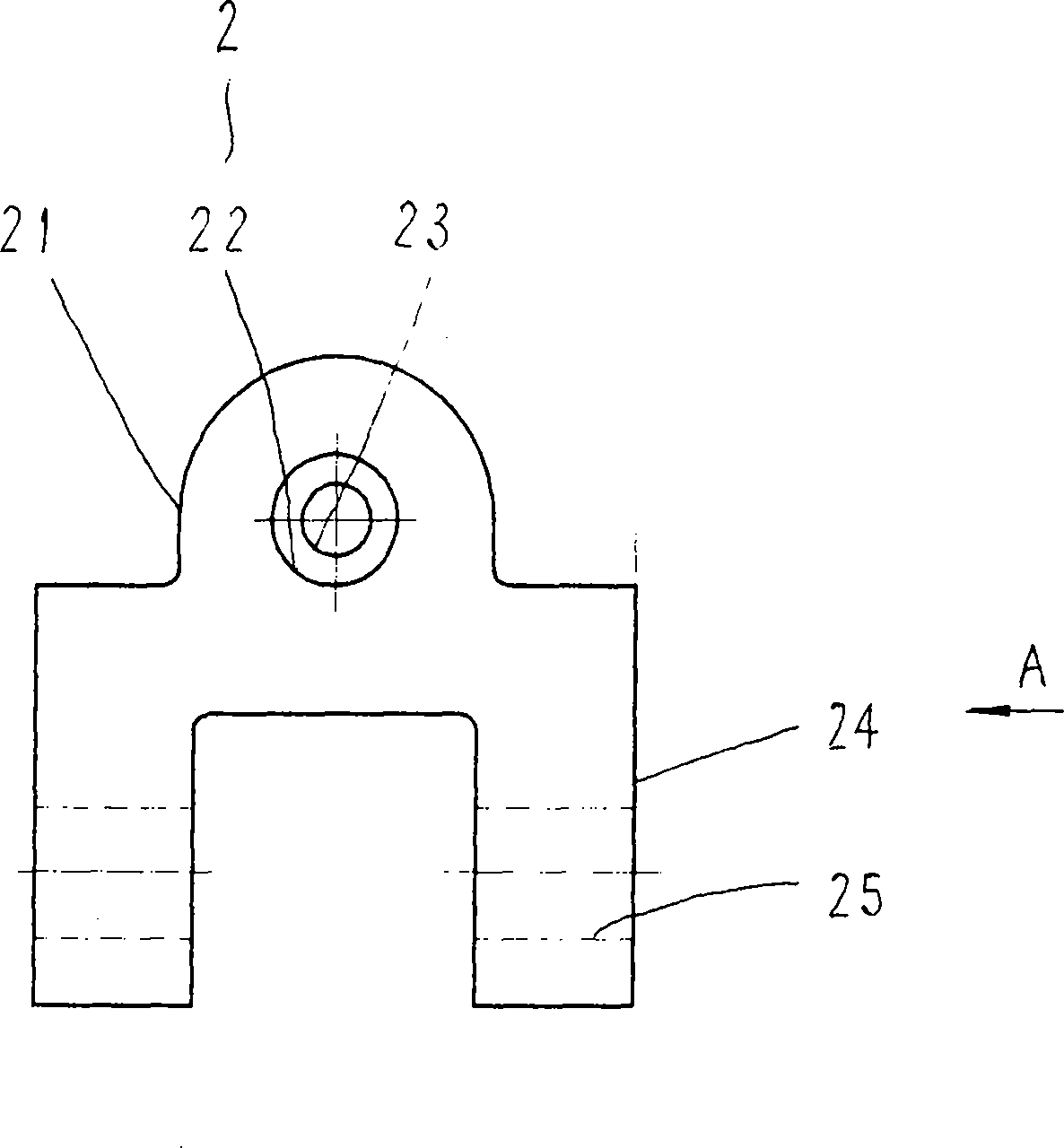

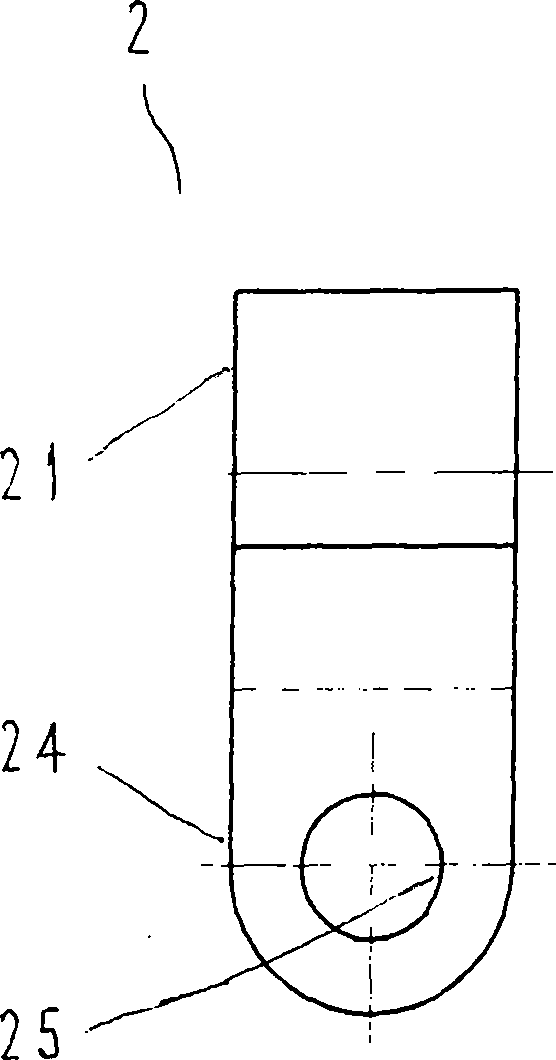

[0021] The upper compass frame 1 has a circular, rectangular or other similarly shaped plate-shaped upper frame body 11, and several through holes can be opened on the upper frame body 11, and the upper compass frame 11 is installed on the hull member or other similar components for piercing bolts. On the component, there are two upper lugs 12 protruding from the bottom surface of the upper frame body 11. The upper frame body 11 and the upper lugs 12 can be cast or welded into one body. The two symmetrical upper lugs 12 have two coaxial upper Shaft holes 13, the left and right shafts 31, 34 of the hinged assembly 3 can be installed on the upper shaft holes 13, the two upper lugs 12 respectively h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com