Leveling structure of assemble type ground

A prefabricated, ground-based technology, applied to floors, building structures, local raised floors, etc., can solve the problems of inconvenient leveling operations and poor leveling effects of leveling supports, and achieve good leveling effects, Easy to operate and increase the effect of the length of the threaded connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

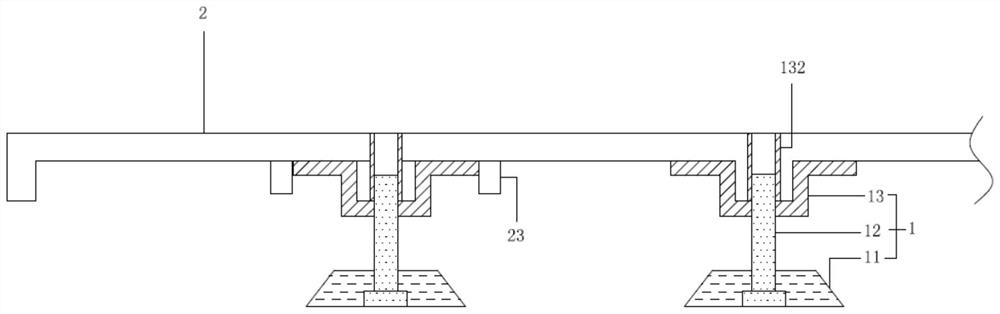

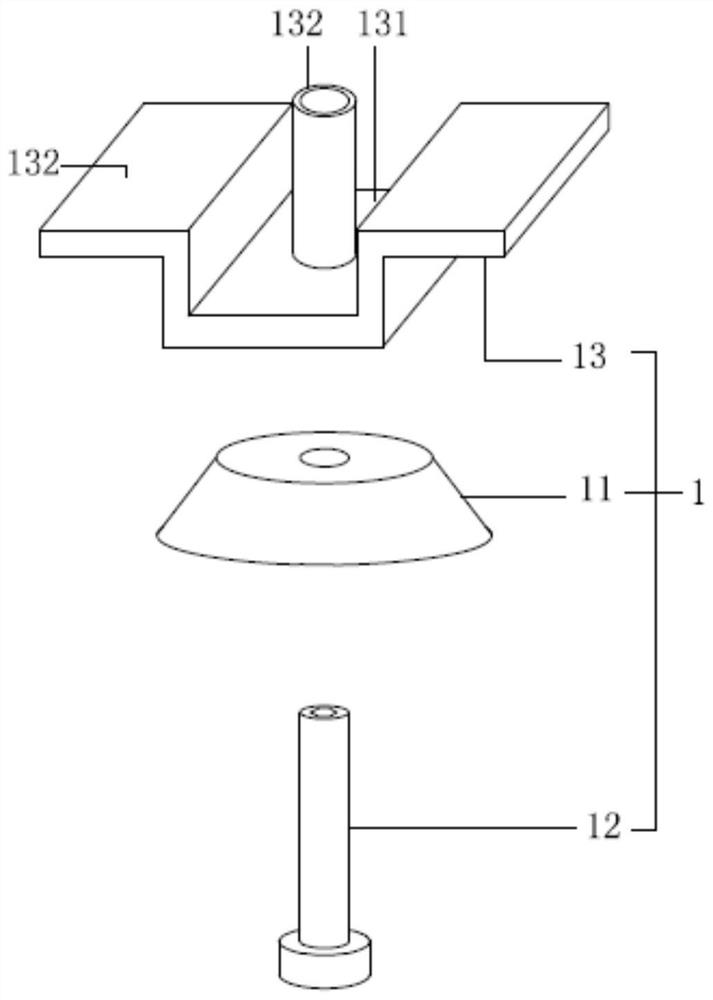

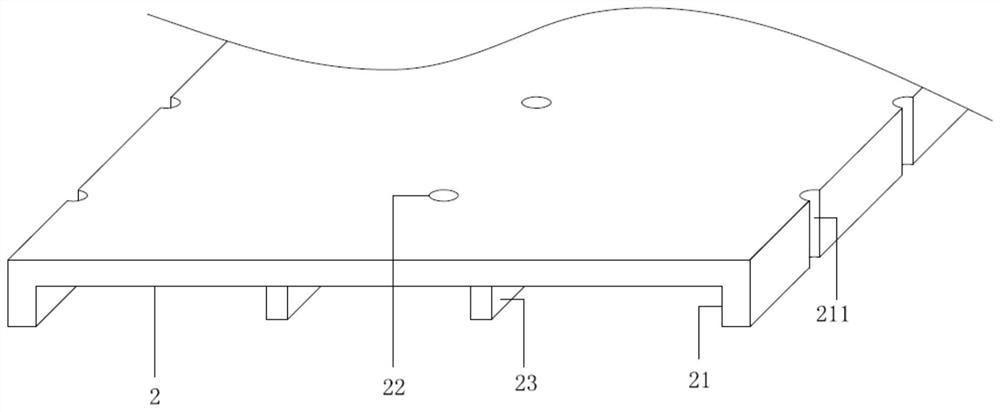

[0023] see Figure 1 to Figure 4 , the figure shows an assembled ground leveling structure provided by Embodiment 1 of the present invention, including a leveling piece 1 and a base plate 2, and the leveling piece 1 includes a base 11, a headless screw 12 and a supporting seat 13, The base 11 is fixedly installed on the ground. The bottom of the headless screw 12 is provided with a mounting block 121. The mounting block 121 is rotatably installed in the groove 11 on the base 11. The headless screw 12 is threaded through the base 11. The headless screw 12 is screwed on the support seat 13, the cross section of the support seat 13 is "U" shape, the side walls 21 of two adjacent substrates 2 are clamped in the installation groove 131 on the surface of the support seat 13, the support seat 13 A column sleeve 132 is provided on the top, and the headless screw 12 is passed through the column sleeve 132 , and the side wall 21 of the base plate 2 is provided with an escape groove 211 ...

Embodiment 2

[0030] see Figure 1 to Figure 4 , the figure shows an assembled ground leveling structure provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the supporting seat 13 Symmetrically arranged support plates 133 are arranged on both sides, and the support plates 133 are against the back of the substrate 2; the surface of the support plate 133 is provided with an adhesive layer.

[0031] The supporting plates at both ends of the supporting seat can effectively improve the supporting effect of the leveling member on the substrate. In order to further ensure the firm installation of the substrates, an adhesive material is provided on the surface of the supporting plate of the leveling member at the joint of the two substrates to bond the supporting base and the substrates together.

Embodiment 3

[0033] see Figure 1 to Figure 4 , the figure shows a prefabricated ground leveling structure provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the substrate 2 is set There are a plurality of through-holes 22 arranged along the length direction of the through-hole, and a leveling member 1 is correspondingly arranged under the through-hole 22, and a column sleeve 132 is pierced through the through-hole 22; symmetrically arranged ribs 23 are arranged on both sides of the through-hole 22, and the bearing The supporting plate 133 of the bracket 13 abuts against the sidewall 23 .

[0034] The through hole is set in the middle of the base plate, and the leveling piece is set under the base plate to provide support for the base plate and ensure the bearing capacity of the base plate. The leveling piece can be adjusted through the through hole to adjust the headless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com