Leveling head

A technology of leveling head and flat plate, which is applied in the field of leveling head, can solve the problems that the flat plate cannot move vertically and the use effect is poor, and achieve the effect of improving work efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

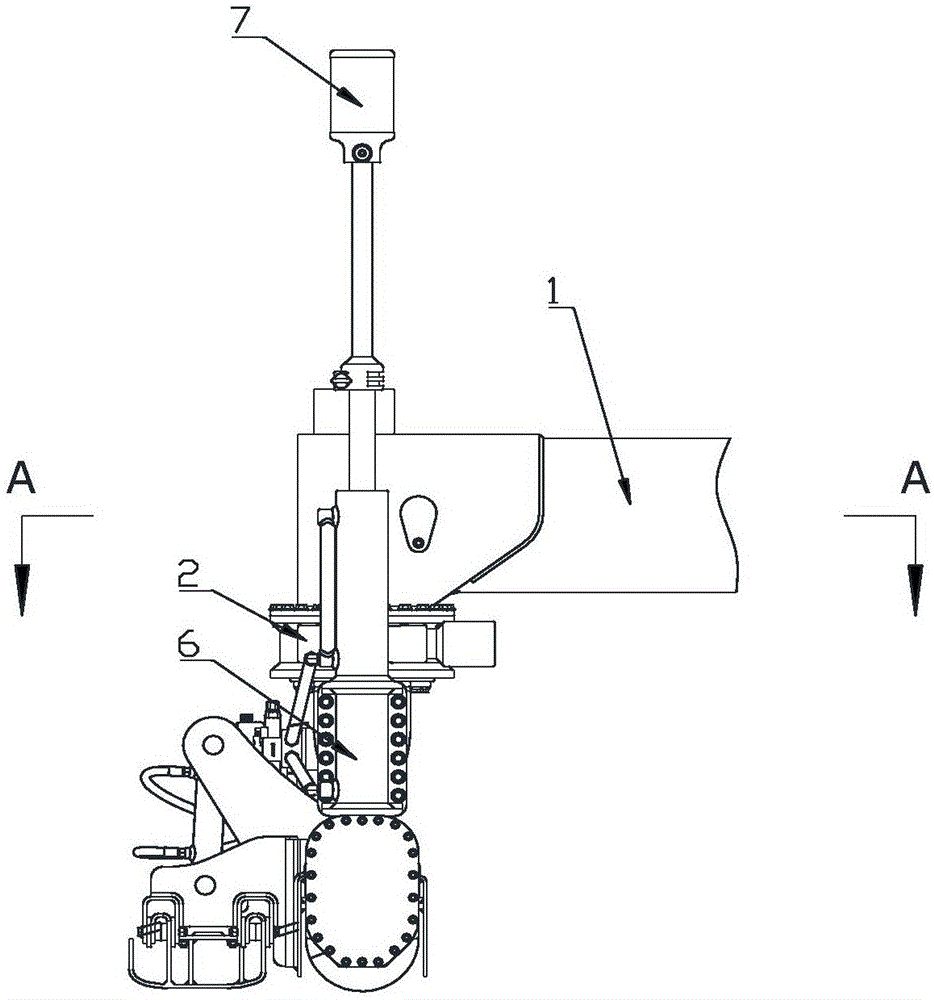

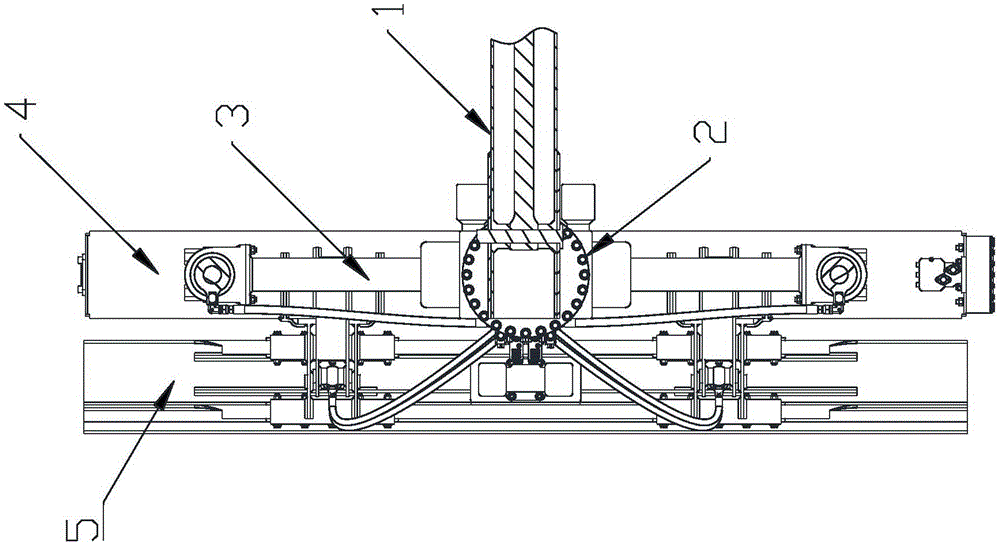

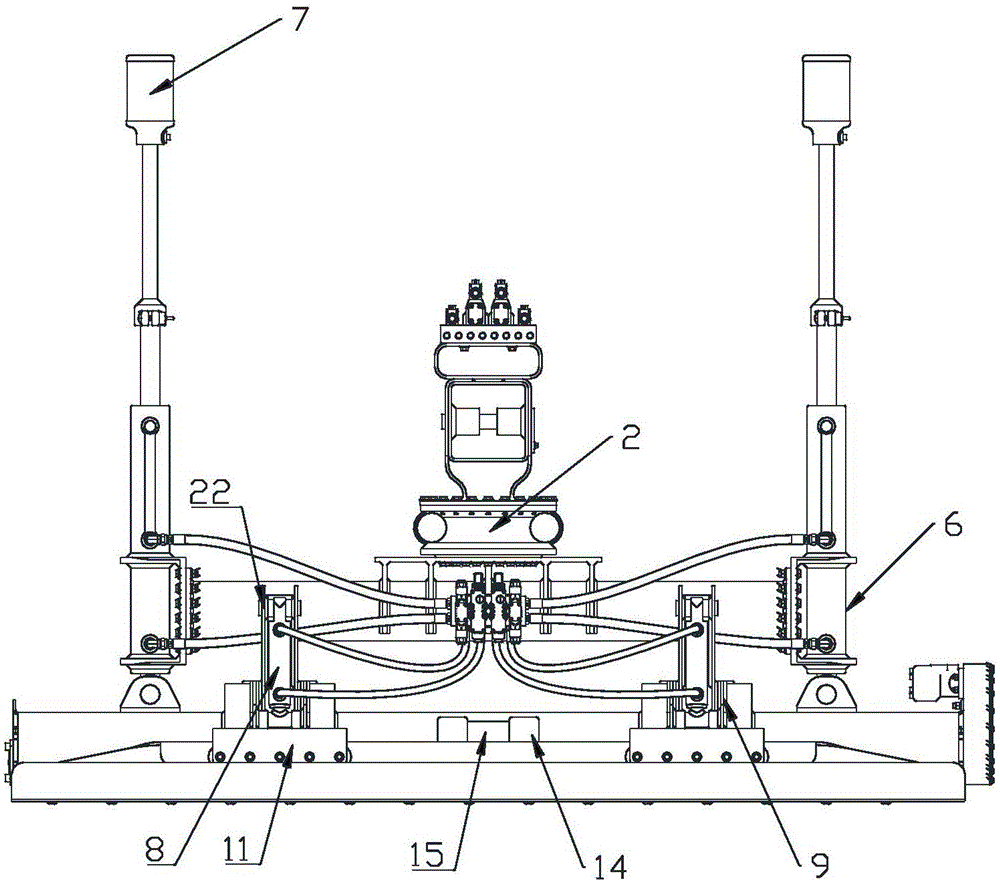

[0018] Embodiment 1: A leveling head, which includes a telescopic beam 1, a rotary joint 2, a leveling head beam 3, a spiral stirring distribution box 4, and a wiper plate 5 arranged sequentially from top to bottom, wherein, the front end of the telescopic beam 1 is provided below There is a rotary joint 2, and the telescopic beam 1 drives the rotary joint 2 to expand and contract. The lower end of the rotary joint 2 is horizontally fixedly connected to the leveling beam 3, and the middle part of the leveling beam 3 is fixedly connected to the lower end of the rotary joint 2; A double-rod cylinder 6 is fixed vertically; a sensor 7 is arranged on the top of the upper piston rod of the double-rod cylinder 6 to control the movement of the sensor 7 in the vertical direction, and the sensor 7 is used to collect operation information and transmit it to the control system , realize the automatic control of leveling process, sensor 7 can be laser sensor etc.; The horizontal angle adju...

Embodiment 2

[0021] Embodiment 2: The overall structure of this embodiment is consistent with that of Embodiment 1, the only difference being that the telescopic beam 1 includes a hollow socketed telescopic beam main body 16, a primary telescopic beam 17 and a secondary telescopic beam 18, and the telescopic beam main body 16 The front end is inserted into the primary telescopic beam 17, and the secondary telescopic beam 18 is inserted into the front end of the primary telescopic beam 17. A telescopic oil cylinder 19 is arranged in the telescopic beam main body 16, and the telescopic oil cylinder 19 is connected with the oil cylinder frame 20 at the rear end of the telescopic beam main body 16. The piston rod of the oil cylinder 19 is connected to the top of the secondary telescopic beam 18, and the primary telescopic beam 17 and the secondary telescopic beam 18 are stretched out or retracted under the power drive of the telescopic oil cylinder 19, so as to realize two-way leveling and have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com